Abstract

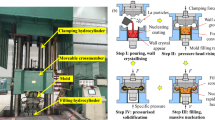

A kind of nickel–aluminum bronze (Cu–10Al–4Fe–4Ni) prepared by centrifugal casting (CC) and gravity casting (GC), respectively, were investigated. The results indicate that CC alloy, which is totally different from GC alloy, consists of α, κI, κII, κIII, κIV, and β′ phases and the microstructures of CC alloy shows nonuniformities from external to internal layer mainly because the distribution of iron and nickel are influenced by centrifugal force. Besides, it is noted that comprehensive mechanical properties of CC alloy are superior to those of GC alloy. Additionally, heat treatments were performed on CC alloy. The results demonstrate the optimal heat treatment is aging at 450 °C/1 h by air cooling after solution treated at 890 °C/1 h by water quench. The ultimate tensile strength and hardness are increased by about 10% and 56%, respectively, and wear resistance is also greatly improved. However, the elongation is decreased by 53%.

Similar content being viewed by others

References

M.S. Rizi and A.H. Kokabi: Microstructure evolution and microhardness of friction stir welded cast aluminum bronze. J. Mater. Process Technol. 214 (8), 1524–1529 (2014).

B. Sabbaghzadeh, R. Parvizi, A. Davoodi, and M.H. Moayed: Corrosion evaluation of multi-pass welded nickel–aluminum bronze alloy in 3.5% sodium chloride solution: A restorative application of gas tungsten arc welding process. Mater. Des. 58, 346–356 (2014).

E. van der Heide, E.D. Stam, H. Giraud, G. Lovato, N. Akdut, F. Clarysse, P. Caenen, and I. Heikillä: Wear of aluminium bronze in sliding contact with lubricated stainless steel sheet material. Wear 261 (1), 68–73 (2006).

J.A. Wharton, R.C. Barik, G. Kear, R.J.K. Wood, K.R. Stokes, and F.C. Walsh: The corrosion of nickel–aluminium bronze in seawater. Corros. Sci. 47 (12), 3336–3367 (2005).

S. Alam, R.I. Marshall, and S. Sasaki: Metallurgical and tribological investigations of aluminium bronze bushes made by a novel centrifugal casting technique. Tribol. Int. 29 (6), 487–492 (1996).

N. Suresh and U. Ramamurty: Aging response and its effect on the functional properties of Cu–Al–Ni shape memory alloys. J. Alloys Compd. 449 (1–2), 113–118 (2008).

J. Anantapong, V. Uthaisangsuk, S. Suranuntchai, and A. Manonukul: Effect of hot working on microstructure evolution of as-cast nickel aluminum bronze alloy. Mater. Des. 60, 233–243 (2014).

M. Kaplan and A.K. Yildiz: The effects of production methods on the microstructures and mechanical properties of an aluminum bronze. Mater. Lett. 57 (28), 4402–4411 (2003).

Y-S. Lee and S-K. Hyun: Centrifugal casting for unpressurized fabrication of lotus-type porous copper. Mater. Lett. 78, 92–94 (2012).

R.A. Mesquita, D.R. Leiva, A.R. Yavari, and W.J. Botta Filho: Microstructures and mechanical properties of bulk AlFeNd(Cu,Si) alloys obtained through centrifugal force casting. Mater. Sci. Eng., A 452–453, 161–169 (2007).

M. Yaşar and Y. Altunpak: The effect of aging heat treatment on the sliding wear behaviour of Cu–Al–Fe alloys. Mater. Des. 30 (3), 878–884 (2009).

G. Chirita, D. Soares, and F.S. Silva: Advantages of the centrifugal casting technique for the production of structural components with Al–Si alloys. Mater. Des. 29 (1), 20–27 (2008).

F. Hasan, A. Jahanafrooz, G.W. Lorimer, and N. Ridley: The morphology, crystallography, and chemistry of phases in as-cast nickel–aluminum bronze. Metall. Mater. Trans. A 13 (8), 1337–1345 (1982).

H. Kubo, H. Otsuka, S. Farjami, and T. Maruyama: Characteristics of Fe–Mn–Si–Cr shape memory alloys in centrifugal casting. Scr. Mater. 55 (11), 1059–1062 (2006).

Y.W. Sui, B.S. Li, A.H. Liu, J.J. Guo, and H.Z. Fu: Evolution of solidification microstructure of centrifugal cast Ti–6Al–4V alloy. Mater. Sci. Technol. 25 (12), 1458–1461 (2013).

Y.S. Sun, G.W. Lorimer, and N. Ridley: Microstructure and its development in Cu–Al–Ni alloys. Metall. Mater. Trans. A 21 (2), 575–588 (1990).

F. Hasan, J. Iqbal, and N. Ridley: Microstructure of as-cast aluminium bronze containing iron. Mater. Sci. Technol. 1 (4), 312–315 (2013).

W.S. **, L.D. Rong, G.J. Jie, L.C. Yun, S.Y. Qing, and F.H. Zhi: Numerical simulation of microstructure evolution of Ti–6Al–4V alloy in vertical centrifugal casting. Mater. Sci. Eng., A 426 (1–2), 240–249 (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lin, G., Wang, H., Wei, Y. et al. Effects of heat treatments on microstructure and properties of nickel–aluminum bronze fabricated by centrifugal casting. Journal of Materials Research 31, 3832–3840 (2016). https://doi.org/10.1557/jmr.2016.455

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2016.455