Abstract

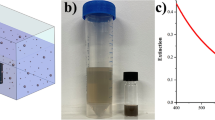

Laser ablation makes it possible to obtain boron-carbide nanoparticles suitable for subsequent use in boron neutron capture therapy. However, particles of boron and boric acid are formed in parallel. Boric acid is harmful to the human body, and boron can naturally form boric acid. A method is proposed for reducing the toxicity of the synthesis of boron-carbide nanoparticles by laser ablation by adding free carbon to the reaction and replacing the traditionally used buffer medium, ethyl acetate. Purified water is used as a dispersing medium. It is shown that the described technology has prospects for reducing the level of toxicity due to the choice of a suitable buffer medium. The formation of boron carbide is recorded by transmission electron microscopy and XRD analysis. The formed particles are predominantly spherical in shape and have a carbon shell. A mechanism is proposed for the formation of such a shell due to the diffusion of carbon from the bulk of the particle through the domain boundaries.

Similar content being viewed by others

REFERENCES

F. Thevenot, J. Eur. Ceram. Soc. 6, 205 (1990).

M. W. Chen, J. W. McCauley, and K. J. Hemker, Science (Washington, DC, U. S.) 299, 1563 (2003).

D. Ghosh, G. Subhash, T. S. Sudarshan, et al., J. Am. Ceram. Soc. 90, 1850 (2007).

V. Domnich, S. Reynaud, R. A. Haber, and M. Chhowalla, J. Am. Ceram. Soc. 94, 3605 (2011).

K. M. Reddy, J. J. Gua, Y. Shinoda, et al., Nat. Commun. 3, 1052 (2012).

K. M. Reddy, P. Liu, A. Hirata, et al., Nat. Commun. 4, 2483 (2013).

R. J. Brook, Concise Encyclopedia of Advanced Ceramic Materials (Pergamon, New York, 1991).

K. H. G. Ashbee, Acta Metall. 19, 1079 (1971).

H. Bai, N. Ma, J. Lang, et al., Mater. Des. 46, 740 (2015).

S. Sankaranarayanan, R. K. Sabat, S. Jayalakshmi, et al., Mater. Des. 56, 428 (2014).

R. F. Barth, A. H. Soloway, and R. G. Fairchild, Am. J. Sci. 263, 100 (1990).

M. W. Mortensen, P. G. Sorensen, O. Björkdahl, et al., Appl. Rad. Isot. 64, 315 (2006).

Y. Ishikawa, Y. Shimizu, T. Sasaki, and N. Koshizak, Appl. Phys. Lett. 91, 161110 (2007).

E. Siegel and S. Wason, J. Pediatr. Clin. North Am. 33, 363 (1986).

A. Sinha, T. Mahata, and B. P. Sharma, J. Nucl. Mater. 301, 165 (2002).

G. L. Messing, K. S. Mazdiyasni, J. W. McCauley, et al., Ceramic Powder Science, Advances in Ceramics (Am. Ceram. Soc., Uetikon, Zurich, 1987).

M. T. Spohn, Am. Ceram. Soc. Bull. 72, 88 (1993).

C. Ganguly, S. K. Roy, and P. R. Roy, Advanced Ceramics, Key Engineering Materials (TransTech, Ohio, 1991).

J. J. Scott, US Patent No. 3161471 (1964).

L. Shi, Y. L. Gu, L. Y. Chen, et al., Solid State Commun. 128, 5 (2003).

S. Chen, D. Z. Wang, J. Y. Huang, et al., Appl. Phys. A 79, 1757 (2004).

X. Y. B. Munge, V. Patel, G. Jensen, et al., J. Am. Chem. Soc. 128, 11199 (2006).

Y. Ishikawa, Q. Feng, and N. Koshizaki, Appl. Phys. A 99, 797 (2010).

E. V. Barmina, I. N. Zavestovskaya, A. I. Kasatova, et al., ar**v: 2109.03608.

V. V. Voronov, P. V. Kazakevich, A. V. Simakin, et al., JETP Lett. 80, 684 (2004).

M. Beauvy, J. Less-Comon. Met. 90, 169 (1983).

U. Hofmann and D. Wilm, J. Zeitschr. Elektr. 42, 504 (1936).

H. K. Clark and J. L. Hoard, J. Am. Chem. Soc. 65, 2115 (1943).

W. H. Zachariasen, Acta Crystallogr. 7, 305 (1954).

ACKNOWLEDGMENTS

We are grateful to A.G. Ivanova for help in carrying out the powder X-ray diffraction experiments.

Funding

This work was supported by a grant from the President of the Russian Federation MD-3790.2021.1.2. Research by P.V. Zinin was supported by the Ministry of Science and Higher Education of the Russian Federation (FFNS-2022-0008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pavlov, I.S., Barmina, E.V., Zhilnikova, M.I. et al. Production of Spherical Boron-Carbide Particles Encapsulated in a Graphite Shell. Nanotechnol Russia 17, 290–296 (2022). https://doi.org/10.1134/S2635167622030132

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2635167622030132