Abstract

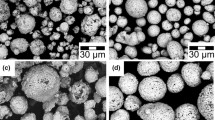

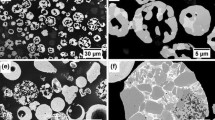

Comparative analysis of the performance characteristics of thermal spray coatings, in particular, detonation coatings formed from commercial tungsten-carbide-based WC−Со (12 wt %) powder (1342VM, Praxair, United States) and cermet TiC−Ме (19 vol %) powder (Ме = NiCr, Co) obtained by self-propagating high-temperature synthesis followed by spheroidization in a plasma jet is performed. It is shown that carbide particles of the cermet powder with a size of greater than 3 µm have structural defects in the form of cracks and pores. Their appearance is explained phenomenologically. It is established that spheroidized particles inherit the internal microstructure. They are dense, whereas the porosity of tungsten carbide based WC−Со (12 wt %) particles attains 40%. The effect of the density of particles on the powder-deposition efficiency and the porosity of coatings is revealed. When a dense powder is sprayed, its deposition efficiency is decreased from 54 to 33%, and the porosity of coatings increases from 0.4 to 1.78%. The WC−Со (19 vol %) coating has the best wear resistance due to the splinter shape of carbide particles with a size of nearly 1 µm.

Similar content being viewed by others

REFERENCES

O. P. Solonenko, V. E. Ovcharenko, V. Y. Ulianitsky, et al., J. Surf. Invest.: X-Ray, Synchrotron Neutron Tech. 10 (5), 1040 (2016). https://doi.org/10.1134/S1027451016050402

V. Y. Ulianitsky, I. S. Batraev, O. P. Solonenko, and A. E. Chesnokov, J. Surf. Invest.: X-Ray, Synchrotron Neutron Tech 12 (2), 250 (2018). https://doi.org/10.1134/S1027451018020179

T.-G. Wang, Sh. -Sh. Zhao, W.-G. Hua, et al., Surf. Coat. Tech. 203 (12), 1637. https://doi.org/10.1016/j.surfcoat.2008.12.012

S. Y. Park, M. C. Kim, and C. G. Park, Mater. Sci. Engin 4, 894 (2007). https://doi.org/10.1016/j.msea.2006.02.444

H. Du, W. Hua, J. Liu, et al., Mater. Sci. Engin 408 (1–2), 202 (2005). https://doi.org/10.1016/j.msea.2005.08.008

L. Valentinelli, T. Valente, F. Casadei, and L. Fedrizzi, Intern. J. Corrosion Processes Corrosion Control 39 (4), 301 (2004). https://doi.org/10.1179/174327804X13884

J. M. Guilemany, S. Dosta, J. Nin, and J. R. Miguel, J. Thermal Spray Tech. 14 (3), 405 (2005). https://doi.org/10.1361/105996305X59350

C. Melnyk, R. G. Cerritos, V. Simi, et al., Proceed. Intern. Thermal Spray Conf. (Hamburg, 2011), p. 157.

V. Yu. Ulianitsky, O. P. Solonenko, A. V. Smirnov, and I. S. Batraev, Proceed. Intern. Thermal Spray Conf. (Barcelona, 2014), p. 668.

V. Yu. Ulianitsky, A. A. Shtertser, S. B. Zlobin, and I. Yu. Smurov, J. Thermal Spray Tech 20 (4), 791.

T. P. Gavrilenko, Yu. A. Nikolaev, V. Yu. Ulianitsky, et al., Proceed. Intern. Thermal Spray Conf. (Nice, 1998), p. 1475.

V. V. Kudinov, Plasma-Sprayed Coatings (Nauka, Moscow, 1977).

O. P. Solonenko, V. E. Ovcharenko, and A. E. Chesnokov, Proc. 6th All-Russian Conf. Interaction of Highly Focused Energy Beams with Materials in High-Potential Technologies and Medicine” (Novosibirsk, 2015), Vol. 1, p. 232.

Funding

The research was carried out within the framework of the Program of Fundamental Scientific Research of the state academies of sciences in 2013–2020 (project no. АААА-А17-117030610124-0).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Chesnokov, A.E., Smirnov, A.V. & Batraev, I.S. Effect of the Microstructure of Cermet Powders on the Performance Characteristics of Thermal Spray Coatings. J. Surf. Investig. 13, 628–634 (2019). https://doi.org/10.1134/S1027451019030248

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451019030248