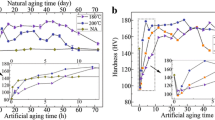

Abstract—Thermodynamic calculations performed with the Thermo-Calc software and experimental methods, in particular, the high-resolution transmission electron microscopy (TEM), are used to study the effect of indium microaddition on heat-treatment-induced changes of the phase composition and character of strengthening of the Al–1.5 wt % Cu and Al–3.5 wt % Cu alloys. The 0.1 wt % indium addition is shown to completely suppress the natural aging of the Al–3.5% Cu alloy. However, indium substantially intensifies the decomposition process of the aluminum solid solution (Al) during artificial aging; this determines the advantages of microalloyed compositions over the base alloys in both the time of reaching the peak strength and hardness. In particular, after aging to the peak strength, the hardness of the Al–3.5% Cu–0.1% In alloy is ~20% higher than that of the base alloy (124 HV against 105 HV), whereas the hardness of the Al–1.5% Cu–0.1% In alloy is more than 60% higher than that of the base Al–1.5% Cu alloy (59 HV against 37 HV). TEM analysis showed that the observed increase in the hardness during aging of the microalloyed compositions is due to the formation of substantially finer structure of aging products (the average linear size of the strengthening θ' phase decreases from 100 to 50 nm) along with the higher particle distribution density.

Similar content being viewed by others

REFERENCES

C. Sigli, F. De Geuser, A. Deschamps, J. Lépinoux, and M. Perez, “Recent advances in the metallurgy of aluminum alloys. Part II: Age hardening,” C. R. Phys. 19 (8), 688–709 (2018). https://doi.org/10.1016/j.crhy.2018.10.012

I. Polmear, D. StJohn, J.-F. Nie, and M. Qian, “Physical metallurgy of aluminum alloys,” in Light Alloys: Metallurgy of the Light Metals, 5th ed. (Elsevier, Amsterdam, 2017), pp. 31–107. https://doi.org/10.1016/B978-0-08-099431-4.00002-6

A. Gloria, R. Montanari, M. Richetta, and A. Varone, “Alloys for aeronautic applications: state of the art and perspectives,” Metals 9, 662 (2019). https://doi.org/10.3390/met9060662

A. Kroupa, O. Zobač, and K. W. Richter, “The thermodynamic reassessment of the binary Al–Cu system,” J. Mater. Sci. 56, 3430–3443 (2021). https://doi.org/10.1007/s10853-020-05423-7

S. Liu, E. Martínez, and J. Lorca, “Prediction of the Al-rich part of the Al–Cu phase diagram using cluster expansion and statistical mechanics,” Acta Mater. 195, 317–326 (2020). https://doi.org/10.1016/j.actamat.2020.05.018

L. Zhu, C. Han, L. Hou, A. Gagnoud, Y. Fautrelle, Z. Ren, and X. Li, “Influence of a static magnetic field on the distribution of solute Cu and interdendritic constitutional undercooling in directionally solidified Al–4.5 wt % Cu alloy,” Mater. Let. 248, 73–77 (2019). https://doi.org/10.1016/j.matlet.2019.03.142

L. Zhou, C. L. Wu, P. **e, F. J. Niu, W. Q. Ming, K. Du, and J. H. Chen, “A hidden precipitation scenario of the θ'-phase in Al–Cu alloys,” J. Mater. Sci. Technol. 75, 126–138 (2021). https://doi.org/10.1016/j.jmst.2020.09.039

X.-H. Zhu, Y. C. Lin, Q. Wu, and Y.-Q. Jiang, “Effects of aging on precipitation behavior and mechanical properties of a tensile deformed Al–Cu alloy,” J. Alloys Compd. 843, 155975 (2020). https://doi.org/10.1016/j.jallcom.2020.155975

L. I. Kaigorodova, D. Yu. Rasposienko, V. G. Pushin, and V. P. Pilyugin, “Structural and phase transformations in Al–Li–Cu–Mg–Zr–Sc–Zn alloy upon storage after megaplastic deformation,” Phys. Met. Metallogr. 120, 1200–1206 (2019).

S. M. Amer, R. Yu. Barkov, O. A. Yakovtseva, and A. V. Pozdniakov, “Comparative analysis of structure and properties of quasibinary Al–6.5Cu–2.3Y and Al–6Cu–4.05Er alloys,” Phys. Met. Metallogr. 121, 476–482 (2020).

Q. Li, Y. Zhang, Y. Lan, R. Pei, X. Feng, T. **a, and D. Liu, “Effect of scandium addition on microstructure and mechanical properties of as-cast Al–5% Cu alloys,” Vacuum 177, 109385 (2020). https://doi.org/10.1016/j.vacuum.2020.109385

I. Poon, R. K. W. Marceau, J. **a, X. Z. Liao, and S. P. Ringer, “Precipitation processes in Al–Cu–Mg–Sn and Al–Cu–Mg–Sn–Ag,” Mater. Des. 96, 385–391 (2016). https://doi.org/10.1016/j.matdes.2016.02.048

F. Lotter, D. Petschke, T. E. M. Staab, U. Rohrmann, T. Schubert, G. Sextl, and B. Kieback, “The influence of trace elements (In, Sn) on the hardening process of Al–Cu alloys,” Phys. Status Solidi A 215, 1800038 (2018). https://doi.org/10.1002/pssa.201800038

Y. Hu, G. Wang, M. Ye, S. Wang, L. Wang, and Y. Rong, “A precipitation hardening model for Al–Cu–Cd alloys,” Mater. Des. 151, 123–132 (2018). https://doi.org/10.1016/j.matdes.2018.04.057

L. Bourgeois, C. Dwyer, M. Weyland, J.-F. Nie, and B. C. Muddle, “The magic thicknesses of θ' precipitates in Sn-microalloyed Al–Cu,” Acta Mater. 60 (2), 633–644 (2012). https://doi.org/10.1016/j.actamat.2011.10.015

G. Genchi, M. S. Sinicropi, G. Lauria, A. Carocci, and A. Catalano, “The effects of cadmium toxicity,” Int. J. Environ. Res. Publ. Health 17 (11), 3782 (2020). https://doi.org/10.3390/ijerph17113782

I. J. Polmear, “Role of trace elements in aged aluminum-alloys,” Mater. Sci. Forum 13–14, 195–214 (1987). https://doi.org/10.4028/www.scientific.net/MSF.13-14.195

G. Wang, Q. Sun, L. Shan, Z. Zhao, and L. Yan, “Influence of Indium trace addition on the precipitation behavior in a 357 cast aluminum alloy,” J. Mater. Eng. Perform. 16, 752–756 (2007). https://doi.org/10.1007/s11665-007-9086-3

F. Lotter, D. Petschke, F. De Geuser, M. Elsayed, G. Sextl, and T. E.M. Staab, “In situ natural ageing of Al–Cu–(Mg) alloys: the effect of In and Sn on the very early stages of decomposition,” Scr. Mater. 168, 104–107 (2019). https://doi.org/10.1016/j.scriptamat.2019.04.031

M. Liu, X. Zhang, B. Körner, M. Elsayed, Z. Liang, D. Leyvraz, and J. Banhart, “Effect of Sn and In on the natural ageing kinetics of Al–Mg–Si alloys,” Materialia 6, 100261 (2019). https://doi.org/10.1016/j.mtla.2019.100261

S. P. Ringer, K. Hono, and T. Sakurai, “Nucleation and growth of θ' precipitation in Sn-modified Al–Cu alloys: APFIM/TEM observations,” Appl. Surf. Sci. 87–88, 223–227 (1995). https://doi.org/10.1016/0169-4332(94)00514-1

Thermo-Calc Software TCAl4 Al-Alloys v. 4.0. http://www.thermocalc.com. Accessed January 22, 2021.

L. F. Mondolfo, Aluminum Alloys: Structure and Properties (Butterworth, London, 1976; Metallurgiya, Moscow, 1979).

T. K. Akopyan, N. A. Belov, and N. V. Letyagin, “Effect of trace addition of Sn on the precipitation hardening in Al–Si–Cu eutectic alloy,” JOM 71, 1768–1775 (2019). https://doi.org/10.1007/s11837-019-03422-x

U. U. Entoni, F. R. Eliot, and M. D. Boll, Aluminum. Properties and Physical Metal Science: A Handbook, Ed. by J. E. Hatch (AMS International, Metals Park, OH, 1984; Metallurgiya, Moscow, 1989).

J. F. Nie and B. C. Muddle, “Strengthening of an Al–Cu–Sn alloy by deformation-resistant precipitate plates,” Acta Mater. 56 (14), 3490–3501 (2008). https://doi.org/10.1016/j.actamat.2008.03.028

C. Wolverton, “Solute–vacancy binding in aluminum,” Acta Mater. 55, 5867–5872 (2007). https://doi.org/10.1016/j.actamat.2007.06.039

Funding

The study was supported by the Russian Science Foundation, project no. 20-79-10373.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Kolchugina

Rights and permissions

About this article

Cite this article

Shurkin, P.K., Akopyan, T.K. & Letyagin, N.V. Effect of Indium Microaddition on the Structure and Strengthening of Binary Al–Cu Alloys. Phys. Metals Metallogr. 122, 807–813 (2021). https://doi.org/10.1134/S0031918X21080159

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X21080159