Abstract

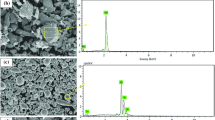

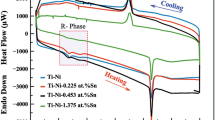

This study investigates the impact of microwave sintering on the microstructure, density, and corrosion behaviour of porous Ti-13.3at.% Nb shape memory alloys (SMAs). The alloys were subjected to microwave sintering at 800 and 1100 °C for 20 and 40 minutes, focusing on understanding the structural changes and corrosion resistance. Microstructural characterization, including scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), X-ray diffraction (XRD), and electron backscatter diffraction (EBSD), were performed. The results revealed the formation of two distinct needle-like morphologies: straight and cross-linked needles (βSC) and irregular lines or spaghetti-like needles (βS). The area fraction of these needle structures increased with prolonged sintering duration and elevated sintering temperature, indicating enhanced diffusion between Ti and Nb elements. Density measurements showed a range of 73–75.5%, with the highest density (75.5%) achieved for samples sintered at 800 °C for 40 minutes. However, a lower density (73%) was observed for samples sintered at 1100°C for 20 minutes, attributed to the rapid heating rate of microwave sintering. Corrosion characteristics were evaluated using potentiodynamic polarization (PDP) and electrochemical impedance spectra (EIS) in simulated body fluid (SBF). The corrosion behaviour was significantly influenced by sintering temperature rather than sintering duration. Samples sintered at 1100 °C exhibited larger capacitive loops on their Nyquist plots compared to those sintered at 800 °C, indicating improved corrosion resistance. With the 800°C sintering temperature, the sintering duration had a less pronounced impact on corrosion behaviour. The EBSD analysis revealed that Ti–Nb diffusion predominantly occurred at grain boundaries, with reduced diffusion in areas further from the grain boundaries. In conclusion, this study elucidates the profound influence of microwave sintering parameters on the microstructure and corrosion behaviour of porous Ti-13.3at.% Nb SMAs. The findings provide valuable insights into optimizing the sintering process for enhanced material properties, offering potential applications in biocompatible and corrosion-resistant engineering components.

Similar content being viewed by others

References

U. Shukla, K. Garg, Journey of smart material from composite to shape memory alloy (SMA), characterization and their applications-a review. Smart Mater. Med. (2022). https://doi.org/10.1016/j.smaim.2022.10.002

O.E. Ozbulut, S. Daghash, M.M. Sherif, Shape memory alloy cables for structural applications. J. Mater. Civ. Eng. 28(4), 04015176 (2016)

J. Van Humbeeck, Shape memory alloys: a material and a technology. Adv. Eng. Mater. 3(11), 837–850 (2001)

V.G. Pushin et al., Effect of severe plastic deformation on the behavior of Ti–Ni shape memory alloys. Mater. Trans. 47(3), 694–697 (2006)

W. Cai, X. Meng, L. Zhao, Recent development of TiNi-based shape memory alloys. Curr. Opin. Solid State Mater. Sci. 9(6), 296–302 (2005)

D. Wever, A. Veldhuizen, J. De Vries, H. Busscher, D. Uges, J. Van Horn, Electrochemical and surface characterization of a nickel–titanium alloy. Biomaterials. 19(7–9), 761–769 (1998)

S. Buxton et al., Concise review of nickel human health toxicology and ecotoxicology. Inorganics. 7(7), 89 (2019)

L.C. Zhang, L.Y. Chen, A review on biomedical titanium alloys: recent progress and prospect. Adv. Eng. Mater. 21(4), 1801215 (2019)

M.K. Ibrahim, M. Kaba, F. Muhaffel, D. Ağaoğulları, H. Cimenoglu, Thermal oxidation of a porous Ti23Nb alloy for wear related biomedical applications: Effect of oxidation duration. Surf. Coat. Technol. 439, 128429 (2022)

M.K. Ibrahim, E. Hamzah, E. Nazim, A. Bahador, Parameter optimization of microwave sintering porous Ti-23% Nb shape memory alloys for biomedical applications. Trans. Nonferrous Metals Soc. China. 28(4), 700–710 (2018)

M.U. Farooq, F.A. Khalid, H. Zaigham, I.H. Abidi, Superelastic behaviour of Ti–Nb–Al ternary shape memory alloys for biomedical applications. Mater. Lett. 121, 58–61 (2014)

A. Bahador et al., Effect of deformation on the microstructure, transformation temperature and superelasticity of Ti–23 at% Nb shape-memory alloys. Mater. Des. 118, 152–162 (2017)

Y. Zhu et al., Linear-superelastic Ti–Nb nanocomposite alloys with ultralow modulus via high-throughput phase-field design and machine learning. npj Comput. Mater. 7(1), 205 (2021)

M. Lai, Y. Gao, B. Yuan, M. Zhu, Effect of pore structure regulation on the properties of porous TiNbZr shape memory alloys for biomedical application. J. Mater. Eng. Perform. 24, 136–142 (2015)

M.K. Ibrahim, E. Hamzah, Effect of Ce and Sb Elements addition on porous Ti–23 wt% Nb–Sn for biomedical applications. Shape Memory Superelast. 7(4), 515–525 (2021)

X. Yi et al., Dam** behaviors and strain recovery characteristics of Hf-modified TiNb-based shape memory alloys. Mater. Res. Bull. 158, 112084 (2023)

X. Yi et al., Unraveling role of Co addition in microstructure and mechanical properties of biomedical Ti–Nb based shape memory alloy. Mater Charact. 200, 112848 (2023)

M. Bönisch et al., Thermal stability and latent heat of Nb–rich martensitic Ti–Nb alloys. J. Alloy. Compd. 697, 300–309 (2017)

H. Tobe, H. Kim, T. Inamura, H. Hosoda, T. Nam, S. Miyazaki, Effect of Nb content on deformation behavior and shape memory properties of Ti–Nb alloys. J. Alloy. Compd. 577, S435–S438 (2013)

S.F. Jawed, C.D. Rabadia, F. Azim, S.J. Khan, Effect of Nb on β→ α ″Martensitic phase transformation and characterization of new biomedical Ti-xNb-3Fe-9Zr alloys. Scanning. (2021). https://doi.org/10.1155/2021/8173425

T. Zhang et al., Microstructure evolution and deformation mechanism of α+ β dual-phase Ti-xNb-yTa-2Zr alloys with high performance. J. Mater. Sci. Technol. 131, 68–81 (2022)

S. Pilz, A. Hariharan, F. Günther, M. Zimmermann, A. Gebert, Influence of isothermal omega precipitation aging on deformation mechanisms and mechanical properties of a β-type Ti–Nb alloy. J. Alloy. Compd. 930, 167309 (2023)

S.N. Saud, H. Bakhsheshi-Rad, F. Yaghoubidoust, N. Iqbal, E. Hamzah, C.R. Ooi, Corrosion and bioactivity performance of graphene oxide coating on TiNb shape memory alloys in simulated body fluid. Mater. Sci. Eng. C. 68, 687–694 (2016)

I. Fidan et al., Recent inventions in additive manufacturing: holistic review. Inventions. 8(4), 103 (2023)

C.Y. Tang, L. Zhang, C. Wong, K.C. Chan, T.M. Yue, Fabrication and characteristics of porous NiTi shape memory alloy synthesized by microwave sintering. Mater. Sci. Eng. A. 528(18), 6006–6011 (2011)

M. K. Ibrahim, E. Hamzah, S. N. Saud, E. Nazim, and A. Bahador, "Influence of Ce addition on biomedical porous Ti-51 atomic percentage (at.%) Ni shape memory alloy fabricated by microwave sintering," in AIP conference proceedings, 2017, vol. 1901, no. 1: AIP Publishing.

S. Singh, D. Gupta, V. Jain, A.K. Sharma, Microwave processing of materials and applications in manufacturing industries: a review. Mater. Manuf. Process. 30(1), 1–29 (2015)

D. Singh, P.M. Pandey, D. Kalyanasundaram, Optimization of pressure-less microwave sintering of Ti6Al4V by response surface methodology. Mater. Manuf. Process. 33(16), 1835–1844 (2018)

A.K. Sharma, S. Gupta, Microwave processing of biomaterials for orthopedic implants: challenges and possibilities. JOM. 72(3), 1211–1228 (2020)

J. Xu et al., Effect of pore sizes on the microstructure and properties of the biomedical porous NiTi alloys prepared by microwave sintering. J. Alloy. Compd. 645, 137–142 (2015)

S. Wakeel, V. Manakari, G. Parande, M.S. Kujur, M. Gupta, Synthesis and mechanical response of NiTi SMA nanoparticle reinforced Mg composites synthesized through microwave sintering process. Mater. Today: Proc. 5(14), 28203–28210 (2018)

L. Tao et al., Preparation and characterization of porous NiTi alloys synthesized by microwave sintering using Mg space holder. Trans. Nonferrous Metals Soc. China. 31(2), 485–498 (2021)

M.-T. Choy, C.-Y. Tang, L. Chen, W.-C. Law, C.-P. Tsui, W.W. Lu, Microwave assisted-in situ synthesis of porous titanium/calcium phosphate composites and their in vitro apatite-forming capability. Compos. B Eng. 83, 50–57 (2015)

B. Yeum, ZSimpWin Version 2.00, Echem Software Ann Arbor, MI, USA, 1999.

H. Bakhsheshi-Rad et al., Mechanical and bio-corrosion properties of quaternary Mg–Ca–Mn–Zn alloys compared with binary Mg–Ca alloys. Mater. Des. 53, 283–292 (2014)

G. Argade, K. Kandasamy, S. Panigrahi, R. Mishra, Corrosion behavior of a friction stir processed rare-earth added magnesium alloy. Corros. Sci. 58, 321–326 (2012)

Y.-H. Hon, J.-Y. Wang, Y.-N. Pan, Composition/phase structure and properties of titanium-niobium alloys. Mater. Trans. 44(11), 2384–2390 (2003)

M.-K. Han, J.-Y. Kim, M.-J. Hwang, H.-J. Song, Y.-J. Park, Effect of Nb on the microstructure, mechanical properties, corrosion behavior, and cytotoxicity of Ti–Nb alloys. Materials. 8(9), 5986–6003 (2015)

M. Ibrahim, E. Hamzah, S. Saud, and A. Bahador, Microwave Sintering Porous Ti-23at.%Nb Shape-Memory Alloys for Biomedical Applications. 2017.

S. Conti, M. Lenz, M. Rumpf, J. Verhülsdonk, B. Zwicknagl, Geometry of needle-like microstructures in shape-memory alloys. Shape Memory Superelast. 9(3), 437–446 (2023)

V. Buscaglia, A. Martinelli, R. Musenich, W. Mayr, W. Lengauer, High-temperature nitridation of Nb–Ti alloys in nitrogen. J. Alloy. Compd. 283(1–2), 241–259 (1999)

H. Wang et al., In-situ precipitated needle like nanocrystalline β-Ti reinforced porous titanium alloy via molten salt electrolysis. Met. Mater. Int. 30(1), 48–60 (2024)

B. Sharma, S.K. Vajpai, K. Ameyama, Microstructure and properties of beta Ti–Nb alloy prepared by powder metallurgy route using titanium hydride powder. J. Alloy. Compd. 656, 978–986 (2016)

A. Nouri, J. Lin, Y. Li, Y. Yamada, P. Hodgson, and C. Wen, Microstructure evolution of TI-SN-NB alloy prepared by mechanical alloying, in Materials forum (CD-ROM), 2007, vol. 31: Institute of Materials Engineering Australasia, pp. 64–70.

J. Young, R. Reddy, Processing and thermoelectric properties of TiNiSn materials: a review. J. Mater. Eng. Perform. 28, 5917–5930 (2019)

J. Kozlík et al., Phase transformations in a heterogeneous Ti-xNb-7Zr-0.8 O alloy prepared by a field-assisted sintering technique. Mater. Des. 198, 109308 (2021)

J. Wang, Y. Liu, P. Qin, S. Liang, T. Sercombe, L. Zhang, Selective laser melting of Ti–35Nb composite from elemental powder mixture: microstructure, mechanical behavior and corrosion behavior. Mater. Sci. Eng. A. 760, 214–224 (2019)

M.A. Hussein, M. Kumar, R. Drew, N. Al-Aqeeli, Electrochemical corrosion and in vitro bioactivity of nano-grained biomedical Ti-20Nb-13Zr alloy in a simulated body fluid. Materials. 11(1), 26 (2017)

M.A. Hussein, C. Suryanarayana, M. Arumugam, N. Al-Aqeeli, Effect of sintering parameters on microstructure, mechanical properties and electrochemical behavior of Nb–Zr alloy for biomedical applications. Mater. Des. 83, 344–351 (2015)

Acknowledgements

The author of this research gratefully acknowledges the supported facilities and funds provided by Imam Ja’afar Al-Sadiq University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ibrahim, M.K., Al-Humairi, S.N.S. Unravelling Role of the Microwave Sintering Effects on Microstructure, Density, and Corrosion Behaviour of Porous Ti-13.3at.% Nb Shape Memory Alloys. Metallogr. Microstruct. Anal. (2024). https://doi.org/10.1007/s13632-024-01091-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13632-024-01091-0