Abstract

In the present study, we discovered a new N-methyl-2-pyrrolidone (NMP) pretreatment solvent with an excellent lignin solubility and preserved β-O-4 linkages available in the original lignin structure. The results indicate that the formation of 4-methylamino butyric acid in NMP pretreatment system increased the polarity of the solvent system. The increased polarity synergistically increased the lignin removal and reduced the amount of lignin condensation. Results indicate a ca. 94% lignin removal was achieved, which is 25.6% higher than ethanol. Meanwhile, size-exclusion chromatography analysis revealed that the residual lignin obtained from NMP pretreated Acacia confusa contained a relatively higher number average (Mn) and weight average (Mw) molecular weights, indicating its higher integrity in terms of preserving the original lignin structure, than ethanol pretreated lignin. The result corresponds to the higher amount of β-O-4 interunit linkages in NMP lignin sample and is supported via HSQC analysis. A new organic hydrolysis factor (OHF) was established and introduced as an indicator in biomass separation experiments. This method can effectively quantify the effects of temperature, time, and acid catalyst concentration. The results showed that NMP exhibited better lignin solubility under the same OHF condition. Meanwhile, the NMP system showed higher tolerance for condensed lignin. In addition, almost 100% of the cellulose conversion was obtained for the NMP pretreated Acacia confusa wood substrates after 60 h of enzymatic hydrolysis with cellulase at a loading of 15 FPU per gram of glucan.

Similar content being viewed by others

References

Bhatia SK et al (2019) Bioconversion of plant biomass hydrolysate into bioplastic (polyhydroxyalkanoates) using Ralstonia eutropha 5119. Biores Technol 271:306–315

Naghshbandi MP, et al. (2019) Progress toward improving ethanol production through decreased glycerol generation in Saccharomyces cerevisiae by metabolic and genetic engineering approaches. Renew Sustain Energy Rev 115:109353

de Paula R.G, et al. (2019) Engineered microbial host selection for value-added bioproducts from lignocellulose. Biotechnol Adv 37(6):107347

Watts N et al (2018) The 2018 report of the Lancet Countdown on health and climate change: sha** the health of nations for centuries to come. The Lancet 392(10163):2479–2514

Yoo CG et al (2017) Insights of biomass recalcitrance in natural Populus trichocarpa variants for biomass conversion. Green Chem 19(22):5467–5478

Leu S-Y, Zhu J (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenergy Research 6(2):405–415

Zhao X, Zhang L, and Liu D (2012) Biomass recalcitrance. Part I: the chemical compositions and physical structures affecting the enzymatic hydrolysis of lignocellulose. Biofuels Bioprod Biorefining 6(4):465–482

Galbe M, Wallberg O (2019) Pretreatment for biorefineries: a review of common methods for efficient utilisation of lignocellulosic materials. Biotechnol Biofuels 12(1):1–26

Ilanidis D, et al. (2020) Effects of redox environment on hydrothermal pretreatment of lignocellulosic biomass under acidic conditions. Bioresource Technol 319:124211

Meng X, et al. (2020) Effects of the advanced organosolv pretreatment strategies on structural properties of woody biomass. Ind Crops Prod 146:112144

Pan X et al (2005) Biorefining of softwoods using ethanol organosolv pul**: Preliminary evaluation of process streams for manufacture of fuel-grade ethanol and co-products. Biotechnol Bioeng 90(4):473–481

Lee J-W, Jeffries TW (2011) Efficiencies of acid catalysts in the hydrolysis of lignocellulosic biomass over a range of combined severity factors. Biores Technol 102(10):5884–5890

Wyman CE (2013) Aqueous pretreatment of plant biomass for biological and chemical conversion to fuels and chemicals. John Wiley & Sons.

Dong C et al (2019) Diol pretreatment to fractionate a reactive lignin in lignocellulosic biomass biorefineries. Green Chem 21(10):2788–2800

Islam MK, et al. (2020) Valorisation of Woody Biomass. Waste Valorisation: Waste Streams in a Circular Economy, p. 87–108

Islam MK, et al. (2020) Sustainability metrics of pretreatment processes in a waste derived lignocellulosic biomass biorefinery. Bioresource Technol 298:122558

Ma J et al (2018) Dispersion of pristine and polyaniline functionalized carbon nanotubes in designed solvent mixtures by Hansen solubility parameters. Materials Today Communications 14:99–105

Roche-Molina M et al (2020) The pharmaceutical solvent N-methyl-2-pyrollidone (NMP) attenuates inflammation through Krüppel-like factor 2 activation to reduce atherogenesis. Sci Rep 10(1):1–16

Lammens TM et al (2010) Synthesis of biobased N-methylpyrrolidone by one-pot cyclization and methylation of γ-aminobutyric acid. Green Chem 12(8):1430–1436

Moshikur RM, et al. (2020) Ionic liquids with N-methyl-2-pyrrolidonium cation as an enhancer for topical drug delivery: Synthesis, characterization, and skin-penetration evaluation. J Mol Liq 299:112166

Shortt J et al (2014) The drug vehicle and solvent N-methylpyrrolidone is an immunomodulator and antimyeloma compound. Cell Rep 7(4):1009–1019

Chen L, et al. (2017) Rapid and near-complete dissolution of wood lignin at≤ 80 C by a recyclable acid hydrotrope. Sci Adv 3(9):e1701735

Sunitha K, et al. (2013) Separation of NMP/water mixtures by nanocomposite PEBA membrane: Part I. Membrane synthesis, characterization and pervaporation performance. Desalination 330:1–8

**e H et al (2012) Enzymatic hydrolysates of corn stover pretreated by a N-methylpyrrolidone–ionic liquid solution for microbial lipid production. Green Chem 14(4):1202–1210

Mu L et al (2015) [N-Methyl-2-pyrrolidone][C1–C4 carboxylic acid]: a novel solvent system with exceptional lignin solubility. Chem Commun 51(70):13554–13557

Asakawa A et al (2016) Cholinium ionic liquid/cosolvent pretreatment for enhancing enzymatic saccharification of sugarcane bagasse. Ind Crops Prod 86:113–119

Sluiter A et al (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory analytical procedure 1617(1):1–16

Van Aelst K et al (2020) Reductive catalytic fractionation of pine wood: elucidating and quantifying the molecular structures in the lignin oil. Chem Sci 11(42):11498–11508

Islam MK, et al. (2021) Biphasic pretreatment for energy and carbon efficient conversion of lignocellulose into bioenergy and reactive lignin. Appl Energy 303:117653

Kalogiannis K et al (2018) Acid assisted organosolv delignification of beechwood and pulp conversion towards high concentrated cellulosic ethanol via high gravity enzymatic hydrolysis and fermentation. Molecules 23(7):1647

Chen L, et al. (2017) Rapid and near-complete dissolution of wood lignin at≤ 80° C by a recyclable acid hydrotrope. Sci Adv 3(9):e1701735

Yeh T-F, Chang M-J, Chang W-J (2014) Comparison of dilute acid and sulfite pretreatments on Acacia confusa for biofuel application and the influence of its extractives. J Agric Food Chem 62(44):10768–10775

Lennon G, et al. (2020) Assessing the oxidative degradation of N-methylpyrrolidone (NMP) in microelectronic fabrication processes by using a multiplatform analytical approach. J Anal Methods Chem 2020

Liu H et al (2016) Toward a fundamental understanding of cellulase-lignin interactions in the whole slurry enzymatic saccharification process. Biofuels, Bioprod Biorefin 10(5):648–663

Li N et al (2018) An uncondensed lignin depolymerized in the solid state and isolated from lignocellulosic biomass: a mechanistic study. Green Chem 20(18):4224–4235

Schunk A and Maurer G (2003) Distribution of hydrochloric, nitric, and sulfuric acid between water and organic solutions of tri-n-octylamine: Part II. Methylisobutylketone as organic solvent. Fluid Phase Equilib 211(2):189–209

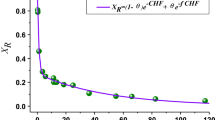

Zhu W et al (2012) Quantitative predictions of bioconversion of aspen by dilute acid and SPORL pretreatments using a unified combined hydrolysis factor (CHF). Process Biochem 47(5):785–791

Leu S.-Y, et al. (2013) Robust enzymatic saccharification of a Douglas-fir forest harvest residue by SPORL. Biomass Bioenerg 59: 393–401

Kim DH et al (2019) Pretreatment and enzymatic saccharification of oak at high solids loadings to obtain high titers and high yields of sugars. Biores Technol 284:391–397

Shen X-J et al (2019) Facile fractionation of lignocelluloses by biomass-derived deep eutectic solvent (DES) pretreatment for cellulose enzymatic hydrolysis and lignin valorization. Green Chem 21(2):275–283

Wang Y et al (2019) Substrate-related factors affecting cellulosome-induced hydrolysis for lignocellulose valorization. Int J Mol Sci 20(13):3354

Chan KL et al (2021) Construction of a structural enzyme adsorption/kinetics model to elucidate additives associated lignin–cellulase interactions in complex bioconversion system. Biotechnol Bioeng 118(10):4065–4075

Bhagia S, Ragauskas AJ (2019) Preserving Aryl Ether Linkages and Higher Yields of Isolated Lignin through Biomass Fibrillation. ACS Sustain Chem Eng 8(1):34–37

Dutta T et al (2018) Characterization of lignin streams during bionic liquid-based pretreatment from grass, hardwood, and softwood. ACS Sustain Chem Eng 6(3):3079–3090

Schneider WDH, et al. (2020) Lignin degradation and detoxification of eucalyptus wastes by on-site manufacturing fungal enzymes to enhance second-generation ethanol yield. Appl Energy 262:114493

Amiri MT et al (2019) Establishing lignin structure-upgradeability relationships using quantitative 1 H–13 C heteronuclear single quantum coherence nuclear magnetic resonance (HSQC-NMR) spectroscopy. Chem Sci 10(35):8135–8142

Zijlstra DS et al (2020) Mild organosolv lignin extraction with alcohols: the importance of benzylic alkoxylation. ACS Sustain Chem Eng 8(13):5119–5131

Lancefield CS et al (2017) Pre-treatment of lignocellulosic feedstocks using biorenewable alcohols: towards complete biomass valorisation. Green Chem 19(1):202–214

Meng X et al (2020) A biomass pretreatment using cellulose-derived solvent Cyrene. Green Chem 22(9):2862–2872

Sherwood J et al (2014) Dihydrolevoglucosenone (Cyrene) as a bio-based alternative for dipolar aprotic solvents. Chem Commun 50(68):9650–9652

Basma NS et al (2018) Local structure and polar order in liquid N-methyl-2-pyrrolidone (NMP). J Phys Chem B 122(38):8963–8971

Author information

Authors and Affiliations

Contributions

Guan Jianyu and Md Khairul Islam share the first authorship for equal contribution. The manuscript is prepared with the contributions of all the authors and all the authors agreed to the submission.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Islam, M.K., Guan, J., Rehman, S. et al. N-Methyl-2-pyrrolidone pre-treatment of lignocellulose for high lignin yield and cellulose digestibility. Biomass Conv. Bioref. 14, 5435–5446 (2024). https://doi.org/10.1007/s13399-022-02655-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02655-2