Abstract

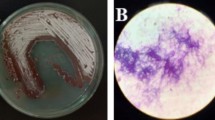

Riboflavin (RF) or vitamin B2 is susceptible to photodegradation. Encapsulation of sensitive components by modified yeast cells is a promising method for their widespread usage at industrial scale. Saccharomyces cerevisiae has been introduced as an appropriate carrier of bioactive compounds. The yeast cell comprises a phospholipid membrane that protects the core from the external environment. In this study, the effect of plasmolysis on efficiency of S. cerevisiae cells in encapsulation of RF were investigated. According to the results, plasmolysis increased the encapsulation efficiency (53.85% versus 58.22% for non-plasmolyzed and plasmolyzed yeast cells, respectively) and loading capacity (14.10 and 16.99% for non-plasmolyzed and plasmolyzed yeast cells, respectively). The loaded intact cells had a tied and intertwined structure while the loaded plasmolyzed cells were seen separately in the Scanning Electron Microscope images. According to the Transmission Electron Microscope images, plasmolysis did not destruct the yeast cells and the cell integrity was retained appropriately after the process but it increased the internal space for encapsulation. In X-ray diffraction analysis, RF had a crystalline structure and its encapsulation within the amorphous non-plasmolyzed and plasmolyzed yeast cells led to slight crystallinity in the structure of complex. The observed spectra of functional groups in Fourier Transform Infrared spectroscopy confirmed the successful entrapment of RF in the yeast cells. Plasmolysis depleted the cell contents susceptible to thermal process through which melting point of the yeast cells increased. Owing to the charged surface of yeast cells, they showed a burst release of RF in the simulated stomach (88% for non-plasmolyzed and 84% for plasmolyzed cells) and intestinal fluid (91% and 96% for non-plasmolyzed and plasmolyzed cells, respectively).

Similar content being viewed by others

References

R. Bou, S. Cofrades, F. Jiménez-Colmenero, LWT-Food Sci. Technol. 59, 621 (2014). https://doi.org/10.1016/j.lwt.2014.06.044

N. Suwannasom, I. Kao, A. Pruß, R. Georgieva, H. Bäumler, Int. J. Mol. Sci. 21, 950 (2020). https://doi.org/10.3390/ijms21030950

D.J. McClements, L. Saliva-Trujillo, R. Zhang, Z. Zhang, L. Zou, M. Yao, H. **ao, Food Res. Int. (2016). https://doi.org/10.1016/j.foodres.2015.11.017

F. Diarrassouba, L. Liang, G. Remondetto, M. Subirade, Food Res. Int. 52, 557 (2013). https://doi.org/10.1016/j.foodres.2013.03.025

D.A. Madalena, Ó.L. Ramos, R.N. Pereira, A.I. Bourbon, A.C. Pinheiro, F.X. Malcata, J.A. Teixeira, A.A. Vicente, Food Hydrocoll. 58, 89 (2016). https://doi.org/10.1016/j.foodhyd.2016.02.015

H. Hu, X. Zhu, T. Hu, I.W.Y. Cheung, S. Pan, E.C.Y. Li-Chan, J. Funct. Foods. (2015). https://doi.org/10.1016/j.jff.2015.09.023

A. Rapoport, I. Guzhova, L. Bernetti, P. Buzzini, M. Kieliszek, A.M. Kot, Metab. 11, 92 (2021). https://doi.org/10.3390/metabo

S.M. Jafari, Release and Bioavailability of Nanoencapsulated Food IngredientsAcademic Press, (2020). Nanoencapsulation in the Food Industry. 5, [1 ed.] 0128156651, 9780128156650

M. Saniani, L. Nateghi, M. Hshemiravan, J. Food Meas. Charact. 17, 3683 (2023). https://doi.org/10.1007/s11694-023-01902-y

S. Beikzadeh, S. Shojaee-Aliabadi, E. Dadkhodazade, Z. Sheidaei, A.S. Abedi, L. Mirmoghtadaie, S.M. Hosseini, Appl. Food Biotechnol. 7, 11 (2020). https://doi.org/10.22037/afb.v7i1.25969

H. Wang, J. Dang, M. Zheng, Adv. Compos. Hybrid. Mater. 6, 165 (2023). https://doi.org/10.1007/s42114-023-00733-1

W. Liu, Q. Lin, S. Chen, Adv. Compos. Hybrid. Mater. 6, 149 (2023). https://doi.org/10.1007/s42114-023-00725-1

J. Liu, N. Zheng, Z. Li, Adv. Compos. Hybrid. Mater. 5, 1899–1909 (2022). https://doi.org/10.1007/s42114-022-00515-1

M.Y. TH.Yan, N. Nguyen, Adv. Compos. Hybrid. Mater. 6, 226 (2023). https://doi.org/10.1007/s42114-023-00811-4

S. Jambhulkar, D. Ravichandran, V. Thippanna, D. Patil, Adv. Compos. Hybrid. Mater. 6(3) (2023). https://doi.org/10.1007/s42114-023-00672-x

M. Kavosi, A. Mohammadi, S. Shojaee-Aliabadi, R. Khaksar, S.M. Hosseini, J. Sci. Food Agric. 98, 2490 (2018). https://doi.org/10.1002/jsfa.8696

B.N. Pham-Hoang, A. Voilley, Y. Waché, Colloids Surf. B Biointerfaces. 148, 220 (2016). https://doi.org/10.1016/j.colsurfb.2016.08.045

S. Yousefi, P. Rajaei, L. Nateghi, H.R. Nodeh, L. Rashidi, Int. J. Biol. Macromol. 242, 124766 (2023). https://doi.org/10.1016/j.ijbiomac.2023.124766

E.I. Paramera, V.T. Karathanos, S.J. Konteles, Microencapsul. Food Ind. (2023). https://doi.org/10.1016/B978-0-12-821683-5.00002-9

E.I. Paramera, S.J. Konteles, V.T. Karathanos, Food Chem. 125, 892 (2011). https://doi.org/10.1016/j.foodchem.2010.09.063

K. Karaman, Lwt. 148, 111640 (2021). https://doi.org/10.1016/j.lwt.2021.111640

E. Dadkhodazade, A. Mohammadi, S. Shojaee-Aliabadi, A.M. Mortazavian, L. Mirmoghtadaie, S.M. Hosseini, Food Biophys. 13, 404 (2018). https://doi.org/10.1007/s11483-018-9546-3

E. Dadkhodazade, E. Khanniri, N. Khorshidian, S.M. Hosseini, A.M. Mortazavian, E. Moghaddas, Kia, Biotechnol. Prog. 37, e3138 (2021). https://doi.org/10.1002/btpr.3138

L.M. Dong, H.T.T. Hang, N.H.N. Tran, D.T.K. Thuy, Microbiol. Biotechnol. Lett. 48, 267 (2020). https://doi.org/10.4014/mbl.1912.12003

E. Zade Ashkezary, M. Vazifedoost, L. Nateghi, Z. Didar, M. Moslemi, Iran. J. Chem. Chem. Eng. (2023). https://doi.org/10.30492/IJCCE.2023.1987100.5808

C. Errenst, M. Petermann, A. Kilzer, J. Supercrit Fluids. 168, 105076 (2021). https://doi.org/10.1016/j.supflu.2020.105076

Z. Takalloo, M. Nikkhah, R. Nemati, N. Jalilian, R.H. Sajedi, World J. Microbiol. Biotechnol. 36, 1 (2020). https://doi.org/10.1007/s11274-020-02840-3

S. Jafarirad, L. Nateghi, M. Moslemi, K.P. Afshari, J. Food Meas. Charact. 1 (2023). https://doi.org/10.1007/s11694-023-02161-7

H. Mirzaee, H. Ahmadi Gavlighi, M. Nikoo, C.C. Udenigwe, F. Khodaiyan, Food Sci. Nutr. 11, 1257 (2023). https://doi.org/10.1002/fsn3.3160

A.-S.Y. Mohammed, A.K.F. Dyab, F. Taha, A.I.A. Abd El-Mageed, Mater. Sci. Eng. C 128, 112271 (2021). https://doi.org/10.1016/j.msec.2021.112271

A. Rezvankhah, M.S. Yarmand, B. Ghanbarzadeh, H. Mirzaee, J. Food Process. Preserv. 45 (2021). https://doi.org/10.1111/jfpp.15932. e15932

H. Mirzaee, F. Khodaiyan, J.F. Kennedy, S.S. Hosseini, Carbohydr. Polym. Technol. Appl. 1, 100004 (2020). https://doi.org/10.1016/j.carpta.2020.100004

N. Haghighatpanah, H. Mirzaee, F. Khodaiyan, J.F. Kennedy, A. Aghakhani, S.S. Hosseini, K. Jahanbin, Int. J. Biol. Macromol. 152, 305 (2020). https://doi.org/10.1016/j.ijbiomac.2020.02.226

A. Sultana, A. Miyamoto, Q. Lan Hy, Y. Tanaka, Y. Fushimi, H. Yoshii, J. Food Eng. 199, 36 (2017). https://doi.org/10.1016/j.jfoodeng.2016.12.002

G.V. Gautério, R.M. da Silva, F.C. Karraz, M.A.Z. Coelho, B.D. Ribeiro, A.C. Lemes, Clean. Chem. Eng. 6, 100112 (2023). https://doi.org/10.1016/j.clce.2023.100112

E.I. Paramera, S.J. Konteles, V.T. Karathanos, Food Chem. 125, 913 (2011). https://doi.org/10.1016/j.foodchem.2010.09.071

K. Karaman, Food Chem. 313, 126129 (2020). https://doi.org/10.1016/j.foodchem.2019.126129

P. Chakraborty, P. Bairi, B. Roy, A.K. Nandi, RSC Adv. 4, 54684 (2014). https://doi.org/10.1039/C4RA09215E

M.A. Sheraz, S.H. Kazi, S. Ahmed, Z. Anwar, I. Ahmad, Beilstein J. Org. Chem. 10208(10), 1999 (2014). https://doi.org/10.3762/bjoc.10.208

R. Salari, B.S.F. Bazzaz, O. Rajabi, Z. Khashyarmanesh, DARU J. Pharm. Sci. 21, 1 (2013). http://www.darujps.com/content/21/1/73

J. Wu, Y. Guan, Q. Zhong, Food Chem. 172, 121 (2015). https://doi.org/10.1016/j.foodchem.2014.09.059

A. Cruz-Gavia, C. Pérez-Alonso, C.E. Barrera-Díaz, J. Alvarez-Ramírez, H. Carrillo-Navas, Guadarrama-Lezama Food Hydrocoll. 82 (2018). https://doi.org/10.1016/j.foodhyd.2018.03.045

Acknowledgements

The authors would like to appreciate the Islamic Azad University of Iran for its support in development of experimental analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None of the authors declared conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ashkezary, E.Z., Vazifedoost, M., Nateghi, L. et al. Characterization of encapsulated riboflavin in plasmolyzed and non-plasmolyzed Saccharomyces cerevisiae yeast cells. Food Measure 18, 4323–4333 (2024). https://doi.org/10.1007/s11694-024-02496-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-024-02496-9