Abstract

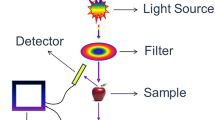

Fruit quality inspection and authentication instruments are the essential requirement at the different stages of fruit processing industries from harvesting to market. In recent years, various intelligent analytical methods such as electronic nose, gas chromatography and mass spectroscopy, UV–Vis–NIR spectroscopy, machine vision, hyperspectral imaging and many more have been evolved to access the fruit quality at different stages such as maturity judgement of an on-tree fruit, shelf life measurement of harvested fruit, other quality parameters measurement of various fruit products at processing industries etc. Information extracted from various analytical methods needs to be processed using different data processing approaches and strategies, which plays the major role to bring the intelligence in the analytical instruments. Although, highly promising results have been reported to process data acquired from similar type of sensory panel (gas sensor array in electronic nose) and single sensing technique (impedance measurement) but still there are several challenges to process data acquired from multiple sensing techniques fusion (similar or complementary in nature) to predict better informative results. Recently, there is a growing interest in the direction of multiple sensing techniques fusion to extract better information from fruit samples in a reliable manner and also in less time. This paper presents an extensive review of classical and modern data processing approaches and strategies that have been used for single and multiple non-destructive sensing methods in the area of fruit quality inspection and authentication. Various approaches and strategies for preprocessing, data fusion, feature extraction, model design, multi-modal data processing, training, testing and validation for single and multiple sensing techniques have been briefly explained in the presented review. The presented review also discusses the need, scope, and challenges of data processing methods for multiple sensing techniques fusion. Different commercially available handheld and lab level analytical instruments also have been reviewed based on their intelligence, complexity and quality parameters prediction.

Similar content being viewed by others

References

Food loss and waste facts (2015), http://www.fao.org/resources/infographics/infographics-details/en/c/317265/ Accessed 3 Feb 2018

L.S. Kantor et al., Estimating and addressing America’s food losses. Food Rev. 20(1), 2–12 (1997)

D.C. Slaughter et al., Comparison of instrumental and manual inspection of clingstone peaches. Appl. Eng. Agric. 22(6), 883–889 (2006)

S. Khalifa, M.H. Komarizadeh, B. Tousi, Usage of fruit response to both force and forced vibration applied to assess fruit firmness-a review. Aust. J. Crop Sci. 5(5), 516 (2011)

F. Röck, B. Nicolae, W. Udo, Electronic nose: current status and future trends. Chem. Rev. 108(2), 705–725 (2008)

N. Kondo et al., Machine vision based quality evaluation of Iyokan orange fruit using neural networks. Comput. Electron. Agric. 29(1–2), 135–147 (2000)

H. Lin, Y. Yibin, Theory and application of near infrared spectroscopy in assessment of fruit quality: a review. Sens. Instrum. Food Qual. Saf. 3(2), 130–141 (2009)

F.J. García-Ramos et al., Non-destructive fruit firmness sensors: a review. Span. J. Agric. Res. 3(1), 61–73 (2005)

B. Diezema Iglesias, M. Ruiz-Altisent, B. Orihuel. Acoustic impulse response for detecting hollow heart in seedless watermelon. In: International Conference: Postharvest Unlimited, vol. 599. 2002

T.C. Pearce (eds.), Handbook of Machine Olfaction: Electronic Nose Technology (Wiley, New York, 2006)

M. Lebrun et al., Discrimination of mango fruit maturity by volatiles using the electronic nose and gas chromatography. Postharvest Biol. Technol. 48(1), 122–131 (2008)

M. Valente et al., Multivariate calibration of mango firmness using vis/NIR spectroscopy and acoustic impulse method. J. Food Eng. 94(1), 7–13 (2009)

D. Cozzolino et al., Multivariate data analysis applied to spectroscopy: potential application to juice and fruit quality. Food Res. Int. 44(7), 1888–1896 (2011)

V. Steinmetz, F. Sevila, V. Bellon-Maurel, A methodology for sensor fusion design: application to fruit quality assessment. J. Agric. Eng. Res. 74(1), 21–31 (1999)

A.D. Wilson, M. Baietto, Applications and advances in electronic-nose technologies. Sensors 9(7), 5099–5148 (2009)

M. Baietto, A.D. Wilson, Electronic-nose applications for fruit identification, ripeness and quality grading. Sensors 15(1), 899–931 (2015)

S. Di Carlo, M. Falasconi. Drift correction methods for gas chemical sensors in artificial olfaction systems: techniques and challenges, in Advances in Chemical Sensors, eds by S. Di Carlo, M. Falasconi (InTech, London, 2012)

H. Liu, Z. Tang, Metal oxide gas sensor drift compensation using a dynamic classifier ensemble based on fitting. Sensors 13(7), 9160–9173 (2013)

R. Gutierrez-Osuna. Signal processing methods for drift compensation. In 2nd NOSE II workshop, Linko**, 2003

S. Saevels et al., Electronic nose as a non-destructive tool to evaluate the optimal harvest date of apples. Postharvest Biol. Technol. 30(1), 3–14 (2003)

S. Ampuero, J.O. Bosset, The electronic nose applied to dairy products: a review. Sensors Actuators B: Chem 94(1), 1–12 (2003)

H. Huang, L. Liu, M.O. Ngadi, Recent developments in hyperspectral imaging for assessment of food quality and safety. Sensors 14(4), 7248–7276 (2014)

A.H.A. Eissa, A.A.K. Ayman, Understanding color image processing by machine vision for biological materials. In: Structure and Function of Food Engineering, ed. by A.H.A. Eissa (Intech, London, 2012)

S. Cubero et al., Advances in machine vision applications for automatic inspection and quality evaluation of fruits and vegetables. Food Bioprocess Technol. 4(4), 487–504 (2011)

E. Ofek et al., Highlight and reflection independent multiresolution textures from image sequences. IEEE Comput. Gr. Appl. 17(2), 18–29 (1997)

T. Chalidabhongse, P. Yimyam, P. Sirisomboon, 2D/3D vision-based mango’s feature extraction and sorting. In: 9th International Conference on Control, Automation, Robotics and Vision, ICARCV’06, IEEE, 2006

A.A. Gowen et al., Hyperspectral imaging: an emerging process analytical tool for food quality and safety control. Trends Food Sci. Technol. 18(12), 590–598 (2007)

S. Cubero et al., Automated systems based on machine vision for inspecting citrus fruits from the field to postharvest—a review. Food Bioprocess Technol. 9(10), 1623–1639 (2016)

Z.J. Dolatowski, J. Stadnik, D. Stasiak, Applications of ultrasound in food technology. Acta Sci. Polonorum Technol. Aliment. 6(3), 88–99 (2007)

D. Molina-Delgado et al., Addressing potential sources of variation in several non-destructive techniques for measuring firmness in apples. Biosyst. Eng. 104(1), 33–46 (2009)

R. Cubeddu et al. Measuring fresh fruit and vegetable quality: advanced optical methods. In: Fruit and Vegetable Processing—Improving Quality. ed. by W. Jongen (CRC Press/Woodhead Publishing Limited, Boca Raton, 2002), pp. 150–169

M. Padilla et al., Drift compensation of gas sensor array data by orthogonal signal correction. Chemom. Intell. Lab. Syst. 100(1), 28–35 (2010)

G. Wei et al. A blind source separation based micro gas sensor array modeling method. In: International Symposium on Neural Networks (Springer, Berlin, Heidelberg, 2004)

M. Blankenburg, J. Krüger, M. Fechteler. Signal separation of gas sensor data for application in counterfeit detection. In: Instrumentation and Measurement Technology Conference (I2MTC) Proceedings, IEEE International. IEEE, 2014

S. Bermejo, J. Solé-Casals. Blind source separation for solid-state chemical sensor arrays. In: Sensor Array and Multichannel Signal Processing Workshop Proceedings, IEEE, 2004

R.J. Barnes, M.S. Dhanoa, S.J. Lister, Standard normal variate transformation and de-trending of near-infrared diffuse reflectance spectra. Appl. Spectrosc. 43(5), 772–777 (1989)

T. Isaksson, T. Næs, The effect of multiplicative scatter correction (MSC) and linearity improvement in NIR spectroscopy. Appl. Spectrosc. 42(7), 1273–1284 (1988)

C.D. Brown, L. Vega-Montoto, P.D. Wentzell, Derivative preprocessing and optimal corrections for baseline drift in multivariate calibration. Appl. Spectrosc. 54(7), 1055–1068 (2000)

N.R. Pal, S.K. Pal, A review on image segmentation techniques. Pattern Recognit. 26(9), 1277–1294 (1993)

A. Chambolle et al., Nonlinear wavelet image processing: variational problems, compression, and noise removal through wavelet shrinkage. IEEE Trans. Image Process 7(3), 319–335 (1998)

E. Borràs et al., Data fusion methodologies for food and beverage authentication and quality assessment–a review. Anal. Chim. Acta 891, 1–14 (2015)

S. Wold, N. Kettaneh, K. Tjessem, Hierarchical multiblock PLS and PC models for easier model interpretation and as an alternative to variable selection. J. Chemom. 10(5-6), 463–482 (1996)

P.N. Peduzzi, R.J. Hardy, T.R. Holford, A stepwise variable selection procedure for nonlinear regression models. Biometrics 36, 511–516 (1980)

D.M. Allen, The relationship between variable selection and data agumentation and a method for prediction. Technometrics 16(1), 125–127 (1974)

B.G. Tabachnick, L.S. Fidell, Experimental designs using ANOVA (Thomson/Brooks/Cole, Grove, 2007)

E. Vigneau et al., Clustering of variables to analyze spectral data. J. Chemom. 19(3), 122–128 (2005)

Z.M. Hira, D.F. Gillies, A review of feature selection and feature extraction methods applied on microarray data. Adv. Bioinform. https://doi.org/10.1155/2015/198363 (2015)

Y. Saeys, I. Inza, P. Larrañaga. A review of feature selection techniques in bioinformatics. Bioinformatics 23(19), 2507–2517 (2007)

I. Guyon (ed.), Feature Extraction: Foundations and Applications, vol. 207 (Springer, New York, 2008)

S. De Backer, A. Naud, P. Scheunders, Non-linear dimensionality reduction techniques for unsupervised feature extraction. Pattern Recognit. Lett. 19(8), 711–720 (1998)

S.M. Holland, Principal Components Analysis (PCA) (Department of Geology, University of Georgia, Athens, GA, 2008), pp. 30602–32501

E. Barshan et al., Supervised principal component analysis: visualization, classification and regression on subspaces and submanifolds. Pattern Recognit. 44(7), 1357–1371 (2011)

B. Schölkopf, A. Smola, K.R. Müller, Kernel principal component analysis. In: International Conference on Artificial Neural Networks (Springer, Heidelberg, 1997)

T. Kohonen, The self-organizing map. Neurocomputing 21(1–3), 1–6 (1998)

F. Camastra, A. Vinciarelli, Feature Extraction Methods and Manifold Learning Methods (Springer, London, 2008)

A. Hyvärinen, J. Karhunen, E. Oja, Independent Component Analysis, vol. 46. (Wiley, New York, 2004)

W. Hämäläinen, Descriptive and predictive modelling techniques for educational technology. Licentiate thesis, Department of Computer Science, University of Joensuu, 2006

B. Zhang et al., Determination of fruit maturity and its prediction model based on the pericarp index of absorbance difference (IAD) for peaches. PLoS ONE 12(5), e0177511 (2017)

H. Stone et al., Sensory evaluation by quantitative descriptive analysis. In: Descriptive Sensory Analysis in Practice (2004), pp. 23–34

J. Gill, P.S. Sandhu, T. Singh, A review of automatic fruit classification using soft computing techniques. In: International Conference on Computing Systems in Electronic Engineering, 2014

W. Wu et al., Comparison of regularized discriminant analysis linear discriminant analysis and quadratic discriminant analysis applied to NIR data. Anal. Chim. Acta 329(3), 257–265 (1996)

M. Haenlein, A.M. Kaplan, A beginner’s guide to partial least squares analysis. Underst. Stat. 3(4), 283–297 (2004)

J.A.K. Suykens, J. Vandewalle, Least squares support vector machine classifiers. Neural Process. Lett. 9(3), 293–300 (1999)

W.C. Seng, S.H. Mirisaee, A new method for fruits recognition system. In: International Conference on Electrical Engineering and Informatics, ICEEI’09, vol. 1, IEEE, 2009

K.V. Branden, M. Hubert, Robust classification in high dimensions based on the SIMCA method. Chemom. Intell. Lab. Syst. 79(1–2), 10–21 (2005)

H. Abdi, Partial least square regression (PLS regression). Encycl. Res. Methods Soc. Sci. 6(4), 792–795 (2003)

D.F. Andrews, A robust method for multiple linear regression. Technometrics 16(4), 523–531 (1974)

W.F. Massy, Principal components regression in exploratory statistical research. J. Am. Stat. Assoc. 60(309), 234–256 (1965)

A. Peirs et al., Uncertainty analysis and modelling of the starch index during apple fruit maturation. Postharvest Biol. Technol. 26(2), 199–207 (2002)

L. Gaete-Garretón et al., A novel noninvasive ultrasonic method to assess avocado ripening. J. Food Sci. 70(3), E187–E191 (2005)

A. Mizrach, Assessing plum fruit quality attributes with an ultrasonic method. Food Res. Int. 37(6), 627–631 (2004)

K.B. Kim et al., Determination of apple firmness by nondestructive ultrasonic measurement. Postharvest Biol. Technol. 52(1), 44–48 (2009)

A. Mizrach, Determination of avocado and mango fruit properties by ultrasonic technique. Ultrasonics 38(1–8), 717–722 (2000)

A. Mizrach et al., Determination of avocado maturity by ultrasonic attenuation measurements. Sci. Hortic. 80(3–4), 173–180 (1999)

A. Bechar et al., Determination of mealiness in apples using ultrasonic measurements. Biosyst. Eng. 91(3), 329–334 (2005)

K.B. Kim et al. Evaluation of fruit firmness by ultrasonic measurement. In: Key Engineering Materials. eds by S.S. Lee, D.J. Yoon, J.H. Lee, S. Lee, vol. 270 (Trans Tech Publications, Switzerland, 2004)

B.E. Verlinden, V.De Smedt, B.M. Nicolaı̈, Evaluation of ultrasonic wave propagation to measure chilling injury in tomatoes. Postharvest Biol. Techno. 32(1), 109–113 (2004)

V. Leemans, M.F. Destain, A real-time grading method of apples based on features extracted from defects. J. Food Eng. 61(1), 83–89 (2004)

A.B. Koc, Determination of watermelon volume using ellipsoid approximation and image processing. Postharvest Biol. Technol. 45(3), 366–371 (2007)

N. Aleixos et al., Multispectral inspection of citrus in real-time using machine vision and digital signal processors. Comput. Electron. Agric. 33(2), 121–137 (2002)

G. ElMasry et al., Hyperspectral imaging for nondestructive determination of some quality attributes for strawberry. J. Food Eng. 81(1), 98–107 (2007)

A. Mizrach et al., Models of ultrasonic parameters to assess avocado properties and shelf life. J. Agric. Eng. Res. 65(4), 261–267 (1996)

I. Aboudaoud et al., The maturity characterization of orange fruit by using high frequency ultrasonic echo pulse method. In: 1st Conference on IOP Conference Series: Materials Science and Engineering. vol. 42, IOP Publishing, 2012

F. Camarena, J.A. Martinez-Mora, Potential of ultrasound to evaluate turgidity and hydration of the orange peel. J. Food Eng. 75(4), 503–507 (2006)

R. Lewis et al., Characterising pressure and bruising in apple fruit. Wear 264(1–2), 37–46 (2008)

K.L. Ha et al., A basic study on nondestructive evaluation of potatoes using ultrasound. Jpn. J. Appl. Phys. Part 1 30, 80–82 (1991)

V. Steinmetz et al., Sensors for fruit firmness assessment: comparison and fusion. J. Agric. Eng. Res. 64(1), 15–27 (1996)

R. Saggin, J.N. Coupland, Concentration measurement by acoustic reflectance. J. Food Sci. 66(5), 681–685 (2001)

K. Peleg, Development of a commercial fruit firmness sorter. J. Agric. Eng. Res. 72(3), 231–238 (1999)

M. Nielsen, H.J. Martens, K. Kaack, Low frequency ultrasonics for texture measurements in carrots (Daucus carota L.) in relation to water loss and storage. Postharvest Biol. Technol 14(3), 297–308 (1998)

U. Flitsanov et al., Measurement of avocado softening at various temperatures using ultrasound. Postharvest Biol. Technol. 20(3), 279–286 (2000)

D. Ariana, D.E. Guyer, B. Shrestha, Integrating multispectral reflectance and fluorescence imaging for defect detection on apples. Comput. Electron. Agric. 50(2), 148–161 (2006)

B.S. Bennedsen, D.L. Peterson, Performance of a system for apple surface defect identification in near-infrared images. Biosyst. Eng. 90(4), 419–431 (2005)

J. Blasco, N. Aleixos, E. Moltó, Machine vision system for automatic quality grading of fruit. Biosyst. Eng. 85(4), 415–423 (2003)

J. Blasco, N. Aleixos, E. Molto, Computer vision detection of peel defects in citrus by means of a region oriented segmentation algorithm. J. Food Eng. 81(3), 535–543 (2007)

G. ElMasry, N. Wang, C. Vigneault, Detecting chilling injury in Red Delicious apple using hyperspectral imaging and neural networks. Postharvest Biol. Technol. 52(1), 1–8 (2009)

J. Blasco et al., Development of a machine for the automatic sorting of pomegranate (Punica granatum) arils based on computer vision. J. Food Eng. 90(1), 27–34 (2009)

X. Liming, Z. Yanchao, Automated strawberry grading system based on image processing. Comput. Electron. Agric. 71, S32–S39 (2010)

L. Lleó et al., Multispectral images of peach related to firmness and maturity at harvest. J. Food Eng. 93(2), 229–235 (2009)

F. Lpez-Garca et al., Automatic detection of skin defects in citrus fruits using a multivariate image analysis approach. Comput. Electron. Agric. 71(2), 189–197 (2010)

S. Cubero et al., Application for the estimation of the standard citrus colour index (CCI) using image processing in mobile devices. Biosyst. Eng. 167, 63–74 (2018)

J. Blasco et al., Recognition and classification of external skin damage in citrus fruits using multispectral data and morphological features. Biosyst. Eng. 103(2), 137–145 (2009)

D.S. Prabha, J. Satheesh, Kumar, Assessment of banana fruit maturity by image processing technique. J. Food Sci. Technol. 52(3), 1316–1327 (2015)

O.K.M. Yahaya et al., Non-destructive quality evaluation of fruit by color based on RGB LEDs system. In: 2nd International Conference on Electronic Design (ICED), IEEE, 2014

S.K. Bejo, S. Kamaruddin, Determination of Chokanan mango sweetness (‘Mangifera indica’) using non-destructive image processing technique. Austr. J. Crop Sci. 8(4), 475 (2014)

Z. Malik et al., Detection and counting of on-tree citrus fruit for crop yield estimation. IJACSA. (2016). https://doi.org/10.14569/IJACSA.2016.070569

H.K. Noh, R. Lu, Hyperspectral laser-induced fluorescence imaging for assessing apple fruit quality. Postharvest Biol. Technol. 43(2), 193–201 (2007)

S. Elsayed et al., Passive reflectance sensing and digital image analysis for assessing quality parameters of mango fruits. Sci. Hortic. 212, 136–147 (2016)

M. Othman et al., Fuzzy ripening mango index using RGB colour sensor model. Res. World 5(2), 1 (2014)

K. Mollazade et al., Analysis of texture-based features for predicting mechanical properties of horticultural products by laser light backscattering imaging. Comput. Electron. Agric. 98, 34–45 (2013)

J. Brezmes et al., Correlation between electronic nose signals and fruit quality indicators on shelf-life measurements with pinklady apples. Sensors Actuators B: Chem. 80(1), 41–50 (2001)

A. Sanaeifar et al., Development and application of a new low cost electronic nose for the ripeness monitoring of banana using computational techniques (PCA, LDA, SIMCA, and SVM). Czech J. Food Sci. 32, 538–548 (2014)

S. Nordiyana et al., Development of electronic nose for fruits ripeness determination. In: 1st International Conference on Sensing Technology, Palmerston North, New Zealand, 2005

E.M. Pruteanu et al. Electronic nose for discrimination of Romanian apples. Lucr. Stiintifice (2009). https://doi.org/10.3390/s150100899

C. Di Natale et al., Electronic nose based investigation of the sensorial properties of peaches and nectarines. Sensors Actuators B: Chem. 77(1–2), 561–566 (2001)

A.H. Gómez et al., Electronic nose technique potential monitoring mandarin maturity. Sensors Actuators B: Chem 113(1), 347–353 (2006)

J. Brezmes et al., Evaluation of an electronic nose to assess fruit ripeness. IEEE Sens. J. 5(1), 97–108 (2005)

S. Benedetti et al., Electronic nose as a non-destructive tool to characterise peach cultivars and to monitor their ripening stage during shelf-life. Postharvest Biol. Technol. 47(2), 181–188 (2008)

J.A. Ragazzo-Sanchez et al., Off-flavours detection in alcoholic beverages by electronic nose coupled to GC. Sensors Actuators B: Chem 140(1), 29–34 (2009)

M. Ruiz-Altisent, L. Lleó, F. Riquelme, Instrumental quality assessment of peaches: fusion of optical and mechanical parameters. J. Food Eng. 74(4), 490–499 (2006)

K.M. Nunes et al., Detection and characterisation of frauds in bovine meat in natura by non-meat ingredient additions using data fusion of chemical parameters and ATR-FTIR spectroscopy. Food Chem. 205, 14–22 (2016)

C. Li, P. Heinemann, R. Sherry, Neural network and Bayesian network fusion models to fuse electronic nose and surface acoustic wave sensor data for apple defect detection. Sensors Actuators B. Chem. 125(1), 301–310 (2007)

J.A. Ragazzo-Sanchez et al., Identification of different alcoholic beverages by electronic nose coupled to GC. Sensors Actuators B. Chem. 134(1), 43–48 (2008)

F.S.A. Sa’ad et al., Bio-inspired sensor fusion for quality assessment of harumanis mangoes. Proc. Chem. 6, 165–174 (2012)

L. Pan et al., Early detection and classification of pathogenic fungal disease in post-harvest strawberry fruit by electronic nose and gas chromatography–mass spectrometry. Food Res. Int. 62, 162–168 (2014)

C. Di Natale et al., Outer product analysis of electronic nose and visible spectra: application to the measurement of peach fruit characteristics. Anal. Chim. Acta 459(1), 107–117 (2002)

K.K. Vursavus et al., Classification of the firmness of peaches by sensor fusion. Int. J. Agric. Biol. Eng. 8(6), 104 (2015)

A. Baltazar, J.I. Aranda, G. González-Aguilar, Bayesian classification of ripening stages of tomato fruit using acoustic impact and colorimeter sensor data. Comput. Electron. Agric. 60(2), 113–121 (2008)

A. Herrero-Langreo et al., Combination of optical and non-destructive mechanical techniques for the measurement of maturity in peach. J. Food Eng. 108(1), 150–157 (2012)

L. Huang et al., Nondestructive measurement of total volatile basic nitrogen (TVB-N) in pork meat by integrating near infrared spectroscopy, computer vision and electronic nose techniques. Food Chem. 145, 228–236 (2014)

V. Steinmetz et al., On-line fusion of colour camera and spectrophotometer for sugar content prediction of apples. J. Agric. Eng. Res. 73(2), 207–216 (1999)

D. Liu et al., Combination of spectra and texture data of hyperspectral imaging for prediction of pH in salted meat. Food Chem. 160, 330–337 (2014)

S. Roussel et al., Authenticating white grape must variety with classification models based on aroma sensors, FT-IR and UV spectrometry. J. Food Eng. 60(4), 407–419 (2003)

F. Mendoza, R. Lu, H. Cen, Comparison and fusion of four nondestructive sensors for predicting apple fruit firmness and soluble solids content. Postharvest Biol. Technol. 73, 89–98 (2012)

C. Ortíz et al., PH—postharvest technology: non-destructive identification of woolly peaches using impact response and near-infrared spectroscopy. J. Agric. Eng. Res. 78(3), 281–289 (2001)

S. Qiu, J. Wang, L. Gao, Discrimination and characterization of strawberry juice based on electronic nose and tongue: comparison of different juice processing approaches by LDA, PLSR, RF, and SVM. J. Agric. Food Chem. 62(27), 6426–6434 (2014)

H. Young et al., Characterization of Royal Gala apple aroma using electronic nose technology potential maturity indicator. J. Agric. Food Chem. 47(12), 5173–5177 (1999)

J. Brezmes et al., Fruit ripeness monitoring using an electronic nose. Sensors Actuators B: Chem 69(3), 223–229 (2000)

H. Guohua et al., Fuji apple storage time predictive method using electronic nose. Food Anal. Methods 6(1), 82–88 (2013)

E. Llobet et al., Non-destructive banana ripeness determination using a neural network-based electronic nose. Meas. Sci. Technol. 10(6), 538 (1999)

L.P. Pathange et al., Non-destructive evaluation of apple maturity using an electronic nose system. J. Food Eng. 77(4), 1018–1023 (2006)

H. Zhang, J. Wang, S. Ye, Predictions of acidity, soluble solids and firmness of pear using electronic nose technique. J. Food Eng. 86(3), 370–378 (2008)

C. Di Natale et al., The evaluation of quality of post-harvest oranges and apples by means of an electronic nose. Sensors Actuators B: Chem. 78(1–3), 26–31 (2001)

E.G. Breijo et al., Odour sampling system with modifiable parameters applied to fruit classification. J. Food Eng. 116(2), 277–285 (2013)

E. Kim et al., Pattern recognition for selective odor detection with gas sensor arrays. Sensors 12(12), 16262–16273 (2012)

T. Nilsson, K.E. Gustavsson, Postharvest physiology of ‘Aroma’apples in relation to position on the tree. Postharvest Biol. Technol 43(1), 36–46 (2007)

M. Su et al., Pulp volatiles measured by an electronic nose are related to harvest season, TSS concentration and TSS/TA ratio among 39 peaches and nectarines. Sci. Hortic. 150, 146–153 (2013)

E. Molto et al., An aroma sensor for assessing peach quality. J. Agric. Eng. Res. 72(4), 311–316 (1999)

H.F. Hawari et al., Highly selective molecular imprinted polymer (MIP) based sensor array using interdigitated electrode (IDE) platform for detection of mango ripeness. Sensors Actuators B: Chem. 187, 434–444 (2013)

M. Lebrun et al., The electronic nose: a fast and efficient tool for characterizing dates. Fruits 62(6), 377–382 (2007)

Y.C. Yang et al., Rapid detection of anthocyanin content in lychee pericarp during storage using hyperspectral imaging coupled with model fusion. Postharvest Biol. Technol. 103, 55–65 (2015)

P.N. Schaare, D.G. Fraser, Comparison of reflectance, interactance and transmission modes of visible-near infrared spectroscopy for measuring internal properties of kiwifruit (Actinidia chinensis). Postharvest Biol. Technol. 20(2), 175–184 (2000)

R. Lu, D.E. Guyer, R.M. Beaudry, Determination of firmness and sugar content of apples using near-infrared diffuse reflectance. J. Texture Stud. 31(6), 615–630 (2000)

Z. Schmilovitch et al., Determination of mango physiological indices by near-infrared spectrometry. Postharvest Biol. Technol. 19(3), 245–252 (2000)

N. Sinelli et al., Evaluation of quality and nutraceutical content of blueberries (Vaccinium corymbosum L.) by near and mid-infrared spectroscopy. Postharvest Biol. Technol. 50(1), 31–36 (2008)

J. Lammertyn et al., Light penetration properties of NIR radiation in fruit with respect to non-destructive quality assessment. Postharvest Biol. Technol. 18(2), 121–132 (2000)

C. Camps, D. Christen, Non-destructive assessment of apricot fruit quality by portable visible-near infrared spectroscopy. LWT-Food Sci. Technol. 42(6), 1125–1131 (2009)

A.H. Gomez, Y. He, A.G. Pereira, Non-destructive measurement of acidity, soluble solids and firmness of Satsuma mandarin using Vis/NIR-spectroscopy techniques. J. Food Eng. 77(2), 313–319 (2006)

S. Saranwong, J. Sornsrivichai, S. Kawano, Prediction of ripe-stage eating quality of mango fruit from its harvest quality measured nondestructively by near infrared spectroscopy. Postharvest Biol. Technol. 31(2), 137–145 (2004)

A. Peirs et al., Prediction of the optimal picking date of different apple cultivars by means of VIS/NIR-spectroscopy. Postharvest Biol. Technol. 21(2), 189–199 (2001)

S. Bureau et al., Rapid and non-destructive analysis of apricot fruit quality using FT-near-infrared spectroscopy. Food Chem 113(4), 1323–1328 (2009)

J. **a et al., Visible-near infrared spectrum-based classification of apple chilling injury on cloud computing platform. Comput. Electron. Agric. 145, 27–34 (2018)

M. Zude et al., Non-destructive analysis of anthocyanins in cherries by means of Lambert–Beer and multivariate regression based on spectroscopy and scatter correction using time-resolved analysis. J. Food Eng. 103(1), 68–75 (2011)

M. Silvestri et al., A mid level data fusion strategy for the varietal classification of lambrusco PDO wines. Chemom. Intell. Lab. Syst. 137, 181–189 (2014)

A.G. Mignani et al., Optical measurements and pattern-recognition techniques for identifying the characteristics of beer and distinguishing Belgian beers. Sensors Actuators B: Chem. 179, 140–149 (2013)

I. Arana, C. Jarén, S. Arazuri, Maturity, variety and origin determination in white grapes (Vitis vinifera L.) using near infrared reflectance technology. J. Near Infrared Spectrosc. 13(6), 349–357 (2005)

R. Beghi et al., Apples nutraceutic properties evaluation through a visible and near-infrared portable system. Food Bioprocess Technol. 6(9), 2547–2554 (2013)

V. Cortés et al., A new internal quality index for mango and its prediction by external visible and near-infrared reflection spectroscopy. Postharvest Biol. Technol. 118, 148–158 (2016)

T. Ignat et al., Nonlinear methods for estimation of maturity stage, total chlorophyll, and carotenoid content in intact bell peppers. Biosyst. Eng. 114(4), 414–425 (2013)

R. Lu, Imaging spectroscopy for assessing internal quality of apple fruit. In: ASAE Annual Meeting. American Society of Agricultural and Biological Engineers, 2003

G.Y. Kim et al., Defect and ripeness inspection of citrus using NIR transmission spectrum. In: Key Engineering Materials, vol. 270, eds. by S.S. Lee, D.J. Yoon, J.H. Lee, S. Lee (Trans Tech Publications, Switzerland, 2004)

Alpha MOS, http://saba.kntu.ac.ir/eecd/ecourses/inst%2086/Projects/Electronic%20Nose/final%20atashzar/New%20Folder/Alpha%20M.O.S..htm. Accessed 08 Feb 2018

Sensight, intelligent sensing solutions, http://www.sensigent.com/products/cyranose.html. Accessed 08 Feb 2018

Air sense analytics, https://airsense.com/en/products/portable-electronic-nose. Accessed 08 Feb 2018

SCIO by Consumer Physics, https://www.consumerphysics.com/scio-for-consumers/. Accessed 08 Feb 2018

ClariFruit Know Your Fruit, https://www.clarifruit.com/. Accessed 08 Feb 2018

Felix instruments, https://felixinstruments.com/food-science instruments/portable-nir-analyzers/f-750-produce-quality-meter/. Accessed 08 Feb 2018

Sunforest, http://sunforest.en.ec21.com/. Accessed 08 Feb 2018

Trturoni, http://www.trturoni.com/en/content/8-da-meter. Accessed 08 Feb 2018

Unitech, http://www.postharvest.biz/en/company/unitecspa/_id:29711,seccion:productcatalog,producto:10531/. Accessed 08 Feb 2018

Omega, http://in.omega.com/pptst/HFH80.html. Accessed 08 Feb 2018

Food sniffer, http://www.myfoodsniffer.com/. Accessed 08 Feb 2018

Y.Y. Pu, Y.Z. Feng, D.W. Sun, Recent progress of hyperspectral imaging on quality and safety inspection of fruits and vegetables: a review. Compr. Rev. Food Sci. Food Saf. 14(2), 176–188 (2015)

M. Falasconi et al., Electronic nose for microbiological quality control of food products. Int. J. Electrochem. (2012). https://doi.org/10.1155/2012/715763

T. Brosnan, D.W. Sun, Improving quality inspection of food products by computer vision: a review. J. Food Eng. 61(1), 3–16 (2004)

C.J. Du, D.W. Sun, Recent developments in the applications of image processing techniques for food quality evaluation. Trends Food Sci. Technol. 15(5), 230–249 (2004)

K.K. Patel et al., Machine vision system: a tool for quality inspection of food and agricultural products. J. Food Sci. Technol. 49(2), 123–141 (2012)

C.J. Du, D.W. Sun, Learning techniques used in computer vision for food quality evaluation: a review. J. Food Eng 72(1), 39–55 (2006)

H. Cen, Y. He, Theory and application of near infrared reflectance spectroscopy in determination of food quality. Trends Food Sci. Technol. 18(2), 72–83 (2007)

S.N. JHA, T. Matsuoka, Non-destructive techniques for quality evaluation of intact fruits and vegetables. Food Sci. Technol. Res. 6(4), 248–251 (2000)

H. Huang et al., Near infrared spectroscopy for on/in-line monitoring of quality in foods and beverages: a review. J. Food Eng. 87(3), 303–313 (2008)

B.M. Nicolai et al., Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: a review. Postharvest Biol. Technol. 46(2), 99–118 (2007)

T.J. Mason, L. Paniwnyk, J.P. Lorimer, The uses of ultrasound in food technology. Ultrason. Sonochem 3(3), S253–S260 (1996)

A. Mizrach, Ultrasonic technology for quality evaluation of fresh fruit and vegetables in pre-and postharvest processes. Postharvest Biol. Technol 48(3), 315–330 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srivastava, S., Sadistap, S. Data processing approaches and strategies for non-destructive fruits quality inspection and authentication: a review. Food Measure 12, 2758–2794 (2018). https://doi.org/10.1007/s11694-018-9893-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-018-9893-2