Abstract

Fe45Cr16Mo16C18B5 amorphous coatings were deposited on the mild steel substrate (0.45 wt.% C) by plasma spraying, and their corrosion resistance in 3.5 wt.% NaCl solution was compared with those of the substrate and 316 stainless steel. Potentiodynamic tests revealed that the as-prepared coatings had higher resistance to local corrosion than 316 stainless steel due to their wide passivation range. Electrochemical impedance spectroscopy (EIS) measurements further explained the long-term corrosion process of the coatings and indicated their excellent corrosion resistance. Based on this analysis, a schematic diagram of the corrosion mechanism of the coatings was proposed. The obtained results imply that Fe45Cr16Mo16C18B5 amorphous coatings have a promising prospect for industrial applications.

Similar content being viewed by others

References

A. Kobayashi, S. Yano, H. Kimura, and A. Inoue, Mechanical Property of Fe-Base Metallic Glass Coating Formed by Gas Tunnel Type Plasma Spraying, Surf. Coat. Technol., 2008, 202, p 2513-2518

A. Inoue, X.M. Wang, and W. Zhang, Development and Applications of Bulk Metallic Glasses, Rev. Adv. Mater. Sci., 2008, 18, p 1-9

Z. Zhou, L. Wang et al., Formation and corrosion behavior of Fe-based amorphous metallic coatings by HVOF thermal spraying, Surf. Coat. Technol., 2009, 204, p 563-570

J. Blink, J. Farmer et al., Applications in the Nuclear Industry for Thermal Spray Amorphous Metal and Ceramic Coatings, Metall. Mater. Trans. A, 2009, 40, p 1344-1354

B. Shen, A. Inoue, and C. Chang, Superhigh strength and good soft-magnetic properties of (Fe, Co)–B–Si–Nb bulk glassy alloys with high glass-forming ability, Acta Mater., 2004, 52, p 4093-4099

D.J. Branagan and M. Breitsameter, High-performance nanoscale composite coatings for boiler applications, J. Therm. Spray Technol., 2005, 14, p 196-204

J. Voyer, Wear-Resistant Amorphous Iron-Based Flame-Sprayed Coatings, J. Them. Spray Technol., 2010, 19, p 1013-1023

X.Q. Liu, Y.G. Zheng et al., Microstructure and Properties of Fe-Based Amorphous Metallic Coating Produced by High Velocity Axial Plasma Spraying, J. Alloys Compd., 2009, 484, p 300-307

J. Farmer, S. Cheng et al., Iron-Based Amorphous-Metals: High-Performance Corrosion-Resistant Materials (HPCRM) Development Final Report, Metall. Mater. Trans. A, 2009, 40, p 1289-1305

J. Farmer, S.D. Day et al., Terahertz Polaritonics, J. Mater. Res., 2007, 22, p 2291-2311

S. Kumar, C. Lee et al., Phase Dependence of Fe-Based Bulk Metallic Glasses on Properties of Thermal Spray Coatings, J. Alloys Compd., 2009, 475, p 9-12

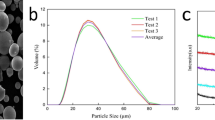

C. Zhang, R.Q. Guo et al., Influence of the Size of Spraying Powders on the Microstructure and Corrosion Resistance of Fe-Based Amorphous Coating, Electrochim. Acta, 2011, 56, p 6380-6388

Y. Yang, C. Zhang et al., Effects of Crystallization on the Corrosion Resistance of Fe-Based Amorphous Coatings, Corros. Sci., 2012, 59, p 10-19

S.D. Zhang, J. Wu, W.B. Qi et al., Effect of Porosity Defects on the Long-Term Corrosion Behaviour of Fe-Based Amorphous Alloy Coated Mild Steel, Corros. Sci., 2016, 110, p 57-70

J.M. Guilemany, N. Espallargas et al., Influence of Spraying Parameters on the Electrochemical Behaviour of HVOF Thermally Sprayed Stainless Steel Coatings in 3.4% NaCl, Surf. Coat. Technol., 2006, 200, p 3064-3072

J. Saaedi, T.W. Coyle et al., Effects of HVOF Process Parameters on the Properties of Ni-Cr Coatings, J. Therm. Spray Technol., 2010, 19, p 521-530

J. Kawakita and S. Kuroda, Corrosion Resistance of HVOF Sprayed HastelloyC Nickel Base Alloy in Seawater, Corros. Sci., 2005, 47, p 2053-2062

M. Naka, K. Hashimoto, and T. Masumoto, Effect of Addition of Chromium and Molybdenum on the Corrosion Behavior of Amorphous Fe-20B, Co-20B and Ni-20B Alloys, J. Non-Cryst. Solids J., 1979, 34, p 257-266

D. Yang, C. Liu et al., Corrosion Behavior of Plasma Sprayed Ceramic and Metallic Coatings on Carbon Steel in Simulated Seawater, Mater. Des., 2013, 52, p 630-637

Acknowledgments

The present work was supported by the National Nature Science Foundation of China (Grant Nos. 51775329 and 51872072), the Nature Science Foundation of Tian** City, China (Grant No. 16JCQNJC03600), and the special funding for the development of science and technology of Shanghai Ocean University (Grant Nos. A2-0203-00-100231 and A2-2006-00-200371).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chu, Z., Deng, W., Zheng, X. et al. Corrosion Mechanism of Plasma-Sprayed Fe-Based Amorphous Coatings with High Corrosion Resistance. J Therm Spray Tech 29, 1111–1118 (2020). https://doi.org/10.1007/s11666-020-01030-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01030-9