Abstract

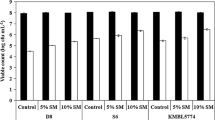

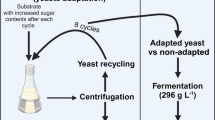

Spray-drying (SD) is widely considered a suitable method to preserve microorganisms, but data regarding yeasts are still scanty. In this study, the effect of growing media, process variables and carriers over viability of a wild wine Saccharomyces (S.) cerevisiae LM52 was evaluated. For biomass production, the strain was grown (batch and fed-batch fermentation) in a synthetic, as well as in a beet sugar molasses based-medium. Drying of cells resuspended in several combinations of soluble starch and maltose was performed at different inlet and outlet temperatures. Under the best conditions–suspension in soluble starch plus maltose couplet to inlet and outlet temperatures of 110 and 55 °C, respectively—the loss of viability of S. cerevisiae LM52 was 0.8 ± 0.1 and 0.5 ± 0.2 Log c.f.u. g−1 for synthetic and molasses-based medium, respectively. Similar results were obtained when S. cerevisiae strains Zymoflore F15 and EC1118, isolated from commercial active dry yeast (ADY), were tested. Moreover, powders retained a high vitality and showed good fermentation performances up to 6 month of storage, at both 4 and −20 °C. Finally, fermentation performances of different kinds of dried formulates (SD and ADY) compared with fresh cultures did not show significant differences. The procedure proposed allowed a small-scale production of yeast in continuous operation with relatively simple equipment, and may thus represent a rapid response-on-demand for the production of autochthonous yeasts for local wine-making.

Similar content being viewed by others

References

Abadias M, Teixidó N, Usall J, Solsona C, Viñas I (2005) Survival of the postharvest biocontrol yeast Candida sake CPA-1 after dehydration by spray-drying. Biocontrol Sci Technol 15:835–846

Blaiotta G, Di Capua M, Aponte M (2009) Monitoring of yeast microflora during Gragnano DOC (Campania Region, Italy) winemaking and selection of autochthonous Saccharomyces cerevisiae strains. II Convegno SIMTREA, Sassari 10-12 Giugno. Poster. Abstract in: Ann Microbiol 59(Special Issue):39

Cerrutti P, de Segovia HM, Galvagno M, Schebor C, del Pilar BM (2000) Commercial baker’s yeast stability as affected by intracellular content of trehalose, dehydration procedure and the physical properties of external matrices. Appl Microbiol Biotechnol 54:575–580

Desmond C, Ross RP, O’Callaghan E, Fitzgerald G, Stanton C (2002) Improved survival of Lactobacillus paracasei NFBC 338 in spray-dried powders containing gum acacia. J Appl Microbiol 93:1003–1011

Fu N, Chen XD (2011) Towards a maximal cell survival in convective thermal drying processes. Food Res Int 44:1127–1149

Gómez-Pastor R, Pérez-Torrado R, Garre E, Matallana E (2011) Recent advances in yeast biomass production. In: Matovic MD (ed) Biomass-detection, production and usage. InTech Publisher, Rijeka

Hazelwood LA, Walsh MC, Luttik MAH, Daran-Lapujade P, Pronk JT, Daran JM (2009) Identity of the growth-limiting nutrient strongly affects storage carbohydrate accumulation in anaerobic chemostat cultures of Saccharomyces cerevisiae. Appl Environ Microbiol 75:6876–6885

International Dairy Federation Standard (1993) Dried milk and dried cream. Determination of water content. 26A. Brussels, Belgium

Isono Y, Hoshino K (2000) Production of ethanol using granulated yeast cells prepared by a spray dryer. J Gen Appl Microbiol 46:231–234

Kristiansen B (1994) Integrated design of fermentation plant. The production of bakers’ yeast. VCH Verlagsgesellschaft mbH, Weinheim

Labuza TP, Le Roux JP, Fan TS, Tannenbaum SR (1970) Engineering factors in single-cell protein production. Spray drying and cell viability. Biotechnol Bioeng 12:135–140

Luna-Solano G, Salgado-Cervantes MA, Garcia-Alvarado MA, Rodriguez-Jimenes GC (1998) Yeast viability (Saccharomyces cerevisiae) dried by fluidized bed and spray drying. Drying ‘98, vol. C, (IDS) Halkidiki, pp 18–21

Luna-Solano G, Salgado-Cervantes MA, Garcia-Alvarado MA, Rodriguez-Jimenes G (2000) Improved viability of spray dried brewer’s yeast by using starch (grits) and maltodextrin as processing aids. J Food Process Eng 23:453–462

Luna-Solano G, Salgado-Cervantes MA, Ramirez-Lepe M, Garcia-Alvarado MA, Rodriguez-Jimenes GC (2003) Effect of drying type and drying conditions over fermentative ability of brewer’s yeast. J Food Process Eng 26:135–147

Luna-Solano G, Salgado-Cervantes MA, Rodrìguez-Jimenes GC, Garcìa-Alvarado MA (2005) Optimization of brewer’s yeast spray drying process. J Food Eng 68:9–18

Manzoni M (2006) Microbiologia Indistriale. Casa Editrice Ambrosiana, Milano, pp 220–223

Maqueda M, Pérez-Nevado F, Regodón JA, Zamora E, Álvarez ML, Rebollo JE, Ramírez M (2011) A low-cost procedure for production of fresh autochthonous wine yeast. J Ind Microbiol Biotechnol 38:459–469

OIV (2012) Guidelines for the characterization of wine yeasts of the genus Saccharomyces isolated from vitivinicultural environments. Resolution Oiv-Oeno p 370

Pérez-Torrado R, Bruno-Bàrcena JM, Matallana E (2005) Monitoring stress-related genes during the process of biomass propagation of Saccharomyces cerevisiae strains used for wine making. Appl Environ Microbiol 71:6831–6837

Rainieri S, Pretorius IS (2000) Selection and improvement of wine yeasts. Ann Microbiol 50:15–31

Redon M, Guillamon JM, Mas A, Rozes N (2008) Effect of active dry wine yeast storage upon viability and lipid composition. World J Microbiol Biotechnol 24:2555–2563

Santivarangkna C, Kulozik U, Foerst P (2008) Inactivation mechanisms of lactic starter cultures preserved by drying processes. J Appl Microbiol 105:1–13

Serafino V, Pepe A, Romano P (2007) Preservation of wine yeasts by Spray-dryer. Poster no P3.19: in International Specialized Symposium on Yeasts, Sorrento. 3–7 June 2007

Silva J, Freixo R, Gibbs P, Teixeira P (2011) Spray-drying for the production of dried cultures. Int J Dairy Technol 64:321–335

Vincenzini M, Romano P, Farris GA (2005) Microbiologia del vino. Casa Editrice Ambrosiana, Milano

Welsh DT (2000) Ecological significance of compatible solute accumulation by microorganisms: from single cells to global climate. FEMS Microbiol Rev 24:263–290

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aponte, M., Troianiello, G.D., Di Capua, M. et al. Impact of different spray-drying conditions on the viability of wine Saccharomyces cerevisiae strains. World J Microbiol Biotechnol 32, 13 (2016). https://doi.org/10.1007/s11274-015-1956-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-015-1956-5