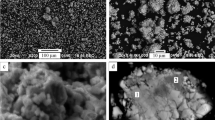

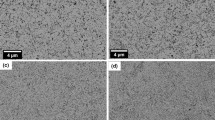

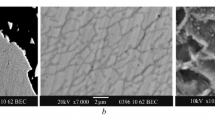

Scanning electron microscopy and X-ray energy-dispersive spectroscopy were employed to study the sintering of powders from the induction-melted industrial ferromagnetic Sm2(Co,Fe,Zr,Cu)17 alloy by the hydrogenation, disproportionation (HD), desorption, recombination (DR) (HDDR) route. The HD stage proceeded at 700°C and DR at 950°C. The experimental results showed that sintering of the powders occurred at the HD stage to produce a mechanically integral highly porous material. The porosity of the sintered materials was found to decrease as the compaction pressure and powder particle refinement increased. The powder compaction pressure was estimated to range from 2 to 5 t/cm2. The decrease in sintering temperature was attributed to the higher diffusion rate of the alloy components resulting from the decrease in particle size, hydrogen-initiated phase transformations, and the hydrogen solid solution present in the alloy. Phase transformations occurred when the pressure changed at high temperatures. If the hydrogen pressure was high, the intermetallic was not thermodynamically stable and disintegrated (disproportionated) into several phases. If the hydrogen pressure was low (vacuum), the rare earth metal hydride was thermodynamically unstable and disintegrated, while the rare earth metal interacted with other phases to form the starting intermetallic. These phenomena are due to chemical reactions within a solid body, proceeding through the diffusion of components. The new sintering method for ferromagnetic materials has process advantages over existing methods: it does not require holding at the highest heating temperatures or usage of complex dies or complex equipment and results in the production of anisotropic nanostructured materials. Ways to improve the properties of sintered materials at low temperatures (in particular, increasing the homogeneity of their microstructure and decreasing the porosity) are proposed, such as optimization of sintering parameters and homogenization of the powders by particle size.

Similar content being viewed by others

Notes

The SmCo7 phase is quasistable, and part of cobalt is replaced by other metals to stabilize this phase. In the literature, this phase is denoted as SmCo7 and ‘SmCo7’, indicating that it includes other metals instead of cobalt. We used the second notation.

References

O. Gutfleisch, M.A. Willard, E. Brück, C.H. Chen, S.G. Sankar, and J. ** Liu, “Magnetic materials and devices for the 21st century: stronger, lighter, and more energy efficient,” Adv. Mater., 23, 821–842 (2011).

REN21. Renewables 2021 Global Status Report, REN21 Secretariat, ISBN 978-3-9818107-0-7, Paris, www.ren21.net.

Y. Yang, A. Walton, R. Sheridan, K. Güth, R. Gauß, O. Gutfleisch, M. Buchert, B.-M. Steenari, T.V. Gerven, P.T. Jones, and K. Binnemans, “REE Recovery from end-of-life NdFeB permanent magnet scrap: a critical review,” J. Sustain. Metall., 3(1), 122–149 (2016).

J. Liu, “Some design considerations using permanent magnets,” in: Magnetics Magazine: Business and Technology, March 13 (2016): https://magneticsmag.com/some-design-considerations-using-permanentmagnets.

J.M.D. Coey, “Perspective and prospects for rare earth permanent magnets,” Engineering, 6(2), 119–131 (2019).

J. Liu, Sm–Co Magnets and Applications, International Magnetics Association, Electron Energy Corporation (2010): https://www.electronenergy.com/brochures-white-papers/; https://cdn2.hubspot.net/hubfs/4788906/Electronenergy_December2018/Docs/SmCo-Magnets-and-Applications.pdf.

E.F. Kneller and R. Hawing, “The exchange-spring magnets: a new material principle for permanent magnets,” IEEE Trans. Magn., 27, 3588–3600 (1991).

H. Fukunaga and H. Nakamura, “Computer simulation of magnetic properties of anisotropic nanocomposite magnets,” IEEE Trans. Magn., 36(5), 3285–3287 (2000).

R. Skomski and J.M.D. Coey, “Giant energy product in nanostructured two-phase magnets,” Phys. Rev., 48, 15812–15816 (1993).

J.P. Liu, E. Fullerton, O. Gutfleisch, and D.J. Sellmyer, Nanoscale Magnetic Materials and Applications, Kyiv (2009), p. 719.

L. Zheng, B. Cui, L. Zhao, W. Li, and G.C. Hadjipanayis, “Sm2Co17 nanoparticles synthesized by surfactant-assisted high energy ball milling,” J. Alloys Compd., 539, 69–73 (2012).

N. Lu, X. Song, X. Liu, and J. Zhang, “Preparation and magnetic properties of amorphous and nanocrystalline Sm2Co17 alloys,” Intermetallics, 18, 1180–1184 (2010).

S. An, L. Zheng, T. Zhang, and C. Jiang, “Bulk anisotropic nanocrystalline SmCo6.6Ti0.4 permanent magnets,” Scr. Mater., 68, 432–435 (2013).

Z. Zhang, X. Song, and W. Xu, “Phase evolution and its effects on the magnetic performance of nanocrystalline SmCo7 alloy,” Acta Mater., 59, 1808–1817 (2011).

M.Q. Huang, Z. Turgut, B. Wheeler, D. Lee, S. Liu, B.M. Ma, Y.G. Peng, S.Y. Chu, D.E. Laughlin, J.C. Horwath, and R.T. Fingers, “Fully dense anisotropic nanocomposite Sm (Co,Fe,Zr,Cu,B)z, z = 7.5–12 magnets,” J. Appl. Phys., 97, 10H104-10H104-3 (2005).

A.M. Gabay, W.F. Li, and G.C. Hadjipanayis, “Effect of hot deformation on texture and magnetic properties of Sm–Co and Pr–Co alloys,” J. Magn. Magn. Mater., 323, 2470–2473 (2011).

C. Rong, Y. Zhang, N. Poudyal, I. Szlufarska, R.J. Hebert, M.J. Kramer, and J. ** Liu, “Self-nanoscaling of the soft magnetic phase in bulk SmCo/Fe nanocomposite magnets,” J. Mater. Sci., 46, 6065–6074 (2011).

Electronic Register, http://www.ccp14.ac.uk.

Electronic Register, http://www.ill.eu/sites/fullprof.

I.I. Bulyk, A.M. Trostyanchin, and V.I. Markovych, “Phase transformations in the SmCo5-based alloy initiated by hydrogen at a pressure to 650 kPa,” Fiz..-Khim. Mekh. Mater., No. 1, 94–98 (2007).

I.I. Bulyk, V.V. Burkhovetskii, and A.M. Trostyanchin, “Change in the phase and structural state of the SmCo5 -based alloy in solid HDDR at lower hydrogen pressure,” Metallofiz. Noveisz. Tekhnol., No. 2, 169–184 (2015).

I.I. Bulyk and P.Ya. Lyutyy, “Effect of hydrogen pressure on Sm2Co17 disproportionation,” Metallofiz. Noveisz. Tekhnol., 35, No. 9, 1283–1294 (2013).

I.I. Bulyk, M.V. Pilat, and P.Ya. Lyutyy, “Hydrogenation, disproportionation, desorption, and recombination in the Sm2Co17–xFex–H2 system (x = 3.9 and 5.95). X-ray diffraction,” Powder Metall. Met. Ceram., 53, No. 5–6, 343–352 (2014).

I.I. Bulyk, “Use of hydrogen for producing sintered anisotropic nanostructured magnets from rare-earth and transition metal alloys,” Fiz.-Khim. Mekh. Mater., No. 6, 10–23 (2018).

Ya.E. Geguzin, Physics of Sintering [in Russian], Moscow (1984), p. 311.

V.V. Skorokhod and S.M. Solonin, Physical and Metallurgical Fundamentals of Powder Sintering [in Russian], Moscow (1984), p. 159.

N. Cannesan and I.R. Harris, “Aspects of NdFeB HDDR powders: fundamentals and processing,” in: G.C. Hadjipanayis (ed.), Bonded Magnets, NATO Science Series: II. Mathematics, Physics and Chemistry, Vol. 118 (2002), pp. 13–36.

“Kinetics and same general features of hydrogen induced diffusive phase transformations in Nd2Fe14B type alloys,” in: Progress in Hydrogen Treatment of Materials, Donetsk–Coral Gables: Kassiopeya (2001), pp. 368–390.

V.I. Pokhmurskii and V.V. Fedorov, Effect of Hydrogen on Diffusion Processes in Metals [in Ukrainian], Moscow (1998), p. 206.

O. Gutfleisch and I.R. Harris, “Fundamental and practical aspects of the hydrogenation, disproportionation, desorption and recombination process,” J. Phys. D: Appl. Phys., 29, 2255–2265 (1996).

D.G. Savvakin, M.M. Gumenyak, M.V. Matviychuk, and O.G. Molar, “Role of hydrogen in the sintering of titanium powders,” Fiz.-Khim. Mekh. Mater., No. 1, 72–81 (2011).

J.W. Kim, S.H. Kim, S.Y. Song, and Y.D. Kim, “Nd–Fe–B permanent magnets fabricated by low temperature sintering process,” J. Alloys Compd., 551, 180–184 (2013).

Acknowledgments

The authors express their gratitude to Prof. M.S. Kovalchenko for the participation in discussion of the research results.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 61, Nos. 9–10 (547), pp. 76–90, 2022

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bulyk, I.I., Kononiuk, O.P. Sintering of Ferromagnetic Materials at Lower Temperatures in Hydrogen I. Sm2Co17 Alloys. Powder Metall Met Ceram 61, 548–559 (2023). https://doi.org/10.1007/s11106-023-00344-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-023-00344-x