Abstract

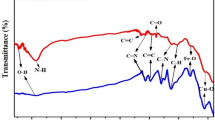

In this research, La0.8Sr0.2FeO3/cauliflower-like polyaniline (PANi) nanocomposite was architected based on a novel complementary method using dodecylbenzenesulfonic acid as a do** agent. The prepared nanocomposite was characterized using Fourier transform infrared, X-ray powder diffraction, field emission scanning electron microscopy, vibrating sample magnetometer diffuse reflection spectroscopy, and vector network analyzer analyses. All of the used analyses attested that the pure structure of materials has been synthesized. Polarizability, energy bandgap, magnetic property, and microwave absorbing features were tailored by loading the various mass fraction of PANi. Exclusive interactions between the nanoparticles with alkaline property and aniline monomers along the experimental route led to the preparation of nanocomposite with unique morphology. Inserting PANi augmented softness and isotropic magnetic property of the prepared nanocomposite, desirable for microwave absorption. Moreover, polyacrylonitrile (PAN) was applied as a novel microwave absorbing matrix. The maximum reflection loss (RL) of La0.8Sr0.2FeO3/PANi10%/PAN was − 69.24 dB at 12.62 GHz with an efficient bandwidth of 6.47 GHz (RL < − 10 dB) meanwhile the efficient bandwidth was enhanced to 6.97 GHz (RL < − 10 dB) for La0.8Sr0.2FeO3/PANi30%/PAN nanocomposite.

Similar content being viewed by others

References

H. Chen, W. Ma, Z. Huang, Y. Zhang, Y. Huang, Y. Chen, Adv. Opt. Mater. 7, 1801318 (2019)

D. Zhang, T. Liu, J. Cheng et al., Nano-Micro Lett. 11, 38 (2019)

Q. Li, Z. Zhang, L. Qi, Q. Liao, Z. Kang, Y. Zhang, Adv. Sci. 6, 1801057 (2019)

R. Peymanfar, M. Rahmanisaghieh, Mater. Res. Express 5, 105012 (2018)

R. Peymanfar, F. Azadi, Nano-Struct. Nano-Objects 17, 112 (2019)

R. Peymanfar, S. Javanshir, M.R. Naimi-Jamal, A. Cheldavi, Mater. Res. Express 6, 075004 (2019)

M.S. Cao, X.X. Wang, M. Zhang et al., Adv. Funct. Mater. 29, 1807398 (2019)

Z. Wu, K. Pei, L. **ng, X. Yu, W. You, R. Che, Adv. Funct. Mater. 29, 1901448 (2019)

P. He, M. Cao, J.-C. Shu et al., ACS Appl. Mater. Interfaces 11, 12535–12543 (2019)

L. Wang, X. Yu, X. Li, J. Zhang, M. Wang, R. Che, Chem. Eng. J. 383, 123099 (2019)

X. Cui, X. Liang, J. Chen, W. Gu, G. Ji, Y. Du, Carbon 156, 49–57 (2019)

B. Zhao, G. Shao, B. Fan et al., J. Mater. Chem. C 3, 10862 (2015)

L. **ng, X. Li, Z. Wu et al., Chem. Eng. J. 379, 122241 (2020)

X. Cui, W. Liu, W. Gu, X. Liang, G. Ji, Inorg. Chem. Front. 6, 590 (2019)

D.-Q. Zhang, T.-T. Liu, J.-C. Shu et al., ACS Appl. Mater. Interfaces 11, 26807 (2019)

X. Liang, X. Zhang, W. Liu, D. Tang, B. Zhang, G. Ji, J. Mater. Chem. C 4, 6816 (2016)

X. Shi, W. You, Y. Zhao, X. Li, Z. Shao, R. Che, Nanoscale 11, 17270 (2019)

J. Ma, X. Wang, W. Cao et al., Chem. Eng. J. 339, 487 (2018)

S.-Q. Lv, W. Xu, W. Huang, G.-C. Lv, G.-S. Wang, RSC Adv. 9, 13088 (2019)

B. Quan, X. Liang, H. Yi et al., J. Mater. Chem. C 6, 11659 (2018)

H. Wang, F. Meng, F. Huang et al., ACS Appl. Mater. Interfaces 11, 12142 (2019)

R. Peymanfar, M. Ahmadi, S. Javanshir, Mater. Res. Express 6, 085063 (2019)

R. Peymanfar, S. Keykavous-Amand, M.M. Abadi, Y. Yassi, Constr. Build. Mater. 263, 120042 (2020)

R. Peymanfar, F. Norouzi, S. Javanshir, Mater. Res. Express 6, 035024 (2018)

R. Wang, E. Yang, X. Qi et al., Appl. Surf. Sci. 516, 146159 (2020)

R. Peymanfar, J. Karimi, R. Fallahi, J. Appl. Polym. Sci. 137, 48430 (2019)

R. Peymanfar, S. Javanshir, M.R. Naimi-Jamal, A. Cheldavi, M. Esmkhani, J. Electron. Mater. 48, 3086 (2019)

R. Peymanfar, F. Norouzi, S. Javanshir, Synth. Met. 252, 40 (2019)

R. Peymanfar, M. Rahmanisaghieh, Mater. Res. Exp. 6, 105025 (2019)

R. Peymanfar, N. Khodamoradipoor, Phys Status Solidi A 216, 1900057 (2019)

M.A. Deshmukh, M. Gicevicius, A. Ramanaviciene, M.D. Shirsat, R. Viter, A. Ramanavicius, Sens. Actuators B 248, 527 (2017)

X. Zhao, Y.-L. Zhang, X.-X. Wang, H.-L. Shi, W.-Z. Wang, M.-S. Cao, J. Mater. Sci.: Mater. Electron. 27, 11518 (2016)

B. Qu, C. Zhu, C. Li, X. Zhang, Y. Chen, ACS Appl. Mater. Interfaces 8, 3730 (2016)

H. Yang, J. Dai, Y. Lin, N. Han, X. Liu, J. Wang, J. Mater. Sci.: Mater. Electron 28, 10853 (2017)

Y. Zuo, Z. Yao, J. Zhou, X. Zhang, Y. Ning, J. Mater. Sci.: Mater. Electron 29, 922 (2018)

R.C. Che, L.M. Peng, X.F. Duan, Q. Chen, A.X. Liang, Adv. Mater. 16, 401 (2004)

J. Liu, R. Che, H. Chen et al., Small 8, 1214 (2012)

Q. Liu, X. Xu, W. **a et al., Nanoscale 7, 1736 (2015)

Y. Lin, J. Wang, H. Yang, L. Wang, J. Mater. Sci.: Mater. Electron. 28, 17968 (2017)

Z. Jia, K. Kou, S. Yin et al., Composites B 189, 107895 (2020)

B. Zhao, X. Guo, W. Zhao et al., ACS Appl. Mater. Interfaces 8, 28917 (2016)

B. Zhao, G. Shao, B. Fan, W. Zhao, Y. **e, R. Zhang, J. Mater. Chem. A 3, 10345 (2015)

R. Peymanfar, F. Fazlalizadeh, Chem. Eng. J. (2020). https://doi.org/10.1016/j.cej.2020.126089

Q. Liu, Q. Cao, X. Zhao et al., ACS Appl. Mater. Interfaces 7, 4233 (2015)

B. Zhao, W. Zhao, G. Shao, B. Fan, R. Zhang, ACS Appl. Mater. Interfaces 7, 12951 (2015)

B. Zhao, X. Guo, W. Zhao et al., Nano Res. 10, 331 (2017)

L. Long, E. Yang, X. Qi et al., ACS Sustain. Chem. Eng. 8, 613 (2019)

L. Long, E. Yang, X. Qi et al., J. Mater. Chem. C 7, 8975 (2019)

B. Zhang, J. Wang, H. Tan et al., J. Mater. Sci.: Mater. Electron. 29, 3348 (2018)

R. Peymanfar, S. Ghorbanian-Gezaforodi, E. Selseleh-Zakerin, A. Ahmadi, A. Ghaffari, Ceram. Int. (2020). https://doi.org/10.1016/j.ceramint.2020.05.139

R. Peymanfar, F. Azadi, J. Mater. Sci.: Mater. Electron. 31, 9586 (2020). https://doi.org/10.1007/s10854-020-03501-9

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Peymanfar, R., Selseleh-Zakerin, E., Ahmadi, A. et al. Regulating microwave absorption and energy bandgap using cauliflower-like polyaniline coated on La0.8Sr0.2FeO3 nanoparticles. J Mater Sci: Mater Electron 32, 25679–25687 (2021). https://doi.org/10.1007/s10854-020-04203-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04203-y