Abstract

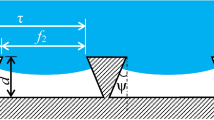

Surfaces with mimic micro-convex domes offer superior functions such as superhydrophobicity, self-cleaning, anti-wear and drag reduction. In this paper, magnetic-filed-assisted laser surface texturing (LST) using long pulse laser was employed to create micro-convex domes on 304L stainless steel. Spherical cap shaped domes with ripples around the bottom were fabricated through LST. The effects of laser power and magnetic flux density on surface morphologies of the created convex domes were investigated. It was found that the height and diameter of the created convex dome increased with the increment of the laser power without magnetic field. Moreover, the height of the created convex dome grew up gradually with the increase of magnetic flux density due to the induced Lorentz force. The height of the convex dome was increased by as much as 14.5% as compared to LST without the applied magnetic field at a laser power of 54 W. However, the applied magnetic field had no evident effect on the diameter of the created convex dome.

Similar content being viewed by others

References

J. Tong, Z. Zhang, Y. Ma, D. Chen, B. Jia, C. Menon, Abrasive wear of embossed surfaces with convex domes. Wear 274, 196–202 (2012)

Z. Han, J. Zhang, C. Ge, L. Wen, L. Ren, Erosion resistance of bionic functional surfaces inspired from desert scorpions. Langmuir 28, 2914–2921 (2012)

Y.C. Jung, B. Bhushan, Contact angle, adhesion and friction properties of micro-and nanopatterned polymers for superhydrophobicity. Nanotechnology 17(19), 4970 (2006)

Z. Han, Z. Mu, W. Yin, W. Li, S. Niu, J. Zhang, L. Ren, Biomimetic multifunctional surfaces inspired from animals. Adv. Colloid. Interface. 234, 27–50 (2016)

L.H. Shu, K. Ueda, I. Chiu, H. Cheong, Biologically inspired design. CIRP Ann. Manuf. Technol. 60, 673–693 (2011)

I. Etsion, State of the art in laser surface texturing. J. Tribol. 127(1), 248–253 (2005)

T. Wang, W. Huang, X. Liu, Y. Li, Y. Wang, Experimental study of two-phase mechanical face seals with laser surface texturing. Tribol. Int. 72, 90–97 (2014)

A. Kovalchenko, O. Ajayi, A. Erdemir, G. Fenske, Friction and wear behavior of laser textured surface under lubricated initial point contact. Wear 271(9), 1719–1725 (2011)

I. Etsion, E. Sher, Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 42, 542–547 (2009)

A. Borghi, E. Gualtieri, D. Marchetto, L. Moretti, S. Valeri, Tribological effects of surface texturing on nitriding steel for high-performance engine applications. Wear 265, 1046–1051 (2008)

T.D. Ling, P. Liu, S. **ong, D. Grzina, J. Cao, Q.J. Wang, Z.C. **a, R. Talwar, Surface texturing of drill bits for adhesion reduction and tool life enhancement. Tribol. Lett. 52, 113–122 (2013)

Y. **ng, J. Deng, X. Wang, K. Ehmann, J. Cao, Experimental assessment of laser textured cutting tools in dry cutting of aluminum alloys. J. Manuf. Sci. E. T. ASME 138(7), 071006 (2016)

X. Wang, P. Han, M. Kang, K. Ehmann, Surface-blended texturing of medical needles for friction reduction using a picosecond laser. Appl. Phys. A Mater. 122(4), 1–9 (2016)

X. Wang, M. Giovannini, Y. **ng, K. Ehmann, Fabrication and tribological behaviors of corner-cube-like dimple arrays produced by laser surface texturing on medical needles. Tribol. Int. 92, 553–558 (2015)

D. Du, Y.F. He, B. Sui, L.J. **ong, H. Zhang, Laser texturing of rollers by pulsed Nd: YAG laser. J. Mater. Process. Technol. 161(3), 456–461 (2005)

J. Zhou, H. Shen, Y. Pan, X. Ding, Experimental study on laser microstructures using long pulse. Opt. Laser. Eng. 78, 113–120 (2016)

X. Wang, Y. Zhang, L. Wang, J. **an, M. **, M. Kang, Fabrication of micro-convex domes using long pulse laser. Appl. Phys. A Mater. 123(1), 51 (2017)

M. Bachmann, V. Avilov, A. Gumenyuk, M. Rethmeier, About the influence of a steady magnetic field on weld pool dynamics in partial penetration high power laser beam welding of thick aluminium parts. Int. J. Heat. Mass. Transf. 60, 309–321 (2013)

L. Wang, J. Yao, Y. Hu, S. Song, Suppression effect of a steady magnetic field on molten pool during laser remelting. Appl. Surf. Sci. 351, 794–802 (2015)

C. Wang, H. Chen, Z. Zhao, L. Cao, P. Jiang, G. Mi, Influence of axial magnetic field on shape and microstructure of stainless steel laser welding joint. Int. J. Adv. Manuf. Techol. (2017). doi:10.1007/s00170-017-0010-1

M. Bachmann, V. Avilov, A. Gumenyuk, M. Rethmeier, Numerical assessment and experimental verification of the influence of the Hartmann effect in laser beam welding processes by steady magnetic fields. Int. J. Therm. Sci. 101, 24–34 (2016)

R. Bjørk, C.R.H. Bahl, A. Smith, N. Pryds, Comparison of adjustable permanent magnetic field sources. J Magn Magn Mater 322(22), 3664–3671 (2010)

Acknowledgements

This work was supported by National Natural Science Foundation of China (Grant No. 51705258), Natural Science Foundation of Jiangsu Province (BK20150685), the Fundamental Research Funds for the Central Universities (KYZ201659), Foundation for Distinguished Young Talents, College of Engineering, Nan**g Agricultural University (YQ201604), and Young Teachers Fund of Nan**g Agricultural University (rcqd16-05).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Wang, X., Xu, W., Liu, L. et al. Magnetic-field-assisted fabrication of micro-convex domes using long pulse laser. Appl. Phys. A 123, 592 (2017). https://doi.org/10.1007/s00339-017-1198-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-017-1198-5