Abstract

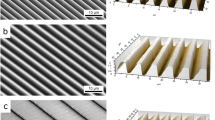

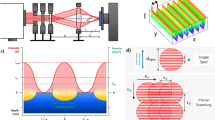

Parallel microgrooves and mesh structure with a line width of about 16 μm, which is much smaller than the diameter of the laser focus spot of 50 μm, are fabricated on Al2O3 ceramic surfaces by picosecond laser patterning with optical fiber induction. The patterned grooves are of high quality without burr, recasting or thermally induced cracks. Grain refinement of the groove surfaces caused by the rapid condensation and redeposition during picosecond laser irradiation with optical fiber induction improved the smoothness and mechanical strength of the grooves. Different patterns can be fabricated by adjusting the optical fiber layout, which is independent of the laser scanning direction. The regions etched by the laser are kept in near-field contact with the optical fibers when the laser beam passes through the fibers and irradiates the ceramic surface. This results in localized field enhancement between the transparent optic fiber and ceramic surface, which produces the precise microgrooves. The developed technique allows high-resolution micromachining of the surfaces of hard and brittle ceramic-type materials.

Similar content being viewed by others

References

A.N. Samant, N.B. Dahotre, J. Eur. Ceram. Soc. 29, 969–993 (2009)

Y.H. Liang, S.P. Dutta, Technovation 21, 61–65 (2001)

R. Nagai, T. Honma, T. Komatsu, J. Am. Ceram. Soc. 93(3), 658–661 (2010)

A. Wehrmann, S. Puttnins, L. Hartmann, M. Ehrhardt, P. Lorenz, K. Zimmer, Opt. Laser Technol. 44, 1753–1757 (2012)

I. Etsion, J. Tribol. 127, 248–253 (2005)

J.D. Majumdar, I. Manna, Sadhana 28(3–4), 495–562 (2003)

P.E. Koziol, A.J. Antończak, P. Szymczyk, B. Stepak, K.M. Abramski, Appl. Surf. Sci. 287, 165–171 (2013)

D. Dhupal, B. Doloi, B. Bhattacharyya, Int. J. Mach. Tools Manuf. 48, 236–248 (2008)

A.J. Harris, B. Vaughan, J.A. Yeomans, P.A. Smith, S.T. Burnage, J. Eur. Ceram. Soc. 33, 2925–2934 (2013)

M. Wakuda, Y. Yamauchi, S. Kanzaki, Y. Yasuda, Wear 254, 356–363 (2003)

L. Hao, J. Lawrence, K.S. Chian, J. Mater. Sci. Mater. Med. 16, 719–726 (2005)

X. Wang, J.D. Shephard, F.C. Dear, D.P. Hand, J. Am. Ceram. Soc. 91(2), 391–397 (2008)

J.P. Parry, J.D. Shephard, F.C. Dear, N. Jones, N. Weston, D.P. Hand, Int. J. Appl. Ceram. Technol. 5(3), 249–257 (2008)

M. Roy, A. Bandyopadhyay, S. Bose, J. Am. Ceram. Soc. 91(11), 3517–3521 (2008)

B. Klimt, Laser Tech. J. 1, 40–43 (2007)

F. Dausinger, H. Hügel, V. Konov, Proc. SPIE 5147, 106–115 (2003)

C. Momma, S. Nolte, B.N. Chichkov, F.V. Alvensleben, A. Tünnermann, Appl. Surf. Sci. 109(110), 15–19 (1997)

W. Kautek, J. Krüger, Proc. SPIE 2207, 600–611 (1994)

T. Herrmann, B. Klimt, 2005 OSA/PhAST, pThB2 (2005)

K.M. Du, S. Brüning, A. Gillner, Proc. SPIE 8244, 82440P1–10 (2012)

S.M. Pimenov, I.I. Vlasov, A.A. Khomich, B. Neuenschwander, M. Muralt, V. Romano, Appl. Phys. A 105, 673–677 (2011)

A. Pena, Z.B. Wang, D. Whitehead, L. Li, Appl. Phys. A 101, 287–295 (2010)

Y.Q. Zhou, T. Shao, L. Yin, Laser Phys. 19(5), 1061–1066 (2009)

A.I. Teixeira, G.A. Abrams, P.J. Bertics, C.J. Murphy, P.F. Nealey, J. Cell Sci. 116(10), 1881–1892 (2003)

K. Weingarten, Laser Tech. J. 1, 51–54 (2009)

D. Breitling, A. Ruf, F. Dausinger, Proc. SPIE 5339, 49–63 (2004)

O. Watanabe, T. Ikawa, M. Hasegawa, M. Tsuchimori, Y. Kawata, Appl. Phys. Lett. 79, 1366–1368 (2001)

N. Arnold, Appl. Surf. Sci. 208–209, 15–22 (2003)

Acknowledgments

This work is supported by National Science Foundation of China (51275011) and New Century Excellent Talents in University (NCET-10-0007). Acknowledgment is also made to Scientific Research Program of Bei**g Municipal Commission of Education (KZ20131005005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., Ji, L., Hu, Y. et al. Picosecond laser surface micropatterning of ceramics by optical fiber induction. Appl. Phys. A 119, 1061–1067 (2015). https://doi.org/10.1007/s00339-015-9068-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9068-5