Abstract

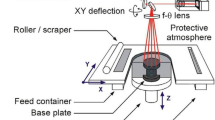

As an advanced metal additive manufacturing technology, laser-directed energy deposition (DED-LB) has attracted a lot of attention in recent years, and is increasingly used in aerospace, automotive, marine, and biomedical applications. However, as industry application standards continue to improve, the challenges of part quality, process stability, and molding efficiency faced by DED-LB are becoming more and more prominent. On-line monitoring and real-time quality regulation can effectively avoid quality defects in processing, which is an effective measure to solve the problem. This paper summarizes the current research status of on-line monitoring means and closed-loop quality regulation technology for DED-LB. The on-line monitoring signals and related sensing devices mainly based on image signals, temperature signals, spectral signals, acoustic emission signals, and X-ray imaging, as well as the closed-loop control strategies and intelligent optimization methods in the process are discussed. Finally, a view on the future direction of on-line monitoring-control system for DED-LB is presented.

Similar content being viewed by others

Data availability

Transparent.

Code availability

Not applicable.

References

Herzog D, Seyda V, Wycisk E, Emmelmann C (2016) Additive manufacturing of metals. Acta Mater 117:371–392. https://doi.org/10.1016/j.actamat.2016.07.019

Gong G, Ye J, Chi Y, Zhao Z, Wang Z, **a G, Du X, Tian H, Yu H, Chen C (2021) Research status of laser additive manufacturing for metal: a review. J Mater Res Technol 15:855–884. https://doi.org/10.1016/j.jmrt.2021.08.050

Gusarov AV, Grigoriev SN, Volosova MA, Melnik YA, Laskin A, Kotoban DV, Okunkova AA (2018) On productivity of laser additive manufacturing. J Mater Process Tech 261:213–232. https://doi.org/10.1016/j.jmatprotec.2018.05.033

John M, Kuruveri UB, Menezes PL (2022) Laser cladding-based surface modification of carbon steel and high-alloy steel for extreme condition applications. Coatings 12:1444. https://doi.org/10.3390/coatings12101444

Lin P, Shen F, Wu K, Hwang S, Lee H (2020) Process optimization for directed energy deposition of SS316L components. Int J Adv Manuf Technol 111:1387–1400. https://doi.org/10.1007/s00170-020-06113-z

Vilar R (1999) Laser cladding. J Laser Appl 11:64–79. https://doi.org/10.2351/1.521888

Weng F, Chen C, Yu H (2014) Research status of laser cladding on titanium and its alloys: a review. Mater Des 58:412–425. https://doi.org/10.1016/j.matdes.2014.01.077

Shi B, Li T, Wang D, Zhang X, Zhang H (2021) Investigation on crack behavior of Ni60A alloy coating produced by coaxial laser cladding. J Mater Sci 56:13323–13336. https://doi.org/10.1007/s10853-021-06108-5

Fang L, Yao J, Hu X, Chai G (2011) Effect of laser power on the cladding temperature field and the heat affected zone. J Iron Steel Res Int 18:73–78. https://doi.org/10.1016/S1006-706X(11)60014-9

Liu Y, Zhang X, Zhang H, Li C, Cho HH, Li C (2023) Investigation on microstructure evolution of iron-based alloy via synchronous powder-feeding underwater laser additive. Mater Des 230:111985. https://doi.org/10.1016/j.matdes.2023.111985

Qi C, Zhan X, Gao Q, Liu L, Song Y, Li Y (2019) The influence of the pre-placed powder layers on the morphology, microscopic characteristics and microhardness of Ti-6Al-4V/WC MMC coatings during laser cladding. Opt Laser Technol 119:105572. https://doi.org/10.1016/j.optlastec.2019.105572

Bi G, Schürmann B, Gasser A, Wissenbach K, Poprawe R (2007) Development and qualification of a novel laser-cladding head with integrated sensors. Int J Mach Tools Manuf 47:555–561. https://doi.org/10.1016/j.ijmachtools.2006.05.010

Li C, Yu Z, Gao J, Zhao J, Han X (2019) Numerical simulation and experimental study of cladding Fe60 on an ASTM 1045 substrate by laser cladding. Surf Coat Technol 357:965–977. https://doi.org/10.1016/j.surfcoat.2018.10.099

Zhu L, Xue P, Lan Q, Meng G, Ren Y, Yang Z, Xu P, Liu Z (2021) Recent research and development status of laser cladding: a review. Opt Laser Technol 138:106915. https://doi.org/10.1016/j.optlastec.2021.106915

Que L, Lian G, Yao M, Lu H (2022) Microstructure and properties of AlCoCrFeNiTi high-entropy alloy coatings prepared by laser cladding based on the response surface methodology. Int J Adv Manuf Technol 123:1307–1321. https://doi.org/10.1007/s00170-022-10225-z

Sexton L, Lavin S, Byrne G, Kennedy A (2002) Laser cladding of aerospace materials. J Mater Process Tech 122:63–68. https://doi.org/10.1016/S0924-0136(01)01121-9

Bartkowski D, Młynarczak A, Piasecki A, Dudziak B, Gościański M, Bartkowska A (2015) Microstructure, microhardness and corrosion resistance of Stellite-6 coatings reinforced with WC particles using laser cladding. Opt Laser Technol 68:191–201. https://doi.org/10.1016/j.optlastec.2014.12.005

Liao T, Wang Z, Wu X, Liu Q, Guo Y, Ding K, Shang X (2023) Effect of V on microstructure, wear and corrosion properties in AlCoCrMoVx high entropy alloy coatings by laser cladding. J Mater Res Technol 23:4420–4431. https://doi.org/10.1016/j.jmrt.2023.02.098

Kwok CT, Man HC, Cheng FT, Lo KH (2016) Developments in laser-based surface engineering processes: with particular reference to protection against cavitation erosion. Surf Coat Technol 291:189–204. https://doi.org/10.1016/j.surfcoat.2016.02.019

Siddiqui AA, Dubey AK (2021) Recent trends in laser cladding and surface alloying. Opt Laser Technol 134:106619. https://doi.org/10.1016/j.optlastec.2020.106619

Sundaraselvan S, Senthilkumar N, Tamizharasan T, Sait AN (2020) Surface modification of AZ61 magnesium alloy with nano TiO2/Al2O3 using laser cladding technique. Mater Today: Proc 21:717–721. https://doi.org/10.1016/j.matpr.2019.06.745

Deng Z, Liu D, **ong Y, Zhu X, Li S, Liu J, Chen T (2022) Preparation of a hydroxyapatite–silver gradient bioactive ceramic coating with porous structure by laser cladding: a study of in vitro bioactivity. Ceram Int 48:30468–30481. https://doi.org/10.1016/j.ceramint.2022.06.327

Zhang Y, Hu Y, Fang W, Li C, Wen Y (2023) Investigation of temperature field for the in-situ fabrication of particle-reinforced alumina ceramics coating via laser induction. Appl Therm Eng 228:120446. https://doi.org/10.1016/j.applthermaleng.2023.120446

Wang K, Liu W, Hong Y, Sohan HS, Tong Y, Hu Y, Zhang M, Zhang J, **ang D, Fu H (2023) An overview of technological parameter optimization in the case of laser cladding. Coatings 13:496. https://doi.org/10.3390/coatings13030496

Herzog T, Brandt M, Trinchi A, Sola A, Molotnikov A (2023) Process monitoring and machine learning for defect detection in laser-based metal additive manufacturing. J Intell Manuf 1–31. https://doi.org/10.1007/s10845-023-02119-y

Li W, Liu W, Saleheen KM, Liu H, **a Y, Al-Hammadi G, Xue L, Wang F, Song X, Zhang Y (2023) Research and prospect of on-line monitoring technology for laser additive manufacturing. Int J Adv Manuf Technol 125:25–46. https://doi.org/10.1007/s00170-022-10758-3

Kahlen F, Kar A (2001) Tensile strengths for laser-fabricated parts and similarity parameters for rapid manufacturing. J Manuf Sci Eng 123:38–44. https://doi.org/10.1115/1.1286472

Shepeleva L, Medres B, Kaplan WD, Bamberger M, Weisheit A (2000) Laser cladding of turbine blades. Surf Coat Technol 125:45–48. https://doi.org/10.1016/S0257-8972(99)00603-9

Qiu X, Liu C (2013) Microstructure and properties of Al2CrFeCoCuTiNix high-entropy alloys prepared by laser cladding. J Alloy Compd 553:216–220. https://doi.org/10.1016/j.jallcom.2012.11.100

Yan X, Dong S, Xu B, Cao Y (2018) Progress and challenges of ultrasonic testing for stress in remanufacturing laser cladding coating. Materials 11:293. https://doi.org/10.3390/ma11020293

Song J, Deng Q, Chen C, Hu D, Li Y (2006) Rebuilding of metal components with laser cladding forming. Appl Surf Sci 252:7934–7940. https://doi.org/10.1016/j.apsusc.2005.10.025

Thawari N, Gullipalli C, Katiyar JK, Gupta T (2023) In-process monitoring of distortion and temperature in multi-layer laser cladding of Stellite 6 and Inconel 718 alloys. Proc Inst Mech Eng Pt B J Eng 237:3–15. https://doi.org/10.1177/09544054221092937

Muvvala G, Mullick S, Nath AK (2020) Development of process maps based on molten pool thermal history during laser cladding of Inconel 718/TiC metal matrix composite coatings. Surf Coat Technol 399:126100. https://doi.org/10.1016/j.surfcoat.2020.126100

Song L, Mazumder J (2010) Feedback control of melt pool temperature during laser cladding process. Ieee T Contr Syst Technol 19:1349–1356. https://doi.org/10.1109/TCST.2010.2093901

Song L, Bagavath-Singh V, Dutta B, Mazumder J (2012) Control of melt pool temperature and deposition height during direct metal deposition process. Int J Adv Manuf Technol 58:247–256. https://doi.org/10.1007/s00170-011-3395-2

Xu H, Huang H (2023) In situ monitoring in laser melt injection based on fusion of infrared thermal and high-speed camera images. J Manuf Process 92:466–478. https://doi.org/10.1016/j.jmapro.2023.02.059

Colodrón P, Fariña J, Rodríguez-Andina JJ, Vidal F, Mato JL, Montealegre MÁ (2011) Performance improvement of a laser cladding system through FPGA-based control, IECON 2011-37th Annual Conference of the IEEE Industrial Electronics Society, IEEE, 2814–2819. https://doi.org/10.1109/IECON.2011.6119758

Hsu H, Lo Y, Lee M (2019) Vision-based inspection system for cladding height measurement in Direct Energy Deposition (DED). Addit Manuf 27:372–378. https://doi.org/10.1016/j.addma.2019.03.017

Smurov I, Doubenskaia M, Grigoriev S, Nazarov A (2012) Optical monitoring in laser cladding of Ti6Al4V. J Therm Spray Techn 21:1357–1362. https://doi.org/10.1007/s11666-012-9808-4

Hofman JT, Pathiraj B, Van Dijk J, De Lange DF, Meijer J (2012) A camera based feedback control strategy for the laser cladding process. J Mater Process Tech 212:2455–2462. https://doi.org/10.1016/j.jmatprotec.2012.06.027

Muvvala G, Karmakar DP, Nath AK (2017) Online assessment of TiC decomposition in laser cladding of metal matrix composite coating. Mater Des 121:310–320. https://doi.org/10.1016/j.matdes.2017.02.061

Sampson R, Lancaster R, Sutcliffe M, Carswell D, Hauser C, Barras J (2020) An improved methodology of melt pool monitoring of direct energy deposition processes. Opt Laser Technol 127:106194. https://doi.org/10.1016/j.optlastec.2020.106194

Muvvala G, Karmakar DP, Nath AK (2018) In-process detection of microstructural changes in laser cladding of in-situ inconel 718/TiC metal matrix composite coating. J Alloy Compd 740:545–558. https://doi.org/10.1016/j.jallcom.2017.12.364

Chen Y, Clark SJ, Sinclair L, Leung CLA, Marussi S, Connolley T, Atwood RC, Baxter GJ, Jones MA, Todd I (2021) Synchrotron X-ray imaging of directed energy deposition additive manufacturing of titanium alloy. Ti-6242. Addit Manuf. 41:101969. https://doi.org/10.1016/j.addma.2021.101969

Chen Y, Clark SJ, Collins DM, Marussi S, Hunt SA, Fenech DM, Connolley T, Atwood RC, Magdysyuk OV, Baxter GJ (2021) Correlative synchrotron X-ray imaging and diffraction of directed energy deposition additive manufacturing. Acta Mater 209:116777. https://doi.org/10.1016/j.actamat.2021.116777

Ren W, Mazumder J (2020) In-situ porosity recognition for laser additive manufacturing of 7075-Al alloy using plasma emission spectroscopy. Sci Rep 10:19493. https://doi.org/10.1038/s41598-020-75131-4

Song L, Wang F, Li S, Han X (2017) Phase congruency melt pool edge extraction for laser additive manufacturing. J Mater Process Tech 250:261–269. https://doi.org/10.1016/j.jmatprotec.2017.07.013

Wolff SJ, Webster S, Parab ND, Aronson B, Gould B, Greco A, Sun T (2021) In-situ observations of directed energy deposition additive manufacturing using high-speed X-ray imaging. JOM-US 73:189–200. https://doi.org/10.1007/s11837-020-04469-x

Lindenmeyer A, Webster S, Zaeh MF, Ehmann KF, Cao J (2021) Template-bayesian approach for the evaluation of melt pool shape and dimension of a DED-process from in-situ X-ray images. CIRP Ann 70:183–186. https://doi.org/10.1016/j.cirp.2021.03.011

Gaja H, Liou F (2018) Defect classification of laser metal deposition using logistic regression and artificial neural networks for pattern recognition. Int J Adv Manuf Technol 94:315–326. https://doi.org/10.1007/s00170-017-0878-9

Gaja H, Liou F (2017) Defects monitoring of laser metal deposition using acoustic emission sensor. Int J Adv Manuf Technol 90:561–574. https://doi.org/10.1007/s00170-016-9366-x

Yan Z, Liu W, Tang Z, Liu X, Zhang N, Wang Z, Zhang H (2019) Effect of thermal characteristics on distortion in laser cladding of AISI 316L. J Manuf Process 44:309–318. https://doi.org/10.1016/j.jmapro.2019.06.011

Khanzadeh M, Tian W, Yadollahi A, Doude HR, Tschopp MA, Bian L (2018) Dual process monitoring of metal-based additive manufacturing using tensor decomposition of thermal image streams. Addit Manuf 23:443–456. https://doi.org/10.1016/j.addma.2018.08.014

Liu S, Farahmand P, Kovacevic R (2014) Optical monitoring of high power direct diode laser cladding. Opt Laser Technol 64:363–376. https://doi.org/10.1016/j.optlastec.2014.06.002

Ocelík V, Bosgra J, de Hosson JTM (2009) In-situ strain observation in high power laser cladding. Surf Coat Technol 203:3189–3196. https://doi.org/10.1016/j.surfcoat.2009.03.050

Smurov I, Doubenskaia M Temperature monitoring by optical methods in laser processing, Laser-Assisted Fabrication of Materials, Springer2012. 375–422. https://doi.org/10.1007/978-3-642-28359-8_9

Bi G, Gasser A, Wissenbach K, Drenker A, Poprawe R (2006) Identification and qualification of temperature signal for monitoring and control in laser cladding. Opt Laser Eng 44:1348–1359. https://doi.org/10.1016/j.optlaseng.2006.01.009

Lin J, Steen WM (1998) Design characteristics and development of a nozzle for coaxial laser cladding. J Laser Appl 10:55–63. https://doi.org/10.2351/1.521821

Aragon C, Madurga V, Aguilera JA (2002) Application of laser-induced breakdown spectroscopy to the analysis of the composition of thin films produced by pulsed laser deposition. Appl Surf Sci 197:217–223. https://doi.org/10.1016/S0169-4332(02)00368-9

Fortes FJ, Moros J, Lucena P, Cabalín LM, Laserna JJ (2013) Laser-induced breakdown spectroscopy. ANAL CHEM 85:640–669. https://doi.org/10.1021/ac303220r

De Baere D, Devesse W, De Pauw B, Smeesters L, Thienpont H, Guillaume P (2016) Spectroscopic monitoring and melt pool temperature estimation during the laser metal deposition process. J Laser Appl 28. https://doi.org/10.2351/1.4943995

Yue HH, Qin SJ, Markle RJ, Nauert C, Gatto M (2000) Fault detection of plasma etchers using optical emission spectra. IEEE Trans Semicond Manuf 13:374–385. https://doi.org/10.1109/66.857948

Scruby CB (1987) An introduction to acoustic emission. J Phys E 20:946. https://doi.org/10.1088/0022-3735/20/8/001

Lhuissier P, Bataillon X, Maestre C, Sijobert J, Cabrol E, Bertrand P, Boller E, Rack A, Blandin J, Salvo L (2020) In situ 3D X-ray microtomography of laser-based powder-bed fusion (L-PBF)—A feasibility study. ADDIT MANUF 34:101271. https://doi.org/10.1016/j.addma.2020.101271

Wolff SJ, Wu H, Parab N, Zhao C, Ehmann KF, Sun T, Cao J (2019) In-situ high-speed X-ray imaging of piezo-driven directed energy deposition additive manufacturing. Sci Rep 9:962. https://doi.org/10.1038/s41598-018-36678-5

De La Garcia A, Pfleger M, Aramendi B, Cabeza M, Zubiri F, Mitter T, Reitinger B, Scherleitner E (2019) Online cracking detection by means of optical techniques in laser-cladding process. Struct Control Health Monit 26:e2291. https://doi.org/10.1002/stc.2291

Svetlizky D, Das M, Zheng B, Vyatskikh AL, Bose S, Bandyopadhyay A, Schoenung JM, Lavernia EJ, Eliaz N (2021) Directed energy deposition (DED) additive manufacturing: physical characteristics, defects, challenges and applications. Mater Today 49:271–295. https://doi.org/10.1016/j.mattod.2021.03.020

Ren Z, Gao L, Clark SJ, Fezzaa K, Shevchenko P, Choi A, Everhart W, Rollett AD, Chen L, Sun T (2023) Machine learning–aided real-time detection of keyhole pore generation in laser powder bed fusion. Science 379:89–94. https://doi.org/10.1126/science.add4667

Zhao C, Fezzaa K, Cunningham RW, Wen H, De Carlo F, Chen L, Rollett AD, Sun T (2017) Real-time monitoring of laser powder bed fusion process using high-speed X-ray imaging and diffraction. Sci Rep 7:3602. https://doi.org/10.1038/s41598-017-03761-2

Liu W, Tang Z, Liu X, Wang H, Zhang H (2017) A review on in-situ monitoring and adaptive control technology for laser cladding remanufacturing. Procedia Cirp 61:235–240. https://doi.org/10.1016/j.procir.2016.11.217

Sun Z, Guo W, Li L (2020) In-process measurement of melt pool cross-sectional geometry and grain orientation in a laser directed energy deposition additive manufacturing process. Opt Laser Technol 129:106280. https://doi.org/10.1016/j.optlastec.2020.106280

Moralejo S, Penaranda X, Nieto S, Barrios A, Arrizubieta I, Tabernero I, Figueras J (2017) A feedforward controller for tuning laser cladding melt pool geometry in real time. Int J Adv Manuf Technol 89:821–831. https://doi.org/10.1007/s00170-016-9138-7

Hofman JT, De Lange DF, Pathiraj B, Meijer J (2011) FEM modeling and experimental verification for dilution control in laser cladding. J Mater Process Tech 211:187–196. https://doi.org/10.1016/j.jmatprotec.2010.09.007

Lei K, Qin X, Liu H, Ni M (2018) Analysis and modeling of melt pool morphology for high power diode laser cladding with a rectangle beam spot. Opt Laser Eng 110:89–99. https://doi.org/10.1016/j.optlaseng.2018.05.022

Donadello S, Motta M, Demir AG, Previtali B (2019) Monitoring of laser metal deposition height by means of coaxial laser triangulation. Opt Laser Eng 112:136–144. https://doi.org/10.1016/j.optlaseng.2018.09.012

Iravani-Tabrizipour M, Toyserkani E (2007) An image-based feature tracking algorithm for real-time measurement of clad height. Mach Vis Appl 18:343–354. https://doi.org/10.1007/s00138-006-0066-7

Yan J, Xu Z, Wu Z, Li Q, Tang M, Ling J (2021) Edge detection method of laser cladding pool image based on morphology, AOPC 2021: Advanced Laser Technology and Applications, SPIE, 246–253. https://doi.org/10.1117/12.2606710

Kao I, Hsu Y, Lai YH, Perng J (2019) Laser cladding quality monitoring using coaxial image based on machine learning. IEEE Trans Instrum Meas 69:2868–2880. https://doi.org/10.1109/TIM.2019.2926878

Zhang Y, Shen S, Li H, Hu Y (2022) Review of in situ and real-time monitoring of metal additive manufacturing based on image processing. Int J Adv Manuf Technol 123:1–20. https://doi.org/10.1007/s00170-022-10178-3

Farahmand P, Kovacevic R (2014) An experimental–numerical investigation of heat distribution and stress field in single-and multi-track laser cladding by a high-power direct diode laser. Opt Laser Technol 63:154–168. https://doi.org/10.1016/j.optlastec.2014.04.016

Köhler H, Thomy C, Vollertsen F (2016) Contact-less temperature measurement and control with applications to laser cladding. Weld World 60:1–9. https://doi.org/10.1007/s40194-015-0275-7

Leonidas E, Ayvar-Soberanis S, Laalej H, Fitzpatrick S, Willmott JR (2022) A comparative review of thermocouple and infrared radiation temperature measurement methods during the machining of metals. Sensors-Basel 22:4693. https://doi.org/10.3390/s22134693

Thawari N, Gullipalli C, Gupta T (2023) Effect of buffer layer on distortion and temperature in laser cladding. Mater Today: Proc 72:1792–1797. https://doi.org/10.1016/j.matpr.2022.09.573

Thawari N, Gullipalli C, Vanmore H, Gupta T (2022) In-situ monitoring and modelling of distortion in multi-layer laser cladding of stellite 6: parametric and numerical approach. Mater Today Commun 33:104751. https://doi.org/10.1016/j.mtcomm.2022.104751

Srisungsitthisunti P, Kaewprachum B, Yang Z, Gao G (2022) Real-time quality monitoring of laser cladding process on rail steel by an infrared camera. Metals-Basel 12:825. https://doi.org/10.3390/met12050825

Muvvala G, Karmakar DP, Nath AK (2017) Online monitoring of thermo-cycles and its correlation with microstructure in laser cladding of nickel based super alloy. Opt Laser Eng 88:139–152. https://doi.org/10.1016/j.optlaseng.2016.08.005

Doubenskaia M, Pavlov M, Grigoriev S, Smurov I (2013) Definition of brightness temperature and restoration of true temperature in laser cladding using infrared camera. Surf Coat Technol 220:244–247. https://doi.org/10.1016/j.surfcoat.2012.10.044

Tang L, Landers RG (2010) Melt pool temperature control for laser metal deposition processes—part I: online temperature control. J Manuf Sci Eng 132. https://doi.org/10.1115/1.4000882

Salehi D, Brandt M (2006) Melt pool temperature control using LabVIEW in nd: YAG laser blown powder cladding process. Int J Adv Manuf Technol 29:273–278. https://doi.org/10.1007/s00170-005-2514-3

Tang L, Landers RG (2010) Melt pool temperature control for laser metal deposition processes—part II: layer-to-layer temperature control. J Manuf Sci Eng 132. https://doi.org/10.1115/1.4000883

Tang Z, Liu W, Wang Y, Saleheen KM, Liu Z, Peng S, Zhang Z, Zhang H (2020) A review on in situ monitoring technology for directed energy deposition of metals. Int J Adv Manuf Technol 108:3437–3463. https://doi.org/10.1007/s00170-020-05569-3

Song L, Huang W, Han X, Mazumder J (2016) Real-time composition monitoring using support vector regression of laser-induced plasma for laser additive manufacturing. IEEE Trans Ind Electron 64:633–642. https://doi.org/10.1109/TIE.2016.2608318

Choi J, Wooldridge M, Mazumder J (2023) Spectroscopy-based smart optical monitoring system in the applications of laser additive manufacturing. J Laser Appl 35. https://doi.org/10.2351/7.0000910

Ni C, Shi Y, Liu J, Huang G (2018) Characterization of Al0. 5FeCu0. 7NiCoCr high-entropy alloy coating on aluminum alloy by laser cladding. Opt Laser Technol 105:257–263. https://doi.org/10.1016/j.optlastec.2018.01.058

Shin J, Mazumder J (2018) Composition monitoring using plasma diagnostics during direct metal deposition (DMD) process. Opt Laser Technol 106:40–46. https://doi.org/10.1016/j.optlastec.2018.03.020

Lednev VN, Sdvizhenskii PA, Stavertiy AY, Grishin MY, Tretyakov RS, Asyutin RD, Pershin SM (2021) Online and in situ laser-induced breakdown spectroscopy for laser welding monitoring. Spectrochimica Acta Part B: at Spectrosc 175:106032. https://doi.org/10.1016/j.sab.2020.106032

Miyagi M, Tsukamoto T, Kawanaka H (2014) Adaptive shape control of laser-deposited metal structures by adjusting Weld pool size. J Laser Appl 26. https://doi.org/10.2351/1.4869499

Sdvizhenskii PA, Lednev VN, Asyutin RD, Grishin MY, Tretyakov RS, Pershin SM (2020) Online laser-induced breakdown spectroscopy for metal-particle powder flow analysis during additive manufacturing. J Anal Atom Spectrom 35:246–253. https://doi.org/10.1039/C9JA00343F

Lednev VN, Sdvizhenskii PA, Asyutin RD, Tretyakov RS, Grishin MY, Stavertiy AY, Pershin SM (2019) In situ multi-elemental analysis by laser induced breakdown spectroscopy in additive manufacturing. Addit Manuf 25:64–70. https://doi.org/10.1016/j.addma.2018.10.043

Song L, Mazumder J (2011) Real time cr measurement using optical emission spectroscopy during direct metal deposition process. IEEE SENS J 12:958–964. https://doi.org/10.1109/JSEN.2011.2162316

Kong F, Kovacevic R (2010) Modeling of heat transfer and fluid flow in the laser multilayered cladding process. Metall Mater Trans B 41:1310–1320. https://doi.org/10.1007/s11663-010-9412-2

Wang S, Liu C (2019) Real-time monitoring of chemical composition in nickel-based laser cladding layer by emission spectroscopy analysis. Materials 12:2637. https://doi.org/10.3390/ma12162637

Lu QY, Wong CH (2018) Additive manufacturing process monitoring and control by non-destructive testing techniques: challenges and in-process monitoring. Virtual Phys Prototyp 13:39–48. https://doi.org/10.1080/17452759.2017.1351201

Kordatos EZ, Aggelis DG, Matikas TE (2012) Monitoring mechanical damage in structural materials using complimentary NDE techniques based on thermography and acoustic emission. Compos Part B: Eng 43:2676–2686. https://doi.org/10.1016/j.compositesb.2011.12.013

Li K, Li T, Ma M, Wang D, Deng W, Lu H (2021) Laser cladding state recognition and crack defect diagnosis by acoustic emission signal and neural network. Opt Laser Technol 142:107161. https://doi.org/10.1016/j.optlastec.2021.107161

Taheri H, Koester LW, Bigelow TA, Faierson EJ, Bond LJ (2019) In situ additive manufacturing process monitoring with an acoustic technique: clustering performance evaluation using K-means algorithm. J Manuf Sci Eng 141:041011. https://doi.org/10.1115/1.4042786

Whiting J, Springer A, Sciammarella F (2018) Real-time acoustic emission monitoring of powder mass flow rate for directed energy deposition. ADDIT MANUF 23:312–318. https://doi.org/10.1016/j.addma.2018.08.015

Wang F, Mao H, Zhang D, Zhao X, Shen Y (2008) Online study of cracks during laser cladding process based on acoustic emission technique and finite element analysis. Appl Surf Sci 255:3267–3275. https://doi.org/10.1016/j.apsusc.2008.09.039

Strantza M, Van Hemelrijck D, Guillaume P, Aggelis DG (2017) Acoustic emission monitoring of crack propagation in additively manufactured and conventional titanium components. MECH RES COMMUN 84:8–13. https://doi.org/10.1016/j.mechrescom.2017.05.009

Li Y, Xu F (2021) Structural condition monitoring and identification of laser cladding metallic panels based on an acoustic emission signal feature optimization algorithm. Struct Health Monit 20:1052–1073. https://doi.org/10.1177/1475921720945637

Wolff SJ, Wang H, Gould B, Parab N, Wu Z, Zhao C, Greco A, Sun T (2021) In situ X-ray imaging of pore formation mechanisms and dynamics in laser powder-blown directed energy deposition additive manufacturing. Int J Mach Tools Manuf 166:103743. https://doi.org/10.1016/j.ijmachtools.2021.103743

Ioannidou C, König H, Semjatov N, Ackelid U, Staron P, Koerner C, Hedström P, Lindwall G (2022) In-situ synchrotron X-ray analysis of metal Additive Manufacturing: current state, opportunities and challenges. MATER Des 219:110790. https://doi.org/10.1016/j.matdes.2022.110790

Tapia G, Elwany A (2014) A review on process monitoring and control in metal-based additive manufacturing. J Manuf Sci Eng 136:060801. https://doi.org/10.1115/1.4028540

Reutzel EW, Nassar AR (2015) A survey of sensing and control systems for machine and process monitoring of directed-energy, metal-based additive manufacturing. RAPID Prototyp J 21:159–167. https://doi.org/10.1108/RPJ-12-2014-0177

Doumanidis C, Kwak Y (2001) Geometry modeling and control by infrared and laser sensing in thermal manufacturing with material deposition. J Manuf Sci Eng 123:45–52. https://doi.org/10.1115/1.1344898

Pinkerton AJ, Li L (2004) Modelling the geometry of a moving laser melt pool and deposition track via energy and mass balances. J Phys D 37:1885. https://doi.org/10.1088/0022-3727/37/14/003

Devesse W, De Baere D, Guillaume P (2014) The isotherm migration method in spherical coordinates with a moving heat source. Int J Heat Mass Transf 75:726–735. https://doi.org/10.1016/j.ijheatmasstransfer.2014.04.015

Yang Q, Yuan Z, Zhi X, Yan Z, Tian H, Chen X (2020) Real-time width control of molten pool in laser engineered net sha** based on dual-color image. Opt Laser Technol 123:105925. https://doi.org/10.1016/j.optlastec.2019.105925

Akbari M, Kovacevic R (2019) Closed loop control of melt pool width in robotized laser powder–directed energy deposition process. Int J Adv Manuf Technol 104:2887–2898. https://doi.org/10.1007/s00170-019-04195-y

Ding Y, Warton J, Kovacevic R (2016) Development of sensing and control system for robotized laser-based direct metal addition system. ADDIT MANUF 10:24–35. https://doi.org/10.1016/j.addma.2016.01.002

Fathi A, Khajepour A, Toyserkani E, Durali M (2007) Clad height control in laser solid freeform fabrication using a feedforward PID controller. Int J Adv Manuf Technol 35:280–292. https://doi.org/10.1007/s00170-006-0721-1

Shi T, Shi J, **a Z, Lu B, Shi S, Fu G (2020) Precise control of variable-height laser metal deposition using a height memory strategy. J MANUF PROCESS 57:222–232. https://doi.org/10.1016/j.jmapro.2020.05.026

Bi G, Gasser A, Wissenbach K, Drenker A, Poprawe R (2006) Characterization of the process control for the direct laser metallic powder deposition. Surf Coat Technol 201:2676–2683. https://doi.org/10.1016/j.surfcoat.2006.05.006

Farshidianfar MH, Khajepour A, Gerlich AP (2016) Effect of real-time cooling rate on microstructure in laser additive manufacturing. J MATER PROCESS TECH 231:468–478. https://doi.org/10.1016/j.jmatprotec.2016.01.017

Farshidianfar MH, Khajepour A, Gerlich A (2016) Real-time control of microstructure in laser additive manufacturing. Int J Adv Manuf Technol 82:1173–1186. https://doi.org/10.1007/s00170-015-7423-5

**ong Y, Smugeresky JE, Schoenung JM (2009) The influence of working distance on laser deposited WC–Co. J MATER PROCESS TECH 209:4935–4941. https://doi.org/10.1016/j.jmatprotec.2009.01.016

Haley JC, Zheng B, Bertoli US, Dupuy AD, Schoenung JM, Lavernia EJ (2019) Working distance passive stability in laser directed energy deposition additive manufacturing. MATER Des 161:86–94. https://doi.org/10.1016/j.matdes.2018.11.021

Zhao Y, Sun W, Wang Q, Sun Y, Chen J, Du C, **ng H, Li N, Tian W (2023) Effect of beam energy density characteristics on microstructure and mechanical properties of Nickel-based alloys manufactured by laser directed energy deposition. J MATER PROCESS TECH 319:118074. https://doi.org/10.1016/j.jmatprotec.2023.118074

Wang J, Xu J, Lu Y, **e T, Peng J, Chen J (2023) Online supervisory system based on machine vision for laser solid forming. Micromachines-Basel, p 14. https://doi.org/10.3390/mi14081558

Chen Y, Guo Y, Xu M, Ma C, Zhang Q, Wang L, Yao J, Li Z (2019) Study on the element segregation and laves phase formation in the laser metal deposited IN718 superalloy by flat top laser and gaussian distribution laser. Mater Sci Eng: A 754:339–347. https://doi.org/10.1016/j.msea.2019.03.096

Shang S, Wellburn D, Sun YZ, Wang SY, Cheng J, Liang J, Liu CS (2014) Laser beam profile modulation for microstructure control in laser cladding of an NiCrBSi alloy. Surf Coat Technol 248:46–53. https://doi.org/10.1016/j.surfcoat.2014.03.018

Bi J, Wu L, Li S, Yang Z, Jia X, Starostenkov MD, Dong G (2023) Beam sha** technology and its application in metal laser additive manufacturing: a review. J Mater Res Technol 26:4606–4628. https://doi.org/10.1016/j.jmrt.2023.08.037

Fathi A, Khajepour A, Durali M, Toyserkani E (2008) Geometry control of the deposited layer in a nonplanar laser cladding process using a variable structure controller. J Manuf Sci Eng. https://doi.org/10.1115/1.2823085

Devesse W, De Baere D, Guillaume P (2014) Design of a model-based controller with temperature feedback for laser cladding. Physics Procedia 56:211–219. https://doi.org/10.1016/j.phpro.2014.08.165

Ma M, **ong W, Lian Y, Han D, Zhao C, Zhang J (2020) Modeling and optimization for laser cladding via multi-objective quantum-behaved particle swarm optimization algorithm. Surf Coat Technol 381:125129. https://doi.org/10.1016/j.surfcoat.2019.125129

Yu J, Sun W, Huang H, Wang W, Wang Y, Hu Y (2019) Crack sensitivity control of nickel-based laser coating based on genetic algorithm and neural network. COATINGS 9:728. https://doi.org/10.3390/coatings9110728

Yang S, Bai H, Li C, Shu L, Zhang X, Jia Z (2022) Numerical simulation and multi-objective parameter optimization of Inconel718 coating laser cladding. Coatings 12:708. https://doi.org/10.3390/coatings12050708

Zhou Z, Du Y, He G, Xu L, Shu L (2023) Optimization and characterization of laser cladding of 15-5PH coating on 20Cr13 Stainless Steel. J MATER ENG PERFORM 32:962–977. https://doi.org/10.1007/s11665-022-07157-w

Zhang Y, Xu Y, Sun Y, Cheng W (2022) Surface quality optimization of laser cladding based on surface response and genetic neural network model. Surf Topogr Metrol Prop 10:044007. https://doi.org/10.1088/2051-672X/aca3bd

Peng S, Li T, Zhao J, Lv S, Tan GZ, Dong M, Zhang H (2019) Towards energy and material efficient laser cladding process: modeling and optimization using a hybrid TS-GEP algorithm and the NSGA-II. J CLEAN PROD 227:58–69. https://doi.org/10.1016/j.jclepro.2019.04.187

Deng Z, Chen T, Wang H, Li S, Liu D (2020) Process parameter optimization when preparing Ti (C, N) ceramic coatings using laser cladding based on a neural network and quantum-behaved particle swarm optimization algorithm. Appl Sci 10:6331. https://doi.org/10.3390/app10186331

Gunasegaram DR, Barnard AS, Matthews MJ, Jared BH, Andreaco AM, Bartsch K, Murphy AB (2024) Machine learning-assisted in-situ adaptive strategies for the control of defects and anomalies in metal additive manufacturing. ADDIT MANUF 81:104013. https://doi.org/10.1016/j.addma.2024.104013

Pandiyan V, Cui D, Richter RA, Parrilli A, Leparoux M (2023) Real-time monitoring and quality assurance for laser-based directed energy deposition: integrating co-axial imaging and self-supervised deep learning framework. J INTELL MANUF. https://doi.org/10.1007/s10845-023-02279-x

Miao L, **ng F, Chai Y (2023) Closed loop control of melt pool width in laser directed energy deposition process based on PSO-LQR. IEEE Access 78170–78181. https://doi.org/10.1109/ACCESS.2023.3292789

Chen L, Yao X, Chew Y, Weng F, Moon SK, Bi G (2020) Data-driven adaptive control for laser-based additive manufacturing with automatic controller tuning. Appl Sci 10:7967. https://doi.org/10.3390/app10227967

Farshidianfar MH, Khajepour A, Zeinali M, Gelrich (2013) A System identification and height control of laser cladding using adaptive neuro-fuzzy inference systems, International Congress on Applications of Lasers & Electro-Optics, Laser Institute of America, 615–623. https://doi.org/10.2351/1.5062940

Chen H, Huang S (2004) Ti6A14V laser alloying process control by using a self-organizing fuzzy controller. Int J Mach Tools Manuf 44:1653–1665. https://doi.org/10.1016/j.ijmachtools.2004.05.002

Li B, Zhang Y, Lei Y, Wei H, Chen C, Liu F, Zhao P, Wang K (2024) A single-sensor multi-scale quality monitoring methodology for laser-directed energy deposition: example with height instability and porosity monitoring in additive manufacturing of ceramic thin-walled parts. ADDIT MANUF 79:103923. https://doi.org/10.1016/j.addma.2023.103923

**a Y, Qin Y, Zhai D, Chai S (2016) Further results on cloud control systems. Sci China Inform Sci 59:1–5. https://doi.org/10.1007/s11432-016-5586-9

Răileanu S, Anton F, Borangiu T, Anton S, Nicolae M (2018) A cloud-based manufacturing control system with data integration from multiple autonomous agents. COMPUT IND 102:50–61. https://doi.org/10.1016/j.compind.2018.08.004

Chen L, Bi G, Yao X, Tan C, Su J, Ng NPH, Chew Y, Liu K, Moon SK (2023) Multisensor fusion-based digital twin for localized quality prediction in robotic laser-directed energy deposition. Robot Cim-Int Manuf 84:102581. https://doi.org/10.1016/j.rcim.2023.102581

Funding

This research work was supported by the National Key Research and Development Program of China (Grant No. 2023YFB4606002), National Natural Science Foundation of China (Grant No. 52175455), University-Industry Collaborative Education Program of China (Grant No. 230800676014006), Liaoning Provincial Natural Science Foundation of China (Grant No. 2023-MSBA-006), and the Guangdong Provincial University Innovation Team Project (Grant No. 2020KCXTD012).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, W., Wang, T., Liu, B. et al. Research of on-line monitoring technology and control strategy for laser-directed energy deposition: a review. Int J Adv Manuf Technol (2024). https://doi.org/10.1007/s00170-024-13893-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00170-024-13893-1