Abstract

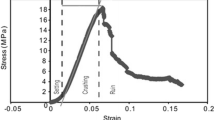

The production of charcoal for its many uses requires a careful selection of biomass and pyrolysis conditions, especially temperature, to ensure suitable quality. To do so, physical, chemical, and mechanical energy must be considered. This study aimed to analyze the yields and properties of charcoal produced at different pyrolysis temperatures. Eucalyptus saligna wood was pyrolyzed in a reactor with final temperatures of 450, 550, 650, 750, 850 and 950 °C. The yields of charcoal, pyroligneous liquid and non-condensable gases were determined. Mass loss was determined for each temperature. Charcoal analysis included the determination of the apparent density, proximate analysis, heating value, mechanical strength, X-ray images for the internal visualization of its structure and hygroscopicity test. Relevant charcoal properties for the steel industry and barbecue, such as density, mechanical strength, heating value and hygroscopicity, show variable trends from pyrolysis at 650 °C. The results show that pyrolysis temperature had a great impact on the properties of charcoal. The apparent density of charcoal rose from 500 °C and had no relation to the breaking strength. When the pyrolysis temperature was raised, an increase in both apparent and true densities, internal fissures and cracks and fixed carbon content of charcoal was observed.

Similar content being viewed by others

References

ABNT (1985) NBR 9165: Determination of apparent relative density, true relative and porosity. Brazilian Association of Technical Standards, Rio de Janeiro

ABNT (2003) NBR 11941: Wood—basic density determination. Brazilian Association of Technical Standards, Rio de Janeiro

ABNT (1984) NBR 8633: Charcoal—determination of calorific value—test method. Brazilian Association of Technical Standards, Rio de Janeiro

ASTM (1977) ASTM D 1762-64: Standard method for chemical analyses of wood charcoal. American Society for Testing and Materials, Philadelphia

ASTM (2010) D4933–99: Standard guide for moisture conditioning of wood and wood-based materials. American Society for Testing Materials, Philadelphia

ASTM (2012) E104-02: Standard practice for maintaining constant relative humidity by means of aqueous solutions. American Society for Testing Materials, Philadelphia

Antal MJ, Allen SG, Dai X, Shimizu B, Tamm S, Grønli M (2000) Attainment of the theoretical yield of carbon from biomass. Ind Eng Chem Res 39:4024–4031

Assis MR, Brancheriau L, Napoli A, Trugilho PF (2016) Factors affecting the mechanics of carbonized wood: literature review. Wood Sci Technol 50:519–536

Bergeron SP, Bradley RL, Munson A, Parsons W (2013) Physico-chemical and functional characteristics of soil charcoal produced at five different temperatures. Soil Biol Biochem 58:140–146

Biswas AK, Umeki K, Yang W, Blasiak W (2011) Change of pyrolysis characteristics and structure of woody biomass due to steam explosion pretreatment. Fuel Process Technol 92:1849–1854

Blankenhorn PR, Barnes DP, Kline DE, Murphey WK (1978) Porosity and pore size distribution of black cherry carbonized in an inert atmosphere. Wood Sci 11:23–29

Brasil (2017) National energy balance. BEN. Brasil. Ministry of Mines and Energy, Rio de Janeiro: Energy Research Company, EPE, pp 62. http://epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-303/topico-419/BEN2018.pdf. Accessed 19 Nov 2018 (in Portuguese)

Bridgwater AV (2012) Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 38:68–94

Brito JO (1990) Carvão Vegetal no Brasil: gestões econômicas e ambientais (Charcoal in Brazil: economic and environmental management). São Paulo Energia 64:221–227

Brito JO (1992) Estudo das influências da temperatura, taxa de aquecimento e densidade da madeira de Eucalyptus maculata e Eucalyptus citriodora sobre os resíduos sólidos da pirólise (Study of the temperature, heating rate and wood density of Eucalyptus maculata and Eucalyptus citriodora on pyrolysis solid residues). Thesis Professor Full. University of São Paulo-ESALQ/USP, Piracicaba, pp 80

Demirbas A (2004) Relationships between carbonization temperature and pyrolysis products from biomass. Energy Explor Exploit 22:411–420

Ding T, Gu L, Li T (2011) Influence of steam pressure on physical and mechanical properties of heat-treated Mongolian pine lumber. Eur J Wood Prod 69:121–126

Dufourny A, Steene LVD, Humbert G, Guibal D, Martin L, Blin J (2019) Influence of pyrolysis conditions and the nature of the wood on the quality of charcoal as a reducing agent. J Anal Appl Pyrol 137:01–13

Faxitron (2013) MX20 digital radioghaphy system. Faxitron 1:1–50. http://www.faxitron.com/sites/default/files/pdf/MX20-Dtasheet-WEB.pdf

Griessacher T, Antrekowitsch J, Steinlechner S (2012) Charcoal from agricultural residues as alternative reducing agent in metal recycling. Biomass Bioenerg 39:139–146

Harris PJF (2005) New perspectives on the structure of graphitic carbons. Crit Rev Solid State Mater Sci 30:235–253

Hata T, Yamane T, Kobayashi E, Imamura Y, Ishihara S (1998) Microstructural investigation of wood charcoal made by spark plasma sintering. J Wood Sci 44:332–340

Ion I, Kovalev Y, Banciu C, Pasuk I, Kuklin A (2006) Structural studies of carbon materials by sans-technique. Roman J Phys 7:783–789

Ishimaru K, Vystavel T, Bronsveld P, Hata T, Imamura Y, Hosson JD (2001) Diamond and pore structure observed in wood charcoal. J Wood Sci 47:414–416

Jenkins GM, Kawamura K, Ban LL (1972) Formation and structure of polymeric carbons. Proc R Soc Lond 327:501–517

Dias Júnior AF, Andrade CR, Brito JO, Milan M (2015a) Desdobramento da função de qualidade (QFD) na avaliação da qualidade do carvão vegetal utilizado para cocção de alimentos (Quality function deployment-QFD, in the evaluation of the quality of charcoal used for food cooking). Floresta Ambiente 22:262–270

Dias Júnior AF, Brito JO, Andrade CR (2015b) Granulometric influence on the combustion of charcoal for barbecue. Revista Árvore 39:1127–1133

Dias Júnior AF, Pirola LP, Takeshyta S, Lana AQ, Brito JO, Andrade AM (2016) Hygroscopicity of charcoal produced in different temperatures. Cerne 22:423–430

Dias Júnior AF (2018) Carvão vegetal para a cocção de alimentos: aspectos mercadológicos e de qualidade para o consumo (Charcoal for food cooking: marketing and quality aspects for consumption). Thesis (Doctorate in Forest Resources). Escola Superior de Agricultura “Luiz de Queiroz”, University of São Paulo. Piracicaba, SP, pp 103

Dias Júnior AF, Andrade CR, Brito JO, Lira SP, Andrade AM, Souza ND (2018) Polycyclic aromatic hydrocarbons in the organic phase extracted from charcoal for barbecue. Revista Árvore 41:e410510

Kwon SM, Kim HN, Cha DS (2009) Na investigation on the transition characteristics of the wood cell walls during carbonization. Wood Sci Technol 43:487–498

Longbottom RJ, Monaghan BJ, Chowdhury AA, Reid MH, Zhang G, Mahoney MR, Hockings K (2016) Effect mineral matter on the reactivity of coke and its replication in a coke analogue. ISIJ Int 9:1553–1558

Ma Z, Yang Y, Ma Q, Zhou H, Luo X, Liu X, Wang S (2017) Evolution of the chemical composition, functional group, pore structure and crystallographic structure of bio-char from palm kernel shell pyrolysis under different temperatures. J Anal Appl Pyrol 127:350–359

Machado GO, Vogel F, Moraes e Silva M (2014) Influência da temperatura final de carbonização nas características físicas, químicas e energéticas do carvão de cinamomo (Melia azedarach L.) (Influence of the final carbonization temperature on the physical, chemical and energetic characteristics of cinnamon (Melia azedarach L.)). Ambiência 10:83–96

Mohan D, Pittman CU, Steele PH (2006) Pyrolysis of wood/biomass for bio-oil: a critical review. Energy Fuels 20:848–889

Morf P, Hasler P, Nussbaumer T (2002) Mechanisms and kinetics of homogeneous secondary reactions of tar from continuous pyrolysis of wood chips. Fuel 81:843–853

Noumi ES, Rousset P, Carneiro ACO, Blin J (2016) Upgrading of carbon-based reductants from biomass pyrolysis under pressure. J Anal Appl Pyrol 118:278–128

Oliveira AC, Carneiro ACO, Vital BR, Almeida W, Pereira BLC, Cardoso MT (2010) Parâmetros de qualidade da madeira e do carvão vegetal de Eucalyptus pellita F. Muell (Wood and charcoal quality parameters of Eucalyptus pellita F. Muell), 38. Scientia Forestalis, Piracicaba, pp 431–439

Oliveira JD, Gomes P, Almeida MD (1982) Carvão vegetal: destilação, carvoejamento, propriedades, controle de qualidade (Charcoal: distillation, charcoal, properties, quality control). CETEC, Belo Horizonte

Pastor-Villegas J, Rodríguez JM, Pastor-Valle J, García MG (2007) Changes in commercial wood charcoals by thermal treatments. J Anal Appl Pyrol 2:507–514

Ranzi E, Cuoci A, Faravelli T, Frassoldati A, Migliavacca G, Pierucci S, Sommariva S (2008) Chemical kinetics of biomass pyrolysis. Energy Fuels 22:4292–4300

Rousset P, Figueiredo C, Souza M, Quirino WF (2011) Pressure effect on the quality of eucalyptus wood charcoal for the steel industry: a statistical analysis approach. Fuel Process Technol 10:1890–1897

Sheldon RA (2014) Green and sustainable manufacture of chemicals from biomass: state of the art. Green Chem 16:950–963

Silva FTM, Ataíde CH (2019) Valorization of Eucalyptus urograndis wood via carbonization: product yields and characterization. Energy 172:509–516

Somerville M, Jahanshahi S (2015) The effect of temperature and compression during pyrolysis on the density of charcoal made from Australian eucalypt wood. Renew Energy 80:471–478

Surup GR, Nielsen HK, Heidelmann M, Trubetskaya A (2019a) Characterization and reactivity of charcoal from high temperature pyrolysis (800–1600 °C). Fuel 235:1544–1554

Surup GR, Timko MT, Deike R, Schubert D, Foppe M, Trubetskaya A (2019b) The effect of feedstock origin and temperature on the structure and reactivity of char from pyrolysis at 1300–2800 °C. Fuel 235:306–316

TAPPI (1974) TAPPI-222 05–74. Industry lignin in wood. Technical Association of Pulp and Paper

TAPPI (1975) TAPPI-12 05–75. Industry preparation of wood for chemical analysis (Including procedures for removal of extractives an determination of moisture content). Technical Association of Pulp and Paper

Telmo C, Lousada J (2011) The explained variation by lignin and extractive contents on higher heating value of wood. Biomass Bioenerg 35:1663–1667

Trugilho PF, Lima JT, Mori FA, Lino AL (2001) Avaliação de clones de Eucalyptus para a produção de carvão vegetal (Evaluation of Eucalyptus clones for charcoal production). Cerne 7:104–114

Trugilho PF, Silva DA (2001) Influência da temperatura final de carbonização nas características físicas e químicas do carvão vegetal de jatobá (Himenea courbaril L.) (Influence of the final carbonization temperature on the physical and chemical characteristics of jatobá (Himenea courbaril L.) charcoal). Scientia Agrária La Rioja 2:45–53

Trugilho PF, Silva JRM, Mori FA, Lima JT, Mendes LM, Mendes LFB (2005) Rendimentos e características do carvão vegetal em função da posição radial de amostragem em clones de Eucalyptus. (Yield and charcoal characteristics in relation of radial sampling in eucalyptus clones). Cerne 11:178–186 (in Portuguese)

Wang S, Dai G, Yang H, Luo Z (2017) Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review. Prog Energy Combust Sci 62:33–86

Weber K, Quicker P (2018) Properties of biochar. Fuel 217:240–261

Wei R, Zhang L, Cang D, Li J, Li X, Xu CC (2017) Current status and potential of biomass utilization in ferrous metallurgical industry. Renew Sustain Energy Rev 68:511–524

Zhao X, Hu Q, Wang X, He Q, Zhang Z, Shen R (2015) Composition profiles of organic aerosols from Chinese residential cooking: case study in urban Guangzhou, south China. J Atmos Chem 72:1–18

Acknowledgments

We would like to thank the Coordination for the Improvement of Higher Education Personnel (CAPES), the Forestry Science and Research Institute (IPEF) and the National Council for Scientific and Technological Development (CNPq/142075/2016-7), research-funding agencies in Brazil, for granting the scholarships.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dias Junior, A.F., Esteves, R.P., da Silva, Á.M. et al. Investigating the pyrolysis temperature to define the use of charcoal. Eur. J. Wood Prod. 78, 193–204 (2020). https://doi.org/10.1007/s00107-019-01489-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-019-01489-6