Abstract

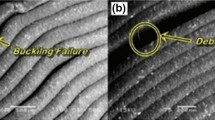

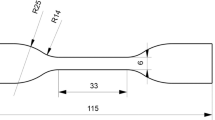

The utilization of additive manufacturing (AM) techniques has revolutionized modern manufacturing processes, allowing for the production of intricate geometries with enhanced design flexibility. Within this context, the exploration of biodegradable materials for AM applications has garnered significant attention due to their environmentally friendly characteristics and potential for sustainable manufacturing. This paper focuses on the experimental analysis of a biodegradable polymer, specifically polylactic acid (PLA), fabricated using extrusion-based AM. Tensile and compression testing, conducted in accordance with ASTM standards, provides valuable insights into the mechanical properties of the PLA components. Additionally, during the fabrication process of the specimens, two different infill orientations (0° and 90°) were employed and analyzed. By incorporating these distinct infill orientations, the study aimed to assess the influence of infill pattern orientation on the mechanical behavior of the fabricated specimens. The analysis of these different infill orientations provides valuable insights into the structural integrity and performance of the specimens under various loading conditions, further enhancing our understanding of the impact of infill orientation on the mechanical properties of the biodegradable polymer components. The experimental analysis contributes to a comprehensive evaluation of the mechanical behavior of the biodegradable polymer, supporting advancements in AM technologies and promoting sustainable manufacturing practices.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Hanon MM, Marczis R, Zsidai L (2021) Influence of the AM process settings on tensile strength of PLA and HT-PLA. Periodica Polytechnica Mech Eng 65(1):38–46

Ferreira RTL, Amatte IC, Dutra TA, Bürger D (2017) Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos Part B Eng 124:88–100

Behzadnasab M, Yousefi AA, Ebrahimibagha D, Nasiri F (2020) Effects of processing conditions on mechanical properties of PLA printed parts. Rapid Prototy** J 26(2):381–389

Zhao L, Jiang Z, Zhang C, Jiang Z (2021) Development model and experimental characterization of residual stress of AM PLA parts with porous structure. Appl Phys A 127:1–10

Aloyaydi B, Sivasankaran S, Mustafa A (2020) Investigation of infill-patterns on mechanical response of 3D printed poly-lactic-acid. Polym Test 87:106557

Hsueh MH, Lai CJ, Wang SH, Zeng YS, Hsieh CH, Pan CY, Huang WC (2021) Effect of printing parameters on the thermal and mechanical properties of 3d-printed pla and petg, using fused deposition modeling. Polymers 13(11):1758

Abbas TF, Othman FM, Ali HB (2018) Influence of layer thickness on impact property of 3D-printed PLA. Int Res J Eng Technol (Irjet) 5:1–4

Mishra PK, Senthil P, Adarsh S, Anoop MS (2021) An investigation to study the combined effect of different infill pattern and infill density on the impact strength of 3D printed polylactic acid parts. Compos Commun 24:100605

Camargo JC, Machado ÁR, Almeida EC, Silva EFMS (2019) Mechanical properties of PLA-graphene filament for FDM AM. Int J Adv Manuf Technol 103:2423–2443

Al Khawaja H, Alabdouli H, Alqaydi H, Mansour A, Ahmed W, Al Jassmi H (2020) Investigating the mechanical properties of 3D printed components. In: 2020 Advances in Science and Engineering Technology International Conferences (ASET). IEEE, pp 1–7

Khan SF, Zakaria H, Chong YL, Saad MAM, Basaruddin K (2018) Effect of infill on tensile and flexural strength of 3D printed PLA parts. In: IOP conference series: materials science and engineering, vol 429, no 1. IOP Publishing, p 012101

Lanzotti A, Grasso M, Staiano G, Martorelli M (2015) The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototy** J

Yang L, Li S, Li Y, Yang M, Yuan Q (2019) Experimental investigations for optimizing the extrusion parameters on FDM PLA printed parts. J Mater Eng Perform 28:169–182

Graupner N, Herrmann AS, Müssig J (2009) Natural and man-made cellulose fibre-reinforced poly (lactic acid)(PLA) composites: An overview about mechanical characteristics and application areas. Compos Part A Appl Sci Manuf 40(6–7):810–821

Naveed N (2021) Investigating the material properties and microstructural changes of fused filament fabricated PLA and tough-PLA parts. Polymers 13(9):1487

Brenken B, Barocio E, Favaloro A, Kunc V, Pipes RB (2018) Fused filament fabrication of fiber-reinforced polymers: a review. Add Manuf 21:1–16

Agu HO, Hameed A, Appleby-Thomas GJ, Wood DC (2019) The dynamic response of dense 3 dimensionally printed polylactic acid. J Dyn Behav Mater 5:377–386

Senatov FS, Niaza KV, Zadorozhnyy MY, Maksimkin AV, Kaloshkin SD, Estrin YZ (2016) Mechanical properties and shape memory effect of 3D-printed PLA-based porous scaffolds. J Mech Behav Biomed Mater 57:139–148

Serra T, Planell JA, Navarro M (2013) High-resolution PLA-based composite scaffolds via 3-D printing technology. Acta Biomater 9(3):5521–5530

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

bhagat, V. et al. (2024). Experimental Investigations on Biodegradable Polymer Fabricated Using Extrusion-Based Additive Manufacturing. In: Kumar, N., Singh, G., Trehan, R., Davim, J.P. (eds) Advances in Materials and Agile Manufacturing. CPIE 2023. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-99-6601-1_13

Download citation

DOI: https://doi.org/10.1007/978-981-99-6601-1_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-6600-4

Online ISBN: 978-981-99-6601-1

eBook Packages: EngineeringEngineering (R0)