Abstract

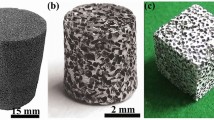

Porous metals or metallic foams are novel lightweight materials employed in various functional and structural applications. The metals like Al, Mg, Fe, Ti, Ni, Cu and their alloys are widely used to prepare porous materials. Metals can be converted into the porous structure through the liquid metallurgy route or powder metallurgy route of their processing easiness. The liquid metallurgy route is adopted for the metals which have a lower melting point. While, for the metals having a higher melting point, the powder metallurgy route is preferred. Melt foaming by blowing agent, gas injection foaming and foam making through porous preform technique are the most common methods for the foam preparation through liquid metallurgy route. In powder metallurgy route, gas entrapment method, slurry foaming, loose powder sintering, space holder technique, gel casting and combustion synthesis are well-known methods of foam synthesis. The cells of the metallic foam may be closed type or open type depending on the specific synthesis process. The density of closed cell foams is higher as compared to open cell foam. Therefore, they are used in structural applications such as impact energy and sound absorber, honeycomb panels and automobile bumpers. The applications of open cell foams are in the area of the heat exchanger, filter and biomedical implants due to open cell properties.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bisht A, Patel VK, Gangil B (2019) Future of metal foam materials in automotive industry. Automotive Tribology, Springer pp 51–63

Fan Z, Liu Y, Xu P (2019) Blast resistance of metallic sandwich panels subjected to proximity underwater explosion. Int J Impact Eng 93:128–135

Meghana M, Shashikanth C (2016) Impact analysis of bumper and car chassis frame due to frontal collision for different materials. Int J Eng Manage Res (IJEMR) 6:131–135

Ashby MF, Evans T, Fleck NA, Hutchinson J, Wadley H, Gibson L (2000) Metal foams: a design guide. Elsevier

Yadav B, Singh P, Mondal D (2020) Fabrication of ultra-light LM13 alloy hybrid foam reinforced by MWCNTs and SiC through stir casting technique. Mater Lett 279:128271

Kaya AC (2020) In situ shear behavior of open-cell austenitic 316L steel foams. Mater Chem Phys 252:123303

Yang D, Guo S, Chen J, Qiu C, Agbedor S-O, Ma A et al (2021) Preparation principle and compression properties of cellular Mg–Al–Zn alloy foams fabricated by the gas release reaction powder metallurgy approach. J Alloy Compd 857:158112

Li H, Yao Z, Zhang J, Cai X, Li L, Liu G et al (2020) The progress on physicochemical properties and biocompatibility of tantalum-based metal bone implants. SN Appl Sci 2:1–14

Niu W, **ao Y, Wan C, Li D, Fu H, He H (2020) Ultrasonic bonding of 2024 Al alloy using Ni-foam/Sn composite solder at ambient temperature. Mater Sci Eng, A 771:138663

Singh P, Shrivastava V, Abhash A, Yadav B, Singh I, Mondal D (2021) Compressive deformation and corrosion behaviour of moderate to highly porous Ti4Al4Co (wt%) alloy foam. Mater Chem Phys 257:123718

Aguilar C, Aguirre T, Martínez C, De Barbieri F, San Martín F, Salinas V et al (2020) Improving the mechanical strength of ternary beta titanium alloy (Ti–Ta–Sn) foams, using a bimodal microstructure. Mater Des 195:108945

Feng Y, Chen S, Wang J, Lu B (2020) Carbon foam with microporous structure for high performance symmetric potassium dual-ion capacitor. J Energy Chem 43:129–138

Jiang H, Ziegler H, Zhang Z, Meng H, Chronopoulos D, Chen Y (2020) Mechanical properties of 3D printed architected polymer foams under large deformation. Mater Des 194:108946

da Costa FP, da Silva Morais CR, Rodrigues AM (2020) Sustainable glass-ceramic foams manufactured from waste glass bottles and bentonite. Ceram Int 46:17957–17961

Machado CM, Benelli P, Tessaro IC (2020) Effect of acetylated starch on the development of peanut skin-cassava starch foams. Int J Biol Macromol 165:1706–1716

Rajaei M, Elahi SH, Asefi A (2020) Modal properties of closed-cell zinc foam. Structures, Elsevier, pp 1380–1383

Onck P, Van Merkerk R, Raaijmakers A, De Hosson JTM (2005) Fracture of open-and closed-cell metal foams. J Mater Sci 40:5821–5828

Tuncer N, Arslan G (2009) Designing compressive properties of titanium foams. J Mater Sci 44:1477–1484

Singh P, Singh I, Mondal D (2019) A comparative study on compressive deformation and corrosion behaviour of heat treated Ti4 wt% Al foam of different porosity made of milled and unmilled powders. Mater Sci Eng, C 98:918–929

Orbulov IN, Szlancsik A, Kemény A, Kincses D (2020) Compressive mechanical properties of low-cost, aluminium matrix syntactic foams. Compos A Appl Sci Manuf 135:105923

Duan Y, Ding Y, Liu Z, Hou N, Zhao X, Liu H et al (2020) Effects of cell size vs. cell-wall thickness gradients on compressive behavior of additively manufactured foams. Compos Sci Technol 199, 108339

Neville B, Rabiei A (2008) Composite metal foams processed through powder metallurgy. Mater Des 29:388–396

Birla S, Mondal D, Das S, Kashyap DK, Ch VA (2017) Effect of cenosphere content on the compressive deformation behaviour of aluminum-cenosphere hybrid foam. Mater Sci Eng, A 685:213–226

Birla S, Mondal D, Das S, Khare A, Singh JP (2017) Effect of cenosphere particle size and relative density on the compressive deformation behavior of aluminum-cenosphere hybrid foam. Mater Des 117:168–177

Banhart J (2001) Manufacture, characterisation and application of cellular metals and metal foams. Prog Mater Sci 46:559–632

Schwartz DS, Shih DS, Evans AG, Wadley HN (1998) Materials research society. In: symposium proceedings, porous and cellular materials for structural applications. Warrendale PA, p 521

Badkul A, Saxena S, Mondal D (2020) A numerical solution to accurately predict deformation behaviour of metallic foam material up-to densification region for the possible use in composite structures. Compos Struct 246:112419

An J, Chen C, Zhang M (2021) Effect of CaCO3 content change on the production of closed-cell aluminum foam by selective laser melting. Opt Laser Technol 141:107097

Bisht A, Gangil B, Patel VK (2020) Selection of blowing agent for metal foam production: a review. J Metals, Mater Miner 30

Simone A, Gibson LJ (1998) Aluminum foams produced by liquid-state processes. Acta Mater 46:3109–3123

Park C, Nutt S (2000) PM synthesis and properties of steel foams. Mater Sci Eng, A 288:111–118

Miyoshi T, Itoh M, Akiyama S, Kitahara A (2000) ALPORAS aluminum foam: production process, properties, and applications. Adv Eng Mater 2:179–183

Song Z-L, Ma L-Q, Wu Z-J, He D-P (2000) Effects of viscosity on cellular structure of foamed aluminum in foaming process. J Mater Sci 35:15–20

Sarajan Z (2015) A356 alloy foaming by titanium hydride. Russian J Non-Ferrous Metals 56:516–521

Wang N, Maire E, Chen X, Adrien J, Li Y, Amani Y et al (2019) Compressive performance and deformation mechanism of the dynamic gas injection aluminum foams. Mater Charact 147:11–20

An J, Chen C, Zhang M (2021) Effect of TiH2 oxidation treatment on foamed aluminum alloys produced by selective laser melting. Phys Metals Metall 1–18

García-Moreno F, Banhart J. Influence of gas pressure and blowing agent content on the formation of aluminium alloy foam. Adv Eng Mater

Kumar N, Bharti A (2021) Review on powder metallurgy: a novel technique for recycling and foaming of aluminium-based materials. Powd Metall Metal Ceram 1–8

Kennedy A (2002) The effect of TiH2 heat treatment on gas release and foaming in Al–TiH2 preforms. Scripta Mater 47:763–767

Yamada Y, Shimojima K, Sakaguchi Y, Mabuchi M, Nakamura M, Asahina T et al (2000) Processing of cellular magnesium materials. Adv Eng Mater 2:184–187

Erryani A, Greenita C, Lestari FP, Utomo MS, Kartika I, Nugraha T (2021) Casting technique of NaCl space-holder using 3D printed PLA template for manufacture porous Mg alloy. In: AIP conference proceedings. AIP Publishing LLC, 030004

Meng J, Liu T-W, Wang H-Y, Dai L-H (2021) Ultra-high energy absorption high-entropy alloy syntactic foam. Compos B Eng 207:108563

Zhang B, Wang L, Zhang J, Jiang Y, Wang W, Wu G (2021) Deformation and energy absorption properties of cenosphere/aluminum syntactic foam-filled circular tubes under lateral quasi-static compression. Int J Mech Sci 192:106126

Kannan S, Pervaiz S, Alhourani A, Klassen RJ, Selvam R, Haghshenas M (2020) On the role of hollow aluminium oxide microballoons during machining of AZ31 magnesium syntactic foam. Materials 13:3534

Vishwakarma A, Mondal D, Birla S, Das S, Prasanth N (2017) Effect of cenosphere size on the dry sliding wear behaviour LM13-cenosphere syntactic foam. Tribol Int 110:8–22

Afolabi LO, Mutalib NAA, Ariff ZM (2019) Fabrication and characterization of two-phase syntactic foam using vacuum assisted mould filling technique. J Market Res 8:3843–3851

Murray N, Schuh C, Dunand D (2003) Solid-state foaming of titanium by hydrogen-induced internal-stress superplasticity. Scripta Mater 49:879–883

Queheillalt DT, Wadley HN, Choi BW, Schwartz DS (2000) Creep expansion of porous Ti6-Al4-V sandwich structures. Metall Mater Trans A 31:261–273

Kulkarni S (1973) Foamed aluminium

Kumar R, Jain H, Sriram S, Chaudhary A, Khare A, Ch VA et al (2020) Lightweight open cell aluminum foam for superior mechanical and electromagnetic interference shielding properties. Mater Chem Phys 240:122274

Davari HR, Gholamzadeh H, Dehghan SA, Paydar MH (2017) Effect of sintering parameters (time and temperature) upon the fabrication process of organic binder-based metallic hollow sphere. Powder Metall 60:363–370

Eisenmann M (1998) Metal powder technologies and applications. ASM Handbook 7:171–221

Singh P, Abhash A, Nair P, Khare A, Singh I, Mondal D (2019) Effect of space holder size on microstructure, deformation and corrosion response of Ti4Al4Co (wt%) alloy foam. Appl Innov Res (AIR) 1:41–47

Bekoz N, Oktay E (2012) Effects of carbamide shape and content on processing and properties of steel foams. J Mater Process Technol 212:2109–2116

Abhash A, Singh P, Kumar R, Pandey S, Sathaiah S, Shafeeq MM et al (2020) Effect of Al addition and space holder content on microstructure and mechanical properties of Ti2Co alloys foams for bone scaffold application. Mater Sci Eng, C 109:110600

Jain H, Gupta G, Kumar R, Mondal D (2019) Microstructure and compressive deformation behavior of SS foam made through evaporation of urea as space holder. Mater Chem Phys 223:737–744

Bansiddhi A, Dunand D (2008) Shape-memory NiTi foams produced by replication of NaCl space-holders. Acta Biomater 4:1996–2007

** F-L, Zhao M, Park M, Park S-J (2019) Recent trends of foaming in polymer processing: a review. Polymers 11:953

Cetinel O, Esen Z, Yildirim B (2019) Fabrication, morphology analysis, and mechanical properties of Ti foams manufactured using the space holder method for bone substitute materials. Metals 9:340

Patnaik P (2003) Handbook of inorganic chemicals. McGraw-Hill, New York

Li D, Zhang Y, Ma X, Zhang X (2009) Space-holder engineered porous NiTi shape memory alloys with improved pore characteristics and mechanical properties. J Alloy Compd 474:L1–L5

Farley C, Turnbull T, Pantoya ML, Hunt EM (2011) Self-propagating high-temperature synthesis of nanostructured titanium aluminide alloys with varying porosity. Acta Mater 59:2447–2454

Biswas A (2005) Porous NiTi by thermal explosion mode of SHS: processing, mechanism and generation of single phase microstructure. Acta Mater 53:1415–1425

Li B-Y, Rong L-J, Li Y-Y, Gjunter V (2000) A recent development in producing porous Ni–Ti shape memory alloys. Intermetallics 8:881–884

Wu Z, Sun L, Pan J, Wang J (2018) Highly porous Y2SiO5 ceramic with extremely low thermal conductivity prepared by foam-gelcasting-freeze drying method. J Am Ceram Soc 101:1042–1047

Sepulveda P, Binner J, Rogero S, Higa O, Bressiani J (2000) Production of porous hydroxyapatite by the gel-casting of foams and cytotoxic evaluation. J Biomed Mater Res Offic J Soc Biomater Japanese Soc Biomater 50:27–34

Yang D, Guo Z, Shao H, Liu X, Ji Y (2012) Mechanical properties of porous Ti–Mo and Ti–Nb alloys for biomedical application by gelcasting. Procedia Eng 36:160–167

Usman M, Pan L, Farid A, Khan AS, Yongpeng Z, Khan MA et al (2020) Carbon nanocoils-Fnickel foam decorated with silver nanoparticles/sheets using a novel stirring assisted electrodeposition technique for non-enzymatic glucose sensor. Carbon 157:761–766

Hutmacher DW, Sittinger M, Risbud MV (2004) Scaffold-based tissue engineering: rationale for computer-aided design and solid free-form fabrication systems. Trends Biotechnol 22:354–362

Yang S, Leong K-F, Du Z, Chua C-K (2002) The design of scaffolds for use in tissue engineering. Part II, Rapid Prototyp Tech Tissue Eng 8:1–11

Krishna BV, Bose S, Bandyopadhyay A (2007) Low stiffness porous Ti structures for load-bearing implants. Acta Biomater 3:997–1006

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Singh, P., Shakya, J.P., Agarwal, P., Jain, S., Mondal, D.P., Verma, K.S. (2023). Synthesis of Lightweight Metallic Foam and Their Applications in Various Engineering Sectors. In: Vignesh, R.V., Padmanaban, R., Govindaraju, M. (eds) Advances in Processing of Lightweight Metal Alloys and Composites. Materials Horizons: From Nature to Nanomaterials. Springer, Singapore. https://doi.org/10.1007/978-981-19-7146-4_3

Download citation

DOI: https://doi.org/10.1007/978-981-19-7146-4_3

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-7145-7

Online ISBN: 978-981-19-7146-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)