Abstract

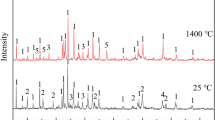

Fe–Mn–Al–C steel can form AlN particles because of its high [Al] content (w[Al] = 8–12 wt%), which can affect the properties of slag during continuous casting. In this study, the dissolution behavior of AlN in a new CaO–Al2O3-based slag without SiO2 was investigated by a static experiment method. Results demonstrated AlN rod could be dissolved in the liquid slag and it only reacted with Li2O, which caused the increase of Al2O3 and the decrease of Li2O in the slag. The interface between slag and AlN was examined by scanning electron microscopy, and the products near the slag side were Al2O3–CaO–BaO–CaF2 complexes, while individual Al2O3 and AlN–Al2O3 complexes were dispersed near AlN side. Additionally, the viscosity and break temperature of the slag increased greatly with the increase of AlN. XRD showed the primary crystalline phase in the slag was 11CaO·7Al2O3·CaF2. This work provided theoretical guidance for future application of the slag for high-Al steel.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Tang D, Zhen-Li MI, Chen YL (2005) Technology and research and development of advanced automobile steel abroad. Iron and Steel 40(6):1–5

Neu RW (2013) Performance and characterization of TWIP steels for automotive applications. ASTM Int 2(1):20130009

Li ZR (2019) Study on reactivity control of mold flux and basic structure and properties of slag for high manganese and high aluminum steel. Chongqing University

Wu T, He SP, Guo YT, Wang Q (2014) Study on reactivity between mould fluxes and high-Al molten steel. In: Characterization of minerals, metals, and materials 2014. TMS, San Diego, pp 265–270

Chen Y, He SP, Li ZR, Zhang XB, Wang QQ, Wang Q (2022) Properties and structure of a new non-reactive mold flux for high-Al steel. J Iron Steel Res Int 29(1):61–70

Chen Y, Pan WJ, Wang QQ, He SP (2022) Study on structure and properties of mold flux for non-reactive high aluminum steel continuous casting. In: The 13th China iron and steel annual conference, Chongqing, China, pp 292–296

Yuan HZ, Dan ZK, Wang QQ, He SP (2020) Contact angle and adhesion of CaO–SiO2- and CaO–Al2O3-based mold slags on solid steel of various compositions. J Market Res 9(4):7828–7837

Wang X, Liu H, Zhao M, Wang Q, Zhang X, He S (2023) Effect of AlN on properties of non-reactive CaO-Al2O3-based mold flux for high-Al steel. Mater Today Commun 34:105432

Wang XF, Wang QQ, Zhang XB, Wang Q, He SP (2022) Effect of AlN on properties of CaO–SiO2 based mold flux for high aluminum steel. Iron and Steel 57(05):64–71

Li ZR, You XC, Li M, Wang QQ, He SP, Wang QQ (2019) Effect of substituting CaO with BaO and CaO/Al2O3 ratio on the viscosity of CaO–BaO–Al2O3–CaF2–Li2O mold flux system. Metals 9(2):1–13

Long X, He SP, Xu JF, Huo XL, Wang Q (2012) Properties of high basicity mold fluxes for peritectic steel slab casting. J Iron Steel Res Int 19(7):39–45

Chen Z, Du WT, Zhang M, Wang Q, He SP (2021) Effects of substituting SiO2 with oxidisers on the reaction performance and physical properties of mould flux for high Ti-bearing steel. ISIJ Int 61(3):814–823

Amadeh A, Labbe JC, Laiemeche A, Quintard P (1996) Influence of boron nitride and carbon additives on the behaviour of sintered AlN in a steel-making environment. J Eur Ceram Soc 16(4):403–408

Labbe JC, Laïmeche A (1996) Study of the behaviour of aluminium nitride in the iron and steel industry. J Eur Ceram Soc 16(8):893–898

Amadeh A, Heshmati-Manesh S, Labbe JC, Laimeche A, Quintard P (2001) Wettability and corrosion of TiN, TiN–BN and TiN–AlN by liquid steel. J Eur Ceram Soc 21(3):277–282

Luo Y, Li M, Scheller PR, Sridhar S, Zhang L (2019) Interaction between liquid steel and AlN substrate containing Al-Y-oxides. Metall and Mater Trans B 50(5):2459–2470

Mills KC, Fox AB (2003) The role of mould fluxes in continuous casting-so simple yet so complex. ISIJ Int 43(10):1479–1486

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Wang, X., **, Z., Wang, Q., He, S., Zhang, X. (2024). Dissolution Behavior of AlN in CaO–Al2O3-Based Slag. In: Wagstaff, S., Anderson, A., Sabau, A.S., Iloeje, C. (eds) Materials Processing Fundamentals 2024. TMS 2024. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-50184-5_5

Download citation

DOI: https://doi.org/10.1007/978-3-031-50184-5_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-50183-8

Online ISBN: 978-3-031-50184-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)