Abstract

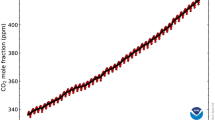

The main contributor to global warming is carbon dioxide (CO2), herewith referred to as a greenhouse gas, with a growth of nearly 2.7%, 60% above that recorded around late twentieth century. Globally, the regulation and minimization of CO2 have consequently become a consensus. In South Africa (SA), most CO2 releases are from burning coal and future forecasts show that CO2 releases will increase more and more should there be no counter-progress in the creation of carbon capture technologies (CCT). Additionally, by integrating CCT into the main sources of anthropogenic CO2 releases, like coal power plants (CPPs), challenges of CO2 releases will be brought to the barest minimal. Despite the challenge it presents, yet an inherent research opportunity therein, with possibility of develo** a novel CCT. Hence, this paper presented a review on the theme “hydrotalcite-derived material from waste metal dust, a solid adsorbent for CO2 capture: Challenges and opportunities in SA’s CPPs”. This theme was subdivided into the following sub-themes: challenges and opportunities inherent in SA’s CPPs; review of past and current publications on CO2 capture from CPP. The conclusions reached are that the use of waste metal dust and/or coal fly ash to produce solid adsorbents will go a long way to saving significant cost of managing CO2 emissions, while the conversion of this waste to product amongst other benefits will strengthen the goal of achieving a circular economy in the mining industry.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Kumar N, Mukherjee S, Harvey-Reid NC, Bezrukov AA, Tan K, Martins V, Vandichel M, Pham T, van Wyk LM, Oyekan K, Kuma A (2021) Breaking the trade-off between selectivity and adsorption capacity for gas separation. Chem 7(11):3085–3098

Thopil GA, Pouris A (2015) Aggregation and internalization of electricity externalities in South Africa. Energy 82:501–511

Dabrowski JM, Ashton PJ, Murray K, Leaner JJ, Mason RP (2008) Anthropogenic mercury emissions in South Africa: coal combustion in power plants. Atmos Environ 42(27):6620–6626

Freiman MT, Piketh SJ (2003) Air transport into and out of the industrial Highveld region of South Africa. J Appl Meteorol Climatol 42(7):994–1002

Kuang C (2021) Analysis of green house gases and positive impact of replacing traditional energy with clean energy. In: E3S Web of Conferences, vol 241. EDP Sciences, p 02005

AR5 Synthesis Report: Climate Change 2014 (n.d.). Accessed 10 Nov 2020. www.ipcc.ch/report/ar5/syr/

Shikwambana L, Mhangara P, Mbatha N (2020) Trend analysis and first time observations of sulphur dioxide and nitrogen dioxide in South Africa using TROPOMI/Sentinel-5 P data. Int J Appl Earth Observ Geoinf 91:102130

Beck B, Surridge T, Hietkamp S (2013) The South African centre for carbon capture and storage delivering CCS in the develo** world. Energy Procedia 37:6502–6507

International Organization for Standardization (2006) Environmental management: life cycle assessment; principles and framework, vol 14044. ISO

Mbohwa C (2013) Life cycle assessment of a coal-fired old thermal power plant. Proc World Cong Eng 1:2078–958

Rathnayake M, Julnipitawong P, Tangtermsirikul S, Toochinda P (2018) Utilization of coal fly ash and bottom ash as solid sorbents for sulfur dioxide reduction from coal fired power plant: Life cycle assessment and applications. J Clean Prod 202:934–945

Mittal ML, Sharma C, Singh R (2012) August. Estimates of emissions from coal fired thermal power plants in India. In: 2012 International emission inventory conference pp 13–16

Liang X, Wang Z, Zhou Z, Huang Z, Zhou J, Cen K (2013) Up-to-date life cycle assessment and comparison study of clean coal power generation technologies in China. J Clean Prod 39:24–31

Liu Y, Dai Z, Zhang Z, Zeng S, Li F, Zhang X, Nie Y, Zhang L, Zhang S, Ji X (2021) Ionic liquids/deep eutectic solvents for CO2 capture: reviewing and evaluating. Green Energy Environ 6(3):314–328

Ochedi FO, Yu J, Yu H, Liu Y, Hussain A (2020) Carbon dioxide capture using liquid absorption methods: a review. Environ Chem Lett 1–33

Shavalieva G, Kazepidis P, Papadopoulos AI, Seferlis P, Papadokonstantakis S (2021) Environmental, health and safety assessment of post-combustion CO2 capture processes with phase-change solvents. Sustainable Prod Consumpt 25:60–76

Wang J, Liu L, Zeng X, Li K (2021) Solar-assisted CO2 capture with amine and ammonia-based chemical absorption: a comparative study. Thermal Sci 25(1 Part B):717–732

Ahmad MZ, Fuoco A, (2021) Porous liquids–future for CO2 capture and separation. Current Res Green Sustainable Chem 4:100070

Cannone SF, Lanzini A, A review on CO2 capture technologies with focus on CO2-enhanced methane recovery from hydrates. Energies 14(2):387

Janakiram S, Santinelli F, Costi R, Lindbråthen A, Nardelli GM, Milkowski K, Ansaloni L, Deng L (2021) Field trial of hollow fiber modules of hybrid facilitated transport membranes for flue gas CO2 capture in cement industry. Chemi Eng J 413:127405

Kratky L, Kolacny J, Sulc R (2021) Experimental study on CO2 membrane separation from slue gas. Chem Eng Trans 86:1075–1080

Wang Y, Lu J, Qi J, Lang X, Fan S, Yu C, Li G (2021) High selectivity CO2 capture from biogas by hydration separation based on the kinetic difference in the presence of 1, 1-Dichloro-1-fluoroethane. Energy Fuels 35:10689–10702

Zunita M, Hastuti R, Alamsyah A, Khoiruddin K, Wenten IG (2021) Ionic liquid membrane for carbon capture and separation. Sep Purif Rev. https://doi.org/10.1080/15422119.2021.1920428

Koohestanian E, Shahraki F (2021) Review on principles, recent progress, and future challenges for oxy-fuel combustion CO2 capture using compression and purification unit. J Environ Chem Eng 9(4):105777

Sun R, Tian H, Song C, Deng S, Shi L, Kang K, Shu G (2021) Performance analysis and comparison of cryogenic CO2 capture system. Int J Green Energy 18(8):822–833

Kim S, Lim YI, Lee D, Seo MW, Mun TY, Lee JG (2021) Effects of flue gas recirculation on energy, exergy, environment, and economics in oxy-coal circulating fluidized-bed power plants with CO2 capture. Int J Energy Res 45(4):5852–5865

Mosaffa AH, Farshi LG (2020) Novel post combustion CO2 capture in the coal-fired power plant employing a transcritical CO2 power generation and low temperature steam upgraded by an absorption heat transformer. Energy Convers Manag 207:112542

Muroyama AP, Beard A, Pribyl-Kranewitter B, Gubler L (2021) Separation of CO2 fromdilute gas streams using a membrane electrochemical cell. ACS ES&T Eng

Cloete S, Giuffrida A, Romano MC, Zaabout A (2020) Economic assessment of the swing adsorption reactor cluster for CO2 capture from cement production. J Clean Prod 275:123024

Dissanayake PD, Choi SW, Igalavithana AD, Yang X, Tsang DC, Wang CH, Kua HW, Lee KB, Ok YS (2020) Sustainable gasification biochar as a high efficiency adsorbent for CO2 capture: a facile method to designer biochar fabrication. Renew Sustain Energy Rev 124:109785

Subraveti SG, Roussanaly S, Anantharaman R, Riboldi L, Rajendran A (2021) Techno economic assessment of optimised vacuumswing adsorption for post-combustion CO2 capture from steam-methane reformer flue gas. Sep Purif Technol 256:117832

Aziz MA, Kassim KA, BakarWAWA, Jakarmi FM, Ahsan AA, Rosid SJM, Toemen S (2019) Traffic pollution: perspective overview toward carbon dioxide capture and separation method. In: Fossil free fuels. CRC Press, pp 149–186

Comfort SM (2017) Synthesis and evaluation of SOD-ZMOF-chitosan adsorbent for post combustion carbon dioxide capture. Doctoral dissertation, Faculty of Engineering and the Built Environment, University of the Witwatersrand, Johannesburg

Kamran U, Park SJ (2021) Chemically modified carbonaceous adsorbents for enhanced CO2 capture: a review. J Clean Prod 290:125776

Mazari SA, Ali E, Abro R, Khan FSA, Ahmed I, Ahmed M, Nizamuddin S, Siddiqui TH, Hossain N, Mubarak NM, Shah A (2021) Nanomaterials: applications, waste-handling, environmental toxicities, and future challenges-a review. J Environ Chem Eng 9(2):105028

Nazarzadeh Zare E, Mudhoo A, Ali Khan M, Otero M, Bundhoo ZMA, Patel M, Srivastava A, Navarathna C, Mlsna T, Mohan D, Pittman CU Jr (2021) Smart adsorbents for aquatic environmental remediation. Small 17(34):2007840

Nie L, Mu Y, ** J, Chen J, Mi J (2018) Recent developments and consideration issues in solid adsorbents for CO2 capture from flue gas. Chin J Chem Eng 26(11):2303–2317

Pardakhti M, Jafari T, Tobin Z, Dutta B, Moharreri E, Shemshaki NS, Suib S, Srivastava R (2019) Trends in solid adsorbent materials development for CO2 capture. ACS Appl Mater Interfaces 11(38):34533–34559

Cormos AM, Cormos CC (2017) Reducing the carbon footprint of cement industry by post combustion CO2 capture: techno-economic and environmental assessment of a CCS project in Romania. Chem Eng Res Des 123:230–239

Sanna A, Maroto-Valer MM (2016) Potassium-based sorbents from fly ash for high-temperature CO2 capture. Environ Sci Pollut Res 23(22):22242–22252

Alhamed YA, Rather SU, El-Shazly AH, Zaman SF, Daous MA, Al-Zahrani AA (2015) Preparation of activated carbon from fly ash and its application for CO2 capture. Korean J Chem Eng 32(4):723–730

Sanna A, Maroto-Valer MM (2016) CO2 capture at high temperature using fly ash-derived sodium silicates. Ind Eng Chem Res 55(14):4080–4088

Panek R, Wdowin M, Franus W, Czarna D, Stevens LA, Deng H, Liu J, Sun C, Liu H, Snape CE (2017) Fly ash-derived MCM-41 as a low-cost silica support for polyethyleneimine in post-combustion CO2 capture. J CO2 Utili 22:81–90

Liu L, Singh R, **ao P, Webley PA, Zhai Y (2011) Zeolite synthesis from waste fly ash and its application in CO2 capture from flue gas streams. Adsorption 17(5):795–800

Muriithi GN, Petrik LF, Doucet FJ (2020) Synthesis, characterisation and CO2 adsorption potential of NaA and NaX zeolites and hydrotalcite obtained from the same coal fly ash. J CO2 Util 36:220–230

Galindo R, López-Delgado A, Padilla I, Yates M (2015) Synthesis and characterisation of hydrotalcites produced by an aluminium hazardous waste: a comparison between the use of ammonia and the use of triethanolamine. Appl Clay Sci 115:115–123

Linda PL, Okanigbe DO, Popoola API, Popoola OM (2021) Characterization of density separated mullite rich tailings from a secondary copper resource, a potential reinforcement material for development of an enhanced thermally conductive and wear resistant ti-6al-4v matrix composite. In: The proceedings of the 60th international conference of metallurgist. Canada

Acknowledgements

The authors wish to thank Tshwane University of Technology, Pretoria, South Africa for the support given during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Okanigbe, D.O., Popoola, A.P., Popoola, O.M., Moshokwa, P.M. (2022). Review on Hydrotalcite-Derived Material from Waste Metal Dust, a Solid Adsorbent for CO2 Capture: Challenges and Opportunities in South African Coal-Fired Thermal Plant. In: Tesfaye, F., et al. REWAS 2022: Energy Technologies and CO2 Management (Volume II). The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-92559-8_9

Download citation

DOI: https://doi.org/10.1007/978-3-030-92559-8_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-92558-1

Online ISBN: 978-3-030-92559-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)