Search

Search Results

-

Improving Microstructure and Corrosion Resistance of Cold Spraying Cu Coating Through Annealing

In order to improve the microstructure and corrosion resistance of the Cu coating prepared by low-pressure cold spraying, the Cu coating was annealed...

-

Preparation of Si-Based Composite Anode for Li-Ion Batteries by Cold Spraying and Its Electrochemical Performance

Silicon-based materials have become one of the most likely materials to replace graphite anodes of Li-ion batteries due to their ultra-high...

-

Microstructural Evaluation of Tungsten Carbide Cobalt (WC-17Co) Alloy Deposited by High-Velocity Oxygen Fuel, High-Velocity Air Fuel, and Cold Spraying Technologies

In this study, microstructural characterization was conducted on WC-17Co coatings produced via high-velocity oxygen fuel (HVOF), high-velocity air...

-

Tungsten-Steel Functionally Graded Coatings for Nuclear Fusion Applications Manufactured by Cold Gas Spraying

In nuclear fusion reactors, the first wall is the name given to the surface which is in direct contact with the plasma. A part of it is the divertor...

-

Effect of Carbon Fiber Orientation when Cold Spraying Metallic Powders onto Carbon Fiber-Reinforced Polymers

A previous study on the pull-off testing of metallized carbon fiber-reinforced polymers (CFRPs) via cold spray showed that better adhesion strengths...

-

Formation of Structure in Articles from Steel 316L Obtained by Cold Gas-Dynamic Spraying

Specimens from steel 316L obtained by four variants of cold gas-dynamic spraying of powders and subsequent hot isostatic pressing at a temperature of...

-

Rolling Contact Fatigue and Thermal Spraying Technique

With the booming development of the remanufacturing industry, the quality control and evaluation of remanufactured products have attracted much...

-

Optimizing the Corrosion Resistance of Cold Spraying Additive Manufactured FeCoNiCrMn High Entropy Alloy: Improving Particle Bonding Quality Through Heat Treatment

The cumulative deposition characteristic of deformed particles in the cold spray (CSAM) deposits forms unique open pore microstructure and poor...

-

In-Flight Measurements of Particle Temperature and Velocity with a High-Speed IR Camera During Cold Gas Spraying of In718 and TiAlCrNb

Unlike other thermal spraying methods, it is difficult to determine the temperature of the particles during cold gas spraying due to the relatively...

-

Development of Silicates and Spraying Techniques for Environmental Barrier Coatings

Currently, silicon carbide fibre-reinforced silicon carbide matrix ceramic matrix composites are widely used as high-temperature components for...

-

Narrow and Thin Copper Linear Pattern Deposited by Vacuum Cold Spraying and Deposition Behavior Simulation

Compared with ceramic materials, the fabrication of dense metal films requires higher impact velocity in vacuum cold spraying (VCS), also known as...

-

The Potential of High-Velocity Air-Fuel Spraying (HVAF) to Manufacture Bond Coats for Thermal Barrier Coating Systems

Driven by the search for an optimum combination of particle velocity and process temperature to achieve dense hard metal coatings at high deposition...

-

Numerical and Experimental Analysis of a Solid Shroud in Multi-arc Plasma Spraying

Plasma spraying is characterized by high flexibility, but has challenges of high energy consumption and oxidation of the metallic spray particles....

-

Microstructure and Deposition Mechanism of Suspension Plasma Spraying Thermal Barrier Coatings

Nanostructured ceramic coatings are a promising research hotspot in the field of thermal protection coatings. Suspension plasma spraying is a...

-

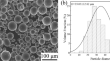

Synthesis of High-Entropy AlNiCoFeCrTi Coating by Cold Spraying

The cold spraying (CS) process was applied to deposit coatings using the AlCoNiFeCrTi high-entropy alloy (HEA) powder. The HEA powder was produced by...

-

Influence of HVOF spraying parameters on microstructure and mechanical properties of FeCrMnCoNi high-entropy coatings (HECs)

The study aimed to investigate the impact of high velocity oxy-fuel (HVOF) spraying parameters on the inflight particle temperature, velocity, and...

-

Cold Gas Spraying of Nickel-Titanium Coatings for Protection Against Cavitation

Cavitation erosion is a sever wear mechanism that takes place in hydrodynamic systems. Examples are turbine vanes of hydropower plants or components...

-

Cold-Sprayed W/B4C/Al Coatings for Neutron and γ-Rays Absorption

With the widespread use of nuclear energy, the storage of surplus spent fuel has emerged as a critical issue that needs to be solved, especially for...

-

Effect of Hot Isostatic Pressing on the Structure and Properties of Articles from Alloy VT6 Obtained by Cold Gas-Dynamic Spraying

Samples of titanium alloy VT6 obtained by the method of cold gas dynamic spraying (CGDS) and subjected to hot isostatic pressing (HIP) for lowering...

-

Induction Plasma Spraying

Induction plasma spraying (IPS), commonly identified as radio frequency induction plasma spraying (RF-IPS), inductively coupled plasma spraying...