Abstract

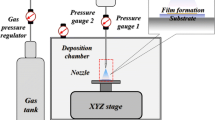

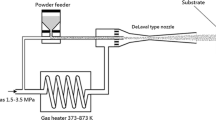

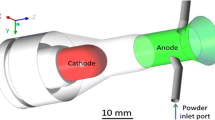

Compared with ceramic materials, the fabrication of dense metal films requires higher impact velocity in vacuum cold spraying (VCS), also known as aerosol deposition method. In this study, a supersonic nozzle for the fabrication of dense, thin and narrow copper lines was designed. The acceleration behavior of gas and copper particles was investigated through CFD numerical simulation. And the impact behavior of copper particles was studied through finite element analysis. The copper lines with the width of about 200 μm and the height of about 4 μm were directly fabricated on silicon wafers at room temperature without masking. The results show that there is an optimum particle diameter for the impact velocity in particle collision deposition systems. In order to obtain a higher particle impact velocity in VCS, the substrate should be placed behind the high-pressure region of gas shock wave, so that the position of the high-pressure region of the free jet and the position of the bow shock with the substrate coincide as much as possible. Copper particles undergo plastic deformation and particle flattening upon impact and subsequent particle compaction. The width of copper line increased with increasing standoff distance, and maximum height decreased with increasing standoff distance.

Similar content being viewed by others

References

K.M. Takahashi, Electroplating Copper onto Resistive Barrier Films, J. Electrochem. Soc., 2000, 147(4), p 1414

J.F. Pierson, D. Wiederkehr, and A. Billard, Reactive Magnetron Sputtering of Copper, Silver, and Gold, Thin Solid Films, 2005, 478(1–2), p 196-205

J.A.T. Norman, B.A. Muratore, and P.N. Dyer, A New Metal-Organic Chemical Vapor Deposition Process for Selective Copper Metallization, Mater. Sci. Eng., B, 1993, https://doi.org/10.1016/0921-5107(93)90085-2

J. Li, Y. Zhang, K. Ma, X.-D. Pan, C.-X. Li, G.-J. Yang, and C.-J. Li, Microstructure and Transparent Super-Hydrophobic Performance of Vacuum Cold-Sprayed Al2O3 and SiO2 Aerogel Composite Coating, J. Therm. Spray Technol., 2018, 27(3), p 471-482

L.-S. Wang, C.-X. Li, K. Ma, S.-L. Zhang, G.-J. Yang, and C.-J. Li, La0.8Sr0.2Ga0.8Mg0.2O3 Electrolytes Prepared by Vacuum Cold Spray under Heated Gas for Improved Performance of SOFCs, Ceram. Int., 2018, 44(12), p 13773-13781

L.-S. Wang, C.-X. Li, K. Ma, S.-L. Zhang, G.-J. Yang, and C.-J. Li, Microstructure and Electrochemical Properties of La0.8Sr0.2Ga0.8Mg0.2O3 Thin Film Deposited by Vacuum Cold Spray for Solid Oxide Fuel Cells, ECS Trans., 2017, 78(1), p 405-412

S.Q. Fan, G.J. Yang, C.J. Li, G.J. Liu, C.X. Li, and L.Z. Zhang, Characterization of Microstructure of Nano-TiO2 Coating Deposited by Vacuum Cold Spraying, Proc. Int. Therm. Spray Conf., 2006, 15(4), p 513-517

Y. Liu, Y.Y. Wang, G.J. Yang, J.J. Feng, and K. Kusumoto, Effect of Nano-Sized TiN Additions on the Electrical Properties of Vacuum Cold Sprayed SiC Coatings, J. Therm. Spray Technol., 2010, 19(6), p 1238-1243

L.S. Wang, H.F. Zhou, K.J. Zhang, Y.Y. Wang, C.X. Li, X.T. Luo, G.J. Yang, and C.J. Li, Effect of the Powder Particle Structure and Substrate Hardness during Vacuum Cold Spraying of Al2O3, Ceram. Int., 2017, 43(5), p 4390-4398

S.-Q. Fan, C.-J. Li, C.-X. Li, G.-J. Liu, G.-J. Yang, and L.-Z. Zhang, Preliminary Study of Performance of Dye-Sensitized Solar Cell of Nano-TiO2 Coating Deposited by Vacuum Cold Spraying, Mater. Trans., 2006, 47(7), p 1703-1709

J. Akedo, Aerosol Deposition of Ceramic Thick Films at Room Temperature: Densification Mechanism of Ceramic Layers, J. Am. Ceram. Soc., 2006, 89(6), p 1834-1839

H. Park, H. Kwon, and C. Lee, Inflight Particle Behavior in the Vacuum Kinetic Spray Process, J. Therm. Spray Technol., 2017, 26(7), p 1616-1631

F. Gärtner, T. Stoltenhoff, T. Schmidt, and H. Kreye, The Cold Spray Process and Its Potential for Industrial Applications, J. Therm. Spray Technol., 2006, 15(2), p 223-232

H. Assadi, T. Schmidt, H. Richter, J.-O. Kliemann, K. Binder, F. Gärtner, T. Klassen, and H. Kreye, On Parameter Selection in Cold Spraying, J. Therm. Spray Technol., 2011, 20(6), p 1161-1176

D.M. Chun, J.O. Choi, C.S. Lee, and S.H. Ahn, Effect of Stand-off Distance for Cold Gas Spraying of Fine Ceramic Particles under Low Vacuum and Room Temperature Using Nano-Particle Deposition System (NPDS), Surf. Coat. Technol., 2012, 206(8–9), p 2125-2132

W.Y. Li, C. Zhang, X.P. Guo, G. Zhang, H.L. Liao, C.J. Li, and C. Coddet, Effect of Standoff Distance on Coating Deposition Characteristics in Cold Spraying, Mater. Des., 2008, 29(2), p 297-304

W.-Y. Li, H. Liao, G. Douchy, and C. Coddet, Optimal Design of a Cold Spray Nozzle by Numerical Analysis of Particle Velocity and Experimental Validation with 316L Stainless Steel Powder, Mater. Des., 2007, 28(7), p 2129-2137

Abaqus Analysis User’s Manual, ABAQUS 6.13 HTML Documentation, Dassault Systèmes, 2013, n.d.

X. Suo, S. Yin, M.-P. Planche, T. Liu, and H. Liao, Strong Effect of Carrier Gas Species on Particle Velocity during Cold Spray Processes, Surf. Coat. Technol., 2015, 268, p 90-93

B. Vreman, B.J. Geurts, N.G. Deen, J.A.M. Kuipers, and J.G.M. Kuerten, Two- and Four-Way Coupled Euler-Lagrangian Large-Eddy Simulation of Turbulent Particle-Laden Channel Flow, Flow Turbul. Combust., 2009, 82(1), p 47-71

S. Yin, X.F. Wang, and W.Y. Li, Computational Analysis of the Effect of Nozzle Cross-Section Shape on Gas Flow and Particle Acceleration in Cold Spraying, Surf. Coat. Technol., 2011, 205(8–9), p 2970-2977

S. Yin, M. Meyer, W. Li, H. Liao, and R. Lupoi, Gas Flow, Particle Acceleration, and Heat Transfer in Cold Spray: A Review, J. Therm. Spray Technol., 2016, 25(5), p 874-896

F.F. Wang, W.Y. Li, M. Yu, and H.L. Liao, Prediction of Critical Velocity during Cold Spraying Based on a Coupled Thermomechanical Eulerian Model, J. Therm. Spray Technol., 2014, 23(1–2), p 60-67

W.Y. Li, K. Yang, S. Yin, and X.P. Guo, Numerical Analysis of Cold Spray Particles Impacting Behavior by the Eulerian Method: A Review, J. Therm. Spray Technol., 2016, 25(8), p 1441-1460

W. Li, K. Yang, D. Zhang, and X. Zhou, Residual Stress Analysis of Cold-Sprayed Copper Coatings by Numerical Simulation, J. Therm. Spray Technol., 2016, 25(1–2), p 131-142

K. Yang, W. Li, X. Guo, X. Yang, and Y. Xu, Characterizations and Anisotropy of Cold-Spraying Additive-Manufactured Copper Bulk, J. Mater. Sci. Technol., 2018, 34(9), p 1570-1579

W. Li, K. Yang, D. Zhang, X. Zhou, and X. Guo, Interface Behavior of Particles upon Impacting during Cold Spraying of Cu/Ni/Al Mixture, Mater. Des., 2016, 95, p 237-246

M. Yu, W.Y. Li, F.F. Wang, and H.L. Liao, Finite Element Simulation of Impacting Behavior of Particles in Cold Spraying by Eulerian Approach, J. Therm. Spray Technol., 2012, 21(3), p 745-752

W.-Y. Li and W. Gao, Some Aspects on 3D Numerical Modeling of High Velocity Impact of Particles in Cold Spraying by Explicit Finite Element Analysis, Appl. Surf. Sci., 2009, 255(18), p 7878-7892

S. Yin, X. Wang, W. Li, H. Liao, and H. Jie, Deformation Behavior of the Oxide Film on the Surface of Cold Sprayed Powder Particle, Appl. Surf. Sci., 2012, 259, p 294-300

C. Zhang, Q. Chen, J. Liu, W. Tang, K. Wang, and J. Song, Numerical Study on the Effect of the Cold Powder Carrier Gas on Powder Stream Characteristics in Cold Spray, Surf. Coat. Technol., 2016, 294, p 177-185

C. Li, N. Singh, A. Andrews, B.A. Olson, T.E. Schwartzentruber, and C.J. Hogan, Mass, Momentum, and Energy Transfer in Supersonic Aerosol Deposition Processes, Int. J. Heat Mass Transf., 2019, 129, p 1161-1171

J. Pattison, S. Celotto, A. Khan, and W. O’neill, Standoff Distance and Bow Shock Phenomena in the Cold Spray Process, Surface Coat. Technol., 2008, 202(8), p 1443-1454

L. de Juan and J. Fernández de la Mora, Sizing Nanoparticles with a Focusing Impactor: Effect of the Collector Size, J. Aerosol Sci., 1998, 29(5), p 589-599

X. Wang, F.E. Kruis, and P.H. McMurry, Aerodynamic Focusing of Nanoparticles: I. Guidelines for Designing Aerodynamic Lenses for Nanoparticles, Aerosol Sci. Technol., 2005, 39(7), p 611-623

T. Schmidt, F. Gärtner, H. Assadi, and H. Kreye, Development of a Generalized Parameter Window for Cold Spray Deposition, Acta Mater., 2006, 54(3), p 729-742

J. Vlcek, L. Gimeno, H. Huber, and E. Lugscheider, A Systematic Approach to Material Eligibility for the Cold-Spray Process, J. Therm. Spray Technol., 2005, 14(1), p 125-133

D.-W. Lee, O.-Y. Kwon, W.-J. Cho, J.-K. Song, and Y.-N. Kim, Characteristics and Mechanism of Cu Films Fabricated at Room Temperature by Aerosol Deposition, Nanoscale Res. Lett., 2016, 11, p 162

X.-T. Luo, C.-X. Li, F.-L. Shang, G.-J. Yang, Y.-Y. Wang, and C.-J. Li, High Velocity Impact Induced Microstructure Evolution during Deposition of Cold Spray Coatings: A Review, Surf. Coat. Technol., 2014, 254, p 11-20

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51761145108).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, K., Li, CJ. & Li, CX. Narrow and Thin Copper Linear Pattern Deposited by Vacuum Cold Spraying and Deposition Behavior Simulation. J Therm Spray Tech 30, 571–583 (2021). https://doi.org/10.1007/s11666-020-01102-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01102-w