Search

Search Results

-

Some Thoughts on Modeling Abrasion-Corrosion: Wear by Hard Particles in Corrosive Environments

Wear by hard particles can involve abrasion or erosion and is one of the most severe forms of wear. When a corrosive environment is present, the...

-

Effect of Electrodeposition Method on the Abrasion Resistance of Ni-SiC Composite Nanocoatings

This work reports the deposition of Ni-SiC composite nanocoatings (CNCs) on Q235 steel surface through different approaches, including direct current...

-

Cationic engineered nanodiamonds for efficient antibacterial surface with strong wear resistance

The spread of diseases caused by bacterial adhesion and immobilization in public places constitutes a serious threat to public health. Prevention of...

-

The Role of Metastable Austenite for Improving Abrasion Wear Resistance of 150KhNML Perlite Steel

AbstractThis article analyzes the influence of quenching in the wide temperature range on the amount of residual austenite, its stability and...

-

Dry and Wet Abrasion Wear Resistance on Borided AISI 1045 Steel

In this study, the abrasion wear behavior of borided AISI 1045 steel under dry and wet conditions was evaluated. The powder-pack boriding process...

-

On the Applicability of Iron-Based Coatings Against Abrasion and Cavitation Erosion Wear

Iron-based coatings are often considered as replacement of hard chromium and WC-Co, as they pose lower health and environmental impact. In many...

-

Wear Behavior of Hot Rolled 400 HB Grade Martensite-Ferrite Duplex Steel under Abrasion-Adhesion Condition

Hot rolled 400 HB grade martensite-ferrite duplex steel is a new type of wear-resistant material which is used in the manufacture of heavy-haul...

-

Wear Resistance and Mechanical Properties of 7085 Alloy via Adding CNTs Based on Ultrasonic Casting

High-energy ultrasound has been proposed to ameliorate the uniform dispersion the reinforcement and used widely fabricating in high strength metal...

-

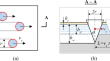

Wear Regimes of Fe–Cr–C Hardfacing Alloys in Microscale Abrasion Tests

Microscale abrasion tests were performed to assess the wear coefficients of six hardfacing materials in the Fe–Cr–C system, having added Ti, Nb,...

-

Wear Resistance and Microstructure of Ultra High Molecular Weight Polyethylene During Uniaxial Tension

The influence of microstructure on wear resistance of prosthetic hip and joint bioimplant material, ultra high molecular weight polyethylene (UHMWPE)...

-

Research on Impact–Abrasion–Corrosion Behavior of Three Typical Wear-Resistant Steels under High Impact Energy

The impact–abrasion–corrosion behavior of three typical wear-resistant steels including low-alloy wear-resistant steel, martensitic stainless steel...

-

Computational Thermodynamics-Aided Design of (Cr-Mo-W-V) Steels with Enhanced Corrosion and Abrasion Resistance

The study evaluates the microstructure, abrasion resistance, and corrosion behavior of newly designed cost-effective (Cr-Mo-W-V) steels. Six steels...

-

Improvement of Corrosion and Wear Resistance of Mg-Li Alloy by Binary- and Ternary-Layered Double Hydroxide/Steam Coating Composite Coatings

In order to improve the corrosion resistance and frictional wear resistance of LA43M Mg-Li alloy, Mg-Al-layered double hydroxide (LDH)/steam coating...

-

Slurry Abrasion and Dry Sliding Behavior of High-Velocity Oxy-Fuel (HVOF) Sprayed WC-12Co and WC-10Co-4Cr Coatings on EN8 Tillage Material

This research focuses on enhancing the wear resistance of EN8 steel, commonly used in agricultural implements by applying WC-12Co and WC-10Co-4Cr...

-

Wear Resistance Behavior of 0.06% C Dual-Phase Steel

The wear resistance behavior of dual-phase steel was examined in dry conditions and compared to plain carbon normalized steel with a similar chemical...

-

Wear Mechanisms/Models

The surfaces are continuously damaged by wear. Friction always leads to wear. According to statistics, wear, fatigue, and corrosion are the three...

-

Microstructure and wear resistance of laser-clad Ni60-Ti-B4C coatings

In order to improve the surface performance of engineering components, a Ni60-Ti-B 4 C hard coating was prepared in-situ on the surface of Q235 using...

-

Effects of K2co3 Flux on the Microstructure and Abrasion Resistance of High-Chromium Hardfacing Alloys

In this study, we assessed the effects of K 2 CO 3 flux on the microstructure and abrasion resistance of high-chromium alloys deposited by open arc...

-

Abrasion Resistance of Cement Paste with Granulated Blast Furnace Slag and Its Relations to Microhardness and Microstructure

The abrasion resistance of cement pastes with 30 wt%, 40 wt% and 50 wt% granulated blast furnace slag (GBFS), and its relations to microhardness and...

-

Wear Conditions-Dependent Tribological Behavior in Q&P Medium-Mn Steels: The Role of TRIP Effect and Strain Hardening

The microstructural evolution during deformation affects the mechanical properties of materials. Studying the response of wear resistance in...