Abstract

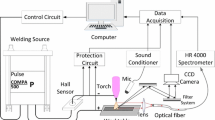

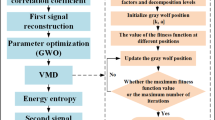

Aiming at the problem of online real-time monitoring of weld quality in traditional welding process, in this paper, a real-time welding quality prediction scheme based on multi-information fusion was proposed. Firstly, in view of the collected arc sound signals, a feature extraction method of short-time average energy and MEL frequency cepstrum (MFCC) is proposed to characterize the energy, timing characteristics and Merle frequency domain characteristics of sound; the image characteristics of weld are analyzed and the image processing method is designed. For straight welds, boundary method should be adopted for segmentation. Centerlines of weld seams can be extracted by means of median filtering, operator edge detection and least square straight line fitting; Based on ROI visual attention mechanism, the front image of the molten pool was extracted, and the edge features of the molten pool were extracted based on SDM method, so as to further obtain the features of the molten pool area, width, and semi-length. The results showed that the arc sound and visual information could support to each other. Finally, combine these two features could achieve online welding quality monitoring.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Chen SB, Lv N (2014) Research evolution on intelligentized technologies for arc welding process. J Manuf Process 16(1):109–122

Ma H, Wei S, Lin T et al (2010) Binocular vision system for both weld pool and root gap in robot welding process. Sens Rev 30(2):116–123

Song HS, Zhang YM (2007) Image processing for measurement of three-dimensional GTA weld pool surface. Weld J NY 86(10):323

Fan CJ, Lv FL, Chen SB (2009) Visual sensing and penetration control in aluminum alloy pulsed GTA welding. Int J Adv Manuf Technol 42:126–137

Huang YM, Wu D, Chen HB, Chen SB (2017) Investigation of porosity in pulsed GTAW of aluminum alloys based on spectral and X-ray image analyses. J Mater Process Technol 243:365–373

Xu Y, Fang G, Lv N et al (2015) Computer vision technology for seam tracking in robotic GTAW and GMAW. Robot Comput-Integr Manuf 32:25–36

He Y, Xu Y, Chen Y et al (2016) Weld seam profile detection and feature point extraction for multi-pass route planning based on visual attention model. Robot Comput-Integr Manuf 37:251–261

Na Lv et al (2014) Real-time control of welding penetration during robotic GTAW dynamical process by audio sensing of arc length. Int J Adv Manuf Technol 74(1–4):235–249

Lv N et al (2017) Automated control of welding penetration based on audio sensing technology. J Mater Process Technol 250:81–98

Lv N et al (2014) Real-time control of welding penetration during robotic GTAW dynamical process by audio sensing of arc length. Int J Adv Manuf Technol 74(1–4):235–249. [18] Wang Y, Zhao P (2001) Plasma-arc welding sound signature for on-line quality control. ISIJ Int 41(2):164–167

Zeng J, Chang B, Du D et al (2016) A visual weld edge recognition method based on light and shadow feature construction using directional lighting. J Manuf Process 24(Part 1):19–30

Zhang G, Wu CS, Liu X (2015) Single vision system for simultaneous observation of keyhole and weld pool in plasma arc welding. J Mater Process Technol 215:71–78

Gao J, Qin G, Yang J et al (2011) Image processing of weld pool and keyhole in Nd:YAG laser welding of stainless steel based on visual sensing. Trans Nonferrous Metals Soc China 21(2):423–428

Wu D et al (2017) VPPAW penetration monitoring based on fusion of visual and acoustic signals using t-SNE and DBN model. Mater Des 123:1–14

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51969001), the Guangxi Natural Science Foundation of China (No. 2018GXNSFAA138080; No. 2016GXNSFAA380188), and the Guangxi Major Science and Technology Projects of China (No. GuikeAA17292003).

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Feng, Z., Jiao, Z., Han, J., Huang, W. (2021). The Intelligent Methodology for Monitoring the Dynamic Welding Quality Using Visual and Audio Sensor. In: Chen, S., Zhang, Y., Feng, Z. (eds) Transactions on Intelligent Welding Manufacturing. Transactions on Intelligent Welding Manufacturing. Springer, Singapore. https://doi.org/10.1007/978-981-33-6502-5_6

Download citation

DOI: https://doi.org/10.1007/978-981-33-6502-5_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-6501-8

Online ISBN: 978-981-33-6502-5

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)