Abstract

Sheet pile wall structures are commonly applied in coastal projects, particularly for the quay wall. This structural type normally is used in places where the ground has a low bearing capacity and is easily penetrable. Many sheet pile quay walls constructed in the past had low front water depth and did not satisfy the requirements of current standards. This issue could be addressed by improving the ground in front of the wall using cement deep mixing (CDM) and then excavating to increase the water depth in front of the wall. This paper numerically evaluated the dynamic behavior of the sheet pile wall after renovation. The numerical model was performed based on the finite element method (FEM) using the PLAXIS 2D program. The study focused on investigating typical parameters of the quay wall improved using the CDM, such as bending moment and displacement of sheet pile and the development of excess pore water pressure (EPWP) in the backfill. These results were compared to those of the quay wall without the CDM to elucidate the advantages of this method. In addition, the influence of some factors on the quay wall behavior, such as earthquake excitation characteristics, CDM area, and CDM strength, was also evaluated. The results demonstrated that the ground improvement using the CDM significantly decreased the bending moment and displacement of the sheet pile wall. The excitation characteristics did not affect the deformed shape of the sheet pile. With the constant CDM depth, the sheet pile displacement decreased with an increase in the improvement width until it reached a limitation. The increasing CDM strength also decreased the displacement of the wall until it raised a certain value. This demonstrated that this method was technically feasible, and it could be considered to study further by experiment before applying in practice.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Improving the capacity of existing quay walls is an important work of the coastal countries. Many existing quay walls built in the last decades has small capacity. Currently, these quay walls are degraded and cannot satisfy the current demand for freight. The studies involving quay wall renovation have attracted the attention of many authors. Azeiteiro et al. [1] provided the design solution for rehabilitating a quay wall constructed from the previous century comprising a wooden pile foundation and a sheet pile wall connected by tie-rods to anchor plates. The study first provided an overview of the field and testing program used to describe the “in situ” soil deposits; then, the proposed solution was introduced. The long and short-term performance of the suggested solution was evaluated using numerical analysis. The results suggested that it should have a stronger solution to satisfy ultimate limit state criteria, emphasizing the importance of applying performance-based design in the present geotechnical engineering practice. Khan et al. [2, 3] evaluated the static and dynamic behavior of a sheet pile quay wall strengthened by cement-treated soil at the seaside using the geo-centrifuge test. Various test cases were carried out, including the sheet pile wall before and after the upgrade. During the test, the deformation of the quay wall, input–output accelerations, and earth pressure behind the wall was recorded to evaluate the static and dynamic response. The results implied that the improvement sharply increased the sheet pile resistance under static and seismic loading. The bending moments of the sheet pile wall decreased. The horizontal displacement also decreased significantly with an increase in the CDM area until it reached a limitation at around 50 m2. Nakamura et al. [4] introduced some new technologies to renovate the sheet pile structure in the harbour using lightweight treated soil replacement for backfill, added tie rods, and new sheet pile in front of the existing sheet pile wall. A study case was conducted based on the suggested idea, which allowed designers to select a suitable design method and structure type as possible. Based on the results, the paper proposed a design process to renovate the sheet pile wall. Senarathne [5] consider the influence of deepening seaside ground on the existing anchored and cantilever sheet pile structures in the cohesionless ground. An additional sheet pile wall was embedded from the seaside of the existing quay wall to support the main structure. The numerical simulation was applied to evaluate the influence of the improvement on the deformation and stability of the quay wall, and the results of this model were verified by a physical model conducted in a laboratory. The results showed that the stability of the quay wall significantly increased after improvement. Van der Eecken et al. [6] strengthened the old quay wall using high-pressure grouting, then deepened it to increase the water depth of the quay wall. The method was applied successfully to some old quay walls in Belgium. Nguyen et al. [7, 8] considered the static response of the caisson-type quay wall strengthened by rubble foundation grouting and excavation. A series of cases of grouted rubble was proposed and analyzed using the FEM to select the most reasonable dimension and shape. The results demonstrated that this method increased 2 m of front water depth and increased the stability of the renovated quay wall. In the next step of this study, Kim et al. [9] and Nguyen [10] compared the dynamic response using the geo-centrifuge test and numerical simulation. Various input motions with increasing amplitude were applied to the models. By comparing experimental and numerical studies, the study implied that the grouting rubble mound under the front toe of the caisson could ensure and increase the seismic resistance of the quay wall after deepening. Ruggeri et al. [11] summarized the main problems related to geotechnical engineering during the design and construction of upgraded quay walls in Italy. The paper focused on the main problems that need to be solved during the design of quay wall renovation, such as reduction of horizontal soil pressure, increase in strength resources in the passive zone, and strengthening of quay wall structures, especially for the medium cases (with the target of seabed deepening was around 2–3 m in front of the quay wall). Several methods were considered to extend the performance of six ports, focusing on using micro-piles and jet grouting to improve the bearing capacity and water depth in front of the quay wall.

As can be seen, the technologies used to renovate the quay wall were varied; it depended on the structure type and real condition of the existing quay wall. This study evaluated the ability to upgrade the sheet pile quay wall by strengthening the ground in front of the wall using the cement deep mixing, then dredging the seabed to increase front water depth. The cement deep mixing (CDM) method is a technique to chemically solidify and strengthen soft ground by in-situ mixing of the soil with cement slurry. Generally, the cement used for this method is normal portland cement or a mixture of portland cement and blast-furnace slag. The cement alone creates cementitious materials through hydration. In addition, the calcium hydroxide liberated from the cement also undergoes a pozzolanic reaction with the soil to create cementitious materials. These cementitious materials gradually fill the void space between the soil particles with time. As a result, the volume compressibility of soil decreases, and strength increases. Until today, the CDM has become one of the most common soil improvement methods with many advantages such as good quality, reasonable cost, wide application range, and less environmental impact. The CDM method is often superior to other methods in a wide range of ground improvement applications, such as preventing embankment instability and settlement, improving ground stability for construction projects, countermeasures against liquefaction, and reinforcement of ground to improve earthquake-response of superstructures [12].

In the previous studies [2, 3], the authors used the geo-centrifuge test to evaluate the dynamic behavior of the upgraded sheet pile quay wall under cyclic loads with a constant period for typical cases. Difference from the studies, in this framework, a study case of upgrading the quay wall conducted in Vietnamese conditions was introduced and numerically analyzed using the PLAXIS 2D program [13]. The input motions used in the research were real earthquake excitations collected from the PEER ground motion database [14]. Based on the analysis, the displacement, bending moment, and EPWP were compared between the quay walls with and without improvement. Especially using the finite element (FE) simulation, this research could conduct the parametric studies by changing some factors that were difficult to perform by the experimental model. Particularly, the paper focused on considering the effect of input excitation characteristic, the improvement area, and CDM strength on the sheet pile behavior.

Case study

The cross-sections of the quay walls before and after renovation are shown in Fig. 1a, b, respectively. The characteristic of steel sheet pile, steel pile, and tie rod are listed in Table 1. This quay wall located in Hai Phong city, Vietnam. The height of the existing quay wall was 13.5 m, the front water depth was 10 m, and it could receive 10,000 DWT of ships. After dredging, the water depth increased by 1.0 m, and the quay wall could be used for 20,000 DWT of vessels.

Numerical simulation

Finite element modeling

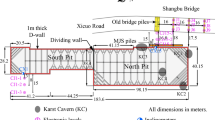

Figure 2 shows the FE models for the quay wall after dredging with and without the CDM improvement. In the models, the plate element simulated the sheet pile, while the embedded beam row element was used for the anchor pile. The node-to-node anchor element modeled the tie rod. The behavior of these structural components was simulated using the Linear elastic model, while the Mohr–Coulomb model was used for the CDM. In the static stage, all the soil layers were modeled using the Hardening soil model with the small-strain stiffness model (the HS small model). In the dynamic stage, the backfill layer was changed to the UBC3D-PLM model to investigate the development of the EPWP and liquefaction potential. The overall length of the models was 150 m, and the height was 36 m. The models were simulated using 15-node triangular plane strain elements. For the static condition, the side boundaries were fixed horizontally, and horizontal and vertical directions were fixed at the base [16]. In the dynamic analysis, the free field boundary condition was applied on both sides, and the compliant base boundary was assigned at the bottom [17]. The interface element simulated the interaction between soil/rubble and sheet pile to consider the gap** and slippage via the Coulomb friction law. The interface angle was taken as 0.7 times the internal friction angle of the material near the sheet pile [18]. The backfill was simulated as drained in the static stages, while the undrained behavior was applied for the dynamic steps. The average element size of the model was preliminarily defined based on the recommendation of Kuhlemeyer and Lysmer [19] to ensure a suitable propagation of the shear wave in the FEM, then it was selected based on a sensitivity analysis.

The parameters of the CDM zone used in this study are listed in Table 2. These values were selected based on the study by Khan et al. [3] and Technical standards and commentaries for port and harbor facilities of Japan [20].

Models and parameters of soil layers

The hardening soil model with small-strain stiffness model (the HS-small model)

In this study, the HS-small model was used to simulate soil behavior in static and earthquake conditions, except for the dynamic response of backfill. The HS-small model was formulated by Benz [21] based on the standard HS model developed by Schanz [22]. The HS-small model was designed to describe the macroscopic phenomena of soil, such as its densification, stiffness depending on stress, soil stress history, plastic yielding, and dilatation. In particular, it can handle other observed properties of the sandy soil in the small strain domain, including a strong stiffness variation with the development of the shear strain amplitude and a hysteretic, nonlinear elastic stress–strain relationship. These characteristics suggest that the HS-small model is suitable for dynamic analysis because it can generate displacement with high accuracy. The details of the HS-small model can be found in the literature [13, 23]. The basic parameters of the model and their values used in this research are listed in Table 3. These values were calculated based on the relative density, Dr, of the material using the equations proposed by Brinkgreve et al. [24], and referred from research by WA Van Elsäcker [15].

The UBC3D-PLM model

The UBC3D-PLM model is an effective stress elastoplastic model suitable for simulating the liquefaction behavior of sands and silty sands under seismic loading [13]. The model construction is based on the original UBCSAND model built by Puebla et al. [25] and Beaty and Byrne [26]. In this study, it was applied to model the dynamic and liquefaction behavior of the backfill. To simulate the yield conditions, the UBC3D-PLM used the Mohr–Coulomb yield equations in a 3D principal stress space for primary loading. However, the secondary loading applied a yield surface with a simplified kinematic hardening rule. In addition, a modified non-associated plastic potential function based on Drucker–Prager’s criterion was applied for the primary yield surface to keep the stress–strain coaxial assumption in the deviatoric plane for a stress path starting from the isotropic line. A criterion of soil densification was also added to predict the exact change of EPWP during cyclic loading. Besides, to receive more precision in the stress paths which start from out of the isotropic line, a correct process of counting the cycles during loading was applied in the model [13, 27].

The parameters of the UBC3D-PLM model applied in this paper were determined based on the relative equations suggested in the Plaxis manuals [13] and the previous study by WA Van Elsäcker [15]. The detail of these parameters is illustrated in Table 4.

Earthquake excitation

The PLAXIS 2D program provides the ability to analyze the system behavior under earthquake loading in the time domain. The ASCE 7-02 Minimum design loads for buildings and other structures [28] suggested using at least five earthquake input motions in the analysis. In this study, five acceleration time history records of earthquake motions namely Imperial Valley, Fruily Italy, Coalinga, Taiwan Smart, and Northridge were used in the analysis. The excitations were collected from the website of the Pacific Earthquake Engineering Research Center [14] had properties close to the Vietnamese design spectrum proposed in the national standard TCVN 9386:2012 [29] for Hai Phong city. Before applying to the analysis, these motions were modified more suitably with the Vietnamese design spectrum, as presented in Figs. 3 and 4. The modification was conducted using the MATLAB program based on the method proposed by Lilhanadn and Tseng [30, 31] and developed by Hancock et al. [32]. The process of this method is as follows:

-

(1)

Calculate the response of an elastic single degree of freedom (SDOF) system under the action of the acceleration time series for each period and dam** level to be matched.

-

(2)

Compare the peak of each SDOF response with the target amplitude and determine the mismatch.

-

(3)

Add wavelets to the acceleration time series with the appropriate amplitudes and phasing so that the peak of each response matches the target amplitude. One wavelet is used to match one SDOF response.

Results and discussion

Deformation and bending moment of the sheet pile wall

To investigate the deformation and bending moment of the sheet pile wall during an earthquake. This section compares the quay wall behavior deepened without improvement and improvement using the CDM under the Coalinga earthquake excitation.

Figure 5a, b compare the deformed shape of the quay walls between two models at the end of the earthquake (Scaled up ten times). In the case without improvement, a large bending occurred, especially in the middle of the sheet pile. The soil in front of the wall was also deformed and raised. In the case of improvement, the strength of the subsoil area in front of the wall increased. The curvature of the sheet pile wall decreased significantly, and the dredge surface was flat.

The horizontal displacement and bending moment of the sheet pile along the depth are depicted in Fig. 6. It can be seen that the improvement using the CDM sharply reduced both the horizontal displacement and bending moment of the sheet pile. The maximum displacement of the sheet pile for the case without improvement was 22.78 cm, which was higher than that of the improvement case at 17.17 cm. The standards [20, 33] suggested that the allowable displacement for the quay wall was 1.5%H (H was the height of the wall from the dredge level to the top). In this study, the height of the wall was 14.5 m; thus, the calculated allowable displacement was 21.75 cm. As shown in Fig. 6, if the quay wall did not improve, the maximum displacement exceeded the allowable limit. In contrast, the improvement reduced displacement lower than the criteria value. Similarly, both positive and negative bending moments of the sheet pile wall in the improvement quay wall were significantly lower than those in the case without improvement. In the improvement case, the maximum positive and negative bending moments were 986.73 and 302.72 kNm, while the values for the without improvement case were 1102.53 and 615.62 kNm.

The comparison of horizontal displacements at Point A (top of the sheet pile) between the quay wall dredged with and without CDM is depicted in Fig. 7. The results indicated that the displacement sharply decreased if the quay wall was improved using the CDM. The maximum and residual displacements at point A were 16.79 and 13.78 cm for the quay walls without CDM, while these values for the quay wall with CDM were 15.92 and 12.45 cm, respectively.

Excess pore water pressure and the possibility of liquefaction

To evaluate the liquefaction possibility of the backfill, the excess pore water pressure ratio, ru, was used in the analysis. ru was calculated as [13, 27]:

where Δu was the EPWP, \(\sigma^{\prime}_{vt}\) was the effective stress at time t, and \(\sigma^{\prime}_{v0}\) was the initial effective stress (beginning of the earthquake). If the EPWP was equal to the initial effective stress, the EPWP ratio was equal to 1.0, and the soil liquefied.

The distribution of the EPWP ratio at various times during the Coalinga earthquake is plotted in Fig. 8. The left-hand side figures show the results for the quay wall without improvement, while the results on the right-hand side belong to the improved case. In each figure, the red area indicated the EPWP close to 1.0 and the soil could liquefy, while the yellow and blue areas had the EPWP around 0.5 and 0.0, respectively, and the soil did not liquefy. In general, the liquefaction mainly occurred far from the sheet pile wall and not right behind the wall. It was due to the displacement of the sheet pile wall to the seaside; thus, the pore volume in the soil near the sheet pile increased, and the EPWP could not increase. Besides, it was observed that the EPWP around the anchor piles increased dramatically because of the fluctuation of these piles. The comparison between the two cases showed that the improvement increased the EPWP ratio in the soil near the sheet pile; at other locations, it was similar for both cases. This difference was due to the lower displacement of the sheet pile in the case improved by CDM and led to the smaller volume of soil near the sheet pile. The pore volume of soil in this area of the case with CDM case lower than that of the case without CDM. Therefore, the EPWP in the soil around this area tended to increase after improvement.

Figure 9a, b show the computed time history of the EPWP ratio at some points in the backfill for the cases with and without CDM. As seen at points 1 and 2, the EPWP ratio mostly did not increase during the earthquake in the case without CDM. In contrast, the improvement increased the EPWP at these points. The EPWP ratio values in the CDM case were approximately 0.6 and 0.2 at points 1 and 2, respectively. On the other hand, points 3 and 4 exhibited a significant increase in the EPWP under earthquake loading in both cases. At point 3, the EPWP ratio in the CDM case was also slightly higher than in the case without CDM during the earthquake. However, after the earthquake, they were similar values, at approximately 0.6. Especially at point 4 near the surface, the EPWP ratio was the same for both cases, reaching close to 1.0. Thus, the liquefaction possibility in this area was considerable.

Effect of earthquake excitation characteristics

Figure 10a, b plot the horizontal displacement and bending moment of the sheet pile wall along with the depth at the end of five earthquake motions, respectively. It is evident that the deformed shape of the sheet pile and the distribution of bending moment did not affect by the excitation characteristics. Both maximum horizontal displacement and bending moment occurred at level around 8 m from the surface. The maximum displacements and displacements at the top of the sheet pile obtained from five earthquake motions are listed in Table 5. The maximum displacement ranged from 13.96 to 17.17 cm, and displacement at the pile top from 9.95 to 12.45 cm. Similarly, Table 6 shows the maximum bending moments of the sheet pile under five earthquake motions. The maximum positive moment ranged from 283.44 to 386.20 kNm, and the negative moment from 921.05 to 1022.37 kNm.

Effect of the improvement area

To consider the influence of improvement area on the behavior of the quay wall, various cases with different area of the CDM was analyzed under the Coalinga earthquake motion. The improvement area was changed by increasing the CDM width, B, from 0 to 15 m, while the improvement depth was kept constant at 5.5 m. Figure 11 compares the horizontal displacement of the sheet pile along with the depth with different CDM widths, while Fig. 12 shows the decrease of displacement at the sheet pile top and maximum displacement with respect to the width of CDM. It can be seen that the displacement of the sheet pile decreased with increasing improvement area. When the CDM width, B, increased from 0 to 10 m, the maximum horizontal displacement decreased significantly from 22.78 to 17.17 cm, while the displacement at the top pile reduced from 15.92 cm to 12.45 cm, respectively. After that, even though the CDM width continuously increased, the sheet pile displacement increased slightly. It follows from Fig. 12 that the sheet pile displacement decreased with increasing improvement area until it reached a certain area. Particularly, when the ratio B/D equaled or over 2 (B was the width and D was the depth of CDM area, respectively), the displacement of the sheet pile was mostly constant. In previous literature, Khan et al. [3] performed centrifuge tests for several cases of CDM area. They also found that when the CDM area reached around 50 m2, the sheet pile displacement remains constant. Thus, it can be seen that the results from the FE model in this study agreed well with the observation from geo-centrifuge tests of Khan et al. [3].

Effect of the CDM strength

In this section, the effect of CDM strength was investigated by analyzing several cases of changing the undrained shear strength (Su) of CDM from 100 to 700 kPa. The range of CDM was determined based on the standard TCVN 9906:2014 [34]. The input motion used in the analysis was the Coalinga motion, and the area of the CDM was 10 × 5.5 m. The horizontal displacement, along with the dept at the end of the earthquake, was depicted in Fig. 13. The summary for the displacement at the wall top and maximum displacement of the sheet pile depended on the undrained shear strength is illustrated in Fig. 14. The results indicated that the CDM strength increase, the decrease the horizontal displacement decreased. For example, without the CDM, the displacements at the wall top and maximum displacements were 15.92 and 22.78 cm, respectively. These values decreased to 12.90 and 17.67 cm for the CDM that had Su of the 300 kPa, and 12.34 and 17.20 cm for Su equaled 500 kPa. However, when Su reached 500 kPa or over, the displacements were almost constant.

Conclusions

In this study, the dynamic behavior of the sheet pile wall dredged and improved seaside subsoil using the CDM was investigated by numerical analysis. Five input motions were modified by matching the Vietnamese design spectrum before being applied to the models. The study compared the response of quay walls with and without the CDM. In addition, the effect of the improvement area and the CDM strength was also accessed. Based on the analysis results, the following main conclusions were reached:

-

(1)

Compared to the case without improvement, the CDM changed in favor of the deformed shape of the sheet pile. The curvature of the sheet pile wall decreased significantly, and the upwelling of the soil in front of the wall did not occur. The improvement decreased the horizontal displacement of the sheet pile by approximately 25% and the bending moment by approximately 10%.

-

(2)

The improvement significantly increased the EPWP in the soil area near the sheet pile. For both cases with and without CDM, the liquefaction mainly occurred far from the sheet pile wall and not right behind the wall. The results also indicated that the soil near the surface was more easily liquified than deeper soil. The EPWP around the anchor piles increased dramatically during the earthquake.

-

(3)

The excitation characteristics did not influence the deformed shape and the bending moment shape of the sheet pile. However, the values were the difference between the five earthquake motions. The largest difference in the horizontal displacement of the sheet pile between the input motions was about 18%, while the distinction of the bending moments was around 10%.

-

(4)

The horizontal displacement of the sheet pile wall decreased with increasing improvement area. However, it decreased to a certain value, and after that, it remained constant regardless of the increasing improvement area. In this study, with the constant of the CDM depth, when the ratio between the width and depth of the CDM zone reached 2, the horizontal displacement almost did not change.

-

(5)

When the undrained shear strength of CDM increased from 100 to 500 kPa, the horizontal displacement of the sheet pile decreased significantly. After that, although it increased over 500 kPa, the horizontal displacements remained stable.

-

(6)

The numerical simulation was conducted to evaluate the dynamic resistance of the sheet pile quay wall dredged and improved seaside subsoil using cement deep mixing. The results proved that the suggested technology was technically feasible. Based on these results, further studies, such as shaking table tests or testbeds, will be performed before applying in practice.

References

Azeiteiro RJN, Skopal V, Clifford F, Widfeldt M (2019) The combined use of geostructures and ground improvement to the rehabilitation of existing quay walls. 17th Eur Conf Soil Mech Geotech Eng ECSMGE 2019-Proc 2019-Sept. 1–8. https://doi.org/10.32075/17ECSMGE-2019-0513

Khan MRA, Hayano K, Kitazume M (2008) Investigation on static stability of sheet pile quay wall improved by cement treated sea-side ground from centrifuge model tests. Soils Found 48:563–575. https://doi.org/10.3208/sandf.48.563

Khan MRA, Hayano K, Kitazume M (2009) Behavior of sheet pile quay wall stabilized by sea-side ground improvement in dynamic centrifuge tests. Soils Found 49:193–206. https://doi.org/10.3208/sandf.49.193

Nakamura S, Mizutani T, Matsumura S, Kagimoto S (2020) Suggestion of design method for upgrading sheet pile quay wall. PARI Technical Note 1375, Port and Airport Research Institute, Japan.

Senarathne D (2017) Study on the effect of dredging on existing sheet pile retaining structure. Master thesis, Department of Civil Engineering, University of Moratuwa, Srilanka.

Van der Eecken K, Maertens J, Dedeyne R, Goossens D, Van Damme L, Thibau W (1994) Underpinning of existing quay walls by mean of very high pressure grouting, in: XIII ICSMFE, New Delhi, India, pp. 185–189.

Nguyen AD, Kim YS, Kang GO, Kim HJ (2020) 2D Finite Element Method Analysis for Deepening of Existing Gravity Quay Walls. In: Proc Int Offshore Polar Eng Conf 2020-Oct. pp. 1724–1729

Nguyen AD, Kim YS, Kang GO, Kim HJ (2021) Numerical analysis of static behavior of caisson-type quay wall deepened by grouting rubble-mound. Int J Geo-Eng 12:1–16. https://doi.org/10.1186/s40703-020-00130-3

Kim YS, Nguyen AD, Kang GO (2021) Seismic behavior of Caisson-type gravity quay wall renovated by rubble mound grouting and deepening. Geomech. Eng. 27:447–463. https://doi.org/10.12989/gae.2021.27.5.447

Nguyen AD (2022) Geo-centrifuge Test and Numerical Analysis for Develo** Renovation Technology of Caisson-type Quay Wall by Grouting and Deepening, Chonnam National University

Ruggeri P, Fruzzetti VME, Scarpelli G (2019) Renovation of quay walls to meet more demanding requirements: Italian experiences. Coast Eng 147:25–33. https://doi.org/10.1016/j.coastaleng.2019.01.003

Cement Deep Mixing Association, Cement Deep Mixing (2015)

Bentley, Plaxis V21 manuals (2021)

Pacific Earthquake Engineering Research Center, PEER ground motion data base, (n.d.) https://ngawest2.berkeley.edu/site.

Van Elsäcker W (2016) Evaluation of seismic induced liquefaction and related effects on dynamic behaviour of anchored quay walls Using UBC3D-PLM constitutive model, TUdelft

Patil VN, Chore HS, Sawant VA (2020) Numerical analysis of reinforced embankment slopes made up of pozzolanic waste materials. International Journal of Geo-Engineering 11, 19 (2020), https://doi.org/10.1186/s40703-020-00126-z

Moniuddin MK, Manjularani P, Govindaraju L (2016) Seismic analysis of soil nail performance in deep excavation. International Journal of Geo-Engineering, 7, 16 (2016), https://doi.org/10.1186/s40703-016-0030-y

Athanasopoulos-Zekkos A, Vlachakis VS, Athanasopoulos GA (2013) Phasing issues in the seismic response of yielding, gravity-type earth retaining walls—overview and results from a FEM study. Soil Dyn Earthq Eng 55:59–70. https://doi.org/10.1016/j.soildyn.2013.08.004

Lysmer J, Kuhlemeyer RL (1969) Finite dynamic model for infinite media. J Eng Mech Div 95:859–876

OCDI (2002) Technical standards and commentaies for port and harbour facilities in Japan, The Overseas Coastal Area Development Institute of Japan, 3-2-4 Kasumigaseki, Chiyoda-ku, Tokyo, 100-0013, Japan

Benz T (2007) Small-strain stiffness of soils and its numerical consequences. University of Stuttgart, Inst. f. Geotechnik, 2007, ISBN: 9783921837559

Schanz T (1998) Zur Modellierung des Mechanischen Verhaltens von Reibungsmaterialen, Habilitation, Stuttgart Universität

Obrzud RF, Truty A (2018) The Harderning Soil model—a practical guidebook, Switzerland

Brinkgreve RBJ, Engin E, Engin HK (2010) Validation of empirical formulas to derive model parameters for sands. In: 7th Eur Conf Numer Methods Geotech Eng (NUMGE ), At Trondheim, Norway. pp. 137–147

Puebla H, Byrne M, Phillips P (1997) Analysis of canlex liquefaction embankments prototype and centrifuce models. Can Geotech J 34:641–657

Beaty M, Byrne P (1998) An effective stress model for predicting liquefaction behaviour of sand. in Panos Dakoulas, Mishac Yegian, Robert D. Holtz Geotechnical Earthquake Engineering and Soil Dynamics III, ASCE, p.766–777, ISBN: 978-0-7844-0361-7

Galavi V, Petalas A, Brinkgreve RBJ (2013) Finite element modelling of seismic liquefaction in soils. Geotech Eng 44:55–64

American Society of Civil Engineers (2000) ASCE 7-02: minimum design loads for buildings and other structures. ANSI/ASCE Stand 552:1–330. https://doi.org/10.1061/9780872629042

Ministry of Construction-Vietnam, TCVN 9386:2012-Design of structures for earthquake resistances (2012)

Lilhanadn K, Tseng S (1987) Generation of synthetic time histories compatible with multiple-dam** design response spectra. In: Trans 9th Int Conf Struct Mech React Technol Lausanne. pp. 105–110

Lilhanadn K, Tseng S (1988) Development and application of realistic earthquake time histiories compatible with multiple-dam** design spectra. In: Proc 9th World Conf Earthq Eng Tokyo Japan. pp. 819–824

Hancock J, Watson-Lamprey J, Abrahamson NA, Bommer JJ, Markatis A, McCoy EMMA, Mendis R (2006) An improved method of matching response spectra of recorded earthquake ground motion using wavelets. J Earthq Eng 10:67–89. https://doi.org/10.1080/13632460609350629

Ministry of Ocean and Fisheries-Korea, Harbor and Fishing Port Design Standard (2020)

Ministry of agriculture and rural development-Vietnam (2014) TCVN 9906:2014-Hydraulic structures-Cement soil columns created by Jet-grouting method-Technical requirement for design, construction and acceptance in the soft ground reinforcement

Acknowledgements

This research is funded by University of Transport and Communications (UTC) under grant number T2022-CT-015.

Author information

Authors and Affiliations

Contributions

ADN: Conceptualization, Methodology, Software, Writing original draft. VTN: Writing review & editing, Validation. YSK: Supervision, Validation, Editing. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nguyen, AD., Nguyen, VT. & Kim, YS. Finite element analysis on dynamic behavior of sheet pile quay wall dredged and improved seaside subsoil using cement deep mixing. Geo-Engineering 14, 9 (2023). https://doi.org/10.1186/s40703-023-00186-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40703-023-00186-x