Abstract

Metallic nanoparticles (NPs) have received recently considerable interest of photonic and photovoltaic communities. In this work, we report the optoelectronic properties of gold NPs (Au-NPs) obtained by depositing very thin gold layers on glass substrates through thermal evaporation electron-beam assisted process. The effect of mass thickness of the layer was evaluated. The polycrystalline Au-NPs, with grain sizes of 14 and 19 nm tend to be elongated in one direction as the mass thickness increase. A 2 nm layer deposited at 250°C led to the formation of Au-NPs with 10-20 nm average size, obtained by SEM images, while for a 5 nm layer the wide size elongates from 25 to 150 nm with a mean at 75 nm. In the near infrared region was observed an absorption enhancement of amorphous silicon films deposited onto the Au-NPs layers with a corresponding increase in the PL peak for the same wavelength region.

Similar content being viewed by others

Introduction

Plasmonic nanoparticles emerged recently as a possible solution to enhance solar cells efficiency1,2,3,4. High losses of photons due to both incomplete absorption of solar spectrum and thermalization are the main drawbacks that have been addressed to overcome limitations in photovoltaics efficiency. Over the past decades several improvements in solar cells were introduced but the highest conversion efficiency achieved so far for a single junction cell is 25% for crystalline silicon and 10.5% for amorphous silicon5.

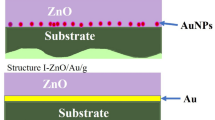

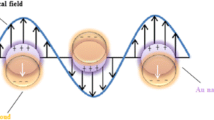

Surface Plasmon Resonance (SPR) arises in metal NPs as a collective oscillation of the surface electrons when subjected to the electric field associated to the incident light. Also, NPs should be smaller than the wavelength of the incident light in order to achieve SPR. As a result, the nanoparticles polarize. The scattering and absorption of light depends on the polarizability of the NPs, which is a function of the size, refractive index, shape, density and surrounding medium, as demonstrated in several theoretical studies6,7. These parameters should be tuned in order to maximize the NPs light scattering, relatively to absorption. Scattering efficiencies lower than 50% may lead to heat dissipation and absorption suppression. This promotes undesired reduction of photocurrent for solar cells having high response in the blue region8. However a change in shape from spherical to ellipsoidal or a change in the NPs medium affects the polarizability with possible red shift in the resonance frequency. In this case, NPs used as front electrode lead to an enhancement of the intrinsic layer absorption above 59% in the infrared region9.

The influence of shape: spheroid10, cylindrical11, nanowires12, size6 and also the distribution13 have been studied mainly for Au and Ag nanoparticles. Other nanoparticles such as Sn9 has also shown an enhancement of light absorption up to 59% when Al-NPs were deposited on the top of the TCO layer of a-Si:H solar cells. Nevertheless, our Au-NPs are embedded in a-Si:H film and the prove is the coincidence of TT and TSp spectra obtained by irradiating the samples from the glass side or from a-Si:H film side (reflectance was not shown also because no difference was observed). As reported by Pillai and Green2, if a semiconductor is close to electric field of an emitting dipole, the absorption is enhanced. Other non-linear processes such as up/down-conversion can be originated by the enhancement of electric field around the surface plasmons. In our results the photoluminescence shows that down-conversion (in terms of energy) is obtained in a-Si:H films deposited on Au-NPs (5 nm Au layer). In the literature, the luminescence of Au-NPs, deposited on glass substrate, has shown a red shift of the peak in the visible wavelength range, which was attributed to the reduction in quantum confinement of Au nanoparticles28. Due to the excitation energy in these measurements (2.71 eV, 457 nm), the excitation should involve just one photon. Besides that, a stronger luminescence signal is observed in the near-infrared region and it increases as the Au-NPs decrease. According to the literature, the above two emission bands in the visible and infrared can be attributed to interband and intraband radiative transitions involving electrons in the sp-conduction band and holes in the d-band of NPs21,23,29. However, NPs embedded in a-Si:H has a different behaviour since the emitted photons can be absorbed by gap states of a-Si:H, followed by recombination or it can induce radiative transitions in the a-Si:H. That would explain the difference in the PL intensity of a-Si:H with Au-NPs 2 nm and Au-NPs 5 and 7 nm. In this analysis we exclude any effect of a-Si:H induced recrystallization during the film deposition, since micro Raman and spectroscopic ellipsometry measurements were performed (standard techniques to evaluated the crystallinity of Si:H film) and no difference was observed in samples with and without NPs. Although the a-Si:H deposited on 7 nm Au layers has high photoluminescence in the near infrared region the low transmission in the visible range unsuited its application to front layers of solar cells.

Overall, we showed a straightforward method to deposit Au-NPs with controllable particle size which consists in the deposition of very thin Au layer by thermal evaporation in heated substrates. The a-Si:H films deposited on Au-NPs layers has enhanced absorption in the infrared region (700–900 nm) opening doors to enhance amorphous silicon based solar cells efficiency through improvement of absorption close to the band gap of silicon and up-conversion of photons. The deposition of NPs can be made in any part of the solar cell, intra or inter layers, according to the size of NPs, by a compatible process.

Methods

Preparation of the Au-NPs and a-Si:H films

Au-NPs were deposited onto glass substrates by e-beam evaporation at substrate temperature of 250°C and deposition rate of 0.1-0.2 nm/s. The layer thickness was controlled, after opening the shutter of the system, by the deposition time and by a calibrated quartz crystal detector. This procedure enable the control of the layer thickness and three different layers were reproduced (2, 5 and 7 nm).

A 200 nm film of hydrogenated amorphous silicon (a-Si:H) was deposited by radio frequency plasma enhanced chemical vapour deposition (RF-PECVD) on the samples (2, 5 and 7 nm layers). During the a-Si:H deposition (20 min) the substrate was heated to 150°C. Details about the a-Si:H films can be found in previous works30,31.

Structural and morphological characterization

To estimate the crystallite size and discard eventual cross-contaminations during the depositions, X-ray diffraction (XRD) measurements of the samples were performed in Panalytical X'Pert PRO with Cu Kα line radiation (λ = 1.540598 Å) using the Bragg-Brentano configuration with a 2Theta range of 15 to 80° and a step size of 0.02°.

The SEM images of samples were performed in a Zeiss Auriga Crossbeam microscope with a Schottky Field Emitter column. The Everhart-Thornley type SE and InLens detectors were used with an aperture size of 30.00 μm, working distance between 4.8 and 5.6 nm and an acceleration voltage from 1 to 20 kV. The transmission electron microscopy (TEM) was performed in a Hitachi H-8100 microscope which runs at 200 kV in samples deposited directly in the Cu TEM grid with 400 nm mesh.

Optical characterization

The transmittance and reflectance spectra were obtained in double beam UV-VIS-NIR Shimadzu spectrophotometer with an integrating sphere for reflectance and total transmittance measurements, in the range of 300-800 nm. The specular transmittance was measured in the range of and 300–2500 nm.

The PL measurements were performed both in the visible and in the infrared regions. In the first case, a Spex 1704 monochromator fitted with a cooled Hamamatsu R928 photomultiplier was used. The excitation source was the 457 nm line of a Melles–Griot laser with a power of ~30 mW. In the second region, a Bruker IFS 66v Fourier transform infrared (FTIR) spectrometer, equipped with a Ge diode detector, was used. The excitation source was a 514.5 nm line of an Ar+ ion laser, with a power of 151 mW. The samples were always inserted in a helium gas flow cryostat to allow the change of the temperature in the range 69–300 K. The excitation power was measured at the front of the cryostat window.

References

Akimov, Y. A., Koh, W. S. & Ostrikov, K. Enhancement of optical absorption in thin-film solar cells through the excitation of higher-order nanoparticle plasmon modes. Optics Express, 17 (12), 10195 (2009).

Pillai, S. & Green, M. A. Plasmonics for photovoltaic applications. Solar Energy Materials & Solar Cells 94, 1481–1486 (2010).

Hägglund, C. & Kasemo, B. Nanoparticle Plasmonics for 2D-Photovoltaics: Mechanisms, optimization and Limits. Optics Express 17 (14), 11944 (2009).

Losurdo, M., Giangregorio, M. M., Bianco, G. V., Sacchetti, A., Capezzuto, P. & Bruno, G. Enhanced absorption in Au nanoparticles/a-Si:H/c-Si heterojunction solar cells exploiting Au surface plasmon resonance. Solar Energy Materials & Solar Cells 93, 1749–1754 (2009).

Green, M. A., Emery, K., Hishikawa, Y. & Warta, W. Prog. Photovolt: Res. Appl. 19, 84–92 (2011).

Kelly, K. L., Coronado, E., Zhao, L. L. & Schatz, G. C. The Optical Properties of Metal Nanoparticles: The Influence of Size, Shape and Dielectric Environment. J. Phys. Chem. B 107, 668–677 (2003).

Coronado, E. A., Ezequiel, R. E. & Stefani, F. D. Optical properties of metallic nanoparticles: manipulation light, heat and forces at the nanoscale. Nanoscale 3, 4002–4059 (2011).

Pillai, S., Catchpole, K. R., Trupke, T. & Green, M. A. Surface plasmon enhanced silicon solar cells. J. Appl. Phys. 101, 093105 (2007).

Akimov, Y. A. & Koh, W. S. Design of Plasmonic Nanoparticles for Efficient Subwavelength Light Trap** in Thin-Film Solar Cells. Plasmonics 6, 155–161 (2011).

El-Sayed, M. A. Some Interesting Properties of Metals Confined in Time and Nanometer Space of Different Shapes. Acc. Chem. Res. 34 (4), 257– (2001).

Fahr, S., Rockstuhl, C. & Lederer, F. Improving the efficiency of thin film tandem solar cells by plasmonic intermediate reflectors. Photonics and Nanostructures – Fundamentals and Applications 8, 291–296 (2010).

Hutter, E. & Fendler, J. H. Exploitation of localized surface plasmon resonance. Adv. Mat. 16, n19, 1685–1705 (2004).

Nakayama, K., Tanabe, K. & Atwater, H. A. Plasmonic nanoparticle enhanced light absorption in GaAs solar cells. App. Phy. Lett. 93, 121904 (2008).

Li, Y., Peng, R., **u, X., Zhang, X. & Zhai, G. Growth of SnO2 nanoparticles via thermal evaporation method. Superlattices and Microstructures 50, 511–516 (2011).

Chang, S.-S. & Park, D. K. Novel Sn powder preparation by spark processing and luminescence properties. Mat. Sci. Eng. B 95, 55–60 (2002).

Buonsanti, R., Llordes, A., Aloni, S., Helms, B. A. & Milliron, D. J. Tunable Infrared Absorption and Visible Transparency of Colloidal Aluminum-Doped Zinc Oxide Nanocrystals. Nano Lett. 11, 4706–4710 (2011).

Skrabalak, S. E. Au, L., Li, X. & **a, Y. Facile Synthesis of Ag Nanocubes and Au Nanocages. Nat. Protoc. 2, 2182–2190 (2007).

Hutter, E. & Fendler, J. H. Exploitation of localized surface plasmon resonance. Adv. Mat. 16, n19, 1685–1705 (2004).

Iida, T. & Ishihara, H. Theoretical Study of the Optical Manipulation of Semiconductor nanoparticles under an Excitonic Resonance Condition. Phys. Rev. Lett. 90, 057403 (2003).

Mcmahon, M. D., Lopez, R., Meyer, H. M., Feldman, L. C. & Haglund, R. F. J. R. Rapid tarnishing of silver nanoparticles, in ambient laboratory air. Appl. Phys. B 80, 915–921 (2005).

Mooradian, A. Photoluminescence of Metals. Phys. Rev. Lett. 22, 185–187 (1969).

Link, S., Beeby, A., Fitzgerald, S., El-Sayed, M. A., Schaaff, T. G. & Whetten, R. L. Visible to Infrared Luminescence from a 28-Atom Gold Cluster. J. Phys. Chem. B 106, 3410–3415 (2002).

Zheng, J., Zhou, C., Yu, M. & Liu, J. Different Sized Luminescent Gold Nanoparticles. Nanoscale 4, 4073–4083 (2012).

Sun, H., Yu, M., Wang, G., Sun, X. & Lian, J. Temperature-Dependent Morphology Evolution and Surface Plasmon Absorption of Ultrathin Gold Island Films. J. Phys. Chem. C 116, 9000–9008 (2012).

Luth H., In Solid Surfaces and Interfaces Thin Films, ed. by W. T. Rhodes, H. E. Stanley, R. Needs, Springer Heidelberg Dordrecht London New York, 2010, cap. 3.

Halas, N. J., Lal, S., Chang, W. S., Link, S. & Nordlander, P. Plasmons in Strongly Coupled Metallic Nanostructures. Chem. Rev. 111, 3913–3961 (2011).

Sangita, J. A. & Sharma, R. P. A study of nanoellipsoids for thin-film plasmonic solar cell applications. J. Phys. D: Appl. Phys. 45, 275101 (2012).

Wilcoxon, J. P. & Martin, J. E. Photoluminescence from nanosize gold clusters. J. Chem. Phys. 108, 9137 (1998).

Link, S., Beeby, A., Gerald, S. F., El-Sayed, M. A., Schaaff, T. G. & Whetten, R. L. Visible to Infrared Luminescence from a 28-Atom Gold Cluster. J. Phys. Chem. B 106, 3410 (2002).

Martins, R., Raniero, L. & Pereira, L. et al. Nanostructured silicon and its application to solar cells, position sensors and thin film transistors. Phil. Mag. 89 (28–30), 2699–2721 (2009).

Águas, H. & Martins, R. et al. Silicon thin film solar cells on commercial tiles. Energy Environ. Sci. 4, 4620–4632 (2011).

Acknowledgements

The authors acknowledge to Strategic Project PEst-C/CTM/LA0025/2011 and QREN-5619 project and also to Joana Vaz Pinto and Luis Pereira for the XRD measurements and SEM images, respectively.

Author information

Authors and Affiliations

Contributions

All the authors have contributed to the paper as follows: D.G. and A.C.P. have performed the deposition of Au layers and their optical characterization including statistics analysis of SEM images; T.M. and A.A. have produced the amorphous silicon layers and performed the electro-optical characterization; J.P.L., J.S. and B.P.F. have performed the PL measurements and interpreted the results; S.A.F. and H.Á. have made the interpretation of Au-NPs optical results; R. M. have contributed to writing the paper; I.F. is the mentor of the work performed.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Gaspar, D., Pimentel, A., Mateus, T. et al. Influence of the layer thickness in plasmonic gold nanoparticles produced by thermal evaporation. Sci Rep 3, 1469 (2013). https://doi.org/10.1038/srep01469

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep01469

- Springer Nature Limited

This article is cited by

-

Transparent sunlight-activated antifogging metamaterials

Nature Nanotechnology (2023)

-

Towards realistic modeling of plasmonic nanostructures: a comparative study to determine the impact of optical effects on solar cell improvement

Journal of Computational Electronics (2022)

-

Bifunctional Au–TiO2 thin films with enhanced photocatalytic activity and SERS based multiplexed detection of organic pollutant

Journal of Materials Science: Materials in Electronics (2019)

-

Physics Models of Plasmonics: Single Nanoparticle, Complex Single Nanoparticle, Nanodimer, and Single Nanoparticle over Metallic Thin Film

Plasmonics (2018)

-

Effect of Systematic Control of Pd Thickness and Annealing Temperature on the Fabrication and Evolution of Palladium Nanostructures on Si (111) via the Solid State Dewetting

Nanoscale Research Letters (2017)