Abstract

Plasma processing appears to be the mainstay of food preservation in the present day due to its effectiveness in controlling microorganisms at low temperatures. Legumes are usually soaked before cooking. Six chickpea varieties (Kripa, Virat, Vishal, Vijay, Digvijay, and Rajas) were soaked in distilled water at room temperature, and Peleg model was fitted after plasma treatment. Cold plasma treatment was used at 40, 50 and 60 Watt with exposure times of 10, 15 and 20 min. K1 (Peleg rate constant) consistently decreased from 32.3 to 4.3 × 10–3 (h % − 1) for all six chickpea cultivars, indicating an increased water absorption rate with increasing plasma power and treatment time. It was lowest in 60 W 20 min plasma treatment in Virat cultivar. K2 (Peleg capacity constant) ranged from 9.4 to 12 × 10–3 (h % − 1) for all six chickpea cultivars. Thus, plasma treatment showed no effect on water uptake capacity (K2), as it did not increase or decrease consistently with increasing plasma power and treatment time. Fitting the Peleg model successfully revealed the correlation between the water absorption of chickpea cultivars. The model fit ranged from R2 ≥ 0.9873 to 0.9981 for all six chickpea cultivars.

Similar content being viewed by others

Introduction

Chickpea (Cicer arietinum L.) is the third most important legume in the world in terms of consumption. There are two main types of chickpeas, Desi and Kabuli. The latter has a thin, white seed coat. The former has a thick, coloured seed coat. Kabuli is larger than Desi1. They are a source of energy, vitamins and minerals, as well as economical sources of protein. Chickpeas have been shown to reduce cardiovascular disease, diabetes, obesity and cancer2.

In the case of legumes, soaking must be carried out prior to their use and processing. For example, the extrusion of pulses should be done after soaking them in water for 16 h to improve their nutritional value 3. Gelatinisation is achieved by soaking starch7. Processes such as soaking, scorching, etc. are used to increase protein digestibility, mineral bioavailability and thus the nutritional value of foods4,5. The water absorption rates and water absorption capacities of grains under different soaking conditions have been investigated6,7,8,9. The water absorbed by pulses during soaking affects subsequent processing and thus the quality of the final product10. The water absorption of seeds is determined by the time of soaking and the temperature of the soaking water. During soaking, water slowly enters the seeds, eventually reaching a constant moisture content11. The processing operations like cooking, germination, milling, and the quality of the final product are dependent on the water sorption during the soaking process. Therefore, the kinetics of water absorption in pulses during soaking has been studied10,12,13,14,15,16. Considerable efforts have been made by scientists under this topic. However, plasma-treated chickpea has not yet been studied in detail. In view of the present scenario of plasma treatment in food processing, it will soon be the most common treatment; therefore, efforts are being made to study it.

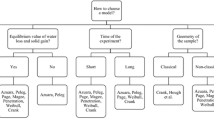

Water absorption has been studied using various theoretical and empirical approaches. In some cases, empirical models tended to be preferred because they seemed relatively easy to use17. Peleg has used a two-parameter empirical model which has been successfully used to describe the water sorption behaviour of chickpeas, field peas, kidney beans, pigeon peas, peanuts and soya beans12,13,14,15,16. It is the most popular model because of its simplicity and has also been used to study sorption processes in wheat, rice, sago starch, papaya and dasheen leaves18,19,20,21,22,23.

Sir William Crookes was the first to describe plasma24. It is the fourth state of matter which is partially or fully ionised state of gas25. Cold plasma is growing rapidly and is starting to show potential for sterilising surfaces of food, packaging and fresh produce26,27,28. Endospore-forming bacteria and spores with durable coat layers, such as Clostridia and Bacillus subtilis, are comparatively resistant to conventional sterilisation methods. Cold plasma offers a practical solution and appears to be a fast, inexpensive and environmentally friendly tool to improve crop yields29,30. Hydrogenation of edible oils, removal of anti-nutritional factors, alleviation of food allergies, modification of seed germination and wastewater management are other areas of its use31. Cold plasma is used to control pollutants and plant growth and as an alternative to pesticides and fertilisers32.

Fresh spinach leaves treated with plasma showed discolouration after 24 h cold storage33,34. It can inactivate hypertonic yeast (Zygosaccharomyces rouxii) in apple juice35. It has also been studied to reduce cooking time36. Soaking plasma treated chickpeas (Cicer arientinum) was investigated by Pathan et al. (2021). This study reported soaking plasma-treated samples in distilled water and 1% sodium bicarbonate solution at room temperature37. Cold plasma has also been successfully used to protect chickpeas against the storage pest Callosobruchus chinensis (Chrysomelidae: Bruchinae) for approximately four years38.

After cold plasma treatment the seed surface oxygen-containing functional group’s intensity increases resulting in increased surface wettability through the surface oxidation process39. The scanning electron micrographs of the plasma-treated surface show erosion in an uppermost layer in the seed coat, viz. the upper epidermis33. Cold plasma pretreatment can reduce soaking and cooking times of legume seeds. The aim of the present research was to investigate the suitability of the Peleg model for predicting the water absorption behaviour of chickpea cultivars treated with cold plasma and to study the characterisation of the equation constants while determining the appropriate conditions for the soaking process.

Materials and methods

Materials

The chickpea samples were procured from the Pulses Improvement Project, MPKV, Rahuri, India. The names of the cultivars procured were Kripa, Virat (Kabuli type) Vishal, Vijay, Digvijay, and Rajas (Desi type). The Initial moisture content of these samples was determined by using the AOAC (2002) method40. Which was 8.4, 8.2, 10, 10.10, 9.3, and 9.1% on a dry basis for all the chickpea cultivars, respectively. These samples were adequately cleaned and kept in a zip-lock pouch before and after plasma treatment.

Methods

Plasma treatment of chickpea cultivars

An in-house built low-pressure glow discharge plasma with bell-jar symmetry was employed for plasma treatment. The reactor walls were made up of Pyrex glass with 3 mm of thickness, a height of 120 mm, and an internal diameter of 300 mm; the material of the base and the opening lid was stainless steel. The electrodes were made of aluminium which has a 20 cm diameter. The electrodes were connected through the Wilson seals on these plates. The base plate had ports to connect the gas/monomer reservoir, Pirani gauge, vacuum pump, air admittance valve, etc. The electrode distance inside the reactor was maintained at 3 cm during all the plasma treatments. The system was capacitively coupled with a radiofrequency power source having a frequency of 13.56 MHz. The system pressure was initially achieved at 0.05 mBar with samples in the system by using HHV vacuum pump ED-20, and the working pressure was adjusted to the optimised value of 0.5 mBar. The plasma glow was observed (Fig. 1), and treatment on chickpea cultivars was performed at 40, 50, and 60 W, each having an exposure time of 10, 15, and 20 min.

Soaking test

Chickpea samples (8 g) were poured into a beaker containing 50 ml of distilled water at room temperature. During soaking, samples were removed from the beaker at the interval of 1 h. and placed on a filter paper until they lost surface moisture. All samples were weighed and returned to the beaker. The beaker was topped up with distilled water. A stopwatch in a cell phone and a precision electronic balance (Model CAH 323, accuracy ± 0.001 g India) were used, respectively, to record soaking time and weigh the sample before and after immersion of chickpea. Experiments were terminated at equilibrium moisture content after a sample mass showed a change of less than 0.001 g in consecutive 1 h of soaking. All the soaking experiments were performed in triplicate. The per cent moisture absorbed was calculated 7,10,37.

Where Wa is water absorption (d.b. %), Wf is the weight of seeds after immersion (g) and Wi is the weight of seeds before immersion (g).

Analysis of soaking data and soaking model

A low amount of water was absorbed by seeds before 3 h, the recorded data for this period were not used for fitting the Peleg model. Also, the control samples did not reach the equilibrium moisture content in 9 h. hence their data of soaking after this was not considered for Peleg Model fitting.

Modelling water absorption of plasma-treated chickpea cultivars

Peleg proposed an equation which is as follows:

Where Mt is moisture content at time t (% d. b.), Mo is initial moisture content (% d. b.), t is time (h), K1 and K2 are the Peleg rate (h%−1), and Peleg capacity constant (%−1) respectively. In Eq. (1), ‘ ± ’ becomes ‘+’ if the process is absorption and ‘−’ if the process is drying or desorption.

The rate of sorption (R) can be obtained from the first derivative of the Peleg equation:

The Peleg rate constant K1 relates to the sorption rate at the starting (Ro), i.e., R at t = to

The Peleg capacity constant K2 relates to the maximum (or minimum) attainable moisture content. As Eq. (4) gives the relation between equilibrium moisture content (Me) and K2

e. Calculation of Coefficient of determination (R2) and Root Mean Square Error

To evaluate Peleg model forecasting, predicted data were plotted against test data for six studied varieties treated at 40, 50, and 60 W each for 10, 15, and 20 min and the coefficient of determination (R2) was determined by following Eq. (6):

Where Mexp, i is the ith experimentally observed moisture content, Mpre, i is the ith predicted moisture content, M exp ave is the average moisture content observed, and n is the number of observations.

The goodness of fit between the experimental and predicted water absorption values was calculated using the Root Mean Square Error (RMSE), as:

Root mean square error, %,

Where Mexp, i is the ith experimentally observed moisture content, Mpre, is the ith predicted moisture content, M exp ave is the average moisture content observed and n is the number of observations.

Statistical analysis

The findings were statistically analysed using SPSS (IBM statistical analysis version 19) and one-way ANOVA for the increase in moisture (%). All samples were analysed in triplicate. The significance between the samples was compared at P < 0.05, where the least significant difference was tested by the Post-hoc and Duncan tests. The averages from three different studies were presented in all of the findings. The testing of the Peleg model and the curve fitting was carried out in Microsoft Excel using the least-squares method.

Research involving plants

The present study complies with relevant institutional, national, and international guidelines and legislation as per the IUCN Policy Statement on research involving species at risk of extinction and the Convention on international trade in endangered wild fauna and flora species.

Ethical approval

This article does not contain any studies with human participants performed by any authors.

Human and animal rights

The research did not involve human participants and/or animals.

Results and discussion

Water absorption characteristics of the legume seeds during soaking

The mean moisture content of cold plasma treated and untreated chickpea cultivars soaked in distilled water at ambient temperature are illustrated in Fig. 2, Table 1, and Supplementary Tables S1 and S2.

The moisture absorption curves reveal that moisture absorbed was much less in all the control samples than in all the plasma-treated chickpea cultivars, increasing from 40 watts 10 min to 60 watts 20 min. Thus, absorption curves showed that the water absorption rate increased with increasing plasma power and treatment time.

The percentage of water absorption was in the range of 75.65–77.75% and 78.57–102.07% for the control and plasma treated samples, respectively, during soaking in distilled water. A significant difference (P < 0.05) in moisture absorbed during distilled water soaking was found in samples exposed to 40, 50 and 60 W power for 10, 15 and 20 min in all chickpea cultivars. These results are in agreement with previous findings by researchers37. In the control samples, after soaking for 9 h, the moisture absorption was lowest in Kripa and highest in Virat. Previous researchers reported that water absorption values were significantly different (P < 0.05) in different chickpea cultivars. This was due to differences in morphological and physiological characteristics of chickpea cultivars grown in different regions. Our results do not agree with those reported results41. In our case, the chickpea's morphological and physiological properties did not differ as these were grown in the same place.

Among all the plasma treated samples of all the cultivars, the moisture absorption was the highest at the power of 60 W for a 20 min treatment during the soaking in distilled water, while it was the lowest at the power of 40 W for a 10 min treatment. The increase in moisture absorption was highest in Kripa at 60 W for 20 min treatment and lowest in Rajas at 40 W for 10 min treatment. The increase in water absorption with increase in plasma power and treatment time showed that plasma treatment may have eroded the surface of chickpea seeds and increased their surface energy. Cold plasma treatment and its effects on the germination of mung beans (Vigna radiata) have been studied42. Authors reported that the surface etching of mung beans is caused by the plasma species, which are responsible for increasing the conductivity of the seed coat and reducing the contact angle, making the surface more hydrophilic. The contact angle quantifies the wettability of a solid surface by a liquid. In the past, researchers observed scanning electron micrographs in black grams to confirm that plasma treatment caused surface etching and made the seed surface hydrophilic. This subsequently allowed easy absorption of water in black grams. They showed that the plasma treatment caused a decrease in the contact angle and an increase in the surface free energy43. The increased water absorption with increasing plasma power and treatment time in our case also confirmed that the rapid water absorption could be due to the surface etching of the plasma treated chickpea samples and also due to the reduced contact angle and increased surface free energy. Bormashenko et al., 2012, also reported that the wetting properties of seed surfaces could be modified by cold radiofrequency air plasma treatment for lentils (Lens culinaris), beans (Phaseolus vulgaris) and wheat (Triticum, species C9)44. The saturation moisture content of the bean varieties was reached at the same time41,46. However, in the case of the chickpea varieties, the saturation moisture content was comparatively shorter at higher water temperatures41,45,46. The increase in water diffusivity in the seeds may be responsible for this phenomenon. High temperatures could cause the seeds to soften and expand41,45,46. When the soaking temperature was closer to the seed gelatinising temperature, it had a higher moisture uptake rate41,45,46.

The water uptake rate in the present study was higher in the early soaking period and gradually decreased in all six chickpea cultivars later. At the 8th and 9th hours of soaking in distilled water, the cold plasma treated chickpea cultivars reached equilibrium. Cultivar Virat showed comparatively higher water uptake than Digvijay, Rajas, Vijay, Kripa and Vishal in decreasing order at each plasma power and exposure time.

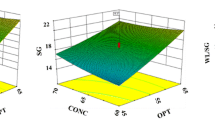

Modelling of the chickpea water absorption as a function of time

The data up to t0 and t∞ were used for the determination of the goodness of fit of the Peleg model. The model fit resulted in R2 ≥ : 0.9981 for Virat, 0.9965 for Digvijay, 0.9953 for Rajas, 0.9950 for Vijay, 0.9941 for Kripa and 0.9873 for Vishal for the control samples. A typical fit is shown in Fig. 3 and the R2 and RMSE % values obtained from the fit of Eq. (2) are given in Table 2.

The water uptake fitted by the Peleg non-linear equation with coefficients shows that the water content of the seeds increased with the soaking time for both the plasma treated seeds and the untreated seeds. Peleg model was successfully fitted to correlate the water uptake of six chickpea cultivars. With increasing soaking time and cold plasma treatment, the R2 ranged from 0.9723 to 0.9999 and the RMSE (%) ranged from 0.010 to 0.098 for all the chickpea cultivars (Table 2) (Supplementary Table S3). Thus, the coefficient of determination (R2) and root mean square error percentage (RMSE) shown in Table 2 were more than 0.9 and less than 1%, respectively. Consequently, it is an indication that Peleg model was reliable enough to predict the moisture content of plasma-treated and control chickpeas41.

Assessment of Peleg rate constant K1

K1 (Peleg rate constant) is a constant related to the rate of mass transfer, e.g. the lower the K1, the higher the initial rate of water uptake. K1 values were expressed as × 10–3 (h % − 1). K1 values for control samples of Rajas were 32.30 to 24.00 for all chickpea samples. K1 for plasma treated samples at 40, 50 and 60 watts for 10, 15 and 20 min respectively decreased from 24 to 9.80 for Kripa, 32.2 to 4.30 for Virat, 31.80 to 12.5 for Vishal, 29.3 to 12.7 for Vijay, 29.4 to 6.6 for Digvijay and 32.3 to 9.10 for Rajas with increase in plasma power and exposure time (Table 2) (Supplementary Table S3).

Peleg model K1 values of all plasma treated samples were lower than control (Fig. 3). Also, K1 values decreased progressively with increasing plasma power and exposure time for all six chickpea cultivars. This suggests that the surface wettability of the seeds was increased by the plasma treatment. Also, the treated seeds may have an eroded surface due to the plasma treatment resulting in increased initial water uptake rates35.

The sensitivity of K1 to plasma power and exposure time indicates the positive effect of cold plasma power and treatment exposure time on water absorption rate. Similar observations have been reported for the soaking studies with increasing temperature of the soaking water10. Researchers stated that water absorption in chickpea and bean varieties increased with increasing temperature of distilled water used for soaking and Peleg model constants were then examined as a function of temperature41,45,46. In the case of bean cultivars, their results showed a linear decrease in the coefficients K1 and K241,46. For chickpeas, only the coefficient K1 decreased linearly, while K2 decreased partially41,45. Our results are consistent with theirs41,45,46.

In the experiment investigating the effect of maize kernel damage on water absorption rate, it was found that the water absorption rate of the most damaged maize kernels was significantly higher than that of the undamaged kernels47. Sensitivity to cold plasma treatment was more pronounced at 60 watts for 20 min, where K1 value was lowest. As determined by K1 values, the initial water uptake rate was highest at 60 watts for 20 min, consistent with Fig. 2. Thus, cold plasma power and treatment exposure time had a positive effect on the water absorption rate of all plasma treated chickpea samples of all cultivars. The plasma-induced change in the surface chemistry of the treated seeds may be the reason for this increased rate of water absorption, wettability or hydrophilicity. Often this is caused by introducing new oxygen-containing functional groups44. Plasma treatment also affects the surface morphology, mainly through its etching mechanisms, resulting in increased surface roughness49. As a result of the change in surface chemistry or etching of the seed surface, wettability was increased44. The latter then led to improved or accelerated water uptake48.

Assessment of Peleg capacity constant K2

K2 (Peleg capacity constant) is a constant related to the maximum water uptake capacity, i.e. the lower K2, the higher the water uptake capacity. K2 values were expressed as × 10–3 (% − 1). K2 for control samples of all chickpea cultivars was found to be 10.40 to 12 for all chickpea cultivars (Table 2) (Supplementary Table S3). K2 for plasma treated chickpea cultivars at 40, 50 and 60 watts for 10, 15 and 20 min respectively ranged from 9.4 to 12 for all chickpea cultivars (Table 2) (Supplementary Table S3). Peleg's model K2 values of all plasma-treated and control samples were not different for all chickpea cultivars (Fig. 3). K2 values did not show a linear decrease with increase in plasma power and treatment time. It shows that plasma power and treatment time only improved the rate of water uptake and not the capacity to absorb water.

In addition, no effect of plasma power and treatment time on K2 was observed for any of the six chickpea cultivars. The effect of soaking temperature on water absorption was investigated in a few experiments. Researchers reported mixed effects of soaking water temperature on moisture absorption capacity K2. It depends on material and soluble solids loss. Shafaei et al. (2016) reported that the water absorption of chickpea and bean cultivars increased with the increase of soaking water temperature. They stated that the obtained Peleg model constants were investigated in relation to temperature. In the case of bean varieties, their results showed a linear decrease in the coefficients K1 and K2. For chickpeas, only the coefficient of K1 decreased linearly, while K2 decreased partially41. Many scientists have found that K2 is not affected by temperature10,13,14,16,22,50,51. At the same time, Turhan et al. (2002) reported an increase in K2 with increase in temperature7. In this study, neither plasma power nor exposure time showed any effect on K2.

Comparison of K1 with K2

To study the comparison of the Peleg rate constant (K1) with the Peleg capacity constant (K2), the plot of K1 and K2 of the control and the samples treated from 40 watts 10 min to 60 watts 20 min was prepared (Fig. 4). K1 values were expressed as × 10–3 (h % − 1). K1 decreased within the range of 32.3 to 4.30 for all chickpea cultivars (Table 2) in plasma-treated samples at 40, 50 and 60 W for 10, 15 and 20 min, respectively (Supplementary Table S3).

For the chickpea cultivars treated with plasma at 40, 50 and 60 watts for 10, 15 and 20 min respectively, K2 values range d from 9.4 to 12 for all the chickpea cultivars (Table 2). K2 values for all plasma-treated and control samples were not different or showed an increasing or decreasing trend for all chickpeas (Table 2) (Supplementary Table S3).

Conclusions

Peleg model has been successfully fitted for the correlation of water absorption of plasma treated six chickpea cultivars. Peleg model satisfactorily predicted water absorption behaviour of cold plasma-treated chickpeas for different cultivars. At the beginning of soaking, when chickpeas were immersed in water, the moisture content increased rapidly. The rate of water absorption slowed down and the moisture content reached the saturation point in the course of time. Peleg rate constant K1 decreased with increasing plasma power and exposure time for all chickpea varieties. Peleg moisture capacity constant K2 was not affected by plasma power and exposure time for all chickpea varieties. It indicates that plasma treatment could cause beneficial changes in chickpea seeds, such as surface etching, which is responsible for the constant decrease in K1 with increasing plasma power and exposure time for all chickpea varieties. Thus, the K1 was lowest at 60W 20 min treatment for all chickpea varieties and found highest in control samples.

Data availability

The authors declare that data supporting the findings of this study are available within the paper and its supplementary Information files. Source data are provided in this paper.

Abbreviations

- K1 :

-

Peleg rate constant, h % d.b.−1

- K2 :

-

Peleg capacity constant, % d.b.−1

- Mt :

-

Moisture content at time t, % d.b.

- M0 :

-

Initial moisture content, % d.b.

- Me :

-

Equilibrium moisture content, % d.b.

- Mexp :

-

Experimental moisture content, % d.b.

- Mpre :

-

Predicted moisture content, % d.b.

- R2 :

-

Co-efficient of determination.

- RMSE:

-

Root Mean Square Error

- W:

-

Plasma power, watt

- T:

-

Time, hours

- N:

-

Number of observations

- d.b.:

-

Dry Basis

References

Thushan, S. W. G., Wanasundara, J. P. D., Pietrasik, Z. & Shand, P. J. Characterization of chickpea (Cicer arietinum L.) flours and application in low-fat pork bologna as a model system. Food Res. Int. 43(2), 617–626 (2010).

Jukanti, A. K., Gaur, P. M., Gowda, C. L. L. & Chibbar, R. N. Nutritional quality and health benefits of chickpea (Cicer arietinum L.): A review. Br. J. Nutr. 108(S1), S11–S26 (2012).

Abd El-Hady, E. A. & Habiba, R. A. Effect of soaking and extrusion conditions on antinutrients and protein digestibility of legume seeds. LWT Food Sci. Technol. 36(3), 285–293 (2003).

Nergiz, C. & Gokgoz, E. Effects of traditional cooking methods on some antinutrients and in vitro protein digestibility of dry bean varieties (Phaseolus vulgaris T.) grown in Turkey. Int. J. Food Sci. Technol. 42, 868–873 (2007).

Iyayi, E. A., Kluth, H. & Rodehutscord, M. Effect of heat treatment on antinutrients and precaecal crude protein digestibility in broilers of four tropical crop seeds. Int. J. Food Sci. Technol. 43(4), 610–616 (2008).

Bello, M., Tolaba, M. P., Aguerre, R. J. & Suarez, C. Modeling water uptake in a cereal grain during soaking. J. Food Eng. 97(1), 95–100 (2010).

Shittu, T. A., Olaniyi, M. B., Oyekanmi, A. A. & Okeleye, K. A. Physical and water absorption characteristics of some improved rice varieties. Food Bioprocess Technol. 5(1), 298–309 (2012).

Kashiri, M., Garmakhany, A. D. & Dehghani, A. A. Modeling of sorghum soaking using artificial neural networks (MLP). Qual. Assurance Saf. Crops Foods 4(4), 179–184 (2012).

Montanuci, F. D., Jorge, L. M. D. M. & Jorge, R. M. M. Kinetic, thermodynamic properties and optimisation of barley hydration. Food Sci. Technol. (Campinas) 33(4), 690–698 (2013).

Turhan, M., Sayar, S. & Gunasekaran, S. Application of Peleg model to study water absorption in chickpea during soaking. J. Food Eng. 53(2), 153–159 (2002).

Ranjbari, A., Kashaninejad, M., Alami, M., Khomeiri, M. & Gharekhani, M. Effect of ultrasonic pre-treatment on water absorption characteristics of chickpeas (Cicer arietinum). Lat. Am. Appl. Res. 43(2), 153–159 (2013).

Peleg, M. An empirical model for description of moisture sorption curves. J. Food Sci. 41, 57–72 (1988).

Hung, T. V., Liu, K. H., Black, R. G. & Trewhella, M. A. Water absorption in chickpea (C. arietinum) and field pea (P. sativum) cultivars using the Peleg model. J. Food Sci. 58, 848–852 (1993).

Abu-Ghannam, N. & McKenna, B. The application of Peleg’s equation to model water absorption during the soaking of red kidney beans (Phaseolus vulgaris L.). J. Food Eng. 32, 391–401 (1997).

Singh, B. P. N. & Kulshrestha, S. P. Kinetics of water sorption by soybean and pigeon pea grains. J. Food Sci. 52, 1538–1541 (1987).

Sopade, P. A. & Obekpa, J. A. Modeling water absorption in soybean, cowpea and peanuts at three temperatures using Peleg’s equation. J. Food Sci. 55, 1084–1087 (1990).

Nussinovitch, A. & Peleg, M. An Empirical model for describing weight changes in swelling and shrinking gels. Food Hydrocolloids 4(1), 69–76 (1990).

Sopade, P. A., Ajisegiri, E. S. & Badau, M. H. The use of Peleg’s equation to model water absorption in some cereal grains during soaking. J. Food Eng. 15, 269–283 (1992).

Bakshi, A. S. & Singh, R. P. Kinetics of water diffusion and starch gelatinisation during rice parboiling. J. Food Sci. 45, 1387–1392 (1980).

Sopade, P. A. & Kaimur, K. Application of Peleg’s equation in desorption studies of food systems: A case study with sago (Metroxylon Sagu rottb.) starch. Drying Technol. 17, 975–989 (1999).

Palou, E., Lopez-Malo, A., Argaiz, A. & Welti, J. Use of Peleg’s equation to osmotic concentration of papaya. Drying Technol. 12, 965–978 (1994).

Maharaj, V. & Sankat, C. K. Rehydration characteristics and quality of dehydrated dasheen leaves. Can. Agric. Eng. 42, 81–85 (2000).

Jideani, V. A. & Mpotokwana, S. M. Modeling of water absorption of Botswana Bambara varieties using Peleg’s equation. J. Food Eng. 92(2), 182–188 (2009).

Crookes, W. On the Fourth State of Matter (Electric Spacecraft, 1879).

Tonks, L. & Langmuir, I. Oscillations in ionised gases. Phys. Rev. 33, 195 (1929).

Turtoi, M. & Nicolau, A. Intense light pulse treatment as alternative method for mould spores destruction on paper-polyethylene packaging material. J. Food Eng. 83(1), 47–53 (2007).

Muranyi, P., Wunderlich, J. & Heise, M. Sterilization efficiency of a cascaded dielectric barrier discharge. J. Appl. Microbiol. 103(5), 1535–1544 (2007).

Critzer, F., Kelly-Wintenberg, K., South, S. & Golden, D. Atmospheric plasma inactivation of foodborne pathogens on fresh produce surfaces. J. Food Prot. 70(10), 2290 (2007).

Setlow, P. Spores of Bacillus subtilis: their resistance to and killing by radiation, heat and chemicals. J. Appl. Microbiol. 101(3), 514–525 (2006).

Tong, J. Y. et al. Effects of atmospheric pressure air plasma pre-treatment on the seed germination and early growth of Andrographis paniculata. Plasma Sci. Technol. 16, 260–266 (2014).

Ekezie, F.-G., Jun, D. W. & Cheng, H. A review on recent advances in cold plasma technology for the food industry: Current applications and future trends. Trends Food Sci. Technol. 69, 46–58 (2017).

Bourke, P., Ziuzina, D., Boehm, D., Cullen, P. J. & Keeener, K. M. The potential of cold plasma for safe and sustainable food production. Trends Biotechnol. 36(6), 615–626 (2018).

Moisan, M. et al. Plasma sterilization. Methods mechanisms. Pure Appl. Chem. 74(3), 349–358 (2002).

Moreau, S. Using the flowing afterglow of plasma to inactivate Bacillus subtilis spores: Influence of the operating conditions. J. Appl. Phys. 88(2), 1166–1174 (2000).

Wang, Y. et al. Application of electrical discharge plasma on the inactivation of Zygosaccharomyces rouxii in apple juice. LWT Food Sci. Technol. 121, 108974 (2020).

Thirumdas, R., Sarangapani, C. & Annapure, U. S. Cold plasma: A novel non-thermal technology for food processing. Food Biophys. 10, 1–11 (2014).

Pathan, F. L., Deshmukh, R. R. & Annapure, U. S. Soaking plasma processed chickpea (Cicer arientinum) cultivars. Legume Sci. 3(2), e102 (2021).

Pathan, F. L., Deshmukh, R. R. & Annapure, U. S. Potential of cold plasma to control Callosobruchus chinensis (Chrysomelidae: Bruchinae) in chickpea cultivars during four-year storage. Sci. Rep. 11, 13425 (2021).

Klockow, P. A. & Keener, K. M. Safety and quality assessment of packaged spinach treated with a novel ozone-generation system. LWT Food Sci. Technol. 42(6), 1047–1053 (2009).

AOAC Official methods of analysis of AOAC International, 17th Edn., Revision I, Gaithersburg, M.D, USA (2002).

Shafaei, S. M., Masoumi, A. A. & Roshan, H. Analysis of water absorption of bean and chickpea during soaking using Peleg model. J. Saudi Soc. Agric. Sci. 15(2), 135–144 (2016).

Sadhu, S., Thirumdas, R., Deshmukh, R. R. & Annapure, U. S. Influence of cold plasma on the enzymatic activity in germinating mung beans (Vigna radiate). LWT Food Sci. Technol. 78, 97–104 (2017).

Sarangapani, C. et al. Physico-chemical properties of low-pressure plasma treated black gram. LWT Food Sci. Technol. 79, 102–110 (2017).

Bormashenko, E., Grynyov, R., Bormashenko, Y. & Drori, E. Cold radiofrequency plasma treatment modifies wettability and germination speed of plant seeds. Sci. Rep. 2, 741 (2012).

Shafaei, S.M., Masoumi, A.A. Using artificial neural network to predict moisture content of three varieties of chickpea in soaking (in Farsi). In: 21st National Congress of Food Science and Technology, October 29–31. Shiraz University, Shiraz, Iran, (2013a).

Shafaei, S.M., Masoumi, A.A. Heydari, A.R. Predicting of water absorption of bean soaking using artificial neural network (in Farsi). In: 21st National Congress of Food Science and Technology, October 29–31. Shiraz University, Shiraz, Iran, (2013b).

Botelho, F. M., Correa, P. C., Martins, M. A., Botelho, S. D. C. C. & Oliveira, G. H. H. D. Effects of the mechanical damage on the water absorption process by corn kernel. Food Sci. Technol. (Campinas) 33(2), 282–288 (2013).

Bormashenko, E. et al. Interaction of cold radiofrequency plasma with seeds of beans (Phaseolus Vulgaris). J. Exp. Bot. 66, 4013–4021 (2015).

Stolárik, T. et al. Effect of low-temperature plasma on the structure of seeds, growth and metabolism of endogenous phytohormones in pea (Pisum Sativum L.). Plasma Chem. Plasma Process. 35, 659–676 (2015).

Sayar, S., Turhan, M. & Gunasekaran, S. Analysis of chickpea soaking by simultaneous water transfer and water–starch reaction. J. Food Eng. 50, 91–98 (2001).

Sopade, P. A., Ajisegiri, E. S. & Okonmah, G. N. Modeling water absorption characteristics of some Nigerian varieties of cowpea during soaking. Trop. Sci. 34, 297–305 (1994).

Acknowledgements

We thank Pulses Research Center, MPKV, Rahuri for providing the authentic seeds of chickpea cultivars for this experiment.

Author information

Authors and Affiliations

Contributions

F.L.P. and U.S.A. conceived and designed the paper. F.L.P., U.S.A., A.M.T., and R.R.D. contributed different sections to the manuscript. U.S.A. revised it critically for important intellectual content.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pathan, F.L., Trimukhe, A.M., Deshmukh, R.R. et al. A peleg modeling of water absorption in cold plasma-treated Chickpea (Cicer arietinum L.) cultivars. Sci Rep 13, 7857 (2023). https://doi.org/10.1038/s41598-023-33802-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-33802-y

- Springer Nature Limited