Abstract

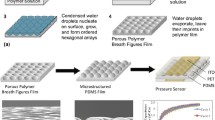

Microengineering the dielectric layers with three-dimensional microstructures has proven effective in enhancing the sensitivity of flexible pressure sensors. However, the widely employed geometrical designs of solid microstructures exhibit limited sensitivity over a wide range of pressures due to their inherent but undesired structural compressibility. Here, a Marangoni-driven deterministic formation approach is proposed for fabricating hollow microstructures, allowing for greater deformation while retarding structural stiffening during compression. Fluid convective deposition enables solute particles to reassemble in template microstructures, controlling the interior cavity with a void ratio exceeding 90%. The hollow micro-pyramid sensor exhibits a 10-fold sensitivity improvement across wider pressure ranges over the pressure sensor utilizing solid micro-pyramids, and an ultra-low detect limit of 0.21 Pa. With the advantages of facilitation, scalability, and large-area compatibility, such an approach for hollow microstructures can be expanded to other sensor types for superior performance and has considerable potential in robotic tactile and epidermal devices.

Similar content being viewed by others

Introduction

Three-dimensional (3D) microstructures have attracted much interest and shown key applications in biomedical monitoring1,2,3,4,5, human-machine interfaces\(w{t}_{{{{{{{\rm{MgCl}}}}}}}_{2}\cdot {{{{{{\rm{6H}}}}}}}_{2}{{{{{\rm{O}}}}}}}\)), indicating that the solution volume has a linear impact on the formation of hollow microstructures (Supplementary Fig. 4). The calculated thickness coefficients of polymer solutions are presented in Fig. 2b, and a linear expression can be used to estimate the corresponding relationship,

a Schematic illustration of geometric parameters of a single HMP, including base width B, film thickness t, cavity height h, total height H, full width at half maximum b. b Thickness factor of the polymer solution with varying do** ratios of MgCl2·6H2O. c Depiction of temperature gradient-induced Marangoni flow within the polymer solution under heating conditions. d Simulation result of flow velocity distribution of polymer solution with a heating temperature of 70 °C (at the bottom of PDMS mold). e Visualization of Marangoni flow in the solution with green fluorescent particles, where the surface position of the solution is about half of the height of the micro pyramid. Scale bar, 2 mm. f–h Cross-sectional SEM images of the HMPs formed under different conditions of f curing temperatures, g solution volumes, and h base widths, and extracted geometric profiles (white dashed lines) of the cavities fitted with Gaussian curves. i–l Geometric parameters of hollow micro-pyramids in terms of curing temperature, solution volume, and base width. i Hollow-to-total height ratio (h/H) versus curing temperature. Error bars show s.d., n = 3. j Contour plot of h/H versus solution volume (V) and base width (B). k Film thickness (t) versus solution volume and curing temperature, respectively. Error bars show s.d., n = 3. l Width ratio (b/B) versus base width.

At a weight ratio of 20%, the solution has a low thickness coefficient of ~1%.

Figure 2c demonstrates the elevated mold temperature and the corresponding temperature gradient-induced outward Marangoni flow at the air-liquid interface. A temperature gradient appears when the pyramidal mold is baked, resulting in an outward Marangoni flow. The numerical result is shown in Fig. 2d with a heating temperature of 70 °C and an ambient temperature of 20 °C. An apparent outward Marangoni flow can be observed near the liquid-air interface, facilitating the supply of solute particles to the deposition far from the center of the pyramidal pit. Furthermore, the fluid flow is visualized by the fluorescein-tracing method. When the solution evaporates to half the height of the pyramid, a dilute green fluorescent droplet is added to the polymer solution (Supplementary Fig. 5). A fast backflow can be observed in Fig. 2e that carries the fluorescent particles to the solid-liquid interface, which is advantageous for the enlargement of the cavity (Fig. 2f). As increasing the curing temperature, and the height ratio also increases linearly (Fig. 2i). At room temperature, the height ratio is 0.34 when B = 125 μm and V = 1 mL. When the temperature increases to 50 and 70 °C, the height ratio grows to 0.45 and 0.57, respectively.

The cross-sectional SEM images of hollow pyramid microstructures formed under different levels of solution volumes and base widths are shown in Fig. 2g, h, respectively. A greater base width provides increased space for solute particle deposition, while a smaller solution volume means fewer remaining solutes, which can produce a more expansive cavity (see more cross-sectional SEM results under different base widths of 39, 79, 125, 141 μm and solution volumes of 0.5, 1, and 1.5 mL in Supplementary Fig. 6). The statistical results of hollow-to-total height ratios in terms of solution volumes and base widths are shown in Fig. 2j. The maximum height ratio, appearing in the lower right corner, is equal to 0.6 for B = 141 μm and V = 0.5 mL. The height ratio is zero, indicating a solid pyramid microstructure, for B = 39 μm and V = 1.5 mL. Notably, the height ratio (h/H) shows a significant linear increase with the base width of the micro pyramid (h/H ∝ B) and a decrease with the solution volume (h/H ∝ -V), as shown in Supplementary Fig. 7.

Consequently, the temperature-induced growth coefficient (i.e., the slope of height ratio-curing temperature curve) of 0.11 per 20 °C is approximate to the volume-induced growth coefficient of 0.1 per 0.5 mL. Both of these factors can enable the height ratio to expand to ~0.6, indicating their equal importance in the formation of hollow microstructures. Nevertheless, producing a hollow microstructure with a high height ratio by minimizing the solution volume will yield an ultrathin film thickness. For instance, when the solution volume decreases from 1 to 0.5 mL, resulting in a height ratio increase of 0.1, the film thickness declines from 8 μm to a mere 4 μm (Fig. 2k). The consequent small thickness will pose a new challenge in peeling such an ultrathin film from a template. The temperature gradient-induced flow compensates for the shortage of changing the solution volume to produce a hollow microstructured dielectric film with a larger height ratio and film thickness, as shown in Fig. 2e. When the heat temperature increases to 50 °C, causing the same improvement in height ratio, the film thickness t increases to 13 μm, which is more conducive to successful demolding.

To further investigate the morphology of hollow pyramids, geometric profiles of the cavities formed under different levels of solution volumes, curing temperatures, and base widths are extracted from the SEM images and then fitted with Gaussian curves, as presented in Fig. 2f–h, respectively (see more curve-fitting results in Supplementary Fig. 8). The curve equation can be given as

where u is equal to 0 for the symmetrical structure, v is related to the full width at the half of the peak (b), and is described by \(v=b/(2\sqrt{2\,{{{{\mathrm{ln}}}}}\,2})\). The cavity height can be expressed by the formula h = α(Btanθ/2 + t), derived from the geometric relationship of pyramids. The template micro-pyramid pits are firstly created by etching (100) silicon wafers using potassium hydroxide (KOH), producing a fixed side angle (θ) of 54.7° for the pyramid53. The root mean square errors (RMSEs) are calculated and plotted in Supplementary Fig. 9, where the maximum RMSE is below 2 μm. The experimental results are in good agreement with theoretical predictions [by Eq. (1)]. Another parameter v of the Gaussian curve is also studied in Fig. 2l. Interestingly, the result indicates that b/B is identically 0.5 under all experimental conditions. Therefore, the geometric profiles of the HMP structures can be rewritten by

where the two parameters α, t can be determined by the linear relationships with B and V according to the above results (Fig. 2i–k).

Compressive behavior of the HMP

The compressive deformation of the micro-pyramid structure with different height ratios has been investigated to elucidate the mechanism of the hollow microstructures on high sensitivity over a wide range by finite element analysis (FEA). Figure 3a illustrates the result of the HMP, which serves as the structural dielectric layer of a CPS, being compressed by a plate. The deformation process can be categorized into three stages, as depicted in Fig. 3b. Under slight pressure, local stress concentrates at the contact point between the micro-pyramid and the top film, producing large deformation of the tip of the structure. As the increment of applied pressure, the cavity within the hollow microstructure experiences the majority of compressive deformation until it is eliminated under the exerted pressure (about 40 kPa). Subsequently, the structure primarily undergoes deformation via self-mutual extrusion, which resembles the behavior observed in solid microstructures. For the solid micro-pyramid (h/H = 0), stress consistently concentrates around the pyramidal tip under external pressure and is significantly larger than that of the HMP, which demonstrates higher resistance to external pressure (see more comparisons in Supplementary Fig. 10).

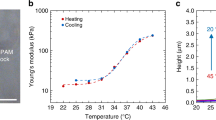

a Illustration of the HMP being compressed by a plate. b FEA results of compressive deformation of the micro-pyramid structures. c Comparison of compressive strains derived from the solid portion (εsolid) and hollow portion (εhollow) of solid and hollow pyramids. d Applied pressure changing with the total compressive strain under different height ratios. e Scaling law of the equivalent compressive stiffness as a function of the combined parameter Em(0.5tanθ + t/B)(1 + h/H)ln(h/H). f Optical images of the modified films with different weight ratios of MgCl2·6H2O to PVA from 0 to 100%, which are hung with a 20 g weight. g Young’s modulus of the modified films versus the weight ratios of MgCl2·6H2O. Error bars show s.d., n = 3. h Comparison of Young’s modulus of PVA/MgCl2 films with those of common elastomers.

To further explore the deformation of the HMP, the compressive strains derived from the solid portion (εsolid) and hollow portion (εhollow) are plotted in Fig. 3c, which elaborates on the three stages mentioned above. The compressive strain within the solid portion of the HMP (the blue line) quickly escalates under small pressures below 0.6 kPa, exhibiting a variation that is almost consistent with that of the solid structure (the red line). This can be attributed to the low compressive stiffness (k) at the pyramid’s apex, which accounts for the high sensitivity in prior research30,53. However, with the pressure increasing, the growth of εsolid has substantially decelerated, signifying a significant descent in sensitivity. For HMPs, the compressive strain within the hollow portion (the blue dashed line) experiences a consistent and swift increase before the cavity is eliminated in stage 3, which can effectively compensate for that deficiency. Figure 3d displays the variations between the applied pressure and the total compression strain among the pyramid dielectric films with different height ratios. For the solid micro-pyramid, the pressure increases rapidly with the total compression strain, indicating a higher equivalent compressive stiffness, especially under large strains. Upon introducing an interior cavity into the micro-pyramid, the pressure is significantly reduced at the same compression strain. This indicates that as the pressure increases, the structural compressive stiffness rises more gradually, highlighting the potential of the proposed HMPs for use in CPSs to achieve high sensitivity over a wide range. Moreover, the relationships between the equivalent compressive stiffness k and four key parameters of the micro-pyramid, including dimension parameters h/H, B, t, and Young’s modulus E, are investigated in Supplementary Fig. 11. It is noted that the top width is much less than the base width according to the SEM image in Supplementary Fig. 12, illustrating that the actual shape of the micro-pyramid structure is typically represented as a frustum. A scaling law of the equivalent compressive stiffness can be derived as k ∝ Em(0.5tanθ + t/B)(1 + h/H)ln(h/H) (see details in Fig. 3e and Supplementary Note 1), where m denotes the top width of the pyramid structure. Distinctly, these two parameters of h/H and E contribute greatly to improving structural compressibility.

The Young’s modulus of the dielectric film can be tailored by adjusting the weight ratio of MgCl2·6H2O to PVA, ascribing to the disruption of hydrogen bonds and the decrease in intermolecular interactions between PVA chains (Supplementary Fig. 13)54,55. The results are presented in Fig. 3f, g. The pure PVA film exhibits poor softness with a much higher Young’s modulus of 839 MPa (Supplementary Fig. 14), approximately 420 times higher than that of PDMS elastomer, which is widely used in flexible pressure sensors. Magnesium chloride has been demonstrated to possess a high plasticizing efficiency for PVA and can disperse within PVA at a molecular level, with excellent compatibility55. Upon do** the inorganic salt MgCl2·6H2O into PVA with weight ratios ranging from 20 to 100%, the modulus significantly decreases, spanning from 2.6 to 0.12 MPa, which are comparable to those of the PDMS and Ecoflex elastomers, respectively. As the do** ratio of MgCl2 increases, the polymer film becomes softer, but elastic recovery also begins to deteriorate (Supplementary Fig. 15). At a do** ratio of 20%, the modified PVA film demonstrates favorable rubber-like mechanical properties and an impressive elastic recovery rate of 99% under a tensile strain of 50%, which is selected to serve as the dielectric layer and fabricate the capacitive pressure sensor. With a further increase to 40% do** ratio, Young’s modulus declines to 0.92 MPa, while maintaining a good elastic recovery ratio of 96%. Consequently, the proposed hollow microstructured dielectric film exhibits great potential as a viable alternative to commonly used elastomeric competitors (Fig. 3h) in develo** high-performance CPSs56,57. In summary, through material and structure engineering, the hollow microstructured film becomes softer for higher sensing sensitivities and enables retarded structural stiffening during compression, which is favorable for an extensive pressure range.

Performance evaluation of the HMP-enhanced CPS

A square pressure sensor with a dimension of 1 cm × 1 cm is prepared to evaluate the sensing performance, as depicted in Fig. 4. To improve the homogeneity of compression load, a thin glass plate (1 cm × 1 cm, 27.5 mg) is placed on the capacitor surface. The sensitivity of a CPS is defined as S = δ(ΔC/C0)/δP, where C0 is the initial capacitance and ΔC is the capacitance change under the applied pressure (P), and is closely related to the compressive deformation of the intermediate dielectric layer. Compared to solid microstructured dielectric layers, hollow microstructured dielectric layers produce a greater compressive displacement (i.e., larger gap changes between capacitor electrodes) under the same pressure, yielding a larger relative capacitance change (ΔC/C0) for high sensitivity. The relative capacitance changes of the HMP-enhanced CPS, prepared with different hollow-to-total height ratios of 0.11, 0.2, and 0.31 are shown in Fig. 4a, where the base width of the pyramid is 79 μm. With a height ratio of 0.31, the pressure sensor reaches a remarkable sensitivity of 3.45 kPa−1 within the pressure range of 0−0.6 kPa. The sensitivity drops slightly with increasing pressure, yet remains at high levels of 1.11 kPa−1 (0.6−2 kPa), 0.33 kPa−1 (2−10 kPa), and 0.13 kPa−1 (10−40 kPa) (the curves of absolute capacitance versus pressure plotted in Supplementary Fig. 16). The results demonstrate that a larger hollow height ratio, corresponding to a more significant interior cavity within the micro-pyramid, leads to higher sensing sensitivity. Such a general mechanical design by introducing an interior cavity is also expected to be effective in enhancing structural compressibility for various shapes of 3D microstructures. For instance, the sensing performances of the CPSs employing pyramid and dome structures with varying height ratios are compared, and a larger height ratio typically leads to an increased sensitivity (Supplementary Fig. 17). While maintaining the same structural parameters (including base width B, spacing d, and overall height H) and material parameter (Young’s modulus E), the sensitivity of the HMP-enhanced CPS can be raised more than ten times compared to the solid microstructure-based CPS, which have been exemplified by the pyramid and dome. This improvement is also verified by the sensitivity comparison with prior publications based on micro-pyramid structure53,58,59,60,61, as shown in Supplementary Table 1. Moreover, owing to the higher height-to-width aspect ratio of the pyramid (0.7) compared to the dome (0.5), the hollow pyramid-based sensor exhibits a distinct advantage in high sensitivity.

a Pressure response of relative capacitance change of the CPS with different height ratios. b Detection of tiny pressures. c Comparison of the HMP-based CPS with previously reported microstructure-based CPSs in three key performance parameters: Sensitivity (preferred to be higher), limit of detection (preferred to be lower), and aspect ratio. d, e Response and recovery times under a range of applied pressures, from low (28 Pa) to high (37 kPa). f Dynamic pressure tests with different magnitudes of 0.22, 0.4, 0.7, 1.7, 3.3, and 12 kPa. g Reliability testing of a sample by cyclic loading with the amplitude of 1.2 kPa for 10,000 cycles. The insets present the capacitance changes at the first and last ten cycles. h Detection of three successive waterdrops and monitoring of human respiration status. i Sensing the tiny deflations of a balloon under a large preload of ~12 kPa when the sensor is attached to the index finger.

Additionally, the sensing performances of the HMP-enhanced CPS, relative to different material and geometric parameters, have been elaborated in detail (Supplementary Note 2). Young’s modulus of the structured dielectric film, as another critical feature that affects the compressibility of the pressure sensor, has also been investigated to improve the sensing performance. The undoped PVA film with high elastic modulus exhibits large compressive stiffness, even engineered with HMP surfaces, and yields a low-pressure sensitivity comparable to that of the pressure sensor using a PDMS dielectric film with solid micro-pyramid surfaces. Upon do** MgCl2 into PVA, the modulus notably decreases to 2.6 MPa, resulting in a substantial enhancement in sensitivity (Supplementary Fig. 18). A sparser distribution by spreading out the microstructures to increase the air-to-elastomer ratio, due to the ineffectiveness of air in resisting deformation, is favorable for higher sensitivity, which represents a simple and universal strategy applicable to all microstructure-based CPSs (Supplementary Figs. 19a–c, 20a). A smaller pyramid will be more favorable to obtain a higher sensitivity, which has been verified in other works (Supplementary Table 1). However, the interior cavity within a smaller micro-pyramid can be easily collapsed under pressure, limiting the high sensitivity to a small pressure range (Supplementary Fig. 20b). Figure 4b shows that the HMP-enhanced CPS can reliably detect the placement or removal of a tiny pinch of cotton (about 2.1 mg). A distinguishable stepwise increase in capacitance can be observed, corresponding to an average pressure of 0.21 Pa. After removing the cotton, the capacitance immediately returns to its initial value, and this variation recurs with subsequent loads. The tiny pressure change is also recognized when the pressure experiences a slight increase to 0.38 Pa. The detection limit of the developed sensor is in accordance with its sensitivity, which can be further optimized as discussed in Supplementary Note 2. Furthermore, the step loading-unloading pressure test is performed to describe the sensor behavior under static loads from 33 to 121 Pa (Supplementary Fig. 21a). The developed sensor based on a hollow micro-pyramid exhibits good stability under different levels of external loads, where the capacitance signals remain almost horizontal during each step pressure and change without hysteresis. Compared to reported structural designs of dielectric layers that aim to improve aspect ratios through develo** advanced, complicated techniques, including various pillar or needle microstructures, hollow microstructures denote another facile and effective direction for achieving high sensitivity. Although the pyramidal structure has a low aspect ratio of 0.7, the HMP-enhanced CPS demonstrates significant advantages in terms of sensitivity and limit of detection22,33,35,43,44,45,58,62, as shown in Fig. 4c. Moreover, due to the merits of hollow microstructures, such as exceptional compressibility and superior resistance to structural stiffening, this mechanical design is promising for using in other types of pressure sensors (e.g., piezoresistive, iontronic, and triboelectric sensing mechanisms) for high performance.

In addition, the response performance of the HMP-enhanced CPS to dynamic loads has been investigated as well. The response and recovery times under various loads, ranging from 28 Pa to 37 kPa, are determined (Fig. 4d and Supplementary Fig. 21b). The device is subjected to external pressure, which is then rapidly released after being sustained for a period. As the pressure increases, the response and recovery times become longer, which can be explained by the greater compression displacements. In Fig. 4e, the shortest response and recovery times are both 16.8 ms at P = 28 Pa, and the longest response and recovery times are 28 ms and 39.2 ms at P = 37 kPa, respectively. The fast response speed of developed CPS allows it to detect dynamic stimuli, such as robotic tactile sensing4h, this sensor without preload could differentiate the static pressures induced by three waterdrops applied one after another, corresponding to approximately 24.2 mg for a drop of water. When the developed sensor is integrated with the inner surface of a mask, it can be used for monitoring the respiratory status of the human to release early-warning signals, e.g., slow and rapid respiration of ~12 times per minute (blue curves) and 32 times per minute (red curves) in the right of Fig. 4h, respectively. Additionally, the HMP-enhanced pressure sensor can also be attached to the index finger for tactile sensing with approximately 12 kPa preload (e.g., gras** the balloon). The initial shape of the balloon is marked with red dotted lines in the inset of Fig. 4i. Then, three consecutive tiny deflations of the balloon produce three consecutive stepwise decreases in pressure, which is hard to feel by hand, but can be detected by the developed sensor. The zoom-in insets illustrate the subtle shape changes of the balloon under three tiny deflations, which are marked with green, purple, and yellow dotted lines, respectively. These experiments demonstrate that the HMP-enhanced pressure sensor has a high sensitivity and robustness over a wide pressure range.

Demonstration of the HMP-enhanced CPS

Encouraged by the impressive performances of HMP-enhanced CPS, the application of developed sensors in the field of robotic tactile is explored, which always involves detecting small pressures under large pre-contact pressure. To demonstrate this concept, the autonomous pulse-diagnosis robotic system (APDRS) is developed that enables a robot to detect pulse signals like a doctor. The system comprises three components: tactile sensing based on the HMP-enhanced CPS, vision-assisted location of pulse-diagnosis point, and a robot arm outfitted with a bionic hand at the end, as depicted in Fig. 5a. The HMP-enhanced CPS is attached to the index fingertip of the bionic robot hand to mimic the human hand feeling pulse beats. The self-developed circuits acquire the sensor signals with a sampling rate of 200 Hz, which is high enough for pulse detection. The capacitance values are firstly converted into stable digital signals by a capacitance-to-digital converter (CDC) chip. The digital signals are then transmitted to the FPGA (Field-programmable gate array) main control board and ultimately sent to the host computer (data collected by the commercial package NI Labview 2017) via Ethernet communication. By employing a monocular camera mounted on the robotic hand, the location information of the pulse-diagnosis point (S) can be accurately predicted, utilizing a combination of the coordinate transformation of monocular imaging and an image processing technique (see details in Supplementary Fig. 23 and Note 3).

a Schematic illustration of the APDRS construction, including the HMP-enhanced CPS-enabled tactile sensing, self-developed capacitance acquisition circuits, vision-aided localization algorithm for determining the pulse-diagnosis point, and a robot arm outfitted with a dexterous hand at the end. Advanced RISC Machine (ARM) is a family of reduced instruction set computing (RISC) architectures designed for computer processors, Double data rate type 3 (DDR3) is a type of synchronous dynamic random access memory used for system memory, and user datagram protocol (UDP) is transport layer protocol. The workflow is illustrated by b–j eye-in-hand captures and c–k eye-to-hand captures. b, c In the first step, the pulse-diagnosis point is recognized using the machine vision technique and denoted with a magenta dot. d, e When the human hand remains stationary for a while and the circular progress bar turns green, the robot arm moves horizontally to allow the sensor (marked by a red rectangle) on the index fingertip of the dexterous hand to overlap with the pulse point and (f, g) then approaches downward. h, i The index finger of the robot hand bends to touch the human hand for pulse detection. j, k Upon completion, the robot arm returns to the initial position for the next patient. l, m Evolution of l the HMP-enhanced CPS signals and m the wrist/artery pulse/pinky metacarpal points throughout the detection process.

Figure 5b–k demonstrate the workflow of the APDRS, while Fig. 5l, m present the evolution of the electrical signals and vision data during the detection process, respectively. When a human hand appears in the capture, the position of the pulse-diagnosis point is quickly determined and marked with a magenta dot in Fig. 5b. To verify the system’s robustness, we wave the hand casually in the captures, the system can still track the pulse-diagnosis point instantly and precisely with a stable frame rate of 20, while the real-time position signals also display a similar waveform in Fig. 5m. If there are no hands in the captures, a corresponding gap of position signal will appear. If the human hand moves onto the pillow and remains stationary for a preset time (Γ = 5 s, corresponding to the condition of ||Sτ − Sτ−1 | | <δ while τ ≤ Γ, where δ is a distance threshold), the position signal will remain unchanged, indicating that the patient is ready for pulse detection. Following the linear coordinate transformation (LCT, bMc), the robot arm moves to the target position and approaches the human arm (Fig. 5f, g). Afterward, the robot index finger equipped with the HMP-enhanced CPS bends to contact with the human arm (Fig. 5h, i). Upon contacting the pulse-diagnosis point, the capacitance signals immediately rise and the typical pulse waveforms (e.g., percussion, tidal, and diastolic peaks) appear, as shown in Fig. 5l. Because the fingers of the robot are relatively hard and there is a noticeable amount of contact pressure, it will result in slight discomfort and wobble of volunteer’s wrist during the pulse detection, leading to the baseline slight fluctuations of the capacitive signal. This will take time for a volunteer to adapt to the press from a robotic hand. It is obversed that the baseline of the signal becomes stable as the longer measurement time. The pulse signals can be consistently reproduced with an average frequency of ≈82 beats per minute, in accordance with the normal adult values. Based on these three peaks, the radial augmentation index (AIr = P2/P1), diastolic augmentation index (DAIr = P3/P1), and digital volume pulse time (ΔTDVP = tP2 − tP1) under relaxed conditions are calculated to be 0.578, 0.222, and 0.402, respectively, which can be used to diagnose arterial stiffness21,65. Finally, after the robot finger releases and returns to the initial position (Fig. 5j, k), the capacitance value of the developed CPS quickly returns to the initial level as well. While the pressure sensor experiences a large pre-contact pressure (about 4 kPa), the small pulse pressure changes can still be recognized clearly and continuously throughout the detection process, which lasts for about one minute. This is attributed to enough sensitivity and excellent stability of HMP-enhanced CPS over a large dynamic range, promising in robotic tactile.

Additionally, for localized pressure detection, a 3 × 3 sensing array with HMP-enhanced capacitive sensors has been constructed (Supplementary Fig. 24). The response of the sensing array is precisely reflected in corresponding pressure map** under a cylinder for single input and an H-shaped acrylic plate for multiple inputs, demonstrating a little influence between the sensor units within the array. For a micro-pressure array, a spacer structure can be inserted between the top and bottom electrode layers of the sensing array to create a strain local confinement effect and effectively eliminate the spatial crosstalk between sensing units under external pressure14, Firstly, 100 g of deionized water is mixed with 2 g of polyvinyl alcohol (PVA 1788 from Usolf Corporation), which is stirred at 95 °C for 2 h until PVA completely dissolves. Then, MgCl2·6H2O (Sinopharm Chemical Reagent Co., Ltd) is added into the PVA solution and stirred at 60 °C for 2 h to obtain the PVA/MgCl2 solution. Different weight ratios of MgCl2·6H2O to PVA of 0, 20, 40, 60, 80, and 100% are produced for comparisons. Finally, a weight ratio of 20% is employed to fabricate the HMP-enhanced CPS. The pure PVA solution is prepared by dissolving 2 g of polyvinyl alcohol into 25 g of deionized water and stirring at 95 °C for 2 h. Then, the PVA film is obtained by pouring the PVA solution onto a 75 mm × 25 mm glass slide and curing at room temperature for 24 h. A self-adhesive paper is patterned by a cutting machine (GRAPHTEC Corporation, Cutting Plotter CE6000-40, Japan) and attached to the PVA film as a shadow mask. The AgNWs solution dissolving in isopropyl alcohol is sprayed on the PVA film and dried at 50 °C for 0.5 h to produce the electrode with a size of 10 mm × 10 mm. Specifically, for the bottom electrode layer, the prepared PDMS (Sylgard 184, Dow Corning) with a weight ratio of base-to-crosslinker of 10:1 is spread on the PVA film, followed by spin coating at 3000 rpm for 40 s, and cured at 70 °C for 8 h, which is acted as a thin insulating layer (<10 μm). This PDMS insulating layer prevents ionic conduction between the AgNWs electrode and PVA/MgCl2 film and enhances the sensor reproducibility61. Differently, for the top electrode layer, the spin-coating speed is 300 rpm to obtain a thick PDMS layer (~230 μm) that serves as an encapsulation layer of the sensor, providing environmental isolation and physical protection. The fabrication process is shown in Supplementary Fig. 25. As a result of the strong adhesion between the silicon mold and the polymer film, the polymer film experiences elongation and fractures instead of interfacial peeling during the peel-off test, with a maximum force of up to 1.2 N (Supplementary Fig. 26). Conversely, the maximum force for successful peeling from the PDMS mold is about 0.3 N. Therefore, two-step replication processes are performed to obtain the PDMS mold with inverted micro-pyramid structures. Firstly, the PDMS mixture is poured onto the silicon mold with etched pyramid micropatterns to obtain an inverse structured template. After fluorination treatment to weaken adhesion, the molded pattern is replicated again to produce the second PDMS mold. In order to prevent the deformation of the molding template in use, hard PDMS (with a base-to-crosslinker ratio of 5:1) is employed in the second molding process, which has a larger Young’s modulus than standard PDMS (with a base-to-crosslinker ratio of 10:1)66. The cross-sectional SEM images of the first and second PDMS molding templates are shown in Supplementary Fig. 27a, b, respectively. Four silicon molds with different base widths of 39, 79, 125, and 141 μm are tried in this work. The pyramid array is replicated precisely without changes in dimensions and side angles (54.7°) (Supplementary Fig. 27c, d). Next, the prepared PVA/MgCl2 solution is poured onto the second PDMS mold to form the HMP film. Finally, the bottom and top electrode layers, consisting of bottom-up stacked PDMS, AgNWs, and PVA layers, are laminated with the HMP film to obtain the pressure sensor. Three independent polymer films are prepared by spreading the PVA/MgCl2 solution on a glass sheet and curing it at room temperature for 24 h. The polymer films are cut into the size of 70 mm × 15 mm. The thickness of films is determined by averaging measuring results of three different parts of the sample using laser scanning confocal microscopy (LSCM, KEYENCE, VK-X200K). The samples are tested by the tensile tester (INSTRON 5944) to obtain Young’s modulus of the polymer films. In addition, the capacitance of the self-developed sensor is acquired by the LCR meter (E4980A, KEYSIGHT) at a testing frequency of 1 kHz. The applied pressures are recorded by using a force gauge (DS2-5N, Zhiqu Precision Instruments Co., Ltd) with a resolution of 1 mN, as shown in Supplementary Fig. 28. Finite element models of micro-pyramid structures are constructed by using commercial software ABAQUS 6.14-1. The compressive deformation of PVA/MgCl2 microstructured film is simulated with the Mooney-Rivlin hyperelastic model, where the material parameters are determined by the standard uniaxial tensile test (see details in Supplementary Fig. 29 and Table 2). Eight-node solid elements (C3D8H), and analytic rigid are used to model the micro-pyramid structures and indenter, respectively. The adoption of refined meshes ensures the precision of numerical simulations. To avoid mesh distortion heavily, the top of the pyramid is treated with a very small width (1 μm). The interface bond strength between the microstructured film and the PDMS/Si molds is measured by the self-developed platform (Supplementary Fig. 26). The mold is fixed on the baseplate with a tilt angle of 45°. The microstructured film formed on the mold is connected to a force gauge via a thick Kapton adhesive tape (~200 μm). The peeling speed in the vertical direction is set to 0.1 mm/s. The experiment of detecting arterial pulse is conducted with the approval of the Ethics Committee of Tongji Medical College, Huazhong University of Science and Technology. This Ethics Committee is constituted and functioned in accordance with ICH-GCP, GCP in China, and the Declaration of Helsinki (2013). Informed consent is obtained from the participants before conducting the experiments. The 41 images of human hands with different gestures and/or arm sizes, which are used to train the vision-aided location prediction model in Supplementary Fig. 23, are collected from the volunteers (aged 20–50 years) of our study group. The images, without any labels, are randomly allocated into the training and testing groups. The arterial pulse data (in Fig. 5) are captured from a healthy male, aged 25–30 years. There is no specific preparation for the human subject. These experimental results are not specific to any particular sex or gender without incorporating sex and gender into the study design. The SEM images of the hollow micro-pyramid structures are collected from more than three independent samples. Arterial pulse detections are conducted more than three times and all testing results show high similarity. Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.Methods

Preparation of the PVA/MgCl2 solution

Preparation of PDMS/AgNWs/PVA electrode layer

Fabrication of the HMP-enhanced pressure sensor

Measurements of mechanical and electrical properties

Compressive simulation by finite element analysis

Peel tests

Arterial pulse detection

Statistics and reproducibility

Reporting summary

Data availability

The data that support the findings of this study are available within this article and its Supplementary Information, and from the corresponding authors upon request.

References

Boutry, C. M. et al. Biodegradable and flexible arterial-pulse sensor for the wireless monitoring of blood flow. Nat. Biomed. Eng. 3, 47–57 (2019).

Meng, K. et al. Wearable pressure sensors for pulse wave monitoring. Adv. Mater. 34, 2109357 (2022).

Yang, R. et al. Iontronic pressure sensor with high sensitivity over ultra-broad linear range enabled by laser-induced gradient micro-pyramids. Nat. Commun. 14, 2907 (2023).

Zhang, F. et al. Rapidly deployable and morphable 3D mesostructures with applications in multimodal biomedical devices. Proc. Natl Acad. Sci. USA 118, e2026414118 (2021).

Yan, D. et al. Soft three-dimensional network materials with rational bio-mimetic designs. Nat. Commun. 11, 1180 (2020).

**ong, Y. et al. A flexible, ultra-highly sensitive and stable capacitive pressure sensor with convex microarrays for motion and health monitoring. Nano Energy 70, 104436 (2020).

Lim, S. et al. Transparent and stretchable interactive human machine interface based on patterned graphene heterostructures. Adv. Funct. Mater. 25, 375–383 (2015).

He, F. et al. Recent progress in flexible microstructural pressure sensors toward human–machine interaction and healthcare applications. Small Methods 5, 2001041 (2021).

Pyo, S., Lee, J., Bae, K., Sim, S. & Kim, J. Recent progress in flexible tactile sensors for human-interactive systems: from sensors to advanced applications. Adv. Mater. 33, 2005902 (2021).

**ong, W. et al. Multifunctional tactile feedbacks towards compliant robot manipulations via 3D-shaped electronic skin. IEEE Sens. J. 22, 9046–9056 (2022).

Osborn, L. E. et al. Prosthesis with neuromorphic multilayered e-dermis perceives touch and pain. Sci. Robot. 3, eaat3818 (2018).

Yang, J. C. et al. Electronic skin: recent progress and future prospects for skin-attachable devices for health monitoring, robotics, and prosthetics. Adv. Mater. 31, 1904765 (2019).

Heng, W., Solomon, S. & Gao, W. Flexible electronics and devices as human–machine interfaces for medical robotics. Adv. Mater. 34, 2107902 (2022).

Zhang, Y. et al. Localizing strain via micro-cage structure for stretchable pressure sensor arrays with ultralow spatial crosstalk. Nat. Commun. 14, 1252 (2023).

Kim, B. H. et al. Three-dimensional electronic microfliers inspired by wind-dispersed seeds. Nature 597, 503–510 (2021).

Yang, R. et al. Multimodal sensors with decoupled sensing mechanisms. Adv. Sci. 9, 2202470 (2022).

Cheng, X. et al. Programming 3D curved mesosurfaces using microlattice designs. Science 379, 1225–1232 (2023).

Lu, L., Leanza, S. & Zhao, R. R. Origami with rotational symmetry: a review on their mechanics and design. Appl. Mech. Rev. 75, 050801 (2023).

Yang, S. & Sharma, P. A tutorial on the stability and bifurcation analysis of the electromechanical behaviour of soft materials. Appl. Mech. Rev. 75, 044801 (2023).

Zhang, Y. et al. A mechanically driven form of Kirigami as a route to 3D mesostructures in micro/nanomembranes. Proc. Natl Acad. Sci. USA 112, 11757–11764 (2015).

Jun et al. Microstructured porous pyramid-based ultra-high sensitive pressure sensor insensitive to strain and temperature. ACS Appl. Mater. Interfaces 11, 19472–19480 (2019).

Wan, Y. et al. A highly sensitive flexible capacitive tactile sensor with sparse and high-aspect-ratio microstructures. Adv. Electron. Mater. 4, 1700586 (2018).

Mishra, R. B., El-Atab, N., Hussain, A. M. & Hussain, M. M. Recent progress on flexible capacitive pressure sensors: from design and materials to applications. Adv. Mater. Technol. 6, 2001023 (2021).

**ong, W. et al. Bio-inspired, intelligent flexible sensing skin for multifunctional flying perception. Nano Energy 90, 106550 (2021).

**ong, W., Guo, D., Yang, Z., Zhu, C. & Huang, Y. Conformable, programmable and step-linear sensor array for large-range wind pressure measurement on curved surface. Sci. China Tech. Sci. 63, 2073–2081 (2020).

Boutry, C. M. et al. A hierarchically patterned, bioinspired e-skin able to detect the direction of applied pressure for robotics. Sci. Robot. 3, eaau6914 (2018).

Lin, Q. et al. Highly sensitive flexible iontronic pressure sensor for fingertip pulse monitoring. Adv. Healthc. Mater. 9, 2001023 (2020).

Ha, K. H. et al. Highly sensitive capacitive pressure sensors over a wide pressure range enabled by the hybrid responses of a highly porous nanocomposite. Adv. Mater. 33, 2103320 (2021).

Mannsfeld, S. C. et al. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 9, 859–864 (2010).

Ruth, S. R. A., Feig, V. R., Tran, H. & Bao, Z. Microengineering pressure sensor active layers for improved performance. Adv. Funct. Mater. 30, 2003491 (2020).

Su, Q. et al. A stretchable and strain-unperturbed pressure sensor for motion interference–free tactile monitoring on skins. Sci. Adv. 7, eabi4563 (2021).

Zhang, Y. et al. Highly stable flexible pressure sensors with a quasi-homogeneous composition and interlinked interfaces. Nat. Commun. 13, 1317 (2022).

Luo, Y. et al. Flexible capacitive pressure sensor enhanced by tilted micropillar arrays. ACS Appl. Mater. Interfaces 11, 17796–17803 (2019).

Li, T. et al. Flexible capacitive tactile sensor based on micropatterned dielectric layer. Small 12, 5042–5048 (2016).

Zhuo, B., Chen, S., Zhao, M. & Guo, X. High sensitivity flexible capacitive pressure sensor using polydimethylsiloxane elastomer dielectric layer micro-structured by 3-D printed mold. IEEE J. Electron Devices Soc. 5, 219–223 (2017).

Wan, Y. et al. Natural plant materials as dielectric layer for highly sensitive flexible electronic skin. Small 14, 1801657 (2018).

Yuan, Y. M. et al. Microstructured polyelectrolyte elastomer‐based ionotronic sensors with high sensitivities and excellent stability for artificial skins. Adv. Mater. 36, 2310429 (2024).

Tian, H. et al. Core–shell dry adhesives for rough surfaces via electrically responsive self-growing strategy. Nat. Commun. 13, 7659 (2022).

Ha, K.-H., Huh, H., Li, Z. & Lu, N. Soft capacitive pressure sensors: trends, challenges, and perspectives. ACS Nano 16, 3442–3448 (2022).

Qiu, Y. et al. Bioinspired, multifunctional dual-mode pressure sensors as electronic skin for decoding complex loading processes and human motions. Nano Energy 78, 105337 (2020).

Bai, N. et al. Graded intrafillable architecture-based iontronic pressure sensor with ultra-broad-range high sensitivity. Nat. Commun. 11, 1–9 (2020).

Chen, Z. et al. Laser-sculptured hierarchical spinous structures for ultra-high-sensitivity iontronic sensors with a broad operation range. ACS Appl. Mater. Interfaces 14, 19672–19682 (2022).

Palaniappan, V., Masihi, S., Panahi, M., Maddipatla, D. & Atashbar, M. Z. Laser-assisted fabrication of a highly sensitive and flexible micro pyramid-structured pressure sensor for E-skin applications. IEEE Sens. J. 20, 7605–7613 (2020).

Asghar, W., Li, F., Zhou, Y., Wu, Y. & Li, R. Piezocapacitive flexible E-skin pressure sensors having magnetically grown microstructures. Adv. Mater. Technol. 5, 1900934 (2020).

Zhou, Q. et al. A bio-inspired cilia array as the dielectric layer for flexible capacitive pressure sensors with high sensitivity and a broad detection range. J. Mater. Chem. A 7, 27334–27346 (2019).

Ruth, S. R. A. et al. Rational design of capacitive pressure sensors based on pyramidal microstructures for specialized monitoring of biosignals. Adv. Funct. Mater. 30, 1903100 (2020).

Chen, S. et al. Noncontact heartbeat and respiration monitoring based on a hollow microstructured self-powered pressure sensor. ACS Appl. Mater. Interfaces 10, 3660–3667 (2018).

Babaie, A., Madadkhani, S. & Stoeber, B. Evaporation-driven low Reynolds number vortices in a cavity. Phys. Fluids 26, 033102 (2014).

Jung, Y., Kajiya, T., Yamaue, T. & Doi, M. Film formation kinetics in the drying process of polymer solution enclosed by bank. Jpn. J. Appl. Phys. 48, 031502 (2009).

Hu, G. et al. A general ink formulation of 2D crystals for wafer-scale inkjet printing. Sci. Adv. 6, eaba5029 (2020).

Mansoor, I. & Stoeber, B. PIV measurements of flow in drying polymer solutions during solvent casting. Exp. Fluids 50, 1409–1420 (2011).

Wang, Z., Orejon, D., Takata, Y. & Sefiane, K. Wetting and evaporation of multicomponent droplets. Phys. Rep. 960, 1–37 (2022).

Tee, B. C. K. et al. Tunable flexible pressure sensors using microstructured elastomer geometries for intuitive electronics. Adv. Funct. Mater. 24, 5427–5434 (2014).

Kubo, J. I. et al. Improvement of poly(vinyl alcohol) properties by the addition of magnesium nitrate. J. Appl. Polym. Sci. 112, 1647–1652 (2009).

Jiang, X., Zhang, X., Ye, D., Zhang, X. & Dai, H. Modification of poly (vinyl alcohol) films by the addition of magnesium chloride hexahydrate. Polym. Eng. Sci. 52, 1565–1570 (2012).

Vaicekauskaite, J., Mazurek, P., Vudayagiri, S. & Skov, A. L. Map** the mechanical and electrical properties of commercial silicone elastomer formulations for stretchable transducers. J. Mater. Chem. C. 8, 1273–1279 (2020).

Kanyanta, V. & Ivankovic, A. Mechanical characterisation of polyurethane elastomer for biomedical applications. J. Mech. Behav. Biomed. Mater. 3, 51–62 (2010).

Boutry, C. M. et al. A stretchable and biodegradable strain and pressure sensor for orthopaedic application. Nat. Electron. 1, 314–321 (2018).

Shi, R., Lou, Z., Chen, S. & Shen, G. Flexible and transparent capacitive pressure sensor with patterned microstructured composite rubber dielectric for wearable touch keyboard application. Sci. China Mater. 61, 1587–1595 (2018).

Luo, S. et al. Tunable-sensitivity flexible pressure sensor based on graphene transparent electrode. Solid·State Electron 145, 29–33 (2018).

Li, Z. et al. Gelatin methacryloyl‐based tactile sensors for medical wearables. Adv. Funct. Mater. 30, 2003601 (2020).

Kumar, S., Yadav, S. & Kumar, A. Flexible microhyperboloids facets giant sensitive ultra-low pressure sensor. Sens. Actuator A-Phys. 328, 112767 (2021).

Chun, S. et al. An artificial neural tactile sensing system. Nat. Electron. 4, 429–438 (2021).

Kim, J. et al. Soft wearable pressure sensors for beat‐to‐beat blood pressure monitoring. Adv. Healthc. Mater. 8, 1900109 (2019).

Nichols, W. W. Clinical measurement of arterial stiffness obtained from noninvasive pressure waveforms. Am. J. Hypertens. 18, 3–10 (2005).

Qin, D., **a, Y. & Whitesides, G. M. Soft lithography for micro-and nanoscale patterning. Nat. Protoc. 5, 491 (2010).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant 51925503 to Y.H., Grant 52375568 to F.Z., and Grant 52188102 to Y.H.), the XPLORER Prize (Grant 2020-1036 to Y.H.), and the Science and Technology Innovation Team of Hubei Province. The authors thank the Flexible Electronics Manufacturing Laboratory in the Comprehensive Experiment Center at Huazhong University of Science and Technology for support in advanced manufacturing equipment.

Author information

Authors and Affiliations

Contributions

Y.H., F.Z., and W.X. conceived the idea and led research efforts. W.X. performed the experiments. S.Q. helped with the preparation of HMP films and the sensor testing. Y.H., F.Z., and K.L. participated in the discussion of experimental results. W.X. wrote the manuscript and designed the figures. F.Z. and L.Y. participated in the design of the figures. Y.H. and F.Z. revised the manuscript and supervised the research. All authors reviewed and commented on the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Meidan Ye, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

**ong, W., Zhang, F., Qu, S. et al. Marangoni-driven deterministic formation of softer, hollow microstructures for sensitivity-enhanced tactile system. Nat Commun 15, 5596 (2024). https://doi.org/10.1038/s41467-024-49864-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-024-49864-z

- Springer Nature Limited