Abstract

SARS-CoV-2 remains infectious for several hours on surfaces. It can be inactivated by UV-C irradiation but optimal conditions for rapid inactivation, especially on non-plastic surfaces remains unclear. A SARS-CoV-2 inoculum was irradiated with a UV-C LED (265 nm) or a UV-C mercury lamp (254 nm). Infectivity titers (TCID50/mL) and inactivation rates were then quantified on plastic, steel, tissue, paper and cardboard surfaces. We demonstrated that efficient SARS-CoV-2 inactivation (> 99.999% on plastic and steel, ≥ 99.8% on tissue, paper and cardboard) can be achieved by both a UV-C mercury lamp and a UV-C LED after 30 s of irradiations at 3 cm, corresponding to UV-C doses of 92.85 and 44.7 mJ/cm2, respectively. Inactivation on a plastic surface was more efficient with the mercury UV-C lamp (p < 0.005). The mercury UV-C lamp could be more relevant than the LED in high-risk settings, such as medical care or research laboratories.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Background

The human coronavirus named SARS-CoV-2 is a Betacoronavirus identified for the first time in late 2019 in Wuhan, China and is now responsible for a major pandemic worldwide. This virus is transmitted mainly via respiratory droplets and also by direct contact with symptomatic or asymptomatic patients or with contaminated surfaces [1]. SARS-CoV-2 can remain infectious for up to 72 h on non-absorbent surfaces like plastic or steel and up to 24 h on absorbent surfaces like cardboard [1]. UV-C irradiation (200–280 nm) is an effective disinfection approach to inactivate pathogens on surfaces, especially when detergents are not suitable (electronic devices or water treatment). UV-C has a strong germicidal activity, particularly at 260 nm, the maximal wavelength of absorption for nucleic acids [2]. They inactivate pathogens by inducing the formation of pyrimidine dimers, thus inhibiting the genome replication [2, 3]. UV-C can inactivate SARS-CoV-2 on plastic or wood surfaces in a few seconds or minutes but have not been evaluated on cardboard or paper [4,5,6,7,8]. UV-C irradiation can be performed with UV light-emitting diodes (UV LEDs) or classical mercury lamps [2]. Our objective was to evaluate the efficiency of a UV-C mercury lamp and a UV-C LED for the inactivation of SARS-CoV-2 on non-absorbent (plastic, steel) and absorbent surfaces (tissue, paper and cardboard).

2 Methods

2.1 Cell culture and virus

Vero cells (ATCC, CCL-81) and Vero-E6 cells (ATCC, CRL-1586) were maintained in DMEM medium supplemented with 10% FCS and 1% penicillin–streptomycin at 37 °C, under an atmosphere containing 5% CO2. A clinical isolate of SARS-CoV-2 was isolated from a nasopharyngeal swab collected from a patient suffering from COVID-19 at the Tours University Hospital. The virus was amplified using Vero cells expressing Transmembrane Protease Serine 2 (TMPRSS2) to prepare a viral stock in DMEM medium supplemented with 2% FCS and 1% penicillin–streptomycin. This supplemented DMEM medium was defined as infection medium. Viral titer was expressed in 50% tissue culture infective dose (TCID50). This measurement reflects the dilution at which 50% of wells show cytopathic effect. This was quantified by endpoint dilution, using the Spearman and Kärber formula [9, 10], previously used for similar applications [8]. The limit of detection was 4 TCID50/mL. Results below 4 TCID50/mL were considered as equivalent to 1 TCID50/mL. Concentration of the viral stock used in this study was 3 × 105 TCID50/mL (5.5-log10 TCID50/mL). Absorbance of this viral stock in DMEM was 2.39 cm−1 and 2.53 cm−1 at 254 and 265 nm, respectively (Denovix DS11 spectrophotometer). Viral stock was stored at – 80 °C.

2.2 UV-C lamps

The first UV-C lamp was the Puritec HNS-L 2G11 UV-C germicidal mercury lamp (OSRAM, Rosny-sous-bois, France), emitting at 254 nm with a nominal wattage of 18 W. Lamp dimensions were 31.5 cm × 4 cm. The second UV-C lamp was the KL265-50 V-SM-WD UV-C LED (Klaran, Green Island, USA), emitting between 260 and 270 nm with a peak at 265 nm and consuming 70 mW of power. LED dimensions were 3.5 × 3.5 mm. Irradiations were performed at 3, 5 or 10 cm with the lamp positioned directly above the irradiated well for durations of 5, 15, 30 or 60 s. UV-C irradiances received by the sample were measured with an optometer X1-5 and a detector UV-3726-5 (Gigahertz-Optik, GmbH). This device was calibrated at 254 nm and a spectral mismatch correction was calculated for measurements at 265 nm. UV-C irradiances (254 nm) received by the sample after irradiation with the mercury lamp at 3, 5 and 10 cm were 3.10 mW/cm2, 3.25 mW/cm2 and 1.43 mW/cm2, respectively. UV-C irradiances (265 nm) received by the sample after irradiation with the LED at 3, 5 and 10 cm were 1.49 mW/cm2, 1.47 mW/cm2 and 0.64 mW/cm2, respectively. UV-C doses (mJ/ cm2) for each duration (seconds) were calculated as follows: \(UV-C dose =UV-C irradiance \times duration of exposure\)

2.3 Quantification of SARS-CoV-2 inactivation after UV-C irradiation

The SARS-CoV-2 inoculum (200 µL at 3 × 105 TCID50 inoculum/ml) was deposited as a drop at a single spot using a pipettor on relevant surfaces in 12-well plates. Plastic (bottom of the well), steel (1 cm2 steel ring), tissue (1 cm2 punch of cotton cloth), paper (1 cm2 punch of 80 g/m2 white paper), and cardboard (1 cm2 punch of solid unbleached board) were used in this experiment.

A five minutes contact time between the inoculum and all tested surfaces was applied. It allowed complete absorption on absorbent surfaces. Viruses were then directly exposed to UV-C irradiation at 3, 5 or 10 cm (on top, without cover) for 5, 15, 30 or 60 s. A control condition without UV-C exposure was considered for each material in duplicate for each experiment. The exposed inoculum (200 µL) was directly collected for non-absorbent surfaces or eluted for absorbent surfaces by 5 min soaking in 200 µL of infection medium (described above). It was then deposited on Vero-E6 cells to amplify remaining infectious viruses. These cells had previously been plated at 3 × 105 cells / well in 12-well plates, 24 h before the experiment. After 1 h of infection, the viral suspension was removed, the cells were washed with 500 µL of PBS and 1 ml of infection medium was added to each well. Twenty-four hours later, the supernatant was collected and the viral titer was determined by endpoint dilution and calculation of the TCID50 (TCID50 UV-C). This amplification step was necessary to ensure optimal sensitivity of the SARS-CoV-2 concentration measurement. A standard curve was performed with tenfold serial dilutions of the stock concentrations titrated before and after amplification in a single experiment to confirm that linearity was maintained after amplification. SARS-CoV-2 concentration after mock-irradiation and amplification (TCID50 control) was used as a control to take into account the amplification step and the intrinsic properties of each surface (absorption and inactivation). SARS-CoV-2 inactivation (%) was calculated as follows: Inactivation (%) = (\(1-\frac{{TCID }_{50}UV-C}{{TCID}_{50} control}\))*100. SARS-CoV-2 inactivation experiments were performed in duplicate in three independent experiments to obtain six individual values used to calculate the mean and standard deviation. SARS-CoV-2 inactivation efficiencies were compared between different UV-C sources, different distance and different durations of irradiation, using the Mann–Whitney (two groups) or the two-way ANOVA tests (more than two groups) with the GraphPad 9 software.

3 Results

3.1 Linearity of SARS-CoV-2 titration is maintained after amplification

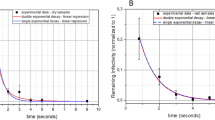

Serial dilutions of the SARS-CoV-2 initial viral stock were titrated before (0.3–5.3 log TCID50/mL) and after viral amplification (1.5–6.2 log TCID50/mL). The amplification step was associated with an increase in SARS-CoV-2 concentration (+ 1.2 log TCID50/mL). Linearity was maintained in this range of concentrations (95% confidence interval for slope = 0.8–1.0) (Fig. 1).

Measurement of SARS-CoV-2 concentration before and after amplification. Results are represented as individual values from a single experiment (circles) with linear regression (plain line) and its 95% confidence interval (dotted lines). Concentration of the last dilution (empty circle) could only be measured after amplification. It was below the limit of detection (4 TCID50/mL) before amplification and was represented with its theoretical value (2 TCID50/mL)

3.2 SARS-CoV-2 inactivation by UV-C on a plastic surface

TCID50 for the control condition was 6.4 ± 0.5 log TCID50/mL (mock irradiated). No infectious virus was detected after irradiation with the mercury UV-C lamp, even for low UV-C doses (7.14 to 48.8 mJ/cm2) (Fig. 2A). This corresponded to a 6.4-log10 decrease in SARS-CoV-2 TCID50. Low doses of UV-C LED light (3.2 to 44.7 mJ/cm2) were associated with a 4-log10 reduction in SARS-CoV-2 TCID50 (Fig. 2A). When considering similar UV-C doses (3.2 to 48.8 mJ/cm2), reduction in SARS-CoV-2 TCID50 on plastic was higher with the mercury lamp than with the LED (p < 0.005). We searched for the optimal distances (3, 5 or 10 cm) and durations (5, 15, 30 or 60 s) of UV-C irradiation for SARS-CoV-2 inactivation on a plastic surface. SARS-CoV-2 inactivation by the UV-C mercury lamp was > 99.9999% in all conditions regardless of the distance or duration of irradiation (Fig. 2B). In contrast, high level SARS-CoV-2 inactivation by the UV-C LED (> 99.999%) required a close position of the lamp (3 or 5 cm) and longer irradiations (≥ 15 s) (Fig. 2B). In these conditions, the irradiance level of the LED was lower than that of the mercury lamp (1.49 mW/cm2 vs 3.10 mW/cm2 at 3 cm). The mercury UV-C lamp was associated with significantly higher SARS-CoV-2 inactivation rates than the LED at 10 cm during 5 s (> 99.999% vs > 99.9%, p < 0.01) (Fig. 2B).

SARS-CoV-2 inactivation on plastic by mercury and LED UV-C lamps. A SARS-CoV-2 TCID50 depending on the dose of UV-C received after irradiation on a plastic surface by the mercury lamp or the LED, compared with the non-irradiated control sample. Results are represented as mean with standard deviation. B SARS-CoV-2 inactivation rates by UV-C lamps on a plastic surface depending on the duration (5 to 60 s) and the distance of irradiation. Distances of 10, 5 and 3 cm are represented with white/orange/red bars for the mercury lamp (plain bars) and the LED (dotted bars). Results are represented as mean with standard deviation. **p < 0.01

3.3 SARS-CoV-2 inactivation on steel, tissue, paper and cardboard

In light of previous results, SARS-CoV-2 inactivation by the UV-C lamps on steel, tissue, paper and cardboard was quantified after 15, 30 and 60 s of irradiation at a single distance of 3 cm (Fig. 3B). These conditions corresponded to UV-C doses between 46.43 and 185.7 mJ/cm2 for the mercury lamp and 22.35 and 89.4 mJ/cm2 for the LED. TCID50s for the mock-irradiated control condition were 3.8 ± 0, 4.2 ± 0.9, 2.9 ± 1.6 and 3.3 ± 1.4 log TCID50/mL for steel, tissue, paper and cardboard, respectively. No infectious virus was detected after irradiation with the mercury or the LED UV-C lamp on a steel surface (Fig. 3A). This corresponded to inactivation rates > 99.999% on steel (Fig. 3B). In contrast, infectious viruses were still detected after irradiation with the mercury or the LED UV-C lamp on absorbent surfaces (tissue, paper or cardboard) (Fig. 3A).There were no significant differences in reduction of SARS-CoV-2 TCID50/mL between both lamps on steel and absorbent surfaces for comparable UV-C doses (40–50 mJ/cm2, Fig. 3A). SARS-CoV-2 inactivation was ≥ 99.8% on steel, tissue, paper and cardboard after irradiation by a UV-C mercury lamp or a UV-C LED, at a distance of 3 cm during 30 s. This condition corresponded to 92.85 and 44.7 mJ/cm2 for the mercury and LED UV-C lamps, respectively (Fig. 3B). Shorter irradiation times (15 vs 30 s) were less effective (90–99% inactivation vs ≥ 99.8%, p < 0.05) on absorbent surfaces (Fig. 3B).

SARS-CoV-2 inactivation on steel, tissue, paper and cardboard by mercury and LED UV-C lamps. A SARS-CoV-2 TCID50 depending on the dose of UV-C received after irradiation on steel, tissue, paper or cardboards surfaces by the mercury lamp (Hg) or the LED. B SARS-CoV-2 inactivation rates by UV-C lamps at 3 cm depending on the irradiated surface (steel, tissue, paper or cardboard) and the duration of irradiation. Durations of 15, 30 and 60 s are represented with white/orange/red bars for the mercury lamp (plain bars) and the LED (dotted bars). Results are represented as mean with standard deviation for both panels. **p < 0.01; ***p < 0.001; ****p < 0.0001

4 Discussion

Efficient inactivation of SARS-CoV-2 on contaminated surfaces (> 99.999% on plastic and steel and ≥ 99.8% on tissue, paper and cardboard) can be achieved by both the UV-C mercury lamp and the UV-C LED at a distance of 3 cm during 30 s. No infectious virus was detected after irradiation with the mercury UV-C lamp on a plastic surface for a UV-C dose of 7.14 mJ/cm2 (10 cm, 5 s), which is in line with most previous studies [8, 11, 12]. Lower performances have been described for less powerful mercury lamps (4 W vs 18 W in this study) [4]. This irradiation (7.14 mJ/cm2) corresponded to a 6.4-log10 decrease in SARS-CoV-2 TCID50/mL, rarely observed with other mercury lamps for comparable UV-C doses (3 to 4-log10 decrease) [8, 11,12,13]. These other studies were probably limited more by a lower infectious titer of the viral inoculum than by the performances of the mercury lamps, because no infectious viruses were detected after irradiation [8, 11, 12].

A 4-log10 reduction in SARS-CoV-2 TCID50 was observed after irradiation with the UV-C LED light at 3.2 mJ/cm2 (10 cm, 5 s) on plastic. These performances were in line with another study, in which a 3.5-log10 decrease was observed after irradiation with comparable UV-C doses [8]. Another study, by Inagaki et al., demonstrated comparable UV-C LED performances with a 3-log10 reduction in SARS-CoV-2 TCID50 after 10 s of irradiation at 2 cm using a deep UV-C LED (280 nm) [5]. Considering that sample droplet thickness was 1 mm and sample absorbance of cell culture medium at 254 and 265 nm was around 2.39–2.53 cm−1, UV-C exposure was reduced by a 25 to 34 factor by comparison with neutral medium (PBS or water) used in other studies [8]. This can be explained by absorbance of amino acids present in the cell culture medium [14]. Inactivation rates are expected to be lower in our experiments than in neutral medium [8] but were considered closer to inactivation rates in biological fluids.

Interestingly, SARS-CoV-2 inactivation on a plastic surface was more efficient with the mercury UV-C lamp than with the UV-C LED lamp, even when considering similar UV-C doses (p < 0.005). The UV-C LED has wider emission peaks than the mercury lamp. This could contribute to a lower irradiance of DNA at 260 nm with the LED than with the mercury lamp. The UV-C LED is associated with twofold lower irradiances than the mercury lamp. Longer irradiations are thus required to reach similar UV-C doses. Both these factors could contribute to lower inactivation rates with the LED than with the mercury lamp.

This study is one of the first description of viral inactivation on steel and absorbent materials by UV-C lamps. Interestingly, inactivation rates were lower on absorbent materials (tissue, paper and cardboard: ≥ 99.8%) than on plastic (> 99.999%). This was probably because a fraction of the inoculum (200 µL) was absorbed inside the materials and shielded from the UV-C light, which is less likely to happen with respiratory droplets (5 µL). In contrast, SARS-CoV-2 inactivation rates on steel were above 99.999% for each lamp, comparable to results obtained on plastic (> 99.999%).

The mercury UV-C lamp demonstrated a higher efficacy than the LED on a plastic surface for a range of UV-C doses between 3.2 and 48.8 mJ/cm2. For this reason, the mercury UV-C lamp could be more relevant in high-risk settings, such as medical care or research laboratories. In contrast, the UV-C LED demonstrated good efficacy on absorbent surfaces and has several advantages over the mercury lamp, especially a lower power consumption (18 mW vs 70 W) and a smaller size (3.5 vs 31 cm). In addition, its performance could probably be improved by combining several LEDs emitting at different wavelengths. For these reasons, the LED could be especially interesting in industry or household applications.

Data availability

Marlet, Julien (2021), “UV-C COVID”, Mendeley Data, V1, https://doi.org/10.17632/6gxgfgdfwc.1. https://data.mendeley.com/datasets/6gxgfgdfwc/1

References

van Doremalen, N., Bushmaker, T., Morris, D. H., et al. (2020). Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. New England Journal of Medicine, 382(16), 1564–1567.

Hadi, J., Dunowska, M., Wu, S., & Brightwell, G. (2020). Control measures for SARS-CoV-2: a review on light-based inactivation of single-stranded RNA viruses. Pathogens, 9(9), 737.

Cutler, T. D., & Zimmerman, J. J. (2011). Ultraviolet irradiation and the mechanisms underlying its inactivation of infectious agents. Animal Health Research Reviews, 12(1), 15–23.

Heilingloh, C. S., Aufderhorst, U. W., Schipper, L., et al. (2020). Susceptibility of SARS-CoV-2 to UV irradiation. American Journal of Infection Control, 48(10), 1273–1275.

Inagaki, H., Saito, A., Sugiyama, H., Okabayashi, T., & Fujimoto, S. (2020). Rapid inactivation of SARS-CoV-2 with deep-UV LED irradiation. Emerging Microbes & Infections, 9(1), 1744–1747.

Storm, N., McKay, L. G. A., Downs, S. N., et al. (2020). Rapid and complete inactivation of SARS-CoV-2 by ultraviolet-C irradiation. Scientific Reports, 10(1), 22421.

Criscuolo, E., Diotti, R. A., Ferrarese, R., et al. (2021). Fast inactivation of SARS-CoV-2 by UV-C and ozone exposure on different materials. Emerging Microbes & Infections, 10(1), 206–210.

Ma, B., Gundy, P. M., Gerba, C. P., Sobsey, M. D., & Linden, K. G. (2021). UV Inactivation of SARS-CoV-2 across the UVC spectrum: KrCl* excimer, mercury-vapor, and light-emitting-diode (LED) sources. Dudley EG, editor. Applied and Environmental Microbiology, 87(22), 1532–1621.

Kärber, G. (1931). Beitrag zur kollektiven Behandlung pharmakologischer Reihenversuche. Archiv f experiment Pathol u Pharmakol., 162(4), 480–483.

Spearman, C. (1908). The method of ‘right and wrong cases’ (‘constant stimuli’) without Gauss’s formulae. British Journal of Psychology, 1904–1920, 2(3), 227–242.

Boegel, S. J., Gabriel, M., Sasges, M., et al. (2021). Robust evaluation of ultraviolet-C sensitivity for SARS-CoV-2 and surrogate coronaviruses. Microbiology Spectrum, 9(2), e00537-e621.

Biasin, M., Bianco, A., Pareschi, G., et al. (2021). UV-C irradiation is highly effective in inactivating SARS-CoV-2 replication. Science and Reports, 11, 6260.

Sabino, C. P., Sellera, F. P., Sales-Medina, D. F., et al. (2020). UV-C (254 nm) lethal doses for SARS-CoV-2. Photodiagnosis and Photodynamic Therapy, 32, 101995.

Zhikhoreva, A. A., Belik, V. P., Belashov, A. V., et al. (2018). Spectral characteristics of the DMEM cell-culture medium. Technical Physics, 63(9), 1300–1303.

Funding

This study was funded by BICE45 (Saint-Ay, France), specialized in electronic cards. This society also provided both lamps.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by both authors. Both authors wrote and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

This research was funded by BICE45 (Saint-Ay, France), which is specialized in electronic cards. This society also provided both lamps. Authors have no other financial interests in BICE45.

Ethical approval

Sample collection was approved by the Ministère de l’Enseignement Supérieur et de la Recherche (authorization n° DC-2020–3961).

Informed consent

Informed consent was obtained from all subjects involved in the study.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maquart, M., Marlet, J. Rapid SARS-CoV-2 inactivation by mercury and LED UV-C lamps on different surfaces. Photochem Photobiol Sci 21, 2243–2247 (2022). https://doi.org/10.1007/s43630-022-00292-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s43630-022-00292-2