Abstract

Purpose

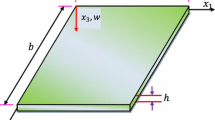

Due to the significance of the effect size on microstructures and also due to the fact that classical continuum theory cannot predict their behavior, higher order continuum theories should be used for modeling and obtaining the governing partial differential equations of microplates. For considering the size effect, the strain gradient theory is used. Vibration control of a microplate is studied using a linear boundary control law, and by utilizing a Lyapunov functional, the boundary stabilization of the system will be proved. The subject of vibration control of a strain gradient microplate utilizing the PDE control theory. The boundary action, in which the actuator is placed on the free sides of the plate, is used to stabilize mechanical vibrations.

Method

The governing equation and boundary condition of strain gradient microplate using Hamilton principle are derived. The boundary control problem of a CFFC (Clamped-Free-Free-Clamped) non-classical microplate using Lyapunov stability theorem and the design of a proper controller for the system are stablisged. A Lyapunov-based functional is used to demonstrate closed-loop system boundary stabilization. The verification of the theoretical results is accomplished using the finite-element method. New non-classical microplate element stiffness and mass matrices are developed based on the strain gradient theory. To derive strain gradient plate element stiffness and mass matrices, a four-node rectangular element is utilized. The verification of the theoretical results is accomplished using the finite-element method. Numerical method (Finite Element Method) is used for microplate simulation.

Results and Conclusion

Boundary stabilization of a vibrating strain gradient plate has been achieved using the Lyapunov stability theorem and boundary control. The boundary action is used to stabilize mechanical vibrations. The boundary PDE control technique used in this study provides various advantages. This simulations shows good agreement with the theoretical results. The deflection, slope, velocity and angular velocity are comprised in open loop and closed loop. Appling control force {F} at the free sides of the plate, causes to stabilize the vibrating system.

Similar content being viewed by others

References

Asghari M, Kahrobaiyan MH, Ahmadian MT (2010) A nonlinear Timoshenko beam formulation based on the modified couple stress theory. Int J Eng Sci 48(12):1749–1761. https://doi.org/10.1016/j.ijengsci.2010.09.025

Baghani M (2012) Analytical study on size-dependent static pull-in voltage of microcantilevers using the modified couple stress theory. Int J Eng Sci 54:99–105. https://doi.org/10.1016/j.ijengsci.2012.01.001

Ghayesh MH, Amabili M, Farokhi H (2013) Nonlinear forced vibrations of a microbeam based on the strain gradient elasticity theory. Int J Eng Sci 63:52–60. https://doi.org/10.1016/j.ijengsci.2012.12.001

Ghayesh MH, Farokhi H (2015) Chaotic motion of a parametrically excited microbeam. Int J Eng Sci 96:34–45. https://doi.org/10.1016/j.ijengsci.2015.07.004

Indermuhle PF, Schürmann G, Racine GA, Rooij NFD (1997) Atomic force microscopy using cantilevers with integrated tips and piezoelectric layers for actuation and detection. Micromech Microeng 7:218–220. https://doi.org/10.1088/0960-1317/7/3/036

Zhang WM, Meng G (2007) Nonlinear dynamic analysis of electrostatically actuated resonant MEMS sensors under parametric excitation. IEEE Sens J 7(3):370–380. https://doi.org/10.1109/JSEN.2006.890158

Shishesaz M, Hosseini M, Naderan Tahan K, Hadi A (2017) Analysis of functionally graded nanodisks under thermoelastic loading based on the strain gradient theory. Acta Mech 228(12):4141–4168. https://doi.org/10.1007/s00707-017-1939-8

Yin L, Qian Q, Wang L, **a W (2010) Vibration analysis of microscale plates based on modified couple stress theory. Acta Mech Solida Sin 23(5):386–393. https://doi.org/10.1016/S0894-9166(10)60040-7

Guo XH, Fang DN, Li XD (1997) Measurement of deformation of pure Ni foils by speckle pattern interferometry. Mech Eng 27:21–25. https://doi.org/10.6052/1000-0992-2004-077

Nix WD (1989) Mechanical-properties of thin-films. Metallurgical transactions. Phys Metal Mater Sci 20:2217–2245. https://doi.org/10.1007/BF02666659

Poole’ WJ, Ashby MF, Fleck NA (1996) 0956–716X (95)00524–2 Micro-Hardness Of Annealed And Work-Hardened Copper Polycrystals. In Ekevier Science Ltd Copyright (Vol. 34, Issue 4). Acta Metallurgica Inc. https://doi.org/10.1016/1359-6462(95)00524-2

Lam DCC, Chong ACM (1999) Indentation model and strain gradient plasticity law for glassy polymers. Mater Res 14:3784–3788. https://doi.org/10.1557/JMR.1999.0512

Chasiotis I, Knauss WG (2003) The mechanical strength of polysilicon films: Part 2. Size effects associated with elliptical and circular perforations. J Mech Phys Solids 51(8):1551–1572. https://doi.org/10.1016/S0022-5096(03)00050

Lam DCC, Yang F, Chong ACM, Wang J, Tong P (2003) Experiments and theory in strain gradient elasticity. J Mech Phys Solids 51(8):1477–1508. https://doi.org/10.1016/S0022-5096(03)00053-X

Cosserat E, Cosserat F (1909) Théorie des corps déformables. Hermann et Fils. Nature 81:67. https://doi.org/10.1038/081067a0

Mindlin R, Tiersten H (1962) Effects of couple-stresses in linear elasticity. Arch Ration Mech Anal 11:415–448. https://doi.org/10.1007/BF00253946

Toupin RA (1962) Elastic materials with couple-stresses. Arch Ration Mech Anal 11:385–414. https://doi.org/10.1007/BF00253945

Yang F, Chong ACM, Lam DCC, Tong P (2002) Couple stress based strain gradient theory for elasticity. Int J Solids Struct 39:2731–2743. https://doi.org/10.1016/S0020-7683(02)00152-X

Mindlin RD (1964) Micro-structure in linear elasticity. Arch Rational Mech Anal 16:51–78. https://doi.org/10.1007/BF00248490

Mindlin RD (1965) Second Gradient Of Strain And Surface-Tension In Linear Elasticity. In: hr. J. Solids Sfrucrures, Vol. 1. Pergamon Press Ltd. https://doi.org/10.1016/0020-7683(65)90006-5

Fleck NA, Muller GM, Ashby MF, Hutchinson JW (1994) Strain Gradient Plasticity: Theory And Experiment. In: Acta metall, mater, Vol. 42, Issue 2. https://doi.org/10.1016/0956-7151(94)90502-9

Li C, Yao LQ, Chen WQ, Li SH (2015) Comments on nonlocal effects in nano-cantilever beams. Int J Eng Sci 87:47–57. https://doi.org/10.1016/j.ijengsci.2014.11.006

Lim CW, Zhang G, Reddy J (2015) A higher-order nonlocal elasticity and strain gradient theory and its applications in wave propegation. J Mech Phys Solids 78:298–313. https://doi.org/10.1016/j.jmps.2015.02.001

Yan JW, Zhu JH, Li C, Zhao XS, Lim CW (2022) Decoupling the effects of material thickness and size scale on the transverse free vibration of bnnts based on beam models. Mech Syst Signal Process 166:108440. https://doi.org/10.1016/j.ymssp.2021.108440

Kong S, Zhou S, Nie Z, Wang K (2008) The size-dependent natural frequency of Bernoulli-Euler micro-beams. Int J Eng Sci 46(5):427–437. https://doi.org/10.1016/j.ijengsci.2007.10.002

Ghadiri M, Shafiei N (2016) Vibration analysis of rotating functionally graded Timoshenko microbeam based on modified couple stress theory under different temperature distributions. Acta Astronaut 121:221–240. https://doi.org/10.1016/j.actaastro.2016.01.003

Jomehzadeh E, Noori HR, Saidi AR (2011) The size-dependent vibration analysis of micro-plates based on a modified couple stress theory. Physica E 43(4):877–883. https://doi.org/10.1016/j.physe.2010.11.005

Ke LL, Wang YS, Yang J, Kitipornchai S (2012) Free vibration of size-dependent Mindlin microplates based on the modified couple stress theory. J Sound Vib 331(1):94–106. https://doi.org/10.1016/j.jsv.2011.08.020

Ghayesh MH, Farokhi H (2015) Nonlinear dynamics of microplates. Int J Eng Sci 86:60–73. https://doi.org/10.1016/j.ijengsci.2014.10.004

Sladek V, Sladek J, Repka M, Sator L (2020) FGM micro/nano-plates within modified couple stress elasticity. Compos Struct. https://doi.org/10.1016/j.compstruct.2020.112294

Kong S, Zhou S, Nie Z, Wang K (2009) Static and dynamic analysis of micro beams based on strain gradient elasticity theory. Int J Eng Sci 47(4):487–498. https://doi.org/10.1016/j.ijengsci.2008.08.008

Arvin H (2017) Free vibration analysis of micro rotating beams based on the strain gradient theory using the differential transform method: Timoshenko versus Euler-Bernoulli beam models. Eur J Mech A/Solids 65:336–348. https://doi.org/10.1016/j.euromechsol.2017.05.006

Yan JW, Tong LH, Li C, Zhu Y, Wang ZW (2015) Exact solutions of bending deflections for nano-beams and nano-plates based on nonlocal elacticity theory. Compos Struct 125:304–313. https://doi.org/10.1016/j.compstruct.2015.02.017

Li C, Lai SK, Yang X (2019) On the Nano-structural dependence of nonlocal dynamics and its relationship to the upper limit of nonlocal scale parameter. Appl Math Model 69:127–141. https://doi.org/10.1016/j.apm.2018.12.010

Yan JW, Zhang W (2021) An atomistic-continuum multiscale approach to determine the exact thickness and bending rigidity of monolayer graphen. J Sound Vib 514:116464. https://doi.org/10.1016/j.jsv.2021.116464

Lazopoulos KA (2004) On the gradient strain elasticity theory of plates. Eur J Mech A/Solids 23(5):843–852. https://doi.org/10.1016/j.euromechsol.2004.04.005

Wang B, Zhou S, Zhao J, Chen X (2011) A size-dependent Kirchhoff micro-plate model based on strain gradient elasticity theory. Eur J Mech A/Solids 30(4):517–524. https://doi.org/10.1016/j.euromechsol.2011.04.001

Ashoori Movassagh A, Mahmoodi MJ (2013) A micro-scale modeling of Kirchhoff plate based on modified strain-gradient elasticity theory. Eur J Mech A/Solids 40:50–59. https://doi.org/10.1016/j.euromechsol.2012.12.008

Ramezani S (2013) Nonlinear vibration analysis of micro-plates based on strain gradient elasticity theory. Nonlinear Dyn 73(3):1399–1421. https://doi.org/10.1007/s11071-013-0872-1

Thai CH, Ferreira AJM, Phung-Van P (2019) Size dependent free vibration analysis of multilayer functionally graded GPLRC microplates based on modified strain gradient theory. Compos B Eng 169:174–188. https://doi.org/10.1016/j.compositesb.2019.02.048

Saghir S, Younis MI (2018) An investigation of the mechanical behavior of initially curved microplates under electrostatic actuation. Acta Mech 229(7):2909–2922. https://doi.org/10.1007/s00707-018-2141-3

Jallouli A, Kacem N, Najar F, Bourbon G, Lardies J (2019) Modeling and experimental characterization of squeeze film effects in nonlinear capacitive circular microplates. Mech Syst Signal Process 127:68–88. https://doi.org/10.1016/j.ymssp.2019.02.060

Zhang B, Li H, Kong L, Zhang X, Shen H (2020) Strain gradient differential quadrature Kirchhoff plate finite element with the C2 partial compatibility. Eur J Mech A/Solids. https://doi.org/10.1016/j.euromechsol.2019.103879

Karamanli A, Aydogdu M (2020) Vibration of functionally graded shear and normal deformable porous microplates via finite element method. Compos Struct. https://doi.org/10.1016/j.compstruct.2020.111934

Timoshin A, Kazemi A, Beni MH, Jam JE, Pham B (2021) Nonlinear strain gradient forced vibration analysis of shear deformable microplates via hermitian finite elements. Thin-Walled Structures. https://doi.org/10.1016/j.tws.2021.107515

Canudas C, Siciliano B, Bastin G (1997) Theory of Robot Control. Springer, London

Chrysafinos K, Gunzburger MD, Hou LS (2006) Semidiscrete approximations of optimal Robin boundary control problems constrained by semilinear parabolic PDE. J Math Anal Appl 323(2):891–912. https://doi.org/10.1016/j.jmaa.2005.10.053

Krstic M (2008) Boundary control of PDEs: a course on backstep** designs class slides, society for industrial and applied mathematics (SIAM)

Vatankhah R, Najafi A, Salarieh H, Alasty A (2015) Lyapunov-based boundary control of strain gradient microscale beams with exponential decay rate. J Vib Acoustics Trans ASME. https://doi.org/10.1115/1.4028964

Najafi A (2015) Mechatronic control of a composite shell containing fluid. JVC/J Vib Control 21(15):2915–2924. https://doi.org/10.1177/1077546314521262

Ali Nojoumian M, Vatankhah R, Salarieh H (2017) Adaptive boundary control of the size-dependent behavior of Euler-Bernoulli micro-beams with unknown parameters and varying disturbance. Proc Inst Mech Eng C J Mech Eng Sci 231(10):1777–1790. https://doi.org/10.1177/0954406215622651

Mehrvarz A, Salarieh H, Alasty A, Vatankhah R (2018) Vibration boundary control of micro-cantilever Timoshenko beam using piezoelectric actuators. Sci Iran 25(2):711–720. https://doi.org/10.24200/sci.2017.4327

Lou J, He L, Du J, Wu H (2016) Buckling and post-buckling analyses of piezoelectric hybrid microplates subject to thermo-electro-mechanical loads based on the modified couple stress theory. Compos Struct 153:332–344. https://doi.org/10.1016/j.compstruct.2016.05.107

Oñate E (2013) Structural analysis with the finite element method linear statics Vol. 2 Beams, Plates and Shells, Springer, Barcelona

Altan BS, Aifantis EC (1997) On some aspects in special theory of gradient elasticity. J Mech Behav Mater 8:231–282. https://doi.org/10.1515/JMBM.1997.8.3.231

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: The Components of Stiffness Matrix

Appendix: The Components of Stiffness Matrix

The stiffness matrix is obtained in Eq. (45)

That

The components of \({K}_{\varepsilon }\), \({K}_{\eta }\),\({K}_{\gamma }\) and \({K}_{\chi }\) are as follows:

The \({\gamma }^{\chi }\) and \({\gamma }^{\eta }\) are diagonal matrices.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Malek Hosseini, Z., Najafi Ardekany, A. Lyapunov-Based Boundary Control of Strain Gradient Microplates. J. Vib. Eng. Technol. 11, 3893–3906 (2023). https://doi.org/10.1007/s42417-022-00790-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-022-00790-8