Abstract

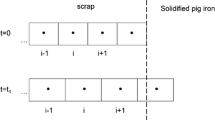

Herein, a numerical simulation with simultaneous heat and mass transfers is carried out to investigate the scrap melting characteristics in molten steel after model verification by published experimental data. The numerical results show that the scrap melting stages consist of the frozen shell formation stage, the frozen shell remelting stage and the parent scrap melting stage. The heat transfer coefficient and the carbon mass transfer coefficient between the scrap and the molten steel are, respectively, in the range of 4209–6249 W m−2 K−1 and 6.4 × 10–5 m s−1. Meanwhile, the effects of process parameters on scrap melting time were studied. An increase in the scrap preheating temperature \(\left( {T_{{{\text{scrap}}}} } \right)\), the molten steel temperature \(\left( {T_{{{\text{steel}}}} } \right)\) and the carbon content of molten steel \(\left( {C_{{{\text{steel}}}} } \right)\), and a decrease in the scrap thickness \(\left( {d_{{{\text{scrap}}}} } \right)\), can reduce the frozen shell existence time, as well as the scrap melting time. On this basis, a quantitative relationship between the aforementioned process parameters and the scrap melting time is obtained to predict the formation of frozen shell (Ψ), which provides process guidance for shortening the scrap melting time. The quantitative relationship is expressed as: \( \ln \left( \varPsi \right) = 311.32 - 2.34\ln \left( {T_{{{\text{scrap}}}} } \right) - 39.99\ln \left( {T_{{{\text{steel}}}} } \right) - 0.08\ln \left( {d_{{{\text{scrap}}}} } \right) - 0.57\ln \left( {C_{{{\text{steel}}}} } \right) \).

Similar content being viewed by others

References

M. Shamsuddin, JOM 38 (1986) 24–31.

C. Wang, M. Brämming, M. Larsson, Steel Res. Int. 84 (2013) 387–394.

R.J. Compañero, A. Feldmann, A. Tilliander, J. Sust. Metall. 7 (2021) 1654–1670.

T. Manabe, M. Miyata, K. Ohnuki, J. Sust. Metall. 5 (2019) 319–330.

G. Wei, R. Zhu, T. Tang, K. Dong, Ironmak. Steelmak. 46 (2019) 609–617.

X. **, S. Yang, J. Li, X. Chen, M. Ye, Ironmak. Steelmak. 47 (2020) 442–448.

J. Li, N. Provatas, G. Brooks, Metall. Mater. Trans. B 36 (2005) 293–302.

X. **, S. Chen, S. Yang, M. Ye, J. Li, ISIJ Int. 61 (2021) 190–199.

X. **, S. Yang, J. Li, J. Wu, M. Zhao, M. Ye, Ironmak. Steelmak. 47 (2019) 748–756.

M. Östman, Pre–study of models and map** physical modeling of scrap melting, Luleå University of Technology, Luleå, Sweden, 2006.

X. **, S. Li, S. Yang, M. Zhao, J. Li, Ironmak. Steelmak. 47 (2020) 1087–1099.

S. Deng, A. Xu, G. Yang, H. Wang, Steel Res. Int. 90 (2019) 1800435.

A. Kruskopf, L. Holappa, Metall. Res. Technol. 115 (2017) 201.

J. Li, N. Provatas, Metall. Mater. Trans. B 39 (2008) 268–279.

M. Gao, J.T. Gao, Y.L. Zhang, S.F. Yang, Int. J. Miner. Metall. Mater. 28 (2021) 380–389.

O.J.P. Gonzalez, M.A. Ramirez-Argaez, A.N. Conejo, ISIJ Int. 50 (2010) 9–16.

N. Arzpeyma, O. Widlund, M. Ersson, P. Joensson, ISIJ Int. 53 (2013) 48–55.

F.M. Penz, J. Schenk, Steel Res. Int. 90 (2019) 1900124.

A. Kemminger, F. Krause, L. Sankowski, N. Uebber, Steel Res. Int. 89 (2017) 1700098.

A.K. Shukla, P.B. Deo, International symposium for research scholars on metallurgy, Materials Science & Engineering, Chennai, India, 2006.

M. Liu, G. Ma, X. Zhang, D. Zheng, Case Studies Thermal Eng. 34 (2022) 101995.

R. Niu, B. Li, Z. Liu, X. Li, Steel Res. Int. 89 (2018) 1700407.

A. Fluent, ANSYS Fluent Theory Guide, ANSYS Inc., Canonsburg, PA, USA, 2011, pp. 621–623.

J. Li, M. Wu, A. Kharicha, A. Ludwig, Int. J. Heat Mass Transf. 72 (2014) 668–679.

N. Ren, J. Li, C. Panwisawas, M. **a, H. Dong, J. Li, Acta Mater. 206 (2021) 116620.

N. Ren, J. Li, N. Bogdan, M. **a, J. Li, Computat. Mater. Sci. 180 (2020) 109714.

C. Yao, H. Zhu, Z. Jiang, T. Pan, Steel Res. Int. 92 (2021) 2000664.

C. Yao, Z. Jiang, H. Zhu, T. Pan, Metals 12 (2022) 390.

S. Zhang, J. Yu, H. Li, Z. Jiang, Y. Geng, H. Feng, B. Zhang, H. Zhu, J. Mater. Sci. Technol. 102 (2022) 105–114.

H. Feng, H. Li, J. Dai, Y. Han, J. Qu, Z. Jiang, Y. Zhao, T. Zhang, Corros. Sci. 204 (2022) 110396.

H. Zhu, H. Li, Z. Ni, Z. He, Z. Jiang, H. Feng, S. Zhang, D. Mao, Metall. Mater. Trans. B 53 (2022) 50–59.

A.K. Shukla, B. Deo, D.G.C. Robertson, Metall. Mater. Trans. B 44 (2013) 1407–1427.

K. Mori, H. Nomura, Tetsu-to-Hagane 55 (2010) 347–354.

Q. Jiao, N. J. Themelis, Can. Metall. Quart. 32 (1993) 75–83.

J. Szekely, Y.K. Chuang, J.W. Hlinka, Metall. Mater. Trans. B 3 (1972) 2825–2833.

F.M. Penz, R.P. Tavares, C. Weiss, J. Schenk, R. Ammer, K. Pastucha, G. Klösch, Int. J. Heat Mass Transfer 138 (2019) 640–646.

J.K. Wright, Metall. Mater. Trans. B 20 (1989) 363–374.

H. Nomura, K. Mori, Tetsu-to-Hagane 55 (1969) 1134–1141.

M.V. Ende, JOM 74 (2022) 1610–1623.

A.G. Belkovskii, Y.L. Kats, Metallurgist 58 (2015) 950–958.

V. Logar, I. Škrjanc, J. Sust. Metall. 7 (2021) 1013–1026.

G. Wei, R. Zhu, X. Wu, L. Yang, K. Dong, T. Cheng, T. Tang, Metall. Mater. Trans. B 49 (2018) 1405–1420.

G. Wei, R. Zhu, S. Yang, X. Wu, K. Dong, Ironmak. Steelmak. 48 (2021) 703–711.

Y.N. Toulouevski, I.Y. Zinurov, Fuel Arc Furnace (FAF) for Effective Scrap Melting: From EAF to FAF, Springer Nature Singapore Pte Ltd., Singapore, 2017, pp. 25–39.

Y.N. Toulouevski, I.Y. Zinurov, Electric Arc Furnace with Flat Bath, Springer International Publishing, Switzerland, 2015, pp. 117–132.

W.Y. Yang, X.F. Jiang, L. Li, X.Y. Peng, X.Q. Shi, Iron and Steel 52 (2017) No. 3, 27–35.

Acknowledgements

This work was funded by the National Key R&D Program of China (Grant No. 2017YFB0304205) and Fundamental Research Funds for the Central Universities (Grant No. N2225046).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yao, Cl., Zhu, Hc., Jiang, Zh. et al. Numerical investigation on melting characteristics of scrap with heat and mass transfers in molten steel. J. Iron Steel Res. Int. 30, 1090–1100 (2023). https://doi.org/10.1007/s42243-022-00864-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00864-7