Abstract

In the quest for creating a sustainable future, coal-fired boilers and nuclear reactors are increasingly moving towards higher steam temperatures and pressures that can help in reducing emissions and increase operational efficiencies. This trend has now transitioned to adopting Advanced Ultra-Supercritical (AUSC) water technology that involves steam temperatures and pressures as high as 760 ℃ and 32 MPa. This transition poses serious material challenges, and one such is the demanding steam oxidation resistance expected of the candidate Ni-base alloys. Steam oxidation is a severe problem that can cause significant downtime in power generation. Several studies have focused on testing the steam oxidation resistance of candidate Ni-base alloys in supercritical water environments under varying test conditions. They differ from each other in terms of various operational parameters, including the time, temperature, pressure, alloy surface condition, dissolved oxygen (DO) content, steam flow/stagnancy conditions, and presence of additional oxidants like acids, salt, etc. The presence of so many such variables and the complex interplay between them makes it challenging to compare the oxidation performance of various Ni-base alloys and understand the effect of each operational parameter towards oxidation. In addition, widely differing opinions are being held about the role of several operating parameters in causing steam oxidation. This review work is an attempt to consolidate all such relevant works, critically analyze the results reported, generalize the trends observed, identify the variations among reported works and throw light on the shortcomings.

(Adapted from Gianfrancesco2).

(Reprinted with permission from7. Copyright 2012 Elsevier)

(Reprinted with permission from26. Copyright 2005 Elsevier).

(Reprinted with permission from14. Copyright 2012 Elsevier).

(Reprinted with permission from14. Copyright 2012 Elsevier).

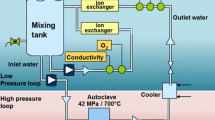

(Reprinted with permission from21. Copyright 2008 Elsevier).

(Reprinted with permission from74. Copyright 2011 Elsevier).

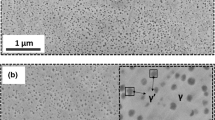

(Reprinted with permission from78. Copyright 2006 Elsevier).

(Adapted from84).

(Reprinted with permission from20. Copyright 2013 Elsevier)

(Reprinted with permission from57. Copyright 2018 Elsevier).

Similar content being viewed by others

References

BP statistical review of world energy 2021, p 70 (2021)

Di Gianfrancesco A (2017) The fossil fuel power plants technology. In: Materials for ultra-supercritical and advanced ultra-supercritical power plants, pp 1–49, (Elsevier. https://doi.org/10.1016/B978-0-08-100552-1.00001-4

Tramošljika B, Blecich P, Bonefačić I, Glažar V (2021) Advanced ultra-supercritical coal-fired power plant with post-combustion carbon capture: analysis of electricity penalty and CO2 emission reduction. Sustainability 13:1–20. https://doi.org/10.3390/su13020801

Chetal SC, Jayakumar T, Bhaduri AK (2015) Materials research and opportunities in thermal (coal-based) power sector including advanced ultra super critical power plants. Proc Indian Natl Sci Acad 81:739–754. https://doi.org/10.16943/ptinsa/2015/v81i4/48294

Nicol K (2013) Status of advanced ultra-supercritical pulverised coal technology, IEA Clean Coal Centre

Basu S, Debnath AK (2019) Advanced ultrasupercritical thermal power plant and associated auxiliaries. In: Power plant instrumentation and control handbook, Elsevier, pp 893–988. https://doi.org/10.1016/B978-0-12-819504-8.00013-5

Guzonas DA, Cook WG (2012) Cycle chemistry and its effect on materials in a supercritical water-cooled reactor: a synthesis of current understanding. Corros Sci 65:48–66. https://doi.org/10.1016/j.corsci.2012.08.006

Olive RP (2012) Pourbaix diagrams, solubility predictions and corrosion-product deposition modelling for the supercritical water-cooled reactor, (University of New Brunswick, 2012)

Kritzer P (2004) Corrosion in high-temperature and supercritical water and aqueous solutions: a review. J Supercrit Fluids 29:1–29. https://doi.org/10.1016/S0896-8446(03)00031-7

Bandura AV, Lvov SN (2005) The ionization constant of water over wide ranges of temperature and density. J Phys Chem Ref Data 35:15. https://doi.org/10.1063/1.1928231

Guo S et al (2020) Corrosion characteristics of typical Ni-Cr alloys and Ni-Cr-Mo alloys in supercritical water: a review. Ind Eng Chem Res 59:18727–18739. https://doi.org/10.1021/acs.iecr.0c04292

Wang D, Wu X, Shen J (2020) An efficient robust predictive control of main steam temperature of coal-fired power plant. Energies 2020:13. https://doi.org/10.3390/en13153775

Chai G, Forsberg U (2016) Sanicro 25: an advanced high-strength, heat-resistant austenitic stainless steel. In: An advanced high-strength, heat-resistant austenitic stainless steel, materials for ultra-supercritical and advanced ultra-supercritical power plants, (Elsevier, 2016). https://doi.org/10.1016/B978-0-08-100552-1.00012-9

Chang KH et al (2012) Corrosion behavior of Alloy 625 in supercritical water environments. Prog Nucl Energy 57:20–31. https://doi.org/10.1016/j.pnucene.2011.12.015

Chang KH, Chen SM, Yeh TK, Kai JJ (2014) Effect of dissolved oxygen content on the oxide structure of Alloy 625 in supercritical water environments at 700°C. Corros Sci 81:21–26. https://doi.org/10.1016/j.corsci.2013.11.034

Zhang Q et al (2009) Corrosion behavior of ni-base alloys in supercritical water. Nucl Eng Technol 41:107–112. https://doi.org/10.5516/NET.2009.41.1.107

Ren X, Sridharan K, Allen TR (2007) Corrosion behavior of alloys 625 and 718 in supercritical water. Corrosion 63:603–612. https://doi.org/10.5006/1.3278410

Zhang Q, Tang R, Yin K, Luo X, Zhang L (2009) Corrosion behavior of Hastelloy C-276 in supercritical water. Corros Sci 51:2092–2097. https://doi.org/10.1016/j.corsci.2009.05.041

Tan L, Allen TR, Yang Y (2011) Corrosion behavior of alloy 800H (Fe-21Cr-32Ni) in supercritical water. Corros Sci 53:703–711. https://doi.org/10.1016/j.corsci.2010.10.021

Zhong X, Han EH, Wu X (2013) Corrosion behavior of Alloy 690 in aerated supercritical water. Corros Sci 66:369–379. https://doi.org/10.1016/j.corsci.2012.10.001

Tan L, Ren X, Sridharan K, Allen TR (2008) Corrosion behavior of Ni-base alloys for advanced high temperature water-cooled nuclear plants. Corros Sci 50:3056–3062. https://doi.org/10.1016/j.corsci.2008.08.024

Smith GD, Sizek HW (2000) Introduction of an advanced superheater alloy for coal-fired boilers. Corrosion 2000:1

Patel SJ, De Barbadillo JJ, Baker BA, Gollihue RD (2013) Nickel base superalloys for next generation coal fired AUSC power plants. Procedia Eng 55:246–252. https://doi.org/10.1016/j.proeng.2013.03.250

Viswanathan R, Sarver J, Tanzosh JM (2006) Boiler materials for ultra-supercritical coal power plants—steamside oxidation. J Mater Eng Perform 15:255–274. https://doi.org/10.1361/105994906X108756

Wright IG, Dooley RB (2010) A review of the oxidation behaviour of structural alloys in steam. Int Mater Rev 55:129–167. https://doi.org/10.1179/095066010X12646898728165

Davies H, Dinsdale A (2005) Theoretical study of steam grown oxides as a function of temperature, pressure and p(O2). Mater High Temp 22:15–25. https://doi.org/10.1179/mht.2005.003

Zhu Z et al (2016) The role of dissolved oxygen in supercritical water in the oxidation of ferritic-martensitic steel. J Supercrit Fluids 108:56–60. https://doi.org/10.1016/j.supflu.2015.10.017

Tomlinson L, Cory NJ (1989) Hydrogen emission during the steam oxidation of ferritic steels: Kinetics and mechanism. Corros Sci 29:939–965. https://doi.org/10.1016/0010-938X(89)90086-3

Saunders SRJ, Monteiro M, Rizzo F (2008) The oxidation behaviour of metals and alloys at high temperatures in atmospheres containing water vapour: A review. Prog Mater Sci 53:775–837. https://doi.org/10.1016/j.pmatsci.2007.11.001

Young DJ (2016) High temperature oxidation and corrosion of metals: second edition, high temperature oxidation and corrosion of metals: second edition. https://doi.org/10.1016/C2014-0-00259-6

Asteman H, Svensson JE, Johansson LG (2002) Evidence for chromium evaporation influencing the oxidation of 304L: the effect of temperature and flow rate. Oxid Met 57:193–216. https://doi.org/10.1023/A:1014877600235

Holcomb GR (2008) Calculation of reactive-evaporation rates of chromia. Oxid Met 69:163–180. https://doi.org/10.1007/s11085-008-9091-4

Young DJ, Pint BA (2006) Chromium volatilization rates from Cr2O3 scales into flowing gases containing water vapor. Oxid Met 66:137–153. https://doi.org/10.1007/s11085-006-9030-1

Norby T (1993) Protonic defects in oxides and their possible role in high temperature oxidation. Le J Phys IV 03:99–106. https://doi.org/10.1051/jp4:1993907

Nakai M et al (2005) Correlation of high-temperature steam oxidation with hydrogen dissolution in pure iron and ternary high-chromium ferritic steel. ISIJ Int 45:1066–1072. https://doi.org/10.2355/isi**ternational.45.1066

Shen J, Zhou L, Li T (1997) High-temperature oxidation of Fe-Cr alloys in wet oxygen. Oxid Met 48:347–356. https://doi.org/10.1007/bf01670507

Essuman E et al (2007) Enhanced internal oxidation as trigger for breakaway oxidation of Fe-Cr alloys in gases containing water vapor. Scr Mater 57:845–848. https://doi.org/10.1016/j.scriptamat.2007.06.058

Sun M, Wu X, Zhang Z, Han EH (2008) Analyses of oxide films grown on Alloy 625 in oxidizing supercritical water. J Supercrit Fluids 47:309–317. https://doi.org/10.1016/j.supflu.2008.07.010

Robertson J (1989) The mechanism of high temperature aqueous corrosion of steel. Corros Sci 29:1275–1291. https://doi.org/10.1016/0010-938X(89)90120-0

Stellwag B (1998) The mechanism of oxide film formation on austenitic stainless steels in high temperature water. Corros Sci 40:337–370. https://doi.org/10.1016/S0010-938X(97)00140-6

Macdonald DD (2004) Effect of pressure on the rate of corrosion of metals in high subcritical and supercritical aqueous systems. J Supercrit Fluids 30:375–382. https://doi.org/10.1016/j.supflu.2003.09.004

Yi Y, Lee B, Kim S, Jang J (2006) Corrosion and corrosion fatigue behaviors of 9cr steel in a supercritical water condition. Mater Sci Eng A 429:161–168. https://doi.org/10.1016/j.msea.2006.05.035

Li Y et al (2016) Early oxidation of Super304H stainless steel and its scales stability in supercritical water environments. Int J Hydrogen Energy 41:15764–15771. https://doi.org/10.1016/j.ijhydene.2016.04.144

Choudhry KI, Guzonas DA, Kallikragas DT, Svishchev IM (2016) On-line monitoring of oxide formation and dissolution on alloy 800H in supercritical water. Corros Sci 111:574–582. https://doi.org/10.1016/j.corsci.2016.05.042

Tawancy HM, Tawancy HM, Ul-Hamid A, Abbas NM (2004) Practical engineering failure analysis. CRC Press, Hoboken, p 595

Birks N, Meier GH, Pettit FS (2006) Introduction to the high temperature oxidation of metals, second edition. In: Introd. to high temp. oxid. met. second Ed., pp 1–338. https://doi.org/10.1017/CBO9781139163903

Million B, Růžičková J, Vřešťál J (1985) Diffusion in Fe-Ni-Cr alloys with an FCC lattice. Mater Sci Eng 72:85–100. https://doi.org/10.1016/0025-5416(85)90069-2

Rothman SJ, Nowicki LJ, Murch GE (1980) Self-diffusion in austenitic Fe-Cr-Ni alloys. J Phys F Met Phys 10:383–398. https://doi.org/10.1088/0305-4608/10/3/009

Zhu Z et al (2021) The corrosion behavior of nickel-based alloy Inconel 740 H in supercritical water. Corros Sci 192:109848. https://doi.org/10.1016/j.corsci.2021.109848

Holcomb GR (2009) Steam oxidation and chromia evaporation in ultrasupercritical steam boilers and turbines. J Electrochem Soc 156:C292. https://doi.org/10.1149/1.3155442

Abe F, Araki H, Yoshida H, Okada M, Watanabe R (1981) The effect of grain size on the corrosion behaviour of inconel 600 in high-temperature steam. Corros Sci 21:819–842. https://doi.org/10.1016/0010-938X(81)90024-X

Abe F, Yoshida H (1985) Corrosion behaviours of heat resisting alloys in steam at 800 degree C and 40 atm pressure. Zeitschr Fuer Met Res Adv Tech 76:219–225. https://doi.org/10.1515/ijmr-1985-760311

Floreen S, Fuchs GE, Yang WJ (2012) The metallurgy of alloy. Superalloys 625:13–37. https://doi.org/10.7449/1994/SUPERALLOYS_1994_13_37

Sundararaman M, Mukhopadhyay P, Banerjee S (1997) Carbide precipitation in nickel base superalloys 718 and 625 and their effect on mechanical properties. Superalloys 718:625. https://doi.org/10.7449/1997/Superalloys_1997_367_378

Lim YS, Kim JS, Kwon HS (2005) Pitting corrosion of the laser surface melted Alloy 600. J Nucl Mater 336:65–72. https://doi.org/10.1016/j.jnucmat.2004.08.015

Was GS et al (2007) Corrosion and stress corrosion cracking in supercritical water. J Nucl Mater 371:176–201. https://doi.org/10.1016/j.jnucmat.2007.05.017

Zhong X, Wu X, Han EH (2018) Characteristics of oxidation and oxygen penetration of alloy 690 in 600 °C aerated supercritical water. J Mater Sci Technol 34:561–569. https://doi.org/10.1016/j.jmst.2016.11.001

Behnamian Y et al (2016) A comparative study of oxide scales grown on stainless steel and nickel-based superalloys in ultra-high temperature supercritical water at 800 °C. Corros Sci 106:188–207. https://doi.org/10.1016/j.corsci.2016.02.004

Chen H et al (2018) Oxidation behavior of Fe-20Cr-25Ni-Nb austenitic stainless steel in high-temperature environment with small amount of water vapor. Corros Sci 145:90–99. https://doi.org/10.1016/j.corsci.2018.09.016

Chen H, Kim SH, Kim C, Chen J, Jang C (2019) Corrosion behaviors of four stainless steels with similar chromium content in supercritical carbon dioxide environment at 650 °C. Corros Sci 156:16–31. https://doi.org/10.1016/j.corsci.2019.04.043

Litz J, Rahmel A, Schorr M (1988) Selective carbide oxidation and internal nitridation of the Ni-base superalloys IN 738 LC and IN 939 in air. Oxid Met 30:95–105. https://doi.org/10.1007/BF00656646

Holcomb GR (2014) High pressure steam oxidation of alloys for advanced ultra-supercritical conditions. Oxid Met 82:271–295. https://doi.org/10.1007/s11085-014-9491-6

Zhang NQ, Zhu ZL, Zhang Q, Li BR, Xu H (2013) Corrosion of TP347HFG in supercritical water with different dissolved oxygen content. Adv Sci Lett 19:2440–2443. https://doi.org/10.1166/ASL.2013.4897

Zhang N, Xu H, Li B, Bai Y, Liu D (2012) Influence of the dissolved oxygen content on corrosion of the ferritic—martensitic steel P92 in supercritical water. Corros Sci 56:123–128. https://doi.org/10.1016/j.corsci.2011.11.013

Was GS, Allen TR (2005) Time, temperature, and dissolved oxygen dependence of oxidation of austenitic and ferritic-martensitic alloys in supercritical water. Proc Am Nucl Soc Int Congress Adv Nucl Power Plants 6:3460–3483

Xu H, Zhu ZL, Zhang NQ (2014) Oxidation of ferritic steel T24 in supercritical water. Oxid Met 82:21–31. https://doi.org/10.1007/s11085-014-9474-7

Ampornrat P, Was GS (2007) Oxidation of ferritic-martensitic alloys T91, HCM12A and HT-9 in supercritical water. J Nucl Mater 371:1–17. https://doi.org/10.1016/j.jnucmat.2007.05.023

Guzonas D et al (2010) Steel corrosion in supercritical water: an assessment of the key parameters

Sanchez RG, Huang X, Liu P (2018) Effect of water density/pressure on the corrosion behavior of 304 and 310 stainless steels. Oxid Met 89:165–182. https://doi.org/10.1007/s11085-017-9812-7

Gómez-Briceño D, Blázquez F, Sáez-Maderuelo A (2013) Oxidation of austenitic and ferritic/martensitic alloys in supercritical water. J Supercrit Fluids 78:103–113. https://doi.org/10.1016/j.supflu.2013.03.014

Shi H et al (2018) Corrosion behavior of alloy C-276 in supercritical water. Adv Mater Sci Eng 2018:5. https://doi.org/10.1155/2018/1027640

Rodriguez D, Merwin A, Karmiol Z, Chidambaram D (2017) Surface chemistry and corrosion behavior of Inconel 625 and 718 in subcritical, supercritical, and ultrasupercritical water. Appl Surf Sci 404:443–451. https://doi.org/10.1016/j.apsusc.2017.01.119

Fulger M, Ohai D, Mihalache M, Pantiru M, Malinovschi V (2009) Oxidation behavior of Incoloy 800 under simulated supercritical water conditions. J Nucl Mater 385:288–293. https://doi.org/10.1016/j.jnucmat.2008.12.004

Fulger M, Mihalache M, Ohai D, Fulger S, Valeca SC (2011) Analyses of oxide films grown on AISI 304L stainless steel and Incoloy 800HT exposed to supercritical water environment. J Nucl Mater 415:147–157. https://doi.org/10.1016/j.jnucmat.2011.05.007

Zhang N, Zhu Z, Cao Q, Gui J, Xu H (2018) Influence of temperature on the oxidation behavior of an austenitic steel in deaerated supercritical water. Mater Corros 69:319–327. https://doi.org/10.1002/maco.201709705

Bsat S, **ao B, Huang X, Penttila S (2017) Oxidation behaviour of alloys 800H, 3033 and 304 in high-temperature supercritical water. Oxid Metal 89:2. https://doi.org/10.1007/s11085-017-9784-7

Yuan J, Wu X, Wang W, Zhu S, Wang F (2013) The effect of surface finish on the scaling behavior of stainless steel in steam and supercritical water. Oxid Met 79:541–551. https://doi.org/10.1007/S11085-013-9380-4

Tan L, Sridharan K, Allen TR (2006) The effect of grain boundary engineering on the oxidation behavior of INCOLOY alloy 800H in supercritical water. J Nucl Mater 348:263–271. https://doi.org/10.1016/j.jnucmat.2005.09.023

Tan L, Ren X, Sridharan K, Allen TR (2008) Effect of shot-peening on the oxidation of alloy 800H exposed to supercritical water and cyclic oxidation. Corros Sci 50:2040–2046. https://doi.org/10.1016/j.corsci.2008.04.008

Goncharov OY (2004) Thermodynamic assessment of high-temperature oxidation of Fe-Cr alloys in air. Inorg Mater 40:1295–1300. https://doi.org/10.1007/s10789-005-0087-z

Tan L, Sridharan K, Allen TR, Nanstad RK, McClintock DA (2008) Microstructure tailoring for property improvements by grain boundary engineering. J Nucl Mater 374:270–280. https://doi.org/10.1016/J.JNUCMAT.2007.08.015

Mudang M, Hamzah E, Bakhsheshi-rad HR, Berto F (2021) Applied sciences effect of heat treatment on microstructure and creep behavior of Fe-40Ni-24Cr alloy. Appl Sci 11:7951

Penttilä S, Toivonen A, Li J, Zheng W, Novotny R (2013) Effect of surface modification on the corrosion resistance of austenitic stainless steel 316L in supercritical water conditions. J Supercrit Fluids 81:157–163. https://doi.org/10.1016/J.SUPFLU.2013.05.002

Xu P, Zhao LY, Sridharan K, Allen TR (2012) Oxidation behavior of grain boundary engineered alloy 690 in supercritical water environment. J Nucl Mater 422:143–151. https://doi.org/10.1016/j.jnucmat.2011.12.022

Machet A et al (2004) XPS and STM study of the growth and structure of passive films in high temperature water on a nickel-base alloy. Electrochim Acta 49:3957–3964. https://doi.org/10.1016/J.ELECTACTA.2004.04.032

Yang J, Wang S, Xu D (2020) High temperature oxidation of alloy 617, 740, HR6W and Sanicro 25 in supercritical water at 650 ° C. Corros Eng Sci Technol 2020:1–9. https://doi.org/10.1080/1478422X.2019.1710665

Choudhry KI, Mahboubi S, Botton GA, Kish JR, Svishchev IM (2015) Corrosion of engineering materials in a supercritical water cooled reactor: characterization of oxide scales on Alloy 800H and stainless steel 316. Corros Sci 100:222–230. https://doi.org/10.1016/j.corsci.2015.07.035

Acknowledgements

This work is supported by (a) Mission Directorate, Advanced Ultra Super Critical Project, Government of India and collaborated and administered by IGCAR, Kalpakkam and (b) National Clean Coal Research and Development, Department of Science and Technology, Government of India and collaborated by Indian Institute of Science, Bangalore. The authors thank Dr. S. Ningshen and Dr. Shaju K. Albert, IGCAR, Kalpakkam and Prof. K. Chattopadhyay, Indian Institute of Science, Bangalore for their support in carrying out these projects.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author declares that there are no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghule, B., Sundaresan, C., Vijayshankar, D. et al. Oxidation Behaviour of Ni-Base Superalloys in Supercritical Water: A Review. J Indian Inst Sci 102, 351–389 (2022). https://doi.org/10.1007/s41745-022-00289-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41745-022-00289-x