Abstract

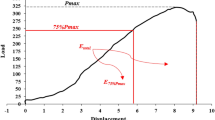

High-rise buildings, bridges, pile foundations, and offshore structures comprise deep beams as an important structural component for transferring heavy loads. The modern era of construction demands speedy construction which led to the need for a change in reinforcement system known as a prefabricated cage system (PFCS). This study focuses on the application of PCS in deep beam construction using self-compacting concrete (SCC). The experimental investigation has been carried out by testing twelve deep beams, out of which two deep beams have been constructed with conventional reinforcement and ten deep beams have been constructed with prefabricated cages. The experimental behaviour of deep beams has been examined with different web reinforcement configurations and shear–span to depth ratios of 0.5, 0.75, and 1. The findings showed that as the a/D ratio rises, the failure mode shifts to flexural shear. Prefabricated cage-reinforced deep beams, incorporating both vertical and horizontal web reinforcement, have demonstrated higher ultimate strength ranging from 7.1% to 10.6% compared to conventional deep beams. A reserve strength factor of 0.45 indicates good reserve strength efficiency. Moreover, an increasing trend in displacement ductility and a decreasing trend in energy absorption capacity have been observed with the increase in the a/D ratio. The energy absorption capacity of PCS-reinforced deep beams has been observed to be in the range of 20.11% to 33.38% higher than conventional ones. The proposed equation for predicting the ultimate strength of prefabricated cage-reinforced deep beams is conservative, while the ACI 318–2019 equation slightly overestimates the ultimate strength. Thus, PCS represents an efficient construction method for deep beams, offering both commendable ultimate strength and ductility.

Similar content being viewed by others

Abbreviations

- Ast :

-

Area of longitudinal steel reinforcement

- Ap :

-

Area of CFS plate

- fy :

-

Yield strength of steel reinforcement

- fyp :

-

Yield strength of CFS plate

- Asv :

-

Area of vertical web reinforcement

- Ash :

-

Area of horizontal web reinforcement

- VH:

-

Vertical and Horizontal web reinforcement

- V:

-

Vertical-only web reinforcement

- H:

-

Horizontal-only web reinforcement

- D:

-

Overall depth

- d:

-

Effective depth

- fcu :

-

Cube compressive strength of concrete

- fc’:

-

Cylinder compressive strength of concrete

- µ∆ :

-

Displacement ductility factor

- µE :

-

Energy ductility index

- Vu :

-

Ultimate strength

- Vc :

-

Shear contribution of concrete

- Vs :

-

Shear contribution of steel

- Vu exp :

-

Experimental ultimate strength

- Vu pred :

-

Predicted ultimate strength based on the proposed equation

- Vu ACI :

-

Predicted ultimate strength based on ACI 318-2019 STM

- CFS:

-

Cold Formed Steel

- ACI:

-

American Concrete Institute

- PFCS:

-

Prefabricated Cage System

- SCC:

-

Self-Compacting Concrete

- GGBS:

-

Ground Granulated Blast furnace Slag

- EFNARC:

-

European Federation of National Associations Representing for concrete

- PCRDB:

-

Prefabricated Cage Reinforced self-compacting concrete Deep Beams

- CRDB:

-

Conventionally Reinforced self-compacting concrete Deep Beams

- LVDT:

-

Linear Variable Displacement Transducers

- ERS:

-

Electrical Resistance strain gauges

References

Abed F, El-Chabib H, Alhamaydeh M (2012) Shear characteristics of GFRP-reinforced concrete deep beams without web reinforcement. J Reinf Plast Compos 31:1063–1073. https://doi.org/10.1177/0731684412450350

ACI committee 318 (2019) Building code requirements for structural concrete (318–19) and commentary (318R-19)

ACI-ASCE Committee 426 (1973) Shear strength of reinforced concrete members. J Struct Div 6: 1091–1187

Al-Abbasi Q, Hannon HK (2023) Enhancing the structural performance of the reinforced precast concrete hybrid deep beams based on tied-arch action. J Build Pathol Rehabilit 9:18. https://doi.org/10.1007/s41024-023-00370-7

Alhamad S, Al Banna Y, Al Osman A, Mouthassseeb J, Abdalla S, Abed F (2017) Effect of shear span-to-depth ratio on the shear behaviour of BFRP-RC deep beams. MATEC Web Conf 120:1–7. https://doi.org/10.1051/matecconf/201712001012

Alsayaed SH, Alhozaimy AM (1999) Ductility of Concrete Beams reinforced with FRP bars and Steel fibres. J Compos Mater 33:1792–1806

Andermatt MF, Lubell AS (2013) Behaviour of concrete deep beams reinforced with internal fiber-reinforced polymer—experimental study. Int J Civil Eng Technol 110:585–594

Ashour AF (2000) Shear capacity of reinforced concrete deep beams. J Struct Eng 126:1045–1052. https://doi.org/10.1061/(ASCE)0733-9445(2000)126:9(1045)

Chithra R, Thenmozhi R, Haresh M (2013) Bending behaviour, deformability and strength analysis of Prefabricated Cage Reinforced Composite beams. Constr Build Mater 38:482–490. https://doi.org/10.1016/j.conbuildmat.2012.08.017

Collins MP, Bentz EC, Sherwood EG, Wight JK (2009) Where is shear reinforcement required? review of research results and design procedures. ACI Struct J 106:556

EFNARC (2005) The European guidelines for self-compacting concrete: specification, production and use.

El-Sayed AK, Shuraim AB (2016) Size effect on shear resistance of high strength concrete deep beams. Mater Struct 49:1871–1882. https://doi.org/10.1617/s11527-015-0619-1

Farghaly AS, Benmokrane B (2013) Shear behaviour of FRP-reinforced concrete deep beams without web reinforcement. J Compos Constr 17:1–10. https://doi.org/10.1061/(asce)cc.1943-5614.0000385

Garay-Moran JDD, Lubell AS (2016) Behaviour of deep beams containing high-Strength longitudinal reinforcement. ACI Struct J 113:17–28

Hason MM, Hanoon AN, Saleem SJ, Hejazi F, Al Zand W (2021) Characteristics of experimental ductility energy index of hybrid-CFRP RC deep beams. SN Appl Sci. https://doi.org/10.1007/s42452-021-04202-6

Hwang SJ, Lu WY, Lee HJ (2000) Shear strength prediction for deep beams. ACI Struct J 97:367–376

IS 10262 (2019) Concrete mix proportioning - Guidelines. Bureau of Indian Standards, New Delhi, India

IS 12269 (2013) Ordinary Portland Cement, 53 grade-specification. Bureau of Indian Standards, New Delhi, India

IS 1608 (2005) Metallic Materials - Tensile Testing At Ambient Temperature. Bureau of Indian Standards, New Delhi, India.

Kong FK (2002) Reinforced Concrete Deep Beams. Taylor & Francis Books, Inc., New York

Kong FK, Robins PJ, Singh A, Sharp GR (1972) Shear Analysis and Design of Reinforced Concrete Deep Beams. Struct Eng 50:405–409

Leonhardt F (1966) Discussion on Strength and behaviour of deep beams in shear. J Stuct Div ASCE

Lim WY, Hong SG (2016) Shear tests for ultra-high performance fiber reinforced concrete (UHPFRC) beams with shear reinforcement. Int J Concrete Struct Mater 10:177–188. https://doi.org/10.1007/s40069-016-0145-8

Londhe RS (2011) Shear strength analysis and prediction of reinforced concrete transfer beams in high-rise buildings. Struct Eng Mech 37:39–59

Lu WY, Lin J, Yu HW (2013) Shear strength of reinforced concrete deep beams. ACI Struct J 110:671

Macgregor JG, Wight JK (2009) Reinforced concrete mechanic and design. Pearson Education Inc, New Jersey, p 07458

Mau ST, Hsu TTC (1989) Formula for the shear strength of deep beams. ACI Struct J 86:516–523

Mihaylov BI, Bentz EC, Collins MP (2010) Behaviour of large deep beams subjected to monotonic and reversed cyclic shear. ACI Struct J 107:726–734

Mohamed K, Farghaly AS, Benmokrane B (2017) Effect of vertical and horizontal web reinforcement on the strength and deformation of concrete deep beams reinforced with GFRP bars. J Struct Eng 143:04017079. https://doi.org/10.1061/(asce)st.1943-541x.0001786

Mohammad M, Jumaat MZ, Bin CM, Ghasemi A, Hakim SJS, Najmeh R (2011) An experimental investigation of the stress-strain distribution in high strength concrete deep beams. Procedia Eng 14:2141–2150. https://doi.org/10.1016/j.proeng.2011.07.269

Nassif MK, Erfan AM, Fadel OT, El-sayed TA (2021) Flexural behaviour of high strength concrete deep beams reinforced with GFRP bars. Case Stud Constr Mater 15:e00613. https://doi.org/10.1016/j.cscm.2021.e00613

Odaa SA, Hason MM, Sharba AAK (2021) Self-compacting concrete beams reinforced with steel fiber under flexural loads: a ductility index evaluation. Mater Today Proc 42:2259–2267. https://doi.org/10.1016/j.matpr.2020.12.313

Schlaich J, Schiifer K (1991) Design and detailing of structural concrete using strut and tie models. Struct Eng 69:113–125

Shakir QM, Alghazali AF (2023) New model of eco-friendly hybrid deep beams with wastes of crushed concrete. Jurnal Teknologi 85:145–154

Shakir QM, Alghazali AF (2024) Effect of the arching action on the behaviour of the RC precast concrete deep beams: comparison between several hybrid models. J Build Pathol Rehabil 9:23

Shakir QM, Hannon HK (2023) A novel hybrid model of reinforced concrete deep beams with curved hybridization. Jurnal Teknologi 85:31–39

Shakir QM, Hannon HK (2024) Innovative model of precast RC curved hybrid deep beams composed partially with high-performance concrete. Arab J Sci Eng 49:6045–6060. https://doi.org/10.1007/s13369-023-08592-0

Shakir QM, Hanoon HK (2023) Behaviour of high-performance reinforced arched hybrid self-compacting concrete deep beams. J Eng Sci Technol 18:792–813

Shamsai M, Sezen H (2005) Fast and easy concrete construction using innovative steel reinforcement. In: Construction Research Congress 2005: Broadening Perspectives - Proceedings of the Congress, pp 635–644. https://doi.org/10.1061/40754(183)63

Shoeib AEK, Arafa ANM, El Rady RAEHA, Tawhed WMF (2022) Experimental and analytical study on the behaviour of hybrid GFRP/steel bars in reinforced concrete deep beams. Curved Layered Struct 9:124–145. https://doi.org/10.1515/cls-2022-0012

Siao WB (1995) Deep beams revisited. ACI Struct J 92:95–102

Smith KN, Vantsiotis AS (1982) Shear strength of deep beams. J Amer Concr Instit 79:201–213

Spadea G, Swamy RN, Bencardino F (2001) Strength and ductility of RC beams repaired with bonded CFRP laminates. J Bridg Eng 6:349–355

Spadea G, Bencardino F, Swamy RN (1997) Strengthening and upgrading structures with bonded CFRP sheets: design aspects for structural integrity. In: Proceedings of the third International Symposium on Non-Metallic (FRP) Reinforcement for Concrete Structures, pp 629–636

Tan KH, Cheng GH (2006) Size effect on shear strength of deep beams: investigating with Strut-and-Tie model. J Struct Eng 132:673–685. https://doi.org/10.1061/(asce)0733-9445(2006)132:5(673)

Tan KH, Lu HY (1999) Shear behaviour of large reinforced concrete deep beams and code comparisons. ACI Struct J 96:836–845

Tasenhod P, Teerawong J (2014) Shear strength prediction of reinforced concrete deep beams using strut-and-tie model. Adv Mater Res 931–932:468–472. https://doi.org/10.4028/www.scientific.net/AMR.931-932:468-472

Thomas J, Ramadass S (2021) Prediction of the load and deflection response of concrete deep beams reinforced with FRP bars. Mech Adv Mater Struct 28:43–66. https://doi.org/10.1080/15376494.2018.1549292

Tuchscherer R, Birrcher D, Huizinga M, Bayrak O (2011) Distribution of stirrups across web of deep beams. ACI Struct J 108:779–781

Wu T, Wei H, Liu X (2018) Experimental investigation of shear models for lightweight aggregate concrete deep beams. Adv Struct Eng 21:109–124. https://doi.org/10.1177/1369433217711618

Wu T, Wei H, Liu X (2020) Shear behaviour of large-scale deep beams with lightweight-aggregate concrete. ACI Struct J 117:75–89

Yang KH, Chung HS, Lee ET, Eun HC (2003) Shear characteristics of high-strength concrete deep beams without shear reinforcements. Eng Struct 25:1343–1352. https://doi.org/10.1016/S0141-0296(03)00110-X

Zhang JH, Li SS, **e W, Guo YD (2020) Experimental study on shear capacity of high strength reinforcement concrete deep beams with small shear span-depth ratio. Materials 13:1218. https://doi.org/10.3390/ma13051218

Acknowledgements

The authors are thankful to the management of the Government College of Technology, Coimbatore and Department of Structural Engineering, Government of Technology, Coimbatore for providing the Structural Engineering Laboratory facilities for carrying out this research work.

Author information

Authors and Affiliations

Contributions

K.V: Conceptualization, Investigation, Methodology, Testing, Validation, Writing – Original draft. R.C: Conceptualization, Supervision, Writing - Review & Editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Therefore, on behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethical approval

Our article does not contain any studies with human participants.

Consent to publish

The author declares their consent to publish the article in the Iranian Journal of Science and Technology, Transactions of Civil Engineering.

Appendices

Appendix

Solved Numerical Example for Predicting Ultimate Strength Using The Proposed Model for the Specimen I-PCR-0.5-VH2

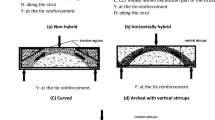

The details of reinforcement and the method to calculate ‘y’ is shown in Fig.

The predicted shear strength equation for prefabricated cage-reinforced deep beams using the proposed model is given below

Referring to Table 5

A1 = Area of longitudinal reinforcement = 600 mm2, A2 = A3 = Area of horizontal web reinforcement = 272 mm2, A4 = Area of compression reinforcement = 216 mm2, A5 = Area of vertical web reinforcement = 136 mm.2

By measurement from the drawing in Fig. 26

y1 = 454.5 mm; y2 = 301 mm; y3 = 159 mm; y4 = mm; y5 = 280 mm

2.1 A. 2 Solved Numerical Example for Predicting Ultimate Strength using ACI 318-2019 Shear Strength Equation for the Specimen I-PCR-0.5-VH2

Figure

27 represents the idealized STM model for the Specimen I-PCR-0.5-VH2.

a = 250 mm; D = 500 mm; Fu = 356 kN; f’c = 38.76 N/mm2;

2.1.1 Calculation of jd

As shown in Fig. 27, By equating forces in strut and tie, Fu BC = Fu AD, we get \(w_{t}\) = 1.25 \(w_{t}{\prime}\) (or) \({\text{w}}_{{\text{t}}}{\prime} = 0.8 {\text{w}}_{{\text{t}}}\).

From Fig. 27, jd = \(D - 1.125w_{t}{\prime}\).

At node B,

where \({\upbeta }_{{\text{s }}}\) = 1 (C–C-C node) and ϕ is the strength reduction factor = 0.75.

From Fig.

28, By taking moment about equilibrium at point A

Solving this equation, \(w_{t}{\prime}\) = 64.89 mm and \(w_{t}\) = 81.11 mm.

2.1.2 Calculation of \({{\varvec{\uptheta}}}\).

From the Values of jd, the value of \({\uptheta }\) is obtained as

2.1.3 Calculation of width of strut

2.1.4 Calculation of Vu ACI

To calculate the shear load in the strut model AB, the node B is considered and by applying the hydrostatic condition the actual load taken by the strut AB is calculated. Consider the Fig.

29 in which the forces acting on the node B has been shown along with the dimensional details on the node and strut AB.

The load acting on the strut AB is 478.85 kN. FAB is acting on the face q-s’, which is used to find the stress on q-s

Also, qs’ = lpl Sin θ + wt’ Cos θ = 130 * sin 59.65 + 64.89 * cos 59.65 = 144.97 mm.

By knowing qs and qs’, from triangle qss’, cos α’ = 144.97 / 145.29.

α’ = 3˚49’.

Strength of strut, Fns = FAB = 478.85 kN.

F’AB = FAB cos α’ = 478.85 * cos 3° 49’ = 477.78 kN.

Since the forces on all faces of the node should be equal, equating the stress in the face q-s and q-r.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vedhasakthi, K., Chithra, R. A Proposed Model and Performance Study on Prefabricated Cage-Reinforced Self-compacting Concrete Deep Beams. Iran J Sci Technol Trans Civ Eng (2024). https://doi.org/10.1007/s40996-024-01440-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40996-024-01440-7