Highlights

-

A facile and generalized design strategy of polymer precursor inks was developed for direct ink writing of metal oxide into submicron 3D architectures.

-

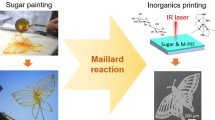

The Maillard reaction between polyethyleneimine and glucose endows the 3D-printed precursors with the excellent shape fidelity during high-temperature pyrolysis.

-

As-printed 3D periodic dielectric structure with woodpile geometry shows a significant light-matter effect in mid-infrared region.

Abstract

Three-dimensional-structured metal oxides have myriad applications for optoelectronic devices. Comparing to conventional lithography-based manufacturing methods which face significant challenges for 3D device architectures, additive manufacturing approaches such as direct ink writing offer convenient, on-demand manufacturing of 3D oxides with high resolutions down to sub-micrometer scales. However, the lack of a universal ink design strategy greatly limits the choices of printable oxides. Here, a universal, facile synthetic strategy is developed for direct ink writable polymer precursor inks based on metal-polymer coordination effect. Specifically, polyethyleneimine functionalized by ethylenediaminetetraacetic acid is employed as the polymer matrix for adsorbing targeted metal ions. Next, glucose is introduced as a crosslinker for endowing the polymer precursor inks with a thermosetting property required for 3D printing via the Maillard reaction. For demonstrations, binary (i.e., ZnO, CuO, In2O3, Ga2O3, TiO2, and Y2O3) and ternary metal oxides (i.e., BaTiO3 and SrTiO3) are printed into 3D architectures with sub-micrometer resolution by extruding the inks through ultrafine nozzles. Upon thermal crosslinking and pyrolysis, the 3D microarchitectures with woodpile geometries exhibit strong light-matter coupling in the mid-infrared region. The design strategy for printable inks opens a new pathway toward 3D-printed optoelectronic devices based on functional oxides.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Metal oxides represent an important class of materials for the electronics industry [1, 2], owing to their diverse properties such as piezoelectricity [3], superconductivity [4], ferromagnetism [5] and electrochemical activity [6]. Patterning metal oxide into micro/nanometer-scale 2D and 3D architectures are significant not only for improving device performance [7,41,42,43]. On the other hand, the more concentrated inks result nozzle clogging due to the solvent evaporation (Fig. S2, Clogging). The storage moduli (G′) are always lower than loss moduli (G″) with an increasing PEI/EDTA concentration (Fig. 2b), implying that the inks exhibit a liquid-like response and are not able to form self-supportive spanning features required for 3D printing (Fig. 2c). To further understand the ink solidification mechanisms, oscillatory rheology measurements are conducted for 51.9 wt% ink (Fig. 2d). As solvent evaporates in dry environment (relative humidity, RH ~ 35%), the inks gradually exhibit a solid-like behavior (G′ > G″). When exposed to humid air (RH ~ 60%), the inks returned to show a liquid-like behavior (G′ < G″). This humidity-dependent viscoelastic response is ideal for DIW, allowing rapid ink solidification upon printing. This gelation process is dominated by the chain entanglement of PEI polymers and the electrostatic attraction between EDTA and PEI (Fig. 1c, c-1). Notably, the printed microscale filaments have a much higher specific surface area than the bulk material, resulting in an accelerated solvent loss of the printed filaments. In fact, the printability tests reveal that the physical gelation of the printed filaments could occur in an environment with a relative humidity of 35 ~ 40%.

Rheological properties of 3D printable polymer inks: a Ink viscosity at a shear rate of 100 s−1 as a function of total concentration of PEI and EDTA (PEI: EDTA = 1:1, by weight). Inset shows viscosity as a function of shear rate for polymer inks of varying PEI/EDTA concentration. b Storage and loss moduli as a function of shear amplitude for polymer inks of varying PEI/EDTA concentration. c Optical image of inks extruded through a 2 µm glass nozzle as spanning filaments on a substrate composed of parallel rectangular silicon ribbons. d Storage and loss moduli as a function of time for inks with 51.9 wt% of PEI/EDTA concentration upon exposure to different humidity environment (oscillatory frequency = 1 Hz, stress amplitude = 10 Pa). The drying-induced gelation occurs in the moment of ink extrusion and endows PEI/EDTA inks with shape-retaining property

3.2 Thermal Crosslinking Mechanism

The structural integrity of the printed samples upon pyrolysis depends strongly on the thermosetting behaviors of the polymer precursors which effectively prevent the 3D structures from softening or collapsing during the organic-to-inorganic transformation [45]. For the precursor inks without glucose, with an increasing temperature, their storage moduli move closer to their loss moduli. However, an abrupt drop in both storage and loss moduli occurs at ~ 105 °C (Fig. S3a), corresponding to the collapsing and spreading of the 3D-printed structures in a process similar to melting (Fig. 3a, bottom right). One possible reason for this phenomenon is the chain scission during thermal degradation of PEI, which involves the activation of carbon–carbon bond by an initially formed hydroperoxide and then breaks into two formamide groups (Fig. 3b, bottom) [46]. The resulting polymers with shorter chains exhibit lower storage moduli than loss moduli which fail to withstand structure fidelity at ~ 105 °C. To overcome such abrupt phase change in printed 3D structures, high-density and permanent covalent cross-links are required. Thanks to the presence of amino groups in PEI polymers, we conduct the Maillard reaction for crosslinking PEI polymers by adding a certain amount of glucose. Many reports in food chemistry have demonstrated that Maillard reaction is a sophisticated polymerization reaction with three main stages [47] (Fig. 3b, top): (i) condensation, (ii) Amadori rearrangement, (iii) browning. Among them, the known mechanism of the initial stage in Maillard reaction involves the condensation between an amino group of a nitrogenous compound and a carbonyl group of reducing sugar. The rheological measurements show that the addition of glucose to precursor inks leads to the crossover point of storage and loss moduli occurring at ~ 95 °C, indicating the formation of crosslinked networks (Fig. S3b-h). However, when glucose/PEI ratios are less than 0.3, a significant drop in these inks moduli still occurs above 105 °C (Fig. S3b–e). Increasing the glucose-to-PEI weight ratio to 0.3 ensures that the derivative of the storage modulus with respect to temperatures remains positive at all temperature points (Fig. 3a). As the temperature increases from 95 to 110 °C, the storage modulus increases by three orders of magnitude continuously (Fig. S3f–h), and the 3D-structured polymer precursor still exhibits the excellent shape-retaining ability (Fig. 3a, upper left). It implies that sufficient crosslinking density were required for preventing the structure collapse due to polymer chain scission.

Thermal crosslinking mechanisms of the polymer precursors with glucose: a Derivative of the storage modulus with respect to temperature at ~ 105 °C as a function of glucose-to-PEI weight ratio. Inset images show the morphologies of 3D polymer precursors after heating to 200 °C with adequate (upper left) and inadequate (bottom right) glucose contents. b Illustration highlights two chemical reaction routes possibly in thermal crosslinking of polymer inks. The blue arrow indicates that polyethyleneimine (PEI) undergoes Maillard reaction with glucose to form a dark brown and robust resin, i.e., advanced glycation end products (AGEs). The red arrow reveals the “melting” and softening phenomenon possibly attributed to chain scission during PEI degradation. c Transmittance change of 380 nm light with temperature increasing from 30 to 120 °C. Inset shows the UV–vis transmittance spectra for precursor films on glass substrates after heating to different temperatures for 1 h. d N 1s XPS spectra of PEI/glucose mixture after heating to 30, 80 and 100 °C for 1 h. The dotted lines are the raw data. After deconvolution using Gauss–Lorentz curves, the blue, green, and red curves represent primary, secondary, and tertiary amino or amide groups centered at 399.16, 398.63, and 399.83 eV, respectively. e In situ ATR-FTIR spectra obtained from the same freeze-dried PEI/glucose mixture samples, heated at 30, 80, and 100 °C for 5 min. (Color figure online)

Meanwhile, we next employed a suite of spectroscopic techniques to characterize the Maillard reaction in PEI/glucose mixtures. The color of PEI/glucose film changes from colorless to dark brown as a proof of the nonenzymatic browning processing (Fig. 3c), which is an important characteristic of Maillard reaction [48, 49]. These resulting dark brown polymeric aggregates known as advanced glycation end products (AGEs) are mainly formed from further crosslinking between Amadori compounds and adjacent amino groups and they exhibit thermosetting property (Fig. 1c, c-2) [47]. We next investigated the changes in the functional groups on PEI after thermal crosslinking by X-ray photoelectron spectroscopy (Fig. 3d). N1s signals of all samples can be deconvoluted into three peaks at the binding energies of 399.16, 398.63 and 399.83 eV, corresponding to primary, secondary, and tertiary amino groups or amide groups, respectively [50,51,52,53]. The shift to higher binding energy of the original N1s peak implies that a large number of primary and secondary amino groups are converted into tertiary amino and amide groups during the Maillard reaction. We also obtained FT-IR spectra on the PEI/glucose films which are heated to 30, 80 and 100 °C using an attenuated total reflectance (ATR) module (Fig. 3e and Table S1). A broadening of peak in the range of 1260–1400 cm−1 (green) is a result of the increasing number of –CH groups (1347 cm−1), possibly attributed to the graft of glucose chains on PEI polymer. Meanwhile, the disappearance of the peak at 1576 cm−1 (blue) demonstrates that –NH groups participate in the reaction with glucose. Notably, the characteristic peaks of –NH2 and –C=N groups overlap with each other. Since –NH2 groups are consumed to form tertiary amino and amide groups, the increase in the intensity of the peak at 1654 cm−1 suggests the appearance of Schiff base (–C=N groups).

3.3 DIW of Metal Oxides

For the design of direct ink writable metal oxide polymer precursor inks, sufficient targeted metal ions should be coordinated in the crosslinked polymer networks to avoid fragmentation of the printed structures after pyrolysis [36]. Therefore, we evaluate the adsorption effect of polymers on metal ions for maximizing the amount of zinc ions in polymer precursor inks after ultrafiltration (Fig. 4a). In an alkaline environment, only non-protonated PEI polymers can produce the lone-pair electrons on the nitrogen atoms and directly coordinate with certain metal cations, such as Zn2+, Cu2+, Ba2+, and Sr2+ for the formation of homogeneous and transparent complex solutions (Fig. S4a, b, g, h). However, the alkaline environment not only causes the highly reactive metal ions (such as In3+, Ga3+, Ti4+, and Y3+) to hydrolyze and precipitate (Fig. S4c–f), but also triggers the nucleophilic attack by non-protonated amino group on the carbonyl group of the glucose to form chemically crosslinked gels even at room temperature [54], resulting in significantly increased ink viscosities and moduli (Figs. 4b and S5). These problems can be solved by introducing EDTA to chelate with metal ions. Different from PEI/Zn2+, the metal-EDTA complexes with negative charges are bound to the protonated PEI electrostatically (Figs. 1a and S4). The maximum retention of Zn2+ ions appears in a pH 4 environment where both amine groups of PEI polymers and partial carboxyl groups of EDTA are ionized [55, 56]. At room temperature, the rheological properties of PEI/EDTA-Zn2+ precursor ink remain stable in a long period of 15 days (Fig. 4b). Based on this composition design in pH 4 solution, the optimal molar ratio of Zn2+ to EDTA is determined as 1:1 for achieving the maximal adsorption of PEI to Zn2+ after ultrafiltration (Fig. S6). Besides, the cross-sectional morphologies shows that the saturated adsorption of PEI to Zn2+ endows extruded ink filaments with rod-like structures after pyrolysis at 650 °C (Fig. S7). The organic-to-inorganic transformation for the polymer precursor is strongly dependent on pyrolysis temperature, which undergoes three typical stages as indicated by TGA–DSC profiles (Fig. 4c). First, the solvent evaporation results in an endothermic peak at 117 °C. Next, a rapid weight loss occurs along with an exothermic reaction at ~ 295 °C which is due to the degradation of oxygen-containing groups (Fig. S8). Finally, as the temperature increases further to 630 °C, the organic compositions are eliminated in a relatively long exothermic process. X-ray diffraction patterns reveal that the pyrolyzed products are identified as ZnO phase with an onset crystallization temperature of ~ 450 °C (Fig. 4d).

3D printing of ZnO architectures: a The adsorbed Zn2+ ions content of purified precursor inks (blue: PEI/EDTA-Zn2+, red: PEI/Zn2+) with varying pH values, measured by ICP-MS analysis. b The effect of pH value on long-term rheological stability demonstrated by the viscosity (shear rate = 1 s−1) and the ratio of G′ to G″ (in the linear viscoelastic range) of inks stored in ambient environment for 0, 10 and 15 days. c Thermogravimetry and differential scanning calorimetry (TG-DSC) curves of zinc-containing ink. d X-ray patterns obtained from samples of crosslinked zinc-containing inks sintered at different temperatures ranging from 400 to 700 °C for 1 h. e SEM images of spanning structure, 1D array, and 2D mesh (patterned with a 2-µm nozzle) after sintering the zinc-containing ink at 650 °C for 1 h. f A 32-layers polymer precursor woodpile (left) printed with a 2-µm nozzle was converted to the ZnO structure (right) upon sintering at 650 °C for 1 h. g High-magnification surface morphologies of 3D-structured ZnO. h Element distribution and the corresponding EDS spectrum of as-fabricated ZnO woodpile. i Low-magnification TEM image of printed ZnO structure and an electron diffraction pattern (inset). j Grain size distribution of 100 particles measured from the dark and bright field TEM images (Fig. S11). (Color figure online)

To demonstrate the high-resolution printing of metal oxide structures achievable with this method, we printed 1D planar array and 2D planar mesh composed of ZnO filaments by extruding polymer precursor inks through a capillary nozzle with a 2 µm inner diameter (Fig. 4e, top). Upon pyrolysis at 700 °C, polymer decomposition results in a reduction of filament width down to ~ 550 nm while the grain growth induces the appearance of nanopores at the grain interface (Fig. S9). Interestingly, the spanning structures of ZnO filaments printed on Si microribbons still maintain their structural fidelity upon pyrolysis (Fig. 4e, bottom). We next printed complex 3D architectures, such as 150-layer cylinder, 100-layer pyramid and 32-layer woodpile, which are composed of parallel arrays of orthogonally stacked filaments (Figs. S10 and 4f). The first layer of the structure is printed on substrates pre-coated with a sacrificial organic layer to mitigate anisotropic shrinkage of the underlying structure. During the pyrolysis process at 650 °C, the 32-layer woodpile undergoes isotropic shrinkage with the overall lateral dimensions change from 437 to 150 µm (Fig. 4f), yet it still retains its initial geometry with final microfilament diameter of 766 nm (Fig. 4g). The energy-dispersive X-ray spectroscopy (EDS) elemental maps of the pyrolyzed structures reveal a uniform distribution of zinc, oxygen, and carbon in the whole structure without apparent element segregation (Fig. 4h, left), showing atomic percentages of Zn and O of 49.04 and 50.96%, respectively (Fig. 4h, right), which is consistent with that of ZnO powders from elemental analysis (Fig. S8). To confirm the conversion of 3D-printed polymer precursor to monolithic polycrystalline ZnO, we analyze the atomic-level microstructures of the 3D-printed structures by transmission electron microscopy (TEM). The electron diffraction pattern taken from the red region confirm the hexagonal wurtzite crystalline phase of ZnO (Fig. 4i), while the bright and dark field TEM images reveal that the pyrolyzed ZnO structures is composed of nanocrystalline with a mean grain size of 58.5 nm (Figs. 4j and S11). Besides ZnO, our ink formulation strategy can be readily applied to a variety of metal ions, such as Cu2+ ions for CuO, In3+ ions for In2O3, Ga3+ ions for Ga2O3, Ti4+ ions for TiO2, and Y3+ ions for Y2O3 (Figs. S12-S16). We also demonstrate the 3D printing of some ternary metal oxides, such as SrTiO3 and BaTiO3 (Figs. S17–S18).

3.4 Optical Properties of 3D-Printed ZnO Woodpile Architectures

We next demonstrate 3D-printed ZnO woodpiles as a three-dimensional photonic crystal. The cross-sectional SEM images of the woodpile samples reveal that the average diameter (\(d\)) of the individual filament is ~ 0.766 µm and the average in-plane distance (\(a\)) between the two adjacent filaments is ~ 2.151 µm in every layer (Fig. 5a). Each layer rotates 90° relative to the layer below and offsets by \(\frac{1}{2}a\) from two layers below. Hence, the structure repeats itself every four layers in the stacking direction, and the four-layer distance (\(h\)) is calculated as 2.961 µm, taking into account tilt correction for the cross-sectional SEM measurement. Notably, the ZnO woodpile belongs to a face-centered-tetragonal (FCT) Bravais lattice because the ratio of \(h\) to \(a\) is not strictly equal to \(\sqrt{2}\). Given the geometric parameters of FCT lattice (Fig. S19a) and a refractive index of Zinc oxide (Fig. S20), we calculated the photonic band structure by probing along all symmetry points in the Brillouin zone of FCT lattice (Fig. S19b, Table S2). The calculated band diagram shows that existence of partial photonic bandgap (PBG) along the symmetry directions of Г–W′-K′–W″–U–Г and Г–X–W–K–Г at the wavelengths of 3.623–3.772 µm and 3.727–3.885 µm, respectively, while along symmetry direction of Г–X′–U′–L–Г, light propagation inside the photonic crystal was not prohibited in the above-mentioned wavelength ranges (Fig. S19c). It is because that the refractive index of ZnO is lower than the threshold value of ~ 2.3 required to open a complete PBG in FCT woodpile (Fig. S21). Nevertheless, a high reflectance/low transmittance band centered at 3.72 µm is detected using a Cassegrain objective with infrared light with an incident angle from 16° to 35° (Fig. 5a, b). To verify the experimental results, we map out the band structure projected along ГX′ orientation (Fig. 5c). The azimuth angle θ is set in range from 0° to 45°, considering the rotational symmetry of tetradecahedron geometry (the first Brillouin zone) about the z-axis. The red and green light lines are plotted in each projected band structure, corresponding to incidence angles of light at 16° and 35°, respectively. Each projected band structure predicts two sets of stop-band positions influenced by off-normal light incidences (Table S3). The group of all sets of stop-band positions indicates the existence of a partial PBG located between 4.14 and 3.47 µm, which match well with the peak and valley of the experimentally characterized reflectance and transmittance spectra (Fig. 5b). We next implement plane wave excitation to simulate the transmittance spectra for the 16-layer woodpile. To mimic actual angular spread of the incident light, we calculated spectra for several incident angle (\(16^\circ \le \theta \le 35^\circ ,0^\circ \le \varphi \le 90^\circ\)) in the respective relevant range and averaged over the obtained results associated with S and P- polarized light illumination (Figs. 5d and S22). The simulated and experimental spectra agree well on the edge of the partial bandgap. However, the deviations of transmittance depth are observed especially in the short wavelength region and partial PBG, attributed to the imperfect periodicity, surface roughness and uncertainty of refractive index [14, 57]. To further investigate the light propagation characteristics in the woodpile, two different electric field distribution profiles are calculated with incident light wavelengths of 5 and 3.8 µm (Fig. 5e). With 5 µm incident light, the electrical field was distributed over the entire simulated domain. By contrast, the significant attenuation of electric field amplitude occurs in the light propagation with the wavelengths of 3.8 µm, due to complete reflection. These results manifest the 3D-printed woodpile photonic crystals show strong coupling effects with mid-infrared light.

Optical characterization and simulation analysis of ZnO woodpile: a Illustration of a standard FT-IR measurement setup with a Cassegrain objective having an acceptance angle range between 16° and 35°, and SEM images of focused ion beam (FIB)-milled cross section of the woodpile structure, obtained with a substrate tilt angle of 55°. b FTIR reflectance and transmittance spectra taken from the ZnO woodpile, and the calculated bandgap in orange region. c Illustration for the first Brillouin zone of the FCT Bravais lattice and calculated band structures projected along ГX′ orientation, with varying azimuth angle, θ. d Simulated transmittance spectra of S and P-polarized light for 16-layer woodpile structure. e Calculated electric field distributions along the xy and yz planes, as the P-polarized light propagates with an elevation angle (φ) of 25.5° (an averaged acceptance angle of Cassegrain objective) and an azimuth angle (θ) of 0°. (Color figure online)

4 Conclusions

In summary, we have developed a facile and generalized design strategy of polymer precursor inks for DIW of metal oxide into 3D architectures with a sub-micrometer resolution. Benefitting from the ink composition with strong adsorption effect on a wide range of metal ions, the design strategy has an ability to expand to other metal elements, and even potential to be compatible with multiple metal ions coexisted in aqueous solution. Furthermore, the homogeneous distribution of compositions at the molecular level facilitates ink extrusion continuously through a micronozzle. The polymer chain entanglement and electrostatic attraction effect are tailored easily upon the solvent evaporation resulting in the ideal rheological properties required for printability. The Maillard reaction between PEI and glucose endows the as-printed polymer precursor with the excellent shape-retaining property during the pyrolysis process. As a demonstration, we fabricated 2D- and 3D-structured metal oxides after the organic-to-inorganic transformation. We further demonstrated that as-printed 3D periodic dielectric structure with woodpile geometry has a significant light-matter effect in mid-infrared region. Importantly, our polymer precursor inks suggest a feasible and versatile pathway to the design and development of new functional oxide inks for DIW.

References

X. Yu, T.J. Marks, A. Facchetti, Metal oxides for optoelectronic applications. Nat. Mater. 15, 383–396 (2016). https://doi.org/10.1038/nmat4599

E. Carlos, R. Branquinho, R. Martins, A. Kiazadeh, E. Fortunato, Recent progress in solution-based metal oxide resistive switching devices. Adv. Mater. 33, 2004328 (2021). https://doi.org/10.1002/adma.202004328

C.R. Bowen, H.A. Kim, P.M. Weaver, S. Dunn, Piezoelectric and ferroelectric materials and structures for energy harvesting applications. Energy Environ. Sci. 7, 25–44 (2014). https://doi.org/10.1039/C3EE42454E

B. Zhang, Q. Zhang, P. He, Y. Ma, L. Shen et al., Efficient fabrication of ultralight YBa2Cu3O7−x superconductors with programmable shape and structure. Adv. Funct. Mater. 31, 2100680 (2021). https://doi.org/10.1002/adfm.202100680

S.B. Ogale, Dilute do**, defects, and ferromagnetism in metal oxide systems. Adv. Mater. 22, 3125–3155 (2010). https://doi.org/10.1002/adma.200903891

J. Jiang, Y. Li, J. Liu, X. Huang, C. Yuan et al., Recent advances in metal oxide-based electrode architecture design for electrochemical energy storage. Adv. Mater. 24, 5166–5180 (2012). https://doi.org/10.1002/adma.201202146

D.G. Georgiadou, J. Semple, A.A. Sagade, H. Forstén, P. Rantakari et al., 100 Ghz zinc oxide schottky diodes processed from solution on a wafer scale. Nat. Electron. 3, 718–725 (2020). https://doi.org/10.1038/s41928-020-00484-7

B. Wang, A. Thukral, Z. **e, L. Liu, X. Zhang et al., Flexible and stretchable metal oxide nanofiber networks for multimodal and monolithically integrated wearable electronics. Nat. Commun. 11, 2405 (2020). https://doi.org/10.1038/s41467-020-16268-8

X. Chen, J.M. Lawrence, L.T. Wey, L. Schertel, Q. **g et al., 3D-printed hierarchical pillar array electrodes for high-performance semi-artificial photosynthesis. Nat. Mater. 21, 811–818 (2022). https://doi.org/10.1038/s41563-022-01205-5

R. Hensleigh, H. Cui, Z. Xu, J. Massman, D. Yao et al., Charge-programmed three-dimensional printing for multi-material electronic devices. Nat. Electron. 3, 216–224 (2020). https://doi.org/10.1038/s41928-020-0391-2

H. Cui, D. Yao, R. Hensleigh, H. Lu, A. Calderon et al., Design and printing of proprioceptive three-dimensional architected robotic metamaterials. Science 376, 1287–1293 (2022). https://doi.org/10.1126/science.abn0090

G. Zhao, Y. Ling, Y. Su, Z. Chen, C.J. Mathai et al., Laser-scribed conductive, photoactive transition metal oxide on soft elastomers for janus on-skin electronics and soft actuators. Sci. Adv. 8, eabp9734 (2022). https://doi.org/10.1126/sciadv.abp9734

J.R. Greer, J. Park, Additive manufacturing of nano- and microarchitected materials. Nano Lett. 18, 2187–2188 (2018). https://doi.org/10.1021/acs.nanolett.8b00724

A. Vyatskikh, R.C. Ng, B. Edwards, R.M. Briggs, J.R. Greer, Additive manufacturing of high-refractive-index, nanoarchitected titanium dioxide for 3D dielectric photonic crystals. Nano Lett. 20, 3513–3520 (2020). https://doi.org/10.1021/acs.nanolett.0c00454

H. Cui, R. Hensleigh, D. Yao, D. Maurya, P. Kumar et al., Three-dimensional printing of piezoelectric materials with designed anisotropy and directional response. Nat. Mater. 18, 234–241 (2019). https://doi.org/10.1038/s41563-018-0268-1

J.R. Greer, V.S. Deshpande, Three-dimensional architected materials and structures: design, fabrication, and mechanical behavior. MRS Bull. 44(10), 750–757 (2019). https://doi.org/10.1557/mrs.2019.232

D.W. Yee, M.L. Lifson, B.W. Edwards, J.R. Greer, Additive manufacturing of 3d-architected multifunctional metal oxides. Adv. Mater. 31, 1901345 (2019). https://doi.org/10.1002/adma.201901345

H. Chen, X. Min, Y. Hui, W. Qin, B. Zhang et al., Colloidal oxide nanoparticle inks for micrometer-resolution additive manufacturing of three-dimensional gas sensors. Mater. Horiz. 9, 764–771 (2022). https://doi.org/10.1039/D1MH01021B

W. Guo, Y. Liu, Y. Sun, Y. Wang, W. Qin et al., Vertical 3d printed forest-inspired hierarchical plasmonic superstructure for photocatalysis. Adv. Funct. Mater. (2021). https://doi.org/10.1002/adfm.202100768

K. Sun, T.S. Wei, B.Y. Ahn, J.Y. Seo, S.J. Dillon et al., 3d printing of interdigitated li-ion microbattery architectures. Adv. Mater. 25, 4539–4543 (2013). https://doi.org/10.1002/adma.201301036

C.C. Yeh, H.W. Zan, O. Soppera, Solution-based micro- and nanoscale metal oxide structures formed by direct patterning for electro-optical applications. Adv. Mater. 30, e1800923 (2018). https://doi.org/10.1002/adma.201800923

J.A. Lewis, B.Y. Ahn, Device fabrication: three-dimensional printed electronics. Nature 518, 42 (2015). https://doi.org/10.1038/518042a

I. Cooperstein, S. Indukuri, A. Bouketov, U. Levy, S. Magdassi, 3d printing of micrometer-sized transparent ceramics with on-demand optical-gain properties. Adv. Mater. 32, 8 (2020). https://doi.org/10.1002/adma.202001675

A. Vyatskikh, A. Kudo, S. Delalande, J.R. Greer, Additive manufacturing of polymer-derived titania for one-step solar water purification. Mater. Today Commun. 15, 288–293 (2018). https://doi.org/10.1016/j.mtcomm.2018.02.010

D. Gailevičius, V. Padolskytė, L. Mikoliūnaitė, S. Šakirzanovas, S. Juodkazis et al., Additive-manufacturing of 3d glass-ceramics down to nanoscale resolution. Nanoscale Horiz. 4, 647–651 (2019). https://doi.org/10.1039/C8NH00293B

J. Liu, Y. Liu, C. Deng, K. Yu, X. Fan et al., 3d printing nano-architected semiconductors based on versatile and customizable metal-bound composite photoresins. Adv. Mater. Technol. 7, 2101230 (2022). https://doi.org/10.1002/admt.202101230

J. Winczewski, M. Herrera, C. Cabriel, I. Izeddin, S. Gabel et al., Additive manufacturing of 3d luminescent ZrO2:Eu3+ architectures. Adv. Opt. Mater. 10, 2102758 (2022). https://doi.org/10.1002/adom.202102758

A. Vyatskikh, S. Delalande, A. Kudo, X. Zhang, C.M. Portela et al., Additive manufacturing of 3d nano-architected metals. Nat. Commun. 9, 593 (2018). https://doi.org/10.1038/s41467-018-03071-9

M.A. Saccone, R.A. Gallivan, K. Narita, D.W. Yee, J.R. Greer, Additive manufacturing of micro-architected metals via hydrogel infusion. Nature 612, 685–690 (2022). https://doi.org/10.1038/s41586-022-05433-2

A. Scholz, L. Zimmermann, U. Gengenbach, L. Koker, Z. Chen et al., Hybrid low-voltage physical unclonable function based on inkjet-printed metal-oxide transistors. Nat. Commun. 11, 5543 (2020). https://doi.org/10.1038/s41467-020-19324-5

G. Cai, P. Darmawan, X. Cheng, P.S. Lee, Inkjet printed large area multifunctional smart windows. Adv. Energy Mater. 7(14), 1602598 (2017). https://doi.org/10.1002/aenm.201602598

T.S. Kim, Y. Lee, W. Xu, Y.H. Kim, M. Kim et al., Direct-printed nanoscale metal-oxide-wire electronics. Nano Energy 58, 437–446 (2019). https://doi.org/10.1016/j.nanoen.2019.01.052

K. Lim, Y.M. Jo, J.W. Yoon, J.H. Lee, Metal oxide patterns of one-dimensional nanofibers: on-demand, direct-write fabrication, and application as a novel platform for gas detection. J. Mater. Chem. A 7, 24919–24928 (2019). https://doi.org/10.1039/c9ta09708b

J.A. Lewis, Direct ink writing of 3d functional materials. Adv. Funct. Mater. 16, 2193–2204 (2006). https://doi.org/10.1002/adfm.200600434

J.C. Conrad, J.A. Lewis, Structural evolution of colloidal gels during constricted microchannel flow. Langmuir 26, 6102–6107 (2010). https://doi.org/10.1021/la1000123

E.B. Duoss, M. Twardowski, J.A. Lewis, Sol-gel inks for direct-write assembly of functional oxides. Adv. Mater. 19, 3485–3489 (2007). https://doi.org/10.1002/adma.200701372

B.Y. Ahn, D.J. Lorang, E.B. Duoss, J.A. Lewis, Direct-write assembly of microperiodic planar and spanning ITO microelectrodes. Chem. Commun. 46, 7118–7120 (2010). https://doi.org/10.1039/c0cc01691h

A.E. Danks, S.R. Hall, Z. Schnepp, The evolution of ‘sol–gel’ chemistry as a technique for materials synthesis. Mater. Horiz. 3, 91–112 (2016). https://doi.org/10.1039/c5mh00260e

Q.X. Jia, T.M. McCleskey, A.K. Burrell, Y. Lin et al., Polymer-assisted deposition of metal-oxide films. Nat. Mater. 3, 529–532 (2004). https://doi.org/10.1038/nmat1163

G.F. Zou, J. Zhao, H.M. Luo, T.M. McCleskey, A.K. Burrell et al., Polymer-assisted-deposition: a chemical solution route for a wide range of materials. Chem. Soc. Rev. 42, 439–449 (2013). https://doi.org/10.1039/c2cs35283d

L. Yu, W. Li, C. Wei, Q. Yang, Y. Shao et al., 3D Printing of NiCoP/Ti3C2 MXene architectures for energy storage devices with high areal and volumetric energy density. Nano-Micro Lett. 12, 143 (2020). https://doi.org/10.1007/s40820-020-00483-5

J. Cai, Z. Fan, J. **, Z. Shi, S. Dou et al., Expediting the electrochemical kinetics of 3D-printed sulfur cathodes for Li–S batteries with high rate capability and areal capacity. Nano Energy 75, 104970 (2020). https://doi.org/10.1016/j.nanoen.2020.104970

L. Yu, Z. Fan, Y. Shao, Z. Tian, J. Sun et al., Versatile N-doped MXene ink for printed electrochemical energy storage application. Adv. Energy Mater. 9, 1901839 (2019). https://doi.org/10.1002/aenm.201901839

H. Ren, Y. Liu, L. Zhang, K. Liu, Synthesis, properties, and applications of large-scale two-dimensional materials by polymer-assisted deposition. J. Semicond. 40, 061003 (2019). https://doi.org/10.1088/1674-4926/40/6/061003

X. Xu, J. Yang, W. Jonhson, Y. Wang, A. Suwardi et al., Additive manufacturing solidification methodologies for ink formulation. Addit. Manuf. 56, 102939 (2022). https://doi.org/10.1016/j.addma.2022.102939

S.A. Idris, O.A. Mkhatresh, F. Heatley, Assignment of 1H NMR spectrum and investigation of oxidative degradation of poly(ethylenimine) using 1H and 13C 1-D and 2-D NMR. Polym. Int. 55, 1040–1048 (2006). https://doi.org/10.1002/pi.2049

B. Gullon, M.I. Montenegro, A.I. Ruiz-Matute, A. Cardelle-Cobas, N. Corzo et al., Synthesis, optimization and structural characterization of a chitosan-glucose derivative obtained by the maillard reaction. Carbohydr. Polym. 137, 382–389 (2016). https://doi.org/10.1016/j.carbpol.2015.10.075

Y. Xu, X. Huang, Y. Zhang, Z. Liu, J. Luo et al., A high bonding performance and antibacterial soybean meal adhesive with maillard reaction based cross-linked structure. Compos. B Eng. 227, 109403 (2021). https://doi.org/10.1016/j.compositesb.2021.109403

L. Khadidja, C. Asma, B. Mahmoud, E. Meriem, Alginate/gelatin crosslinked system through maillard reaction: preparation, characterization and biological properties. Polym. Bull. 74, 4899–4919 (2017). https://doi.org/10.1007/s00289-017-1997-z

T. Xu, Q. Wu, S. Chen, M. Deng, Preparation of polypropylene based hyperbranched absorbent fibers and the study of their adsorption of CO2. RSC Adv. 5, 32902–32908 (2015). https://doi.org/10.1039/C5RA02182K

R.J.J. Jansen, H. van Bekkum, XPS of nitrogen-containing functional groups on activated carbon. Carbon 33, 1021–1027 (1995). https://doi.org/10.1016/0008-6223(95)00030-H

C. Zhang, J. Su, H. Zhu, J. **ong, X. Liu et al., The removal of heavy metal ions from aqueous solutions by amine functionalized cellulose pretreated with microwave-H2O2. RSC Adv. 7, 34182–34191 (2017). https://doi.org/10.1039/C7RA03056H

H. He, X. Hou, B. Ma, L. Zhuang, C. Li et al., The oxidation of viscose fiber optimized by response surface methodology and its further amination with PEI for CO2 adsorption. Cellulose 23, 2539–2548 (2016). https://doi.org/10.1007/s10570-016-0955-5

F. Ledl, E. Schleicher, New aspects of the maillard reaction in foods and in the human body. Angew. Chem. Int. Ed. 29, 565–594 (1990). https://doi.org/10.1002/anie.199005653

C.N. Fredd, H.S. Fogler, Alternative stimulation fluids and their impact on carbonate acidizing. SPE J. 3, 34–41 (1998). https://doi.org/10.2118/31074-PA

B.M. Jun, T.P.N. Nguyen, S.H. Ahn, I.C. Kim, Y.N. Kwon, The application of polyethyleneimine draw solution in a combined forward osmosis/nanofiltration system. J. Appl. Polym. Sci. 132, 42198 (2015). https://doi.org/10.1002/app.42198

I. Staude, M. Thiel, S. Essig, C. Wolff, K. Busch et al., Fabrication and characterization of silicon woodpile photonic crystals with a complete bandgap at telecom wavelengths. Opt. Lett. 35, 1094–1096 (2010). https://doi.org/10.1364/OL.35.001094

Acknowledgements

The authors thank the financial support of this research by the National Natural Science Foundation of China (No. 51905446). The authors thank Instrumentation and Service Center for Physical Sciences and Molecular Sciences at Westlake University for the technical assistance. The authors thank Westlake Center for Micro/Nano Fabrication for the facility support and technical assistance. The authors thank the Research Center for Industries of the Future (RCIF) at Westlake University for partially supporting this work.

Funding

Open access funding provided by Shanghai Jiao Tong University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, H., Wang, J., Peng, S. et al. A Generalized Polymer Precursor Ink Design for 3D Printing of Functional Metal Oxides. Nano-Micro Lett. 15, 180 (2023). https://doi.org/10.1007/s40820-023-01147-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40820-023-01147-w