Abstract

A simple approach is proposed to study the main factors related to the mining activity’s impact on society, through a corporate social responsibility (CSR) qualitative analysis based on the type of raw materials extracted, either by mine site or firm. A CSR index is defined by 30 environmental and socioeconomic elements and, subsequently, it is weighted by three primary factors; the recycling rate, the transition to green energy, and geographical conditions. The proposed method is adaptable to any change in raw material needs over time and, depending on the analyzed country or region, is applicable to any type of mineral resource. The system can be used to drive engagement with the different stakeholders, add value to a project, and establish a CSR continuous improvement system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Mineral raw materials are in every part of our daily lives, and some of them are crucial for the correct development of society. Thus, the concept of critical raw materials (CRM) considers the supply risk and economic importance for an industrial ecosystem's functioning and its goals in the mid- and long-term (Graedel et al. 2012; Ziemann et al. 2013). For instance, the current global trend toward a green energy transition requires a higher intensity of certain elements (Pommeret et al. 2022), particularly for electrical and battery systems for transportation (Riva Sanseverino and Luu 2022), while the capabilities of recycling or some regional agendas can also have an important relevance in that regard (Černý et al. 2021). Besides, secondary raw materials still require a long path to achieve a dominant fraction of the inputs (Bailey et al. 2008). In addition, the projection of the global population will also influence the demand for raw materials (van Dijk et al. 2021), with an outlook of around a 90% increase in raw material demands up to 2060 (World Bank Group 2017).

Specific CRM analysis has been done in countries like the US, Japan, and China, as well as in supranational organizations like the European Union (EU), with the idea of securing the supply chain of resources, either internally or through partnerships with other countries, based on their regional possibilities to secure the provision of each specific element or mineral (Blengini et al. 2017; USGS 2018; DeWit 2021). However, the approach to analyzing when a certain mineral is critical follows the same idea: a combination of economic importance and supply risk, ordered by a numeric scale, based on the combination of both variables. The analysis is usually done every few years to update the framework, as the type of product demanded by society changes over time (Buijs et al. 2012).

Hence, based on the situation previously described, it is crucial to obtain the raw materials through mining and recycling. Even though recycling techniques have been improved over the last decades (UNEP 2013), it is not possible to provide enough quantity because of the following: the lack of circularity of the whole materials (Bailey et al. 2008), difficulties in the recovery process (Bailey et al. 2008), and a gap caused by economy context differences in terms of raw materials associated (Amighini et al. 2023). Having materials available to recycle from several years or decades ago, when the mix of raw material demand was different from the moment of recycling (UNEP 2013), all these important facts imply that open pit and underground mining are currently required to a large extent, as well as in mid- and long-term scenarios.

Despite the need for raw material sources to meet regional and global demand, there is increasing pressure to not open new mining projects and close ongoing mines. In this regard, the social license to operate (SLO) is becoming a must to be accepted by the influenced area and local and regional stakeholders, where the mine is going to be established (Eerola 2022). SLO tries to address the community–company relationship, requiring a particular approach depending on the region (Lesser et al. 2021).

The impacts generated by mining have been long studied and proven, varying from environmental to social to political (Franks et al. 2014; Sairinen et al. 2017; Owen et al. 2022). Besides, it is a matter of fact that mines will continue to have a certain impact, despite the efforts made by the mining companies and the regulations applied due to the intrinsic characteristics of the activity (Warhate et al. 2006; Werner et al. 2019), making it necessary to achieve a source of the raw materials as responsible as possible (Di Noi et al. 2020). In this regard, several strategies have been proposed for the reclamation and post-closure of mining operations to achieve more sustainable activities (Samadi et al. 2023; Krzyszowska Waitkus 2022). Including important environmental and social factors such as the management of tailings and waste dumps generated during the extraction phase (Bakhtavar et al. 2023) or acid mine drainage (Faybishenko et al. 2023). Post-closure solutions are crucial to increase the value of a mining project (Bakhtavar et al. 2019), from a holistic point of view, requiring its inclusion from the initial mine concept.

Therefore, a methodology is required to assess the mining projects, based on objective parameters such as the technical characteristics of the projects, the type of raw material extracted, and social and environmental conditions. Here is where corporate social responsibility (CSR) assessments can play an important role (Jenkins and Yakovleva 2006; Hilson 2012), providing a qualitative and quantitative analysis by mining project. However, while qualitative CSR analysis has been extensively studied, quantitative approaches are quite rare (Bascompta et al. 2022), with mainly general quantitative analysis for the whole firm (Trumpp and Guenther 2017) or environmental, social, and corporate governance (ESG) indexes such as the Dow Jones Sustainability Indices (DJSI) (Fowler and Hope 2007; Lee and Faff 2009). In this regard, some standards developed by well-known organizations, like the Responsible Mining Foundation (RMF) or the International Council on Mining and Metals (ICMM), are not applicable from a quantitative point of view at the mine-site level (Bascompta et al. 2022). In addition, CSR analysis, or any other index from the sector, does not discriminate by the type of resource extracted, even though society is an important stakeholder and certain resources can play a fundamental role in the society’s goals previously mentioned. This concept is in the same vein as climate stakeholders, clean energy stakeholders, and mining stakeholders as defined by the World Bank. Therefore, these implications should be included in any quantitative CSR analysis.

The study aims to define a quantitative CSR system that considers some corrective factors relevant to society, such as energy transition, recycling availability, or regional conditions. The index, with its corrective factors, is prepared to be applied to mine-site projects at any stage.

2 CSR Index

A quantitative index for corporate social responsibility has been developed based on the approach from Bascompta et al. (2022), henceforth called CSR basic index. It is an index to analyze corporate social responsibility at the mine-site level and any stage of the project. It consists of two dimensions focused on the technical features, socioeconomic (S) and environmental (E), with 30 elements that allow studying the potential negative and positive impacts of the specific mining activity (11 and 19 elements, respectively), being able to make the analysis using an overall value, including all the elements, or by dimension. Besides, it gives the flexibility to add new elements or dimensions if needed due to some specific project characteristics or new elements found to be relevant.

There are 20 positive elements and 10 negative elements, adding or subtracting value to the basic CSR index. Each element is assessed on a Likert scale of 1–5. The scale of the global CSR basic index is established by a 100-point scale, where a value between 80 and 100 points is considered as a good corporate social responsibility performance, 60–79 satisfactory, 40–59 weak, 20–39 poor, and less than 20 points means a very poor performance. Figure 1 defines the structure and procedure of the index, while Table 1 gathers all the elements included in its determination, sorted by each dimension.

On the other hand, elements such as child labor, health and safety, or the conservation of World Heritage elements, among any other compulsory items, remain outside the scope of the index proposed in this study. General elements such as political and legal components are also excluded from the proposed methodology.

The goal of the approach proposed is to set up a procedure that drives continuous improvement of CSR matters at a mine-site or mining project. The particular analysis of each element is explained by Bascompta et al. (2022). However, it is necessary to include some corrective factors to better define the implications of each particular mining project toward society.

3 CSR Correction Factors

The influence of the corrective factors on the quantitative CSR analysis of a mine-site project or a company is complex to determine and still unsolved. However, it is obvious that the obtaining of some minerals or elements plays a key role in a more sustainable society, and, therefore, the development of a particular project can positively affect the society as a whole, either at a local, regional, national, or global level, as well as at the environmental aspect. Therefore, it is necessary to include and balance all the positive and negative socioeconomic and environmental contributions of mining (Samadi et al. 2023).

The correction factors have been based on: (a) the demand–supply risk of the raw material; (b) environmental and climate implications in terms of the need for the raw material; and (c) recycling capability.

In the field of corporate social responsibility (CSR) analysis, there is currently no established reference for correction factors. Consequently, to prevent the overestimation of the impact of correction factors on the analysis, a cautious approach has been adopted, cap** the maximum influence of correction factors to 10% on the derived results. Any higher impact is deemed too significant, potentially compromising the initial CSR analysis, such as the CSR basic index explained in Sect. 2. Conversely, when a factor analyzed has no discernible impact, it is assigned a value of 1, which allows for a focus on the broader and more general elements of CSR. While there is a need for further research and standardization in this area, this approach offers a practical solution for the current limitations in CSR quantitative analysis.

3.1 Green Transition

One of the main megatrends related to raw materials is the transformation toward a more sustainable and greener economy, shifting from a fossil fuel economy to a clean energy model (Bogdanov et al. 2021; Pörtner et al. 2022). Thus, the production of raw materials such as graphite, cobalt, or lithium must increase around five times to meet the projected demand for energy production and storage, under the scenario of less than 2 °C temperature increase (Hund et al. 2020), as well as many other critical raw materials (World Bank Group 2017; Luderer et al. 2019). The associated increase in mineral demand and, therefore, the need for new mines and expansion of the current ones, will require adequate management of the impacts from a holistic and sustainable perspective (Kügerl et al. 2023). In that sense, corporate social responsibility analysis can be very helpful to drive a proper clean energy transition (Hund et al. 2020; Airike et al. 2016; Deberdt and Billon 2021). Table 2 gathers the different minerals required for the energy transition (OECD 2021), considering the projected annual demand increase in 2050 with 2018 as the baseline scenario (less than 2 °C temperature increase scenario). Thereafter, a normalizing and scaling of the values from Table 2 will be done to integrate them in the CSR analysis (Sect. 3.4).

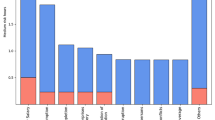

There are 17 different raw materials with a substantial increase of their demand (Table 2), which is particularly high for raw materials used in energy storage purposes as it can be seen with increase above 200% for, cobalt, graphite, nickel, lithium, indium and vanadium. While other elements are also crucial for power generation and transportation.

The total annual demand, in terms of tons, is not considered since the variation is very different depending on the type of mineral. In addition, the corrector factor is suggested solely for the minerals used in the transition to clean energy, taking into account the existing recycling rates. It must also be considered that these projections are based on no substitution or improvement in efficiency in the period analyzed, while the raw materials demanded are only for green energy technology, requiring additional materials for the power grid, construction materials, etc.

3.2 Recycling Potential

The possibility of obtaining resources from scratch and secondary sources may allow for the requirement of less or no additional resources from conventional mining activities. However, different factors may prevent achieving this goal: (a) It is difficult to reintroduce all the raw materials to the system (Castro et al. 2004; Meskers 2008), (b) many times it is not possible to recover the total quantity introduced in the system (Atherton 2007; Birat 2015) or with the quality required (Van Schaik and Reuter 2004; Gaustad et al. 2010), (c) the lack of an eco-design of the product and built elements makes it very difficult, or impossible, to recover all the elements, and, sometimes, the technique required for the recovery of one eliminates the possibility of recovering the other ones (Hagelüken 2007), (d) the raw materials demanded over the evolution of technology creates a disruption between the secondary raw materials available to recycle and the current demand, and (e) the economic growth generates a demand increase for raw materials compared to the available secondary sources (Buchner 2015; Ciacci et al. 2016).

Thus, there is a wide range of recycling efficiency depending on the raw material, requiring more or less production from traditional mining. Based on the publication from the International Resource Panel (UNEP 2013), five ranges of recycling rates are defined: (1) more than 50%, (2) 25–50%, (3) more than 10–25%, (4) 1–10%, and (5) less than 1%. A numeric value from 1 to 5 is used to define these recycling ranges. Table 3 displays the elements with the value defined, following the procedure described, that corresponds to their recycling rate. Subsequently, a normalizing and scaling of the recycling rates, shown in Table 3, will be carried out in order to make a joint analysis, as shown in Sect. 3.4.

Some elements, such as mercury, should not be considered in the analysis due to their environmental implications, and their prohibited usage. Aggregates and industrial minerals are kept out of the analysis due to the type of mining activity and its size and implications.

3.3 Regional Factors

Each region, all over the globe, has different requirements for raw materials based on the availability within its territory and the economic characteristics (Černý et al. 2021). Thus, the major world economies have developed some sort of list, such as the US, the European Union, Japan, Canada, Australia, and China. These studies are focused on achieving a more resilient system in terms of geopolitical and economic factors, ensuring the supply chain of raw materials, and considering recycling techniques and a circular approach.

In the case of the EU, the raw materials are analyzed as a function of supply risk (SR), from 0 to 7, and economic importance (EI), from 0 to 9. It is considered CRM when SR ≥ 1 and EI ≥ 2.8. Hence, it has been defined the criticality of raw materials as: criticality factor = SR × EI, as long as SR ≥ 1 and EI ≥ 2.8, with a minimum value of 2.8 and a maximum value of 63 defined by the EU criteria. The economic importance provides insight into the relevance of any material for the EU economy, considering the potential substitutes for that material. On the other hand, the supply risk displays the potential disruption of having at its disposal the specific material from the producing countries, considering the global supply mixture and country governance indicators. The potential critical stage is also considered in the EU approach: extraction or processing, as well as substitution and recycling possibilities. Table 4 gathers the supply risk, economic importance, based on the EU perspective, and the criticality factor by raw material as a result of multiplying the two first columns. Following this, the criticality factor will need to undergo a normalization and scaling process for integration into the proposed CSR analysis system.

Three groups of raw materials are included in Table 4. The PGM group is composed of iridium, palladium, platinum, rhodium, and ruthenium. The LREEs group includes cerium, lanthanum, neodymium, praseodymium, and samarium, while the HREEs is formed by dysprosium, erbium, europium, gadolinium, holmium, lutetium, terbium, thulium, ytterbium, and yttrium.

Regional factors are important since the need for certain raw materials may vary considerably depending on the region. For instance, for electric vehicle batteries and energy storage, the EU will need up to 18 times more lithium and 5 times more cobalt in 2030 and almost 60 times more lithium and 15 times more cobalt in 2050, compared to the current supply to the whole EU economy (European Commission 2018), while the global increase in demand will follow a different pattern based on each internal condition (Hund et al. 2020). Other regions could also be analyzed similarly to the EU approach included in the previous paragraphs and Table 4, only varying some parts of the methodology to determine the criticality factor.

3.4 CSR Correction Factor Usage

The elements defined as relevant to apply as a CSR corrective factor were previously detailed. The data from Sects. 3.1, 3.2, and 3.3 have been normalized and scaled to a range between 1 and 2, achieving more suitable values to work with. As an example, Table 5 includes some of the raw material data processed and considered in terms of recycling, energy transition, and criticality by the EU.

As mentioned, a maximum influence on CSR performance has been established, such as by Bascompta et al. (2022), allowing a certain variation on the basic index. Figure 1 defines the structure and procedure of the index, while Table 1 gathers all the elements included in its determination, sorted by each dimension.

The inclusion of the three elements in the corporate social responsibility performance (recycling, green transition, and regional CRM analysis) cannot be done by their simple addition to the final result. The reason is that the regional analysis already considers the raw material recycling rates. In this regard, it has been considered the average of two approaches: (a) recycling and green transition and (b) green transition and regional CRM analysis (Table 6). Results without the weighting factor (see Sect. 3) are in the left columns, and with the weighting factor are in the right columns. The system proposed is flexible enough to adapt to the specific casuistry of each case.

Thus, the overall corrective factor achieved for the critical raw materials analyzed in Table 6 shows a variation between 10 and 20%, which is considered high enough to influence the initial results but also small enough to not downplay the importance of the CSR index initially obtained.

The approach can be applied directly to a particular project, or company, by using a mineral resource weighting factor and the CSR assessment detailed in Sects. 2 and 3. The system can also be employed to correct a quantitative analysis of a mining activity, whether it is a new project or an operating mine.

The corrective factor is used as the average value of (a) recycling + green transition or (b) green transition + regional CRM analysis, Eq. (1) and stage 2 from Fig. 2, achieving the modified CSR index in stage 3.

where CSRmi is the corporate social responsibility modified index; Si is the socioeconomic dimension; Ei is the environmental dimension; K is the corrective factor based on the two scenarios proposed.

Figure 2 describes the entire procedure necessary to quantify corporate social responsibility in three stages, based on the methodology defined in this study. As previously mentioned, the basic CSR index is defined using the approach defined by Bascompta et al. (2022). The corrective factors can be applied to the CSR basic index, either in an overall value for a mining project or by dimension.

4 Discussion

The CSR correction system proposed can help to quantify the intrinsic value of mineral extraction based on national or regional needs in terms of social, economic, and environmental development, as well as the raw materials needed for the energy transition and carbon footprint reduction. Besides, the approach proposed can be adapted to any change in the future demand for mineral resources or regional criticality based on their supply and demand. Rational application increases the resilience of the raw materials supply chain. Additionally, the proposed approach can help obtain the social license to operate (SLO), improving relationships with stakeholders and gaining their credibility and trust. (Thomson and Boutilier 2011; Thomson and Boutilier 2012).

This study is grounded in the corporate social responsibility quantitative approach detailed in the CSR basic index and its subsequent correction factors, which add more value to CSR quantification. However, the corrective factors should only be applied to an overall CSR analysis or by dimension—socioeconomic or environmental. These corrective factors do not suit the study of a single element or some discretionary analysis of several elements because the corrective factors proposed may not be directly related to these specific elements, misrepresenting the significance of some specific features of a particular case study.

The determination of the 10% weight for the basic CSR quantitative index was based on the fact that the factors defined are quite relevant for society to influence whether a mining project is basic or not in a broad sense. The two approaches, in terms of applying a corrective factor using a mean value, are considered to an equivalent in importance. The flexibility of the proposal allows for modifying the factors or weights if further research is done in this regard, while still maintaining the validity of the approach proposed. The application of the modified CSR index would also be an important vector of improvement in terms of using weights and testing the robustness of the whole approach proposed.

The system proposed can be useful to discriminate among the group of critical raw materials, providing an instrument to prioritize the specific projects that give more value to society and the environment in a holistic approach. On the other hand, it could be a useful tool for ESG investment to allocate capital based on the need for the resource extracted in terms of environmental and social needs. It can be a driver toward the concept of responsible mining, evolving the sector to achieve companies that do more than just mere mining, including a larger value chain and integrating recycling and waste management, becoming material solution providers.

Further research could be done regarding the type of minerals used. It should be considered if the demand risk is a cross-cutting technology (such as copper, chromium, and molybdenum) or concentrated in one particular technology (such as lithium, graphite, indium, and cobalt). Additional studies should also be done to consider the role of the development minerals, especially in develo** countries where it is crucial to have minerals and materials required for basic sectors like construction, agriculture, or manufacturing. It is necessary to have these raw materials provided on a regional or local scale (Franks et al. 2022).

Additional improvements could be made in the CRM regional analysis, including a factor that encompasses elements such as environmental treatment, human rights, health and safety, or the carbon footprint associated with the mineral extraction and processing in other main supplier countries. Even though critical raw materials lists have some limitations and are based on certain methodologies that may vary depending on the region or over time (Buijs et al. 2012), proposing even some modifications (Martin et al. 2022), the approach suggested can be adapted to any modification. For instance, the regional critical raw materials list could include alloys whose supply assurance may be threatened, which would go beyond the strict mining sector. Moreover, most CRM is associated with the extraction of more common metals, such as copper, zinc, tin, nickel, platinum, aluminum, iron, or lead. Therefore, these metals may also be indirect critical raw materials; otherwise, many of the CRMs required for technological and green energy would not be available. Other modifications, such as the recycling rates or the raw materials required in the green energy transition, would not affect the usage of the system proposed due to its flexibility and adaptability to external inputs.

Additional corrective factors, based on technical components to extract any raw material, may be considered at each mine-site and mining project. For instance, the energy return on investment (EROI), which is the quantity of energy generated versus the energy needed to produce the raw material, or the fulfillment of the UN Sustainable Development Goals (SDGs).

5 Conclusions

Some relevant factors for the mining sector and the development, as a whole, of society and the environment have been quantified, considering recycling, green energy, and regionally critical raw materials through a corporate social responsibility index as the main vector to include these factors and analyze the mining activity, being able to apply these factors by mine-site or mining company.

Three main drivers have been considered as the corrective factors of CSR quantitative analysis: (1) recycling rate, (2) green energy transition, and (3) regional critical raw materials approach, achieving an overall factor based on two approaches to avoid redundant analysis.

-

(a) Approach 1:

A combination of the recycling potential and the requirement of raw materials for the green energy transition.

-

(b) Approach 2:

A combination of the raw materials required for the green energy transition and the regional availability of minerals from a primary source point of view.

The system proposed can be adapted to any region, country, or development level of the area where the mine would be placed. In addition, the factors could be modified using weights as society’s needs and technical solutions evolve. Further research should be done to study the implications of applying this approach as well as the intrinsic characteristics of critical raw materials as they are currently conceived.

Data availability

All relevant data are included within the manuscript. Additional data or materials related to this study are available from the corresponding author upon reasonable request.

References

Alves Dias, P., D. Blagoeva, C. Pavel, and N. Arvanitidis. 2018. Cobalt: Demand-supply balances in the transition to electric mobility. Publications Office of the European Union 6(10): 97710. https://doi.org/10.2760/97710.

Amighini A, Maurer A, Garnizova E, Hagemejer J, Stoll P, Dietrich M, Roy R, Skowronek A, &Tentori D. 2023. Global value chains: potential synergies between external trade policy and internal economic initiatives to address the strategic dependencies of the EU. Policy Department, Directorate-General for External Policies, Publications Office of the European Union. ISBN: 978-92-848-0310-1.

Atherton, J. 2007. Declaration by the metals industry on recycling principles. The International Journal of Life Cycle Assessment 12(1): 59–60. https://doi.org/10.1065/lca2006.11.283.

Bailey, R., B. Bras, and J.K. Allen. 2008. Measuring material cycling in industrial systems. Resources, Conservation and Recycling 52(4): 643–652.

Bakhtavar, E., R. Aghayarloo, S. Yousefi, K. Hewage, and R. Sadiq. 2019. Renewable energy based mine reclamation strategy: A hybrid fuzzy-based network analysis. Journal of Cleaner Production 230: 253–263. https://doi.org/10.1016/j.jclepro.2019.05.073.

Bakhtavar, E., S. Saberi, G.J. Hu, R. Sadiq, and K. Hewage. 2023. Fuzzy cognitive-based goal programming for waste rock management with in-pit dum** priority: Towards sustainable mining. Resources Policy 86: 104095. https://doi.org/10.1016/j.resourpol.2023.104095.

Bascompta, M., L. Sanmiquel, C. Vintró, and M. Yousefian. 2022. Corporate social responsibility index for mine sites. Sustainability 14(20): 13570. https://doi.org/10.3390/su142013570.

Birat, J.-P. 2015. Life-cycle assessment, resource efficiency and recycling. Metallurgical Research & Technology 112(2): 206. https://doi.org/10.1051/metal/2015009.

Blengini, G.A., Blagoeva, D., Dewulf, J., Torres de Matos, C., Nita, V., Vidal-Legaz, B., Latunussa, C.E.L., Kayam, Y., Talens Peirò, L., Baranzelli, C., Manfredi, S., Mancini, L., Nuss, P., Marmier, A., Alves-Dias, P., Pavel, C., Tzimas, E., Mathieux, F., Pennington, D., & Ciupagea, C. 2017. Assessment of the Methodology for Establishing the EU List of Critical Raw Materials, Publications Office of the European Union, Luxemburg, 978-92-79-69612-1, https://doi.org/10.2760/73303, JRC106997

Bogdanov, D., M. Ram, A. Aghahosseini, A. Gulagi, A.S. Oyewo, M. Child, U. Caldera, K. Sadovskaia, J. Farfan, L.D.S.N.S. Barbosa, M. Fasihi, S. Khalili, T. Traber, and C. Breyer. 2021. Low-cost renewable electricity as the key driver of the global energy transition towards sustainability. Energy 227: 120467. https://doi.org/10.1016/j.energy.2021.120467.

Boutilier, R.G., and I. Thomson. 2012. Modelling and measuring the social license to operate: Fruits of a dialogue between theory and practice. Social Licence 1: 1–10.

Buchner, H., D. Laner, H. Rechberger, and J. Fellner. 2015. Future raw material supply: Opportunities and limits of aluminium recycling in Austria. Journal of Sustainable Metallurgy 1: 253–262. https://doi.org/10.1007/s40831-015-0027-3.

Buijs, B., Sievers, H., Tercero Espinoza, LA. 2012. Limits to the critical raw materials approach. Proceedings of the Institution of Civil Engineers-Waste and Resource Management 165(4): 201–208. https://doi.org/10.1680/warm.12.00010

Castro, M.B.G., J.A.M. Remmerswaal, M.A. Reuter, and U.J.M. Boin. 2004. A thermodynamic approach to the compatibility of materials combinations for recycling. Resources, Conservation and Recycling 43(1): 1–19. https://doi.org/10.1016/j.resconrec.2004.04.011.

Černý, I., M. Vaněk, E.W. Maruszewska, and F. Beneš. 2021. How economic indicators impact the EU internal demand for critical raw materials. Resources Policy 74: 102417. https://doi.org/10.1016/j.resourpol.2021.102417.

Ciacci, L., E.M. Harper, N.T. Nassar, B.K. Reck, and T.E. Graedel. 2016. Metal dissipation and inefficient recycling intensify climate forcing. Environmental Science & Technology 50(20): 11394–11402. https://doi.org/10.1021/acs.est.6b02714.

Deberdt, R., and P.L. Billon. 2021. Conflict minerals and battery materials supply chains: A map** review of responsible sourcing initiatives. The Extractive Industries and Society 8(4): 100935. https://doi.org/10.1016/j.exis.2021.100935.

DeWit, A. 2021. Decarbonization and critical raw materials: Some issues for japan (n.d.). The Asia-Pacific Journal Japan Focus Retrieved 74(4): 1–25.

Di Noi, C., A. Ciroth, L. Mancini, U. Eynard, D. Pennington, and G.A. Blengini. 2020. Can S-LCA methodology support responsible sourcing of raw materials in EU policy context? The International Journal of Life Cycle Assessment 25(2): 332–349. https://doi.org/10.1007/s11367-019-01678-8.

Eerola, T. 2022. Corporate conduct, commodity and place: Ongoing mining and mineral exploration disputes in Finland and their implications for the social license to operate. Resources Policy 76: 102568. https://doi.org/10.1016/j.resourpol.2022.102568.

Faybishenko, B., E. Bakhtavar, K. Hewage, and R. Sadiq. 2023. Chemical composition of arsenic-based acid mine drainage in the downstream of a gold mine: Fuzzy regression and clustering analysis. Journal of Hazardous Materials. https://doi.org/10.1016/j.jhazmat.2023.133250.

Fowler, S.J., and C. Hope. 2007. A critical review of sustainable business indices and their impact. Journal of Business Ethics 76(3): 243–252. https://doi.org/10.1007/s10551-007-9590-2.

Franks, D.M., R. Davis, A.J. Bebbington, S.H. Ali, D. Kemp, and M. Scurrah. 2014. Conflict translates environmental and social risk into business costs. Proceedings of the National Academy of Sciences 111(21): 7576–7581. https://doi.org/10.1073/pnas.1405135111.

Franks, D.M., J. Keenan, and D. Hailu. 2022. Mineral security essential to achieving the sustainable development goals. Nature Sustainability 6(1): 21–27. https://doi.org/10.1038/s41893-022-00967-9.

Gaustad, G., E. Olivetti, and R. Kirchain. 2010. Design for recycling: Evaluation and efficient alloy modification. Journal of Industrial Ecology 14(2): 286–308. https://doi.org/10.1111/j.1530-9290.2010.00229.x.

Graedel, T.E., R. Barr, C. Chandler, T. Chase, J. Choi, L. Christoffersen, E. Friedlander, C. Henly, C. Jun, N.T. Nassar, D. Schechner, S. Warren, M. Yang, and C. Zhu. 2012. Methodology of metal criticality determination. Environmental Science & Technology 46(2): 1063–1070. https://doi.org/10.1021/es203534z.

Hagelüken, C. 2007. The challenge of open cycles-barriers to a closed loop economy demonstrated for consumer electronics and cars. Proceedings of R 7: 3–5.

Hilson, G. 2012. Corporate social responsibility in the extractive industries: Experiences from develo** countries. Resources Policy 37(2): 131–137. https://doi.org/10.1016/j.resourpol.2012.01.002.

Hund, K.L., La Porta, D., Fabregas, T. P., Laing, T., & Drexhage, J.R. 2020. Minerals for Climate Action: The Mineral Intensity of the Clean Energy Transition. Washington, D.C.: World Bank Group. http://documents.worldbank.org/curated/en/099052423172525564/P16627806f5aa400508f8c0bdcba0878a3e.

IEA. 2021. The Role of Critical Minerals in Clean Energy Transitions, OECD Publishing, Paris, https://doi.org/10.1787/f262b91c-en.

Interior releases 2018’s Final list of 35 minerals deemed critical to US National security and the economy | US Geological survey. (n.d.). Retrieved Mar 7, 2023, from https://www.usgs.gov/news/national-news-release/interior-releases-2018s-final-list-35-minerals-deemed-critical-us.

IPCC. 2022. Climate Change 2022: Impacts, Adaptation and Vulnerability. Contribution of Working Group II to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge, UK and New York, NY, USA, 3056, https://doi.org/10.1017/9781009325844.

Jenkins, H., and N. Yakovleva. 2006. Corporate social responsibility in the mining industry: Exploring trends in social and environmental disclosure. Journal of Cleaner Production 14(3–4): 271–284. https://doi.org/10.1016/j.jclepro.2004.10.004.

KrzyszowskaWaitkus, A. 2022. Sustainable reclamation practices for a large surface coal mine in shortgrass prairie, semiarid environment (Wyoming, USA): Case study. International Journal of Coal Science and Technology 9: 32. https://doi.org/10.1007/s40789-022-00502-3.

Kügerl, M.-T., M. Hitch, and K. Gugerell. 2023. Responsible sourcing for energy transitions: Discussing academic narratives of responsible sourcing through the lens of natural resources justice. Journal of Environmental Management 326: 116711. https://doi.org/10.1016/j.jenvman.2022.116711.

Lee, D.D., and R.W. Faff. 2009. Corporate sustainability performance and idiosyncratic risk: A global perspective. Financial Review 44(2): 213–237. https://doi.org/10.1111/j.1540-6288.2009.00216.

Lesser, P., K. Gugerell, G. Poelzer, M. Hitch, and M. Tost. 2021. European mining and the social license to operate. The Extractive Industries and Society 8(2): 100787. https://doi.org/10.1016/j.exis.2020.07.021.

Luderer, G., M. Pehl, A. Arvesen, T. Gibon, B.L. Bodirsky, H.S. De Boer, O. Fricko, M. Hejazi, F. Humpenöder, G. Iyer, S. Mima, I. Mouratiadou, R.C. Pietzcker, A. Popp, M. Van Den Berg, D. Van Vuuren, and E.G. Hertwich. 2019. Environmental co-benefits and adverse side-effects of alternative power sector decarbonization strategies. Nature Communications 10(1): 5229. https://doi.org/10.1038/s41467-019-13067-8.

Martin, N., C. Madrid-López, G. Villalba-Méndez, and L. Talens-Peiró. 2022. New techniques for assessing critical raw material aspects in energy and other technologies. Environmental Science & Technology 56(23): 17236–17245. https://doi.org/10.1021/acs.est.2c05308.

Meskers, C.E.M. 2008. Coated magnesium—Designed for sustainability? Doctoral tesis. ISBN: 978-9-064643-05-7. http://resolver.tudelft.nl/uuid:1e8b287c-3de8-4c3b-961a-9b091e1a5aa1.

Owen, J.R., D. Kemp, A.M. Lechner, J. Harris, R. Zhang, and É. Lèbre. 2022. Energy transition minerals and their intersection with land-connected peoples. Nature Sustainability 6(2): 203–211. https://doi.org/10.1038/s41893-022-00994-6.

Pommeret, A., F. Ricci, and K. Schubert. 2022. Critical raw materials for the energy transition. European Economic Review 141: 103991. https://doi.org/10.1016/j.euroecorev.2021.103991.

Riva Sanseverino, E., and L.Q. Luu. 2022. Critical raw materials and supply chain disruption in the energy transition. Energies 15(16): 5992. https://doi.org/10.3390/en15165992.

Sairinen, R., H. Tiainen, and T. Mononen. 2017. Talvivaara mine and water pollution: An analysis of mining conflict in Finland. The Extractive Industries and Society 4(3): 640–651. https://doi.org/10.1016/j.exis.2017.05.001.

Samadi, M., E. Bakhtavar, G. Hu, K. Hewage, and R. Sadiq. 2023. Assessment of mine post-closure strategies by integrating evidential reasoning and fuzzy cognitive maps: Toward sustainable mining policy. Resources Policy 83: 103719. https://doi.org/10.1016/j.resourpol.2023.103719.

Thomson, I., and R.G. Boutilier. 2011. The social license to operate. In SME Mining Engineering Handbook, ed. P. Darling, 1779–1796. Littleton: Society for Mining, Metallurgy and Exploration.

Trumpp, C., and T. Guenther. 2017. Too little or too much? Exploring u-shaped relationships between corporate environmental performance and corporate financial performance: U-shaped relationship between environmental and financial performance. Business Strategy and the Environment 26(1): 49–68. https://doi.org/10.1002/bse.1900.

UNEP. 2013. Metal Recycling: Opportunities, Limits, Infrastructure, A Report of the Working Group on the Global Metal Flows to the International Resource Panel. United Nations Environment Programme. ISBN: 978-92-807- 3267-2

USGS. 2018. Interior releases 2018’s final list of 35 minerals deemed critical to u. S. National security and the economy | u. S. Geological survey. (n.d.). Retrieved March 7, 2023, from https://www.usgs.gov/news/nationalnews- release/interior-releases-2018s-final-list-35-minerals-deemed-critical-us

van Dijk, M., T. Morley, M.L. Rau, and Y. Saghai. 2021. A meta-analysis of projected global food demand and population at risk of hunger for the period 2010–2050. Nature Food 2(7): 494–501. https://doi.org/10.1038/s43016-021-00322-9.

Van Schaik, A., and M.A. Reuter. 2004. The time-varying factors influencing the recycling rate of products. Resources, Conservation and Recycling 40(4): 301–328. https://doi.org/10.1016/S0921-3449(03)00074-0.

Warhate, S.R., M.K.N. Yenkie, M.D. Chaudhari, and W.K. Pokale. 2006. Impacts of mining activities on water and soil. Journal of Environmental Science & Engineering 48(2): 81–90.

Werner, T.T., A. Bebbington, and G. Gregory. 2019. Assessing impacts of mining: Recent contributions from GIS and remote sensing. The Extractive Industries and Society 6(3): 993–1012. https://doi.org/10.1016/j.exis.2019.06.011.

World Bank Group. 2017. The growing role of minerals and metals for a low carbon future. Washington: World Bank. https://doi.org/10.1596/28312.

Ziemann, S., A. Grunwald, L. Schebek, D.B. Müller, and M. Weil. 2013. The future of mobility and its critical raw materials. Revue De Métallurgie 110(1): 47–54. https://doi.org/10.1051/metal/2013052.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. The author(s) received no financial support for the research, authorship, and publication of this article.

Author information

Authors and Affiliations

Contributions

All authors contributed equally to the conception, design, data collection, analysis, and writing of this manuscript. Each author participated in drafting the article and revising it critically for important intellectual content. All authors have approved the final version of the manuscript and agree to be accountable for all aspects of the work.

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declare no potential conflict of interests with respect to the research, authorship, and publication of the article.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bascompta, M., Yousefian, M., Vintró, C. et al. Sustainability Assessment in Mining: A CSR-Based Analysis Model for Social and Environmental Impact. Fudan J. Hum. Soc. Sci. (2024). https://doi.org/10.1007/s40647-024-00419-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40647-024-00419-y