Abstract

To investigate the dynamic characteristics and long-term dynamic stability of the new subgrade structure of medium–low-speed (MLS) maglevs, cyclic vibration tests were performed under natural and rainfall conditions, and the dynamic response of the subgrade structure was monitored. The dynamic response attenuation characteristics along the depth direction of the subgrade were compared, and the distribution characteristics of the dynamic stress on the surface of the subgrade along the longitudinal direction of the line were analyzed. The critical dynamic stress and cumulative deformation were used as indicators to evaluate the long-term dynamic stability of the subgrade. Results show that water has a certain effect on the dynamic characteristics of the subgrade, and the dynamic stress and acceleration increase with the water content. With the dowel steel structure set between the rail-bearing beams, stress concentration at the end of the loaded beam can be prevented, and the diffusion distance of the dynamic stress along the longitudinal direction increases. The dynamic stress measured in the subgrade bed range is less than 1/5 of the critical dynamic stress. The postconstruction settlement of the subgrade after similarity ratio conversion is 3.94 mm and 7.72 mm under natural and rainfall conditions, respectively, and both values are less than the 30 mm limit, indicating that the MLS maglev subgrade structure has good long-term dynamic stability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Compared to the traditional wheel–rail transportation system, a maglev train does not contact directly with the track structure. Therefore, the maglev transportation system has the advantages of low vibration, low noise, and fast acceleration [1]. It is pretty suitable for urban rail transportation. A medium–low-speed (MLS) maglev has a running speed of less than 160 km/h, and future research studies on MLS maglev transportation will aim to achieve an operating speed of 200 km/h [2]. At present, many test lines for MLS maglev trains have been built in various countries, including Japan's Eastern Hills Line [3], South Korea's Incheon Airport Line [4], the MLS test line of the German Company Borg [5], the Changsha test line of the National University of Defense Technology [6], the Qingchengshan test line of Southwest Jiaotong University [7], the Shanghai Lingang test line of Tongji University [8], the CRRC Tangshan test line [9], the Zhuzhou test line [10], and the Bei**g S1 test line [11]. An increasing number of cities are planning to build MLS maglev lines, and the prospects of MLS maglev transportation are promising.

A previous study [12] showed that the suspension gap between a maglev train and track structure is small, and the subgrade structure has difficulty controlling the deformation. Thus, many experts believe that the subgrade structure should not be used for the maglev traffic line. A subgrade structure built on a soft soil foundation, in particular, has more difficulty meeting the deformation requirement. Furthermore, when the foundation treatment method is adopted, the investment budget of these structures will exceed the budget of the viaduct. As a result, viaducts are applied widely in MLS maglev lines. The dynamic characteristics of bridge structures [13] and vehicle–bridge coupled vibrations [14] have been investigated. However, investment in using the subgrade structure is economical for some sections with good foundation conditions and low filling heights. In the Chinese code for the design of MLS maglev transit [15], the construction of the MLS maglev subgrade should refer to the standard of the subgrade of an intercity railway ballastless track. But the track load intensity, track load distribution width, and train load impact coefficient of MLS maglevs are smaller than those of intercity railways, and the subgrade bed filling standards of the two are the same, making MLS maglev systems uneconomical. In addition, the standards of the MLS maglev subgrade in the Changsha test line [16, 17] and Zhuzhou test line [10] reference the standard for a high-speed railway ballastless track, as shown in Fig. 1. Since the lack of technical standards of the MLS maglev subgrade, few studies have assessed the MLS maglev subgrade. Liu [18] and Wang et al. [2] studied the dynamic characteristics of the MLS maglev subgrade through theoretical analyses and numerical simulations. They optimized the subgrade structure of an MLS maglev with the thickness of the upper roadbed being 0.3 m, the fill being graded gravel or group A-fill, and the compaction coefficient K ≥ 0.95. The thickness of the lower roadbed was 1.2 m, the fill was group A&B-fill (including group A-fill and group B-fill) or chemically treated soil, and the compaction coefficient K ≥ 0.93. The structure of the new MLS maglev subgrade is shown in Fig. 2.

For the long-term dynamic stability of the MLS maglev subgrade structure, we can refer to the long-term dynamic stability of a railway subgrade structure, which mainly includes the critical dynamic stress method, effective vibration velocity method, and critical dynamic shear strain method [19]. Among them, the effective vibration velocity method and the critical dynamic shear strain method require many parameters, some of which are difficult to obtain. In contrast, previous studies have frequently used the critical dynamic stress to evaluate the long-term dynamic stability of subgrades [20]. When the dynamic stress exceeds the critical dynamic stress, the cumulative plastic strain and elastic strain of the subgrade increase rapidly with an increasing number of cyclic loads. When the dynamic stress is less than the critical dynamic stress, the elastic strain and elastic modulus of the subgrade remain unchanged with an increasing number of cyclic loads. Wang et al. [21] used the critical dynamic stress method to study the long-term dynamic stability of the silty clay subgrade of the Qinghai–Tibet Railway. Yang et al. [22] analyzed the long-term dynamic stability of cement-treated soil subgrade using the critical dynamic stress method. However, the dynamic stress in the subgrade soil is less than the critical dynamic stress, indicating that the plastic deformation rate of the subgrade fill gradually decreases and eventually reaches a stable state [23], but the cumulative deformation of the subgrade may still exceed the specification limit. An experimental study revealed that the vertical total strain corresponding to the critical dynamic stress of cohesive soil reaches 9%–10% [24, 25]. Therefore, for the long-term dynamic stability of the subgrade structure, a combination of the critical dynamic stress method and cumulative deformation are necessary. For instance, Shang et al. [26] used the critical dynamic stress method and cumulative deformation to comprehensively evaluate the long-term dynamic stability of a cement-stabilized expansive soil subgrade for a heavy-haul railway.

In summary, the existing MLS maglev subgrade is built with reference to the standard of the high-speed railway subgrade, which is very uneconomical for building the MLS maglev subgrade. Few studies have investigated the dynamic characteristics of MLS maglev subgrade structures, and no one has studied the long-term dynamic characteristics of subgrade structures. In this paper, a 2:1 indoor model test is performed for the new MLS maglev subgrade structure, and 210,000 load cycles are performed successfully on the test model under natural and rainfall conditions. The dynamic characteristics of the subgrade structure are analyzed in terms of the dynamic stress and acceleration, and the long-term dynamic stability is evaluated based on the critical dynamic stress and cumulative deformation. The research results can be a reference for the subsequent engineering design and construction of MLS maglev subgrade structures.

2 Model design scheme

2.1 Model scale design

The similarity constant is the ratio of the physical quantities of the prototype to those of the test model. We comprehensively considered the limit conditions for the size of the test model site and performance capacity, and selected a geometric similarity constant of 2. In the 1g gravity field, the similarity constants for the density, reinforcement ratio, and material elasticity model are controlled at 1. Similar constant values for other physical parameters are derived according to the Buckingham π theorem, as shown in Table 1.

2.2 Model construction

2.2.1 Test model box production

The test model box is assembled from modular skeletons, which are welded with square steel, the inner panel is composed of acrylic boards, the joints of the acrylic plate are sealed with glass adhesives, and the whole is a rectangular open box. The inner size of the model box is 12.59 m × 2.5 m × 1.45 m, and the actual model box is shown in Fig. 3.

2.2.2 Rail-bearing beam and subgrade construction

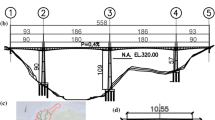

After conversion by the similarity ratio of geometry, the cross-sectional view of the rail-bearing beam structure and the subgrade structure is shown in Fig. 4.

In this model test, the group A-fill is filled on the upper roadbed, the group B-fill is filled in the lower roadbed, the cement-treated soil is filled in the subgrade body, and a coarse sand cushion about 10 cm thick is designed at the bottom of the model box. Backfill is set up from the top surface of the subgrade to the top surface of the base [15], which is filled with cement-treated soil. Screening tests and heavy compaction tests were performed on group A-fill and group B-fill (Fig. 5). The curve showing the relation between the moisture content and dry density is shown in Fig. 6a, and particle size distribution is shown in Fig. 6b. After each layer of subgrade construction, using Evd (dynamic deformation modulus) as the index to detect the compaction quality of the subgrade, the Evd test is shown in Fig. 5d. According to the corresponding relationship among K (compaction coefficient), K30 (ground coefficient) and Evd (dynamic deformation modulus) [27, 28], the minimum values of Evd in the upper and the lower roadbed are 39 and 37 MPa, respectively.

Rail-bearing beams are composed of blocks and base plates, both of which are reinforced concrete structures. The single-span rail-bearing beam structure consists of a base plate and 10 door-shaped blocks, and the single-span rail-bearing beam structure is shown in Fig. 5b. There are two-span rail-bearing beam structures along the longitudinal direction of the text model, namely, the loaded beam and the nonloaded beam (Fig. 7). The two-span rail-bearing beam structure is connected by five dowel steels. The dowel steel material is Q235 steel, and the specification is 150 mm. A plain concrete cushion should be laid between the base plate and the surface of the subgrade, as shown in Fig. 5f.

The specific parameters of the test model are shown in Table 2.

2.3 Layout monitoring equipment and data collection

In a previous study [2, 18], the numerical simulation results show that the position of the peak value of the dynamic stress is near the edge of the base plate. Therefore, in this study, earth pressure cells and accelerometers are also installed at the edge of the base plate. The model test mainly includes dynamic stress, acceleration, and cumulative deformation. Two test sections were selected in the loaded beam, namely monitoring Sect. 1 and monitoring Sect. 2. The earth pressure cells and accelerometers were buried at the top (T2 and T4) and bottom (T10 and T13) of the upper roadbed and the middle (T11 and T14) and bottom (T12 and T15) of the lower roadbed, and displacement meters (S1 and S2) were installed on the top surface of the base plate. Along the longitudinal direction of the line, the test model buries nine earth pressure cells on the top surface of the upper roadbed: five (T1–T5) in the loaded beam section and four (T6–T9) in the nonloaded beam section. The layout of the sensor elements of the test model is shown in Fig. 7. The sensor is buried as shown in Fig. 8. The sensor element information is shown in Table 3. The data collection frequency of the model test is 2000 Hz. After a certain number of cyclic loadings, the data are continuously collected for 30 s as sample data, and then classified according to the same test indicators. After eliminating the significant abnormal data, the upper limit of the 95% confidence interval is obtained, which is the dynamic response amplitude after a certain number of load cycles for analysis.

3 Model loading scheme

3.1 Load scheme

The long-term dynamic stability of a high-speed railway subgrade is generally controlled by low-frequency loads [29, 30]. Therefore, the cycle load is combined with different speeds; namely, the loading frequency is calculated at a speed of 100 km/h, and the load amplitude is calculated at a speed of 200 km/h.

3.1.1 Load frequency

The model loading frequency (f) is calculated by Eq. (1):

where v is the train speed (100 km/h), l is the length of a single train (16.34 m) [31], and the similarity ratio of cycle loading frequency of the test model is 2−1/2. Then, the loading frequency of the test model after conversion using the similarity ratio is 1.20 Hz, and a single load cycle is 0.83 s.

3.1.2 Load amplitude

The maximum value for loading is composed of the static load of the track structure and the dynamic load of the train, and the minimum value for loading is the static load of the track structure.

The static load of the track is calculated by Eq. (2):

where Ps is the static load of the track (kN), ps is the unit weight of the maglev track (kN·m−1), and L is the length of the rail-bearing beam (m).

The train dynamic load amplitude [15] is calculated by Eq. (3):

where Pd is the dynamic load of the train (kN), P is the static load of the train (kN), μ is the dynamic coefficient and is calculated using Eqs. (4) and (5):

where g is the acceleration of gravity (m·s−2), v is the designed speed (m·s−1), α is the crossed slope angle of the line (°), β is the longitudinal slope angle of the line (°), Rh is the radius of the plane curve (m), and Rv is the radius of the vertical curve (m).

In this test, the 200 km/h load dynamic coefficient is calculated under the most unfavorable conditions. The maximum value of some parameters, such as the crossed slope angle of the line (α), the longitudinal slope angle of the line (β), the radius of the plane curve (Rh), and the radius of the vertical curve (Rv), were adopted by the code [15]. The calculation parameters of the dynamic coefficient are shown in Table 4.

The maximum and minimum values for the test model load are calculated using Eqs. (6) and (7), respectively:

where CF is the similarity constant of the concentrated load.

The literature [31] shows that the unit weight of the maglev track is 4.5 kN/m, the unit weight of the maglev train is 25.8 kN/m, and the length of a single rail-bearing beam is 12 m. The calculated testing model load amplitude (Fmin, Fmax), dynamic coefficient (μ), and load frequency (\(f\)) are shown in Table 5.

3.1.3 Load waveform

The length of a single MLS maglev train is approximately 16 m; the maglev load is only generated at the coil position, which is defined as the “maglev load action region”; and gaps exist between adjacent coils, which is defined as the “maglev load vacuum region” [16, 31], as shown in Fig. 9. Additionally, the time history curve of dynamic stress on the top surface of the rail-bearing beam [31] is shown in Fig. 9. Therefore, the load waveform of a single maglev train is an equilateral trapezoid, which is simulated by the vibration exciter, and a load cycle represents a train passing through the monitoring section. The test model load waveform is shown in Fig. 9.

3.2 Service environment simulation and testing process

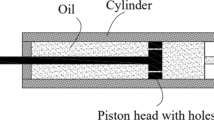

3.2.1 Loading devices and rainfall equipment

In the indoor model testing site, the loading system (MTS) in the laboratory, which consists of a reaction frame, actuators, and a distribution girder, is used to generate equivalent vertical loadings at the rail-bearing beam to simulate the dynamic excitations. In contrast to the traditional railway point load, the maglev train produces a uniform distributed force on the top surface of the rail-bearing beam. Thus, the more vibration exciters that exist to simulate the MLS maglev load, the better the result. Since the loading equipment and site factors were restricted, two vibration exciters were selected for this model test (Fig. 10a), which are controlled via a single terminal and loaded simultaneously. To uniformly distribute the MLS maglev train load on the rail-bearing beam, a uniform distributed load tool is designed and fabricated, which is installed between the vibration exciters and the rail-bearing beams. The main body of the uniform distributed load tool is made of three steel plates welded together to form an I-steel structure (Fig. 10b). Then, ribbed plates are set at the position on both sides of the abdomen. The two vibration exciters are located at approximately 1/4 of the position of the uniform distributed load tool (as shown in Fig. 7a). Rainfall equipment was designed to simulate rainfall conditions, which consists of a water tank, a water pump, a hose, a spray device, and a steel pipe bracket, as shown in Fig. 10c and d.

3.2.2 Testing process

The cumulative number of cyclic loadings can simulate the traffic volume of the line. As the departure interval is 6 min, the maximum daily traffic volume is approximately 192 trains, and the annual traffic volume is approximately 70,000 trains. Three-carriage marshaling is adopted in the Changsha maglev test line in China, so the maximum number of carriages per year is 210,000. One cycle of excitation represents a carriage passing through the monitoring section.

After the model is built, model loading is started. Four main steps are involved in the loading of the test model, as described below:

-

Step 1 Before formal loading, the test model is preloaded 1000 times.

-

Step 2 The testing model successfully performs 210,000 cyclic loadings, and the data are recorded from the model test.

-

Step 3 Cyclic loading is stopped and rainfall begins. The values for the rain speed and rainfall are 12 mm/h and 4.17 m3, respectively, which are based on the largest rainfall in history in Changsha, China.

-

Step 4 The rainfall is stopped, 210,000 cyclic loadings are continued, and the data are recorded from the model test.

After completing the first three steps listed above, the test model completed 420,000 excitations. The cyclic loading condition before rainfall is named the “natural condition,” and the cyclic loading condition after rainfall is named the “rainfall condition.” The test model box did not implement fully enclosed waterproof measures, and rainwater flowed out of the model box after flowing through the subgrade.

4 Test results and analysis

4.1 Typical time history curve of dynamic stress and acceleration

Figure 11 shows the typical time history curves of the dynamic stress and acceleration on the top surface of the subgrade. The dynamic stress time history curve, which is similar to the loading curve, is a trapezoid with a single load cycle. The dynamic stress fluctuation is small within the maglev load action region; conversely, it is large within the maglev load vacuum region. For the acceleration time history curve, there are sudden load changes within the maglev load vacuum region, resulting in large acceleration fluctuations; however, the loads within the maglev load action region are uniform and the acceleration fluctuations are small.

4.2 Variation curve of the moisture of the subgrade

The moisture content of the subgrade fill was tested during the construction period and the demolition period of the test model, as shown in Fig. 12. After the test model is loaded under rainfall conditions, the moisture content of the subgrade fill increases as a whole; at depths of 0, 0.15, 0.45, and 0.75 m, the moisture content increases by 9.1%, 37.5%, 26.4%, and 26.1%, respectively. Combined with particle size distribution in the subgrade filling soil, as shown in Fig. 6b, the group A-fill and groups B-fill are coarse-grained fills with good permeability. Therefore, most of the water flows through the upper roadbed and the lower roadbed.

4.3 Dynamic stress analysis

4.3.1 Dynamic stress distribution along the depth direction of the subgrade

Figure 13 shows the variation in the dynamic stress peak of the subgrade with load cycles under different working conditions. Along the depth of the subgrade, a depth of 0 m represents the top surface of the subgrade and is the same in subsequent figures. Under natural conditions, the dynamic stress increases slowly at the initial stage of loading and tends to be stable when the number of load cycles reaches 60,000. Under rainfall conditions, the dynamic stress of the subgrade fluctuates substantially during loading from 0 to 40,000 cycles and tends to be stable after 40,000 load cycles.

Under natural and rainfall conditions, the dynamic stress peak is averaged after 60,000 load cycles and 40,000 load cycles, respectively. The attenuation curves of the dynamic stress along the depth direction of the subgrade are obtained, as shown in Fig. 14. Near the edge of the base plate, at depths of 0.0, 0.15, 0.45, and 0.75, the dynamic stress values are 11.69, 8.96, 7.46, and 4.44 kPa under natural conditions, respectively, and the corresponding dynamic stress stability values are 12.03, 10.64, 9.65 and 7.04 kPa under rainfall conditions, respectively. The corresponding increases in the dynamic stress from the natural condition to the rainfall condition are 2.9%, 18.8%, 29.4%, and 58.6%. Combined with the variation of the moisture content of the subgrade fill (Fig. 12), the results show that water exerts a certain effect on the dynamic stress of the subgrade. Under rainfall conditions, the water content inside the subgrade increases relatively, the pore water pressure increases, the effective stress decreases, and the dynamic stress attenuation decreases; therefore, the dynamic stress along the depth direction of the subgrade is larger than under natural conditions [32]. Under natural and rainfall conditions, the dynamic stress in the subgrade bed range is attenuated by 62% and 42%, respectively.

4.3.2 Longitudinal distribution of the dynamic stress

Under different working conditions, the longitudinal distribution curves of the dynamic stress on the top surface of the subgrade are shown in Fig. 15. According to a previous study [15], the rail-bearing beam is an elastic foundation beam, and the beam ends are prone to stress concentration. The ratios of the dynamic stress at the ends of the loaded beam to the average dynamic stress of the three measuring points in the middle of the loaded beam are listed in Table 6. Under natural and rainfall conditions, the stress ratios far from the dowel steel structures (T1) are 1.07 and 1.03, respectively. Through an on-site dynamic test, Yi [16] found that the ratio of the dynamic stress between the beam end and the beam middle was 1.11, and the structural form of the rail-bearing beam was similar to that of the present study, both of which were door-shaped block railing-bearing beams. However, the rail-bearing beam connection in the literature [16] adopted an error-proof platen. The aforementioned result is similar to the findings of Ref. [16]. In contrast, under natural and rainfall conditions, the stress ratios close to the dowel steel structures (T5) are 0.80 and 0.83, respectively. These results indicate that the dowel steel structures prevent stress concentration at the end of the loaded beam.

Based on the Winkler elastic foundation beam model, the subgrade structure and the rail-bearing beam structure are simplified, the longitudinal diffusion distance of the dynamic stress on the surface of the subgrade is calculated, and the linear attenuation amplitude of dynamic stress is analyzed. Finally, the attenuation amplitude of the dynamic stress calculated by theory is compared with that of the test.

When the analytical model is simplified according to the Winkler elastic foundation beam theory, the stiffness of the superimposed beam formed by the block and the base plate is much greater than the dowel steel structure; therefore, the dowel steel structure can be ignored, and a single-span rail-bearing beam structure is adopted. The maglev train loads are transferred through the base plate to the concrete cushion, and the load exerted by the base plate on the concrete cushion is simplified as a uniformly distributed load. The concrete cushion is simplified as an infinite beam, and the subgrade is simplified as a continuous Winkler elastic foundation. The longitudinal distribution length of the dynamic stress on the surface of the subgrade under the single-span rail-bearing beam is calculated. The simplified model is shown in Fig. 16.

The differential equation of the deflection deformation of the Winkler elastic foundation beam under uniformly distributed load is shown as follows:

where EI is the stiffness of the concrete cushion, ω is the deflection deformation of the concrete cushion, K30 is the support stiffness of the subgrade, K30 is calculated using Eq. (9), and b is the width of the concrete cushion.

Equation (8) is simplified into a fourth-order homogeneous constant coefficient differential equation as follows:

The standard form of Eq. (10) is transformed into a fourth-order homogeneous constant coefficient differential equation, as follows:

where \(\lambda = \sqrt[4]{{\frac{{K_{30} b}}{4EI}}}\). The general solution of Eq. (11) is shown in Eq. (12):

Let \(\omega = 0\), and the special solution to Eq. (11) is

Using the superposition principle, for a single-span rail-bearing beam under uniform distributed load, the distribution length of the dynamic stress on the surface of the subgrade along the longitudinal direction is calculated by Eq. (14):

where Lwz is the distribution length of the dynamic stress along the longitudinal direction, and L is the length of the single-span rail-bearing beam.

The calculation parameters of Eq. (8) are shown in Table 7. When there is no dowel steel structure, the calculation results show that the distribution length of the dynamic stress on the surface of the subgrade is 7.15 m under the single-span rail-bearing beam, and the length of the single-span rail-bearing beam is 5.79 m; therefore, the increase in the dynamic stress diffusion distance along one side of the line is 0.68 m. The distance between T6 and the end of the loaded beam is 0.2 m, therefore, the linear attenuation amplitude of the dynamic stress at T6 is 29%. Figure 15 shows that under natural and rainfall conditions, the dynamic stress attenuation amplitudes from T5 to T6 are 39% and 32%, respectively. The test results of the dynamic stress attenuation amplitude are larger than the theoretical calculation result, mainly because of the dowel steel structure in the base plate of the rail-bearing beam. The dynamic load at the end of the loaded beam is transmitted by the dowel steel and shared by the nonloaded beam; therefore, the dynamic stress is transmitted farther along the longitudinal direction of the line. Under rainfall conditions, the dynamic stress attenuation value is smaller than that under natural conditions and is 3.72 kPa under natural conditions, and 2.93 kPa under rainfall conditions. The main reason is that the dynamic deformation of the loaded beam increases under rainfall conditions; therefore, the nonloaded beam bears more dynamic stress at the connection position.

4.4 Acceleration analysis

Figure 17 shows the variation in the acceleration amplitude of the subgrade with different numbers of load cycles. Under natural conditions, the acceleration amplitude fluctuates substantially from 0 to 30,000 load cycles and then tends to be stable after 30,000 load cycles. Under rainfall conditions, the acceleration amplitudes tend to be stable after 40,000 load cycles, mainly because the moisture content inside the subgrade increases, and the pore water pressure in the subgrade increases rapidly, resulting in an increase in the instantaneous stiffness of the subgrade, which is not conducive to the attenuation of acceleration [33]. As the number of loadings increased, the rainwater inside the subgrade gradually flowed out of the model box, the moisture content gradually decreased and stabilized inside the subgrade. The instantaneous stiffness of the subgrade gradually decreased thus the acceleration amplitude tended to become stable with the increase in load cycles.

Under natural and rainfall conditions, the acceleration amplitudes were averaged after 30,000 and 40,000 load cycles, respectively, and the acceleration attenuation along the depth direction of the subgrade is shown in Fig. 18. The variation in the acceleration amplitudes along the depth direction of the subgrade is similar to the variation in the dynamic stress. Along the depth direction of the subgrade, the acceleration under rainfall conditions is larger than that under natural conditions. At the depth of 0, 0.15, 0.45, and 0.75 m, the acceleration under rainfall conditions are increased by 0.002, 0.011, 0.018, and 0.025 m/s2, respectively, compared with the natural condition. Considering the variation curve of the moisture content of the subgrade fill (Fig. 12), water exerts a certain effect on the acceleration of the subgrade. In the case of the same test load, the acceleration increases with the water content. Namely, under rainfall conditions, acceleration attenuation is slower than that under natural conditions, indicating that when the moisture content of the subgrade increases, the stiffness of the subgrade decreases, the vibration energy attenuation is weakened, the subgrade vibrations are more severe, and the vibration load is transmitted to a deeper position in the subgrade than that under natural conditions [30]. Under natural and rainfall conditions, the acceleration in the subgrade bed range is attenuated by 93% and 78%, respectively. The subgrade exerts obvious absorption and dissipation effects on vertical vibrations under both conditions.

4.5 Long-term dynamic stability analysis

In this paper, the critical dynamic stress method combined with cumulative deformation is used to evaluate the long-term dynamic stability of the MLS maglev subgrade structure.

4.5.1 Long-term dynamic stability analysis based on critical dynamic stress

When the dynamic stress is greater than a certain limit, the internal structure of the soil is damaged by cyclic loading, the bearing capacity of the soil decreases rapidly, and the deformation of the soil increases sharply with a small number of load cycles; namely, macroscopic damage to the soil is observed. When the applied dynamic stress is less than this limit, cyclic loading results in the pore volume of the soil being continuously compressed until its compression is stable, and this limit value is the critical dynamic stress [34]. Therefore, the critical dynamic stress is the key parameter used to evaluate the long-term dynamic stability of the subgrade, and the method used to obtain it is mainly triaxial testing in the laboratory. In a previous study [35], the critical dynamic stress of group B-fill with optimal and saturated moisture contents was obtained through a large-scale triaxial test. In other studies [34, 36], the critical dynamic stress of group A-fill with optimal and saturated water contents was obtained. The critical dynamic stresses of group A-fill and group B-fill with optimal and saturated water contents at different states are listed in Table 8. Among them, the sample with a confining pressure of 20 kPa approximately represents the fill near the surface of the subgrade, and the confining pressure of 40 kPa approximately represents the fill 1.5 m below the surface of the subgrade [37].

The dynamic stress at the top surface of the upper roadbed (corresponding to a subgrade depth of 0 m) and the top surface of the lower roadbed (corresponding to a subgrade depth of 0.15 m) are selected to assess the long-term dynamic stability of the subgrade, and the subgrade dynamic stresses are averaged after 60,000 load cycles under natural conditions and 40,000 load cycles under rainfall conditions. The measured dynamic stress and critical dynamic stress are listed in Table 9. Under both working conditions, the dynamic stress level is less than 1/5 of the critical dynamic stress. Thus, the dynamic strength of the new subgrade structure is in a stable state under natural and rainfall conditions.

4.5.2 Long-term dynamic stability analysis combined with cumulative deformation

The long-term dynamic stability of the subgrade based on the cumulative deformation is judged based on two primary factors. Figure 19 shows the cumulative deformation curve and the variation curve for the plastic strain rate on the top surface of the base plate. In this paper, indoor simulation tests for rainfall conditions are conducted after the completion of the natural conditions. Therefore, the cumulative deformation under rainfall conditions is the sum of rainfall conditions and natural conditions.

(1) Cumulative deformation growth rate

Referring to the research experience of Werkmeister et al. [38], for the stable state of the coarse-grained soil of the subgrade fill, the plastic strain rate \(\dot{\varepsilon }_{{\text{p}}} { = 1} \times {10}^{ - 5}\) is used as the boundary standard. The plastic strain rate \(\dot{\varepsilon }_{{\text{p}}}\) is defined by

where \({\text{d}}\varepsilon_{{\text{p}}}\) is the change in the plastic strain in each load cycle and N is the number of load cycles.

From Fig. 19, the cumulative deformation under both working conditions gradually becomes stable with increasing numbers of load cycles, and the maximum plastic strain rates under natural and rainfall conditions are 5.87 × 10−8 and 1.11 × 10−7, respectively, which are far less than the 10−5 limit. Therefore, the subgrade structure is in a stable state under long-term dynamic loading.

(2) Cumulative deformation limit

For a subgrade structure with deformation as the control target, even if the subgrade dynamic stress is lower than its critical dynamic stress and the structure is not damaged, permanent deformation exceeding the limit of the specification may occur. Therefore, assuming that the cumulative deformation growth rate has a certain regularity, the cumulative deformation must not exceed the standard limit [23].

Figure 19 shows that the cumulative deformation tends to be stable after 30,000 and 40,000 load cycles under natural and rainfall conditions, respectively. The stable final values of the cumulative deformation under natural and rainfall conditions are 1.97 and 3.86 mm, respectively. The corresponding actual cumulative deformations after similarity ratio conversion are 3.94 and 7.72 mm, respectively. The Chinese code for the design of MLS maglev transit [15] stipulates that the cumulative deformation of the subgrade postconstruction is 30 mm, so the cumulative deformation under both working conditions is within the allowable range. Under rainfall conditions, the subgrade deformation increment is 3.78 mm, accounting for 49% of the total settlement under rainfall conditions, indicating that good subgrade waterproofing and drainage facilities are crucial for reducing postconstruction subgrade settlement [39].

5 Conclusions

In this paper, the new subgrade structure of an MLS maglev is the research object. The dynamic loads of the subgrade structure generated by a maglev train are simulated using two vibration exciters. A uniform distributed load tool and rain equipment are designed, and indoor cyclic excitation tests are performed under natural and rainfall conditions. The dynamic parameters of the subgrade structure at different positions under different working conditions are obtained, and the long-term dynamic stability of the subgrade structure is evaluated. The following conclusions are drawn from the test results:

-

1.

Under natural and rainfall conditions, the stable mean values of dynamic stress on the top surface of the subgrade near the edge of the base plate are 11.69 kPa and 12.03 kPa, respectively. The dynamic stress in the subgrade bed range is attenuated by 62% and 42%, and the acceleration in the subgrade bed range is attenuated by 93% and 78%. The subgrade exerts obvious absorption and dissipation effects on vertical vibrations.

-

2.

Water has a certain effect on the dynamic characteristics of the subgrade; the dynamic stress and acceleration increase with increasing moisture content, and the cumulative deformation of the subgrade under natural conditions increases by 49% compared to the rainfall conditions. Therefore, strengthening the anti-drainage measures of the subgrade can effectively reduce the dynamic response degree, control the settlement deformation of the subgrade, and reduce subgrade damage.

-

3.

By setting the dowel steel structure between the rail-bearing beams, stress concentration at the end of the loaded beam can be prevented, and the diffusion distance of the dynamic stress along the longitudinal direction increases. At the connection between the loaded beam and the nonloaded beam, the test results of the dynamic stress attenuation amplitude are larger than the calculated result, owing to the dowel steel structure in the base plate of the rail-bearing beam.

-

4.

Under natural and rainfall conditions, the measured dynamic stresses in the subgrade are all less than 1/5 of the critical dynamic stress, and the plastic strain rates of the subgrade fills are 5.87×10−8 and 1.11×10−7, respectively, which are far less than the boundary standard of 1×10−5. The actual cumulative deformations after conversion by the similarity ratio are 3.94 mm and 7.72 mm, which are less than the limit of 30 mm for the postconstruction settlement of the subgrade structure. Based on these results, the new MLS maglev subgrade structure has good long-term dynamic stability.

References

Zhai W, Zhao C (2016) Frontiers and challenges of sciences and technologies in modern railway engineering. J Southwest Jiaotong Univ 51(2):209–226 (in Chinese)

Wang W, Deng Z, Li Y, Huang Z, Niu Y, **e K (2022) Numerical analysis of subgrade behavior under a dynamic maglev train load. Adv Civ Eng 2022:1–17

Yasuda Y, Fu**o M, Tanaka M, Ishimoto S (2004) The first HSST maglev commercial train in Japan. In: The 18th International Conference on Magnetically Levitated Systems and Linear Drives, Shanghai, China, Oct, 2004

Park D, Shin B, Han H (2009) Korea’s urban maglev program. Proc IEEE 97(11):1886–1891

Guardo J L (2007) Magnetic levitation transport system. U.S. Patent US20070089636A1, 26 April 2007

Ding J, Long Z, Yang X (2017) Numerical analysis of eddy current effect of EMS system for medium-low speed maglev train. In: 2nd International Conference on Robotics and Automation Engineering (ICRAE), Shanghai, China, December, 2017, pp 301–305

Li W, Li D, Zhang X, Cao J (2016) Status and research progress of the linear rail transit system in China. Transport Syst Technol 2(1):16–41

Wei N, Chen Y, Yi Y, Zhang F, Wang S (2016) Design and optimization of positioning and speed measuring system in engineering application for medium-low speed maglev train. In: 2016 IEEE International Conference on Vehicular Electronics and Safety (ICVES). Bei**g, China, Jul, 2016. IEEE, pp 1–5

Yang Q, Yu P, Li J, Chi Z, Wang L (2020) Modeling and control of maglev train considering eddy current effect. In: 2020 39th Chinese Control Conference (CCC), Shenyang, China, Jul. 2020. IEEE, pp 5554–5558

Feng Y, Zhao C, Zhai W, Tong L, Liang X, Shu Y (2022) Dynamic performance of medium speed maglev train running over girders: field test and numerical simulation. Int J Struct Stab Dyn 1:1–26

Tan Q, Qi H, Li J, Ying T (2012) The reliability modeling and analysis on brake system of medium-low speed maglev train. In: 2012 International Conference on Computer Distributed Control and Intelligent Environmental Monitoring. Zhangjiajie, China, Apr, 2012. IEEE, pp 772–777

Yao H (2021) Research on the technical standard of low-lying structure of medium and low speed maglev traffic engineering. J Railw Eng Soc 38(91–95):101 (in Chinese)

Li M, Luo S, Ma W, Lei C, Li T, Hu Q, Zhang Z, Han Y (2021) Experimental study on dynamic performance of medium and low speed maglev train-track-bridge system. Int J Rail Transport 9(3):232–255

Song Y, Lin G, Ni F, Xu J, Chen C (2021) Study on coupled vertical vehicle-bridge dynamic performance of medium and low-speed maglev train. Appl Sci 11(13):1–17

China Railway Construction Corporation Limited (2019) Code for design of medium and low speed maglev transit (Q/CRCC 32803–2019). People's Transportation Press, Bei**g, 2019 (in Chinese)

Yi X (2014) Performance study on subgrade-beam structure in medium and low speed maglev test line. Dissertation, Southwest Jiaotong University, Chengdu

Wang D (2013) Study on space coupling vibration of low-medium speed maglev train and low-lying structure. Ph.D. Thesis, Southwest Jiaotong University, Chengdu

Liu J (2017) Research on design of subgrade bed and bearing beam for medium and low speed maglev. Ph.D. Thesis, Southwest Jiaotong University, Chengdu

Wang Y, Guo P, Shan S, Yuan H, Yuan B (2016) Study on strength influence mechanism of fiber reinforced expansive soil using jute. Geotech Geol Eng 34(4):1079–1088

Shang Y, Xu L, Cai Y, Liu W (2019) Dynamic characteristics of cement-improved expansive soil subgrade under cyclic dynamic load of heavy haul railway. China Railw Sci 40(6):19–29 (in Chinese)

Wang L, Weng Z, Wang T et al (2021) Critical dynamic stress and accumulative deformation evolution of embankment silty clay subjected to cyclic freeze-thaw. Shock Vib 2021:1–9

Yang G, Wang X, Zhang B (2011) Dynamic characterization of cement-treated high-speed railway subgrade. Adv Mater Res 250–253:3909–3912

Ma X, Zhang Z, Zhang P, Wang X (2020) Long-term dynamic stability of improved loess subgrade for high-speed railways. Proc Inst Civ Eng Geotech Eng 173(3):217–227

Heath DL, Waters JM, Shenton MJ, Sparrow RW (1972) Design of conventional rail track foundations. Proc Inst Civ Eng 51(2):251–267

Cai Y, Cao X (1996) Study of the critical dynamic stress and permanent strain of the subgrade-soil under repeated load. J Southwest Jiaotong Univ 31(1):1–5 (in Chinese)

Shang Y, Xu L, Cai Y (2020) Study on dynamic characteristics of cement-stabilized expansive soil subgrade of heavy-haul railway under immersed environment. Rock Soil Mech 41(2739–2745):2755 (in Chinese)

National Railway Administration of the people’s Republic of China (2017) Code for design of railway earth structure (TB 10001–2016). China Railway Press, Bei**g, 2017 (in Chinese)

Yang YH, Huang DW, Lai GQ, **a Q (2011) Analysis of ground coefficient and modulus of deformation of gobi area filler in high-speed railway subgrade. Rock Soil Mech 32:2051–2056 (in Chinese)

Hu Y, Li N (2010) Design principle of ballastless track subgrade for high-speed railway. China Railway Press, Bei**g (in Chinese)

Qiu M, Yang G, Shen Q, Yang X, Wang G, Lin Y (2017) Dynamic behavior of new cutting subgrade structure of expensive soil under train loads coupling with service environment. J Cent South Univ 24(4):875–890

Shi L (2021) Indoor test and numerical analysis of subgrade bed for low-lying structure under medium-low-speed maglev train. Dissertation, Southwest Jiaotong University, Chengdu

Huang J, Chen J, Ke W, Liu K, Bian Y (2021) Impacts of initial deviator stress and cyclic confining pressure on mechanical behaviors of Ningbo clay under cyclic loading. Int J Geomech 21:1–7

Wang L, Yang G (2013) Model tests on static and dynamic performances of cut subgrade of railways in medium-strong expensive soil area. Chin J Geotech Eng 1:137–143 (in Chinese)

Zhai B, Leng W, Xu F, Zhang S, Ye X, Leng H (2020) Critical dynamic stress and shakedown limit criterion of coarse-grained subgrade soil. Transport Geotech 23:1–8

Yang Y (2009) Experiment study on typical filler for passenger dedicated railway subgrade roadbed by static and dynamic triaxial test. Ph.D. Thesis, Southwest Jiaotong University, Chengdu

Wang K, Zhuang Y (2021) Characterizing the permanent deformation response-behavior of subgrade material under cyclic loading based on the shakedown theory. Constr Build Mater 311:125325

**ao J, Hsein J, Xu C (2014) Strength and deformation characteristics of compacted silt from the lower reaches of the Yellow River of China under monotonic and repeated loading. Eng Geol 178:49–57

Werkmeister S, Dawson A, Wellner F (2001) Permanent deformation behavior of granular materials and the shakedown concept. Transp Res Rec 1757(1):75–81

Cai Y, Xu L, Liu W, Shang Y, Su N, Feng D (2020) Field test study on the dynamic response of the cement-improved expansive soil subgrade of a heavy-haul railway. Soil Dyn Earthq Eng 128:105878

Acknowledgements

This work was supported by the 2018 Major Science and Technology Project of China Railway Construction Corporation Limited (No. 2018-A01) and the National Natural Science Foundation of China (No. 51978588).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dong, M., Wang, W., Wang, C. et al. Physical modeling of long-term dynamic characteristics of the subgrade for medium–low-speed maglevs. Rail. Eng. Science 31, 293–308 (2023). https://doi.org/10.1007/s40534-022-00294-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40534-022-00294-x