Abstract

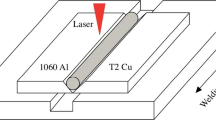

In the past research, there was a gap in the field of Al/Cu dissimilar metal welding with Ag intermediate layer, and attention to the joint resistivity is insufficient. This paper has used laser welding to study this problem. The mechanical and electrical properties of the joints were tested, and the microstructure and fracture surface of the weld were observed, along with the analysis of their phase composition and formation mechanism. The results show that the Ag–Al–Cu ternary system forms on the weld, and Ag inhibits the formation of IMC in the Al/Cu system, with the main IMCs being Al2Cu and Ag3Al. Part of the Ag-rich and Al-rich phases are dispersed in small particle shape, providing a strengthening effect in various areas. After adjusting the welding parameters, excellent joints can be obtained, with a tensile strength of 98.05 MPa, which is 78.5% of the base metal, and a resistivity of 2.47 μΩ cm. The fracture occurs in the softened zone of the Al-side base metal, indicating a ductile fracture. These findings have demonstrated that good mechanical and electrical properties can be obtained by adding Ag as an intermediate layer of the joint.

Similar content being viewed by others

References

Go, B. S., Kim, K. H., Ro, C. S., & Bang, H. S. (2022). Influence of process parameters on formation of Al/Cu dissimilar weld using ultrasonic welding. International Journal of Precision Engineering and Manufacturing, 23, 1359–1365. https://doi.org/10.1007/s12541-022-00748-6

Kang, J. W., Zhang, S. W., Thi, T. A., Hong, S. T., Lee, S. W., & Han, H. N. (2023). Friction-assisted dissimilar solid state lap joining of aluminum and copper pipes. International Journal of Precision Engineering and Manufacturing, 24, 199–208. https://doi.org/10.1007/s12541-022-00745-9

Kang, J. W., Zhang, S. W., Thi, T. B., Hong, S. T., Lee, S., & Han, H. N. (2022). Friction-assisted dissimilar solid-state lap joining of aluminum and copper pipes. International Journal of Precision Engineering and Manufacturing, 9, 175–190. https://doi.org/10.1007/s12541-022-00745-9

Zhao, S. S., & Li, Y. M. (2023). Numerical analysis of welding Direction and sequence for controlling distortion and residual stress in aluminum plate-sleeve structures. International Journal of Precision Engineering and Manufacturing, 24, 1011–1031. https://doi.org/10.1007/s12541-023-00794-8

Guo, Y., Liu, G., **, H., Shi, Z., & Qiao, G. (2011). Intermetallic phase formation in diffusion-bonded Cu/Al laminates. Journal of Materials Science, 46(8), 2467–2473. https://doi.org/10.1007/s10853-010-5093-0

Lei, Z., Zhang, X., Liu, J., & Li, P. (2021). Interfacial microstructure and reaction mechanism with various weld fillers on laser welding-brazing of Al/Cu lap joint. Journal of Manufacturing Processes, 67, 226–240. https://doi.org/10.1016/j.jmapro.2021.04.065

Weigl, M., Albert, F., & Schmidt, M. (2011). Enhancing the ductility of laser-welded copper–aluminum connections by using adapted filler materials. Physics Procedia, 12, 332–338. https://doi.org/10.1016/j.phpro.2011.03.141

Gan, G., Chen, S., Jiang, L., Liu, C., Ma, P., Huang, T., Cheng, D., & Liu, X. (2023). Influence of bonding temperature on the properties of Cu/ (SAC mixed powder)/Al joints under ultrasonic-assisted. Soldering & Surface Mount Technology. https://doi.org/10.1108/SSMT-07-2022-0047

Alex, A. J., Vaira, V. R., Padmanaban, R., & Govindaraju, M. (2020). Effect of Fe particles on the microstructural evolution and mechanical properties of friction welded Al–Cu components. Australian Journal of Mechanical Engineering, 20(3), 855–865. https://doi.org/10.1080/14484846.2020.1756184

Kurabayashi, K., Tokita, S., & Sato, Y. S. (2022). Effect of Ni addition on the interfacial strength of Al/Cu dissimilar welds produced by friction stir lap welding. Metals, 12(3), 453. https://doi.org/10.3390/met12030453

Sahu, P. K., Pal, S., & Pal, S. K. (2017). Al/Cu dissimilar friction stir welding with Ni, Ti, and Zn foil as the interlayer for flow control, enhancing mechanical and metallurgical properties. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 48, 3300–3317. https://doi.org/10.1007/s11661-017-4093-y

Pietrzak, K., et al. (2018). Effect of carbon forms on properties of Ag–C composites contact materials. Materials Science, 24(1), 69–74. https://doi.org/10.5755/j01.ms.24.1.17769

Wang, D. D., Tian, W. B., Ma, A. B., Ding, J. X., Wang, C. S., You, Y. Y., et al. (2019). Anisotropic properties of Ag/Ti3ALC2 electrical contact materials prepared by equal channel angular pressing. Journal of Alloys and Compounds, 784, 431–438. https://doi.org/10.1016/j.jallcom.2019.01.083

Hwang, B., Shin, H. A. S., Kim, T., Joo, Y. C., & Han, S. M. (2015). Highly Reliable Ag nanowire flexible transparent electrode with mechanically welded junctions. Small (Weinheim an der Bergstrasse, Germany), 10(16), 3397–3404. https://doi.org/10.1002/smll.201303906

Aizamddin, M. F., Mahat, M. M., Ariffin, Z. Z. Z., Samsudin, I., Razali, M. S. M., & Amir, M. A. (2021). Synthesis, characterisation and antibacterial properties of silicone-silver thin film for the potential of medical device applications. Polymers, 13(21), 3822. https://doi.org/10.3390/polym13213822

Luo, Q., Xue, S., & Wu, J. (2021). Influences of Sn on properties of Ag-based and Cu-based brazing filler metals. Crystals, 11(11), 1403. https://doi.org/10.3390/cryst11111403

Witusiewicz, V. T., Hecht, U., Fries, S. G., & Rex, S. (2005). The Ag–Al–Cu system: II. A thermodynamic evaluation of the ternary system. Journal of Alloys and Compounds, 387, 217–227. https://doi.org/10.1016/j.jallcom.2004.06.078

Kwak, Y., Kang, T. H., Lee, S. H., & Kang, M. J. (2023). Effects of laser and tungsten arc welding processes on the thermal. International Journal of Precision Engineering and Manufacturing, 24, 531–536. https://doi.org/10.1007/s12541-023-00772-0

Varol, T., Guler, O., Akcay, S. B., & Aksa, H. C. (2021). The effect of silver coated copper particle content on the properties of novel Cu–Ag alloys prepared by hot pressing method. Power Technology, 384, 236–246. https://doi.org/10.1016/j.powtec.2021.02.020

Drevermann, A., Hecht, U., Witusiewicz, V., Böttger, B., & Rex, S. (2005). Univariant Eutetic growth in ternary Al–Cu–Ag-alloys. Microgravity Science and Technology, 16(1–4), 45–49. https://doi.org/10.1007/BF02945944

Fu, S. W., & Lee, C. C. (2018). A study on intermetallic compound formation in Ag–Al system and evaluation of its mechanical properties by micro-indentation. Journal of Materials Science: Materials in Electronics, 29, 3985–3991. https://doi.org/10.1007/s10854-017-8340-1

Yang, H., Reisinger, G., Flandorfer, H., & Richter, K. W. (2020). Phase equilibria in the system Ag–Cu–Si. Journal of Phase Equilibrium and Diffusion, 41(1), 79–92. https://doi.org/10.1007/s11669-020-00781-w

Zhang, Y., Hu, B., Yin, H. Q., Liu, S. H., & Du, Y. (2022). Phase equilibria of the Ag–Cu–M (M = Nb, Fe, Pb) systems. Journal of Phase Equilibrium and Diffusion, 43(5), 533–546. https://doi.org/10.1007/s11669-022-00998-x

Du, D., Fautrelle, Y., Dong, A. P., Shu, D., Zhu, G. L., Sun, B. D., & Li, X. (2018). Effect of Ag content on the microstructure and crystallization of coupled eutectic growth in directionally solidified Al–Cu–Ag alloys. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 49, 4735–4747. https://doi.org/10.1007/s11661-018-4799-5

Acknowledgements

This work was supported by the Fundamental Research Funds for the Central Universities (JZ2021HGTB0098).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, T., Liu, F., Pang, L. et al. Microstructure and Performance Study of Al/Cu Laser Welding with Ag Interlayer. Int. J. Precis. Eng. Manuf. 25, 79–89 (2024). https://doi.org/10.1007/s12541-023-00921-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-023-00921-5