Abstract

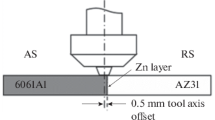

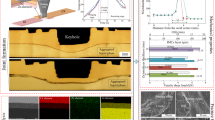

The pure Zn foils with different thicknesses (0.02, 0.05, 0.1, 0.2 and 0.3 mm) were selected as interlayers to improve the quality of friction stir lap welding joint of 7075-T6 Al and AZ31B Mg dissimilar alloys. The effects of the interlayer thickness on joint formation, microstructure and tensile strength were analyzed. The results displayed that the maximum length of the boundary between stir zone (SZ) and thermo-mechanically affected zone in lower plate was obtained by the addition of the Zn interlayer with 0.05 mm thickness. The Mg–Zn intermetallic compounds (IMCs) were discontinuously distributed in the SZ, replacing the continuous Al–Mg IMCs. The size of Mg–Zn IMCs increased with the increase in the thickness of the Zn interlayer. The maximum tensile shear strength of 276 N mm−1 was obtained by the addition of 0.05 mm Zn foil, which increased by 45.6% of that of the joint without the Zn foil addition.

Similar content being viewed by others

References

D. Mishra, R.B. Roy, S. Dutta, S.K. Pal, D. Chakravarty, J. Manuf. Process. 36, 373 (2018)

F.B. Argesi, A. Shamsipur, S.E. Mirsalehi, Acta Metall. Sin. (Engl. Lett.) 31(11), 1183 (2018)

R. Borrisutthekul, Y. Miyashita, Y. Mutoh, Sci. Technol. Adv. Mater. 6, 199 (2005)

H.T. Zhang, J.Q. Song, Mater. Lett. 65, 3292 (2011)

L.H. Shah, N.H. Othman, A. Gerlich, Sci. Technol. Weld. Join. 23, 256 (2018)

H.J. Liu, H. Fujii, M. Maeda, K. Nogi, J. Mater. Process. Technol. 142, 692 (2003)

W.S. Chang, S.R. Rajesh, C.K. Chun, H.J. Kim, J. Mater. Sci. Technol. 27, 199 (2011)

Y.F. Wang, J. An, K. Yin, M.S. Wang, Y.S. Li, C.X. Huang, Acta Metall. Sin. (Engl. Lett.) 31(8), 878 (2018)

W.F. Xu, Y.X. Luo, M.W. Fu, Mater. Charact. 138, 48 (2018)

Y. Huang, X. Meng, Y. **e, L. Wan, Z. Lv, J. Cao, J. Feng, Compos. Part A Appl. Sci. Manuf. 105, 235 (2018)

Z.J. Yan, X.S. Liu, H.Y. Fang, Acta Metall. Sin. (Engl. Lett.) 29(12), 1161 (2016)

B. Fu, G. Qin, F. Li, X. Meng, J. Zhang, C. Wu, J. Mater. Process. Technol. 218, 38 (2015)

S. Ji, Z. Li, L. Zhang, Z. Zhou, P. Chai, Mater. Des. 103, 160 (2016)

J. Mohammadi, Y. Behnamian, A. Mostafaei, H. Izadi, T. Saeid, A.H. Kokabi, A.P. Gerlich, Mater. Charact. 101, 189 (2015)

R. Gan, Y. **, Sci. Technol. Weld. Join. 23, 164 (2018)

S. Niu, S. Ji, D. Yan, X. Meng, X. **ong, J. Mater. Process. Technol. 263, 82 (2019)

S. Ji, S. Niu, J. Liu, X. Meng, J. Mater. Process. Technol. 267, 141 (2019)

M. Farahani, M. Divandari, Int. J. Syst. Signal Control Eng. Appl. 9, 86 (2016)

S. Ji, Z. Li, Z. Zhou, B. Wu, J. Mater. Eng. Perform. 26, 5085 (2017)

P.L. Li, Z.F. Xu, C. Yu, H. Lu, J.S. Yao, G.Y. Chen, Acta Metall. Sin. (Engl. Lett.) 25(3), 225 (2012)

Y. Yue, Z. Li, S. Ji, Y. Huang, Z. Zhou, J. Mater. Sci. Technol. 32, 671 (2016)

X. Dai, H. Zhang, H. Zhang, J. Liu, J. Feng, Mater. Sci. Technol. 32, 164 (2016)

B. Chen, Y. Wang, C. **ao, M. Zhang, G. Ni, D. Li, Mater. Sci. Technol. 34, 703 (2018)

B.A. Saad, W.D. Mohammad, J.H. Daniel, A.W. Muhammad, M.O. Ayman, T.W. Liao, Acta Metall. Sin. (Engl. Lett.) 29(9), 869 (2016)

S. Firouzdor, V. Kou, Weld. J. 88, 213 (2009)

A. Abdollahzadeh, A. Shokuhfar, J.M. Cabrera, A.P. Zhilyaev, H. Omidvar, J. Manuf. Process. 34, 18 (2018)

F. Liu, Z. Zhang, L. Liu, Mater. Charact. 69, 84 (2012)

Y. Zhang, Z. Luo, Y. Li, Z.M. Liu, Z.Y. Huang, Mater. Des. 75, 166 (2015)

H.J. Liu, Y.Y. Hu, Y.X. Peng, C. Dou, Z.G. Wang, J. Mater. Process. Technol. 238, 244 (2016)

S.T. Jose, Water Energy Int. 69, 24 (2012)

Acknowledgement

This work is supported by the National Natural Science Foundation of China (No. 51874201).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Available online at http://springer.longhoe.net/journal/40195

Rights and permissions

About this article

Cite this article

Liu, J., Niu, S., Ren, R. et al. Improving Joint Morphologies and Tensile Strength of Al/Mg Dissimilar Alloys Friction Stir Lap Welding by Changing Zn Interlayer Thickness. Acta Metall. Sin. (Engl. Lett.) 32, 1385–1395 (2019). https://doi.org/10.1007/s40195-019-00937-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-019-00937-9