Abstract

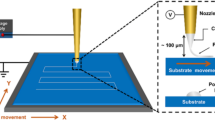

Flexible electronic technology has laid the foundation for complex human-computer interaction system, and has attracted great attention in the field of human motion detection and soft robotics. Graphene has received an extensive attention due to its excellent electrical conductivity; however, how to use it to fabricate wearable flexible sensors with complex structures remains challenging. In this study, we studied the rheological behavior of graphene/polydimethylsiloxane ink and proposed an optimal graphene ratio, which makes the ink have an good printability and conductivity at the same time. Then, based on the theory of Peano fractal layout, we proposed a two-dimensional structure that can withstand multi-directional tension by replacing the traditional arris structure with the arc structure. After that, we manufactured circular arc fractal structure sensor by adjusting ink composition and printing structure through direct ink writing method. Finally, we evaluated the detection performance and repeatability of the sensor. This method provides a simple and effective solution for fabricating wearable flexible sensors and exhibits the potential to fabricate 3D complex flexible electronic devices.

摘要

柔性电子技术为复杂的人机交互系统奠定了基础, 并在人体运动检测和软机器人领域引起了极大的关注。石墨烯由于其优异的导电性而受到广泛关注, 然而, 如何使用它来制造具有复杂结构的可穿戴柔性传感器仍然具有挑战性。在本研究中, 我们研究了石墨烯/PDMS油墨的流变行为, 并提出了最佳石墨烯比例, 使油墨同时具有良好的印刷性和导电性。然后, 基于Peano分形布局理论, 我们提出了一种可以承受多向张力的二维结构, 将传统的棱角结构替换为弧形结构。之后, 我们通过直接墨水写入法调整墨水成分和打印结构, 制造了圆弧分形结构传感器。最后, 我们评估了传感器的检测性能和重复性。该方法为制造可穿戴柔性传感器提供了一种简单有效的解决方案, 并显示出制造3D复杂柔性电子设备的潜力。

Similar content being viewed by others

References

SACHYANI KENETH E, KAMYSHNY A, TOTARO M, et al. 3D printing materials for soft robotics [J]. Advanced Materials, 2021, 33(19): 2003387.

CHEN Y X, DENG Z R, OUYANG R, et al. 3D printed stretchable smart fibers and textiles for self-powered e-skin [J]. Nano Energy, 2021, 84: 105866.

DAVOODI E, MONTAZERIAN H, HAGHNIAZ R, et al. 3D-printed ultra-robust surface-doped porous silicone sensors for wearable biomonitoring [J]. ACS Nano, 2020, 14(2): 1520–1532.

O’DRISCOLL D P, MCMAHON S, GARCIA J, et al. Printable G-putty for frequency- and rate-independent, high-performance strain sensors [J]. Small, 2021, 17(23): 2006542.

HUA Q L, SUN J L, LIU H T, et al. Skin-inspired highly stretchable and conformable matrix networks for multifunctional sensing [J]. Nature Communications, 2018, 9: 244.

KIM S J, SONG W, YI Y, et al. High durability and waterproofing rGO/SWCNT-fabric-based multifunctional sensors for human-motion detection [J]. ACS Applied Materials & Interfaces, 2018, 10(4): 3921–3928.

KOUH R, ZHANG L, TANQ L, et al. Wireless flexible pressure sensor based on micro-patterned graphene/PDMS composite [J]. Sensors and Actuators A: Physical, 2018, 277: 150–156.

NIU D, JIANG W T, YE G Y, et al. Graphene-elastomer nanocomposites based flexible piezoresistive sensors for strain and pressure detection [J]. Materials Research Bulletin, 2018, 102: 92–99.

HEO J S, SOLEYMANPOUR R, LAM J, et al. Wide-range motion recognition through insole sensor using multi-walled carbon nanotubes and polydimethylsiloxane composites [J]. IEEE Journal of Biomedical and Health Informatics, 2022, 26(2): 581–588.

LEE C G, WEI X D, KYSAR J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene [J]. Science, 2008, 321(5887): 385–388.

ZHANG Y B, TAN Y W, STORMER H L, et al. Experimental observation of the quantum Hall effect and Berry’s phase in graphene [J]. Nature, 2005, 438(7065): 201–204.

WALLIN T J, PIKUL J, SHEPHERD R F. 3D printing of soft robotic systems [J]. Nature Reviews Materials, 2018, 3(6): 84–100.

GUO S Z, QIU K Y, MENG F B, et al. 3D printed stretchable tactile sensors [J]. Advanced Materials, 2017, 29(27): 1701218.

WANG H R, GUO K, ZHANG L M, et al. Valve-based consecutive bioprinting method for multimaterial tissue-like constructs with controllable interfaces [J]. Biofabrication, 2021, 13(3): 035001.

GUO K, WANG H R, LI S J, et al. Collagen-based thiol–norbornene photoclick bio-ink with excellent bioactivity and printability [J]. ACS Applied Materials & Interfaces, 2021, 13(6): 7037–7050.

ZHANG L M, ZHANG H, WANG H R, et al. Fabrication of multi-channel nerve guidance conduits containing schwann cells based on multi-material 3D bio-printing [J]. 3D Printing and Additive Manufacturing, 2023, 10(5): 1046–1054.

ROH S, PAREKH D P, BHARTI B, et al. 3D printing by multiphase silicone/water capillary inks [J]. Advanced Materials, 2017, 29(30): 1701554.

JI Z Y, JIANG D, ZHANG X Q, et al. Facile photo and thermal two-stage curing for high-performance 3D printing of poly(dimethylsiloxane) [J]. Macromolecular Rapid Communications, 2020, 41(10): 2000064.

WANG H H, CEN Y M, ZENG X Q. Highly sensitive flexible tactile sensor mimicking the microstructure perception behavior of human skin [J]. ACS Applied Materials & Interfaces, 2021, 13(24): 28538–28545.

NAFICY S, JALILI R, ABOUTALEBI S H, et al. Graphene oxide dispersions: Tuning rheology to enable fabrication [J]. Materials Horizons, 2014, 1(3): 326–331.

HUANG K, DONG S M, YANG J S, et al. Three-dimensional printing of a tunable graphene-based elastomer for strain sensors with ultrahigh sensitivity [J]. Carbon, 2019, 143: 63–72.

CAO K L, WU M A, BAI J B, et al. Beyond skin pressure sensing: 3D printed laminated graphene pressure sensing material combines extremely low detection limits with wide detection range [J]. Advanced Functional Materials, 2022, 32(28): 2202360.

YUK H, ZHAO X H. 3D printing: A new 3D printing strategy by harnessing deformation, instability, and fracture of viscoelastic inks (adv. mater. 6/2018) [J]. Advanced Materials, 2018, 30(6): 1870037.

LIU H, XUE R Y, HU J Q, et al. Systematic study on the mechanical and electric behaviors of the non-buckling interconnect design of stretchable electronics [J]. Science China Physics, Mechanics & Astronomy, 2018, 61(11): 114611.

FAN J A, YEO W H, SU Y W, et al. Fractal design concepts for stretchable electronics [J]. Nature Communications, 2014, 5: 3266.

DUAN L Y, D’HOOGE D R, CARDON L. Recent progress on flexible and stretchable piezoresistive strain sensors: From design to application [J]. Progress in Materials Science, 2020, 114: 100617.

YOU X A, YANG J S, WANG M M, et al. Novel graphene planar architecture with ultrahigh stretch-ability and sensitivity [J]. ACS Applied Materials & Interfaces, 2020, 12(16): 18913–18923.

JEONG Y R, PARK H, JIN S W, et al. Highly stretchable and sensitive strain sensors using fragmentized graphene foam [J]. Advanced Functional Materials, 2015, 25(27): 4228–4236.

TEWARI A, GANDLA S, BOHM S, et al. Highly exfoliated MWNT-rGO ink-wrapped polyurethane foam for piezoresistive pressure sensor applications [J]. ACS Applied Materials & Interfaces, 2018, 10(6): 5185–5195.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest The authors declare no conflict of interest.

Additional information

Foundation item: the National Key Research and Development Program of China (No. 2020YFB1313100), the Strategic Priority Research Program of the Chinese Academy of Sciences (No. XDA16020803), the National Natural Science Foundation of China (Nos. 51875557 and 52205319), the Research Equipment Development Program of the Chinese Academy of Sciences (No. YJKYYQ20190045), and the Foundation of State Key Laboratory of Robotics (Nos. 2021-Z01, 2022-Z04 and 2023-Z01)

Rights and permissions

About this article

Cite this article

Chen, J., Gao, F., Zhang, L. et al. Direct Ink Writing Method of Fractal Wearable Flexible Sensor Based on Conductive Graphene/Polydimethylsiloxane Ink. J. Shanghai Jiaotong Univ. (Sci.) (2023). https://doi.org/10.1007/s12204-023-2687-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12204-023-2687-7