Abstract

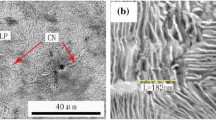

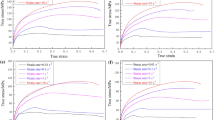

In order to research the flow behavior of 20CrMnTi and obtain its constitutive equation, the isothermal compression tests of 20CrMnTi were carried out using the Gleeble—3500 thermo-simulation machine, up to a 60% height reduction of the sample at strain rate range from 0.01 s−1 to 10 s–1 and deformation temperature range from 1123 K to 1273 K. According to the experimental results, the constitutive equation of 20CrMnTi was established based on Arrhenius model. In addition, the compensation of strain was taken into account and a new method of modifying the constitutive equation was proposed by introducing a coefficient K related to the deformation temperature and stain rate, which effectively improved the prediction accuracy of the developed constitutive equation. The results show that the flow stress decreases with increasing deformation temperature and decreasing strain rate, and the proposed constitutive equation well predicts the flow stress of 20CrMnTi during the high temperature deformation.

摘要

为了研究20CrMnTi 的高温流变行为,获得其高温状态下的本构方程,在Gleeble–3500 热模拟 试验机上进行了20CrMnTi 的等温压缩试验。试样压缩量为60%,应变速率从0.01 s–1 到10 s–1,热变 形温度范围为1123 K 到1273 K。根据试验结果,基于阿伦尼斯模型建立了20CrMnTi 的本构方程。 为了进一步提高模型的精度,考虑到应变的影响提出了一种新的建立方法。引入了一个和变形温度和 应变速率相关的系数K 对模型进行了修**,修**后的模型精度得到有效的提高。根据结果发现,随着 变形温度的升高和应变速率的降低,流变应力降低。结果表明:采用新方法建立的本构方程可以有效 预测20CrMnTi 高温变形的流变应力,提高模拟的精度。

Similar content being viewed by others

References

DENG **ao-bin, HUA Lin, HAN **ng-hui, SONG Yan-li. Numerical and experimental investigation of cold rotary forging of a 20CrMnTi alloy spur bevel gear [J]. Material and Design, 2011, 32: 1376–1389.

LV You, LEI Li-qun, SUN Li-na. Influence of different combined severe shot peening and laser surface melting treatments on the fatigue performance of 20CrMnTi steel gear [J]. Materials Science and Engineering A, 2016, 658: 77–85.

HAN **ng-hui, HUA Lin. Plastic deformation behaviors and mechanical properties of rolled rings of 20CrMnTi alloy in combined radial and axial ring rolling [J]. Material and Design, 2014, 58: 508–517.

ZHAO **n-hai, LIU Dan-dan, WANG **ng-hui, WU **ang-hong. Optimization of the isothermal forging process of a spur bevel gear [J]. Materials Science Forum, 2017, 878: 28–32.

BUCHKREMER S, WU B, LUNG D, BLECK W. FE-simulation of machining processes with a new material model [J]. Journal of Materials Processing Technology, 2014, 214(3): 599–611.

SCHMITZ G, PRAHL U. Toward a virtual platform for materials processing [J]. The Journal of the Minerals, Metals & Materials Society (TMS), 2009, 61(5): 19–23.

QIAN Dong-sheng, PENG Ya-ya, DENG Jia-dong. Hot deformation behavior and constituive modeling of Q345E alloy steel under hot compression [J]. Journal of Central South University, 2017, 24: 284–295.

LIN You-cheng, CHEN **ao-min. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working [J]. Material and Design, 2011, 32: 1733–1759.

RUSINEK A, RODRIGUEZ J A, ARIAS A. A thermoviscoplastic constitutive model for FCC metals with application to OFHC copper [J]. International Journal of Mechanical Sciences, 2010, 52: 120–135.

SHIN Hyun-ho, KIM Jong-bong. A phenomenological constitutive equation to describe various flow stress behaviors of materials in wide strain rate and temperature regimes [J]. Journal of Engineering Materials Technology, 2010, 132: 1–6.

YAN Jie, PAN Qing-lin, ZHANG **ang-kai, SUN Xue. Characterization of hot deformation behavior of Al-Zn-Mg-Mn-Zr alloy during compression at elevated temperature [J]. Journal of Central South University, 2017, 24: 515–520.

ALIREZA A B, ABBAS Z H, HASSAN P N, HAGHDADI. A comparative study on the capability of Johnson-Cook and Arrhenius-type constitutive equations to describe the flow behavior of Mg-6Al-1Zn alloy [J]. Mechanics of Materials, 2014, 72: 52–61.

SELLAR C M, TEGART W J. On the mechanism of hot deformation [J]. Acta Metallurgica, 1966, 14(9): 1136–1138.

CHEN Liang, ZHAO Guo-qun, YU Jun-quan. Hot deformation behavior and constitutive modeling of homogenized 6026 aluminum alloy [J]. Material and Design, 2015, 74: 25–35.

CHEN Liang, ZHAO Guo-qun, YU Jun-quan, ZHANG Wen-dong. Constitutive analysis of homogenized 7005 aluminum alloy at evaluated temperature for extrusion process [J]. Material and Design, 2015, 66: 129–136.

QU F S, REN Z Y, MA R R, WANG Z H, CHEN D M. The research on the constitutive modeling and hot working characteristics of as-cast V-5Cr-5Ti alloy during hot deformation [J]. Journal of Alloys and Compounds, 2016, 663: 552–559.

SHAMSOLHODAEI A, HANZAKI Z, GHAMBARI M, MOEMENI S. The high temperature flow behavior modeling of NiTi shape memory alloy employing phenomenological and physical based constitutive models: A comparative study [J]. Intermetallics, 2014, 53: 140–149.

MIRZAEI A, HANZAKI Z, HAGHDADI N, MARANDI A. Constitutive description of high temperature flow behavior of Sanicro-28 super-austenitic stainless steel [J]. Materials Science and Engineering A, 2014, 589: 76–82.

XIA **an-sheng, CHEN Qiang, HUANG Shu-hai, LIN Jun, HU Chuan-kai, ZHAO Zu-de. Hot deformation behavior of extruded Mg-Zn-Zr alloy [J]. Journal of Alloys and Compounds, 2015, 644: 308–316.

KHAMEI A A, DEHGHANI K. Modeling the hotdeformation behavior of Ni60-Ti40 intermetallic alloy [J]. Journal of Alloys and Compounds, 2010, 490: 377–381.

ASTM E209. Standard practice for compression tests of metallic materials at elevated temperatures with conventional or rapid heating rates and strain rates [M]// Annual Book of ASTM Standard. West Conshohocken: ASTM International, 2010.

LIN Yong-cheng, CHEN Ming-song, ZHANG Jun. Modeling of flow stress of 42CrMo steel under hot compression [J]. Materials Science and Engineering A, 2009, 499: 88–92.

ASTM: E 112-12. Standard test methods for determining average grain size [M]// Annual Book of ASTM Standard. West Conshohocken: ASTM International, 2012.

MCQUEEN H J. Development of dynamic recrystallization theory [J]. Materials Science and Engineering A, 2004, 387: 203–208.

LI Hui-zhong, WANG Hai-jun, LI Zhou. Flow behavior and processing map of as-cast Mg-10Gd-4.8Y-2Zn-0.6Zr alloy [J]. Materials Science and Engineering A, 2010, 528: 154–160.

WANG L, LIU Feng, ZUO Q, CHEN C F. Prediction of flow stress for N08028 alloy under hot working conditions [J]. Material and Design, 2013, 47: 737–745.

XIAO Yu-de, WANG Wei, LI Wen-xia. High temperature deformation behavior and mechanism of spray deposited A1-Fe-V-Si alloy [J]. Transactions of Nonferrous Metals Society of China, 2007, 17: 1175–1180.

FENG Wei, FU You-heng. High temperature deformation behavior and constitutive modeling for 20CrMnTiH steel [J]. Material and Design, 2014, 57: 461–471.

CAI Zhi-wei, CHEN Fu-xiao, GUO Jun-qin. Constitutive model for elevated temperature flow stress of AZ41M magnesium alloy considering the compensation of strain [J]. Journal of Alloys and Compounds, 2015, 648: 215–222.

FAN Q C, JIANG X Q, ZHOU Z H, JI W, CHAO H Q L. Constitutive relationship and hot deformation behavior of Armco-type pure iron for a wide range of temperature [J]. Material and Design, 2015, 16: 193–203.

ZENER C, HOLLOMOM H. Effect of strain rate upon plastic flow of steel [J]. Journal of Applied Physics, 1944, 15: 22–32.

JONAS J, SELLERS C M, TEGART W J. Strength and structure under hot working conditions [J]. International Materials Reviews, 1969, 14: 1–24.

SHI H, MCLAREN A J, SELLERS C M. Constitutive equations for high temperature flow stress of aluminum alloys [J]. Materials Science and Engineering A, 1997, 13: 210–216.

SCHOTTEN K, WOLFGANG B, WINFRIED D. Modelling of flow curves for hot deformation [J]. Steel Research International, 1998, 69: 193–197.

YIN Fei, HUA Lin, MAO Hua-jie, HAN **ng-hui. Constitutive modeling for flow behavior of GCr15 steel under hot compression experiments [J]. Material and Design, 2013, 43: 393–401.

LIN Yong-cheng, CHEN Ming-song, ZHONG Jue. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel [J]. Computational Materials Science, 2008, 42(3): 470–477.

PENG **ao-na, GUO Hong-zhen, SHI Zhi-feng, QIN Chun, ZHAO Zhang-long. Constitutive equations for high temperature flow stress of TC4-DT alloy incorporating strain, strain rate and temperature [J]. Material and Design, 2013, 50: 198–206.

LI Hong-yong, HU Ji-dong, WEI Dong-dong, WANG **ao-feng, LI Yang-hua. Artificial neural network and constitutive equations to predict the hot deformation behavior of modified 2.25Cr-1Mo steel [J]. Material and Design, 2012, 35: 557–562.

WU R H, LIU J T, CHANG H B. Prediction of the flow stress of 0.4C-1.9Cr-1.5Mn-1.0Ni-0.2Mo steel during hot deformation [J]. Journal of Materials Processing Technology, 2011, 116(2): 211–218.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2014JC024) supported by the Interdisciplinary Training Project of Shandong University, China

Rights and permissions

About this article

Cite this article

Zhao, Xh., Liu, Dd., Wu, Xh. et al. Flow behavior and constitutive description of 20CrMnTi steel at high temperature. J. Cent. South Univ. 25, 1013–1024 (2018). https://doi.org/10.1007/s11771-018-3801-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3801-0