Abstract

Recent studies revealed that multiphase microstructures in Al0.5NbTa0.8Ti1.5V0.2Zr, Fe15Co15Ni20Mn20Cu30 and TiZrNbTa multi-principal element alloys (MPEAs) developed via spinodal decomposition assisted phase transformation pathways offer better properties than single-phase MPEAs. Although spinodal decomposition has been widely studied for the past six decades, it has not been explored in detail as a design strategy to develop multiphase MPEAs. In this work, we illustrate high-throughput CALPHAD calculations necessary to design MPEAs with spinodal decomposition assisted multiphase microstructures by using Fe-Co-Ni-Mn-Cu system as an example. Firstly, the MPEAs that possess single solid solution phase at high temperatures and can undergo spinodal decomposition are identified through solid solution stability analysis and phase equilibrium calculations. The spinodal temperature as a function of alloy composition is visualized through Morral’s constant core component diagrams and the MPEAs of interest are selected based on further phase equilibrium calculations at the ageing temperature. Lastly, the critical features of spinodal decomposition such as the initial compositional modulations are calculated for the chosen alloy compositions. We find that the alloying elements could be divided into three groups: (i) Fe and Co, (ii) Ni and Mn, and (iii) Cu, based on the spinodal decomposition features predicted by the PanHEA database, and the restricted solubility of Cu in Fe and Co has led to the miscibility gap in FCC solid solutions of Fe-Co-Ni-Mn-Cu MPEAs. However, the addition of Ni and Mn is crucial in attaining spinodal microstructures as they aid in shifting the miscibility gap below the solidus curve in these MPEAs.

Similar content being viewed by others

References

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng., A, 2004, 375–377, p 213–218. https://doi.org/10.1016/j.msea.2003.10.257

F. Otto, A. Dlouhý, K.G. Pradeep, M. Kuběnová, D. Raabe, G. Eggeler, and E.P. George, Decomposition of the Single-Phase High-Entropy Alloy CrMnFeCoNi After Prolonged Anneals at Intermediate Temperatures, Acta Mater., 2016, 112, p 40–52. https://doi.org/10.1016/j.actamat.2016.04.005

O. Senkov, D. Isheim, D. Seidman, and A. Pilchak, Development of a Refractory High Entropy Superalloy, Entropy, 2016, 18, p 102. https://doi.org/10.3390/e18030102

V. Soni, B. Gwalani, O.N. Senkov, B. Viswanathan, T. Alam, D.B. Miracle, and R. Banerjee, Phase Stability as a Function of Temperature in a Refractory High-Entropy Alloy, J. Mater. Res., 2018, 33, p 3235–3246. https://doi.org/10.1557/jmr.2018.223

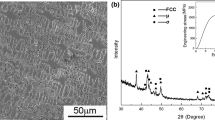

T.Y. Liu, J.C. Huang, W.S. Chuang, H.S. Chou, J.Y. Wei, C.Y. Chao, Y.C. Liao, and J.S. Jang, Spinodal Decomposition and Mechanical Response of a TiZrNbTa High-Entropy Alloy, Materials., 2019, 12, p 3508. https://doi.org/10.3390/ma12213508

Z. Rao, B. Dutta, F. Körmann, W. Lu, X. Zhou, C. Liu, A.K. Silva, U. Wiedwald, M. Spasova, M. Farle, D. Ponge, B. Gault, J. Neugebauer, D. Raabe, and Z. Li, Beyond Solid Solution High-Entropy Alloys: Tailoring Magnetic Properties via Spinodal Decomposition, Adv. Func. Mater., 2021, 31, p 2007668. https://doi.org/10.1002/adfm.202007668

K. Kadirvel, S.R. Koneru, and Y. Wang, Exploration of spinodal decomposition in multi-principal element alloys (MPEAs) using CALPHAD modeling, Scripta Mater., 2022, 214, 114657. https://doi.org/10.1016/j.scriptamat.2022.114657

Thermo-Calc Software TCHEA/High Entropy Alloys database, n.d. thermocalc com/products/databases/high-entropy-alloys/. (accessed April 6, 2022).

Computherm LLC. Pandat software PanHEA/High Entropy Alloy database, n.d. computherm.com/panhea. (accessed April 6, 2022).

D. Choudhuri, B. Gwalani, S. Gorsse, C.V. Mikler, R.V. Ramanujan, M.A. Gibson, and R. Banerjee, Change in the Primary Solidification Phase From Fcc to Bcc -Based B2 in High Entropy or Complex Concentrated Alloys, Scripta Mater., 2017, 127, p 186–190. https://doi.org/10.1016/j.scriptamat.2016.09.023

T. Rieger, J.-M. Joubert, M. Laurent-Brocq, L. Perrière, I. Guillot, and J.-P. Couzinié, Study of the FCC+L12 Two-Phase Region in Complex Concentrated Alloys Based on the Al–Co–Cr–Fe–Ni–Ti System, Materialia., 2020, 14, p 100905. https://doi.org/10.1016/j.mtla.2020.100905

T.E. Whitfield, E.J. Pickering, L.R. Owen, C.N. Jones, H.J. Stone, and N.G. Jones, The Effect of Al on the Formation and Stability of a BCC – B2 Microstructure in a Refractory Metal High Entropy Superalloy System, Materialia., 2020, 13, p 100858. https://doi.org/10.1016/j.mtla.2020.100858

O.N. Senkov, J.D. Miller, D.B. Miracle, and C. Woodward, Accelerated exploration of multi-principal element alloys with solid solution phases, Nature Communicat., 2015. https://doi.org/10.1038/ncomms7529

R. Feng, C. Zhang, M.C. Gao, Z. Pei, F. Zhang, Y. Chen, D. Ma, K. An, J.D. Poplawsky, L. Ouyang, Y. Ren, J.A. Hawk, M. Widom, and P.K. Liaw, High-throughput design of high-performance lightweight high-entropy alloys, Nature Communicat., 2021. https://doi.org/10.1038/s41467-021-24523-9

R. Li, L. **e, W.Y. Wang, P.K. Liaw, and Y. Zhang, High-Throughput Calculations for High-Entropy Alloys: A Brief Review, Frontiers Mater., 2020. https://doi.org/10.3389/fmats.2020.00290

P.L.J. Conway, T.P.C. Klaver, J. Steggo, and E. Ghassemali, High entropy alloys towards industrial applications: High-throughput screening and experimental investigation, Mater. Sci. Eng., A, 2022, 830, p 142297. https://doi.org/10.1016/j.msea.2021.142297

T. Klaver, D. Simonovic, and M. Sluiter, Brute Force Composition Scanning with a CALPHAD Database to Find Low Temperature Body Centered Cubic High Entropy Alloys, Entropy, 2018, 20, p 911. https://doi.org/10.3390/e20120911

D. Miracle, J. Miller, O. Senkov, C. Woodward, M. Uchic, and J. Tiley, Exploration and Development of High Entropy Alloys for Structural Applications, Entropy, 2014, 16, p 494–525. https://doi.org/10.3390/e16010494

O.N. Senkov, J.K. Jensen, A.L. Pilchak, D.B. Miracle, and H.L. Fraser, Compositional variation effects on the microstructure and properties of a refractory high-entropy superalloy AlMo0.5NbTa0.5TiZr, Mater. Design., 2018, 139, p 498–511. https://doi.org/10.1016/j.matdes.2017.11.033

J.K. Jensen, B.A. Welk, R.E.A. Williams, J.M. Sosa, D.E. Huber, O.N. Senkov, G.B. Viswanathan, and H.L. Fraser, Characterization of the microstructure of the compositionally complex alloy Al1Mo0.5Nb1Ta0.5Ti1Zr1, Scripta Mater., 2016, 121, p 1–4. https://doi.org/10.1016/j.scriptamat.2016.04.017

S.M. Allen, and J.W. Cahn, Mechanisms of Phase Transformations within the Miscibility Gap of Fe-rich Fe-Al Alloys, Acta Metall., 1976, 24, p 425–437. https://doi.org/10.1016/0001-6160(76)90063-8

W.A.Soffa, D.E.Laughlin, Recent experimental studies of continuous transformations in alloys: An overview, Proceedings of the International Conference on Solid to Solid Phase Transformations (Met.Soc.AIME). (1982) 159–183.

K. Kadirvel, Z. Kloenne, J.K. Jensen, H. Fraser, and Y. Wang, Phase-field modelling of transformation pathways and microstructural evolution in multi-principal element alloys, Appl. Phys. Lett., 2021, 119, p 171905. https://doi.org/10.1063/5.0065522

Z.T. Kloenne, K. Kadirvel, J.-P. Couzinie, G.B. Viswanathan, Y. Wang, and H.L. Fraser, High temperature phase stability of the compositionally complex alloy AlMo0.5NbTa0.5TiZr, Appl. Phys. Lett., 2021, 119, p 151903. https://doi.org/10.1063/5.0069497

P. Shi, R. Li, Y. Li, Y. Wen, Y. Zhong, W. Ren, Z. Shen, T. Zheng, J. Peng, X. Liang, P. Hu, N. Min, Y. Zhang, Y. Ren, P.K. Liaw, D. Raabe, and Y.-D. Wang, Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys, Science, 2021, 373, p 912.

J.W. Cahn, On spinodal decomposition, Acta Metall., 1961, 9, p 795–801.

A.G. Khachaturyan, Theory of Structural Transformations in Solids, Courier Corporation, 2013.

A.G. Khachaturyan, Soviet Physics, Solid State. 9 (1968).

D. De Fontaine, An analysis of clustering and ordering in multicomponent solid solutions—I. Stability criteria, J. Phys. Chem. Solids, 1972, 33, p 297–310. https://doi.org/10.1016/0022-3697(72)90011-X

D.D. Fontaine, An Analysis of Clustering and Ordering in Multicomponent Solid Solutions-Ii Fluctuations and Kinetics, J. Phys. Chem. Solids, 1973, 34, p 1285–1304.

J.E. Morral, and J.W. Cahn, Spinodal decomposition in ternary systems, Acta Metall., 1971, 19, p 1037–1045. https://doi.org/10.1016/0001-6160(71)90036-8

J. E. Morral, Stability limits for ternary regular system, Acta Metallurgica. 20 (1972).

J.E. Morral, and S. Chen, Stability of High Entropy Alloys to Spinodal Decomposition, J. Phase Equilib. Diffus., 2021, 42, p 673–695. https://doi.org/10.1007/s11669-021-00915-8

P. Singh, A.V. Smirnov, and D.D. Johnson, Atomic Short-Range Order and Incipient Long-Range Order in High-Entropy Alloys, Phys. Rev. B, 2015. https://doi.org/10.1103/PhysRevB.91.224204

W. Cao, S.-L. Chen, F. Zhang, K. Wu, Y. Yang, Y.A. Chang, R. Schmid-Fetzer, and W.A. Oates, PANDAT Software with PanEngine, PanOptimizer and PanPrecipitation for Multi-Component Phase Diagram Calculation and Materials Property Simulation, Calphad, 2009, 33, p 328–342. https://doi.org/10.1016/j.calphad.2008.08.004

J.-O. Andersson, T. Helander, L. Höglund, P. Shi, and B. Sundman, Thermo-Calc & DICTRA, Computational Tools for Materials Science, Calphad, 2002, 26, p 273–312. https://doi.org/10.1016/S0364-5916(02)00037-8

Baker, Hugh, Okamoto, Hiroaki, ASM Handbook Volume 3: Alloy Phase Diagrams - ASM International, 1992. http://www.asminternational.org/search/-/journal_content/56/10192/25871543/PUBLICATION (accessed June 5, 2017).

D. Orlikowski, C. Sagui, A. Somoza, and C. Roland, Large-scale simulations of phase separation of elastically coherent binary alloy systems, Phys. Rev. B., 1999, 59, p 8646–8659. https://doi.org/10.1103/PhysRevB.59.8646

A. Onuki, and H. Nishimori, Anomalously Slow Domain Growth Due to A Modulus Inhomogeneity In Phase-Separating Alloys, Phys. Rev. B., 1991, 43, p 13649–13652. https://doi.org/10.1103/PhysRevB.43.13649

J.L. Li, Z. Li, Q. Wang, C. Dong, and P.K. Liaw, Phase-Field Simulation of coherent BCC/B2 Microstructures in High Entropy Alloys, Acta Mater., 2020, 197, p 10–19. https://doi.org/10.1016/j.actamat.2020.07.030

Acknowledgement

The authors would like to acknowledge the financial support by Air Force Office of Scientific Research (AFOSR) under grant FA9550-20-1-0015.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special tribute issue of the Journal of Phase Equilibria and Diffusion dedicated to the memory of former JPED Editor-in-Chief John Morral. The special issue was organized by Prof. Yongho Sohn, University of Central Florida; Prof. Ji-Cheng Zhao, University of Maryland; Dr. Carelyn Campbell, National Institute of Standards and Technology; and Dr. Ursula Kattner, National Institute of Standards and Technology.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Koneru, S.R., Kadirvel, K. & Wang, Y. High-Throughput Design of Multi-Principal Element Alloys with Spinodal Decomposition Assisted Microstructures. J. Phase Equilib. Diffus. 43, 753–763 (2022). https://doi.org/10.1007/s11669-022-00977-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-022-00977-2