Abstract

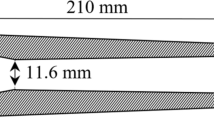

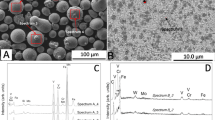

Lowering the thermal energy and increasing the kinetic energy of hard metal particles sprayed by the newly developed HVAF systems can significantly reduce their decarburization, and increases the sliding wear and corrosion resistance of the resulting coatings, making the HVAF technique attractive, both economically and environmentally, over its HVOF predecessors. Two agglomerated and sintered feedstock powder chemistries, WC-Co (88/12) and WC-CoCr (86/10/4), respectively, with increasing primary carbides grain size from 0.2 to 4.0 microns, have been deposited by the latest HVAF-M3 process onto carbon steel substrates. Their dry sliding wear behaviors and friction coefficients were evaluated at room temperature via Ball-on-disk (ASTM G99-90) wear tests against Al2O3 counterparts, and via Pin-on-disk (ASTM G77-05) wear tests against modified martensitic steel counterparts in both dry and lubricated conditions. Sliding wear mechanisms, with the formation of wavy surface morphology and brittle cracking, are discussed regarding the distribution and size of primary carbides. Corrosion behaviors were evaluated via standard Neutral Salt Spray, Acetic Acid Salt Spray, accelerated corrosion test, and electrochemical polarization test at room temperature. The optimization of the tribological properties of the coatings is discussed, focusing on the suitable selection of primary carbide size for different working load applications.

Similar content being viewed by others

References

M. Bielewski, Replacing Cadmium and Chromium, Research and Technology Organization and NATO, RTO-AG-AVT-140, 2011, Chp.23, pp. 1-22

L.-M. Berger, P. Vuoristo, T. Mäntylä, W. Kunert, W. Lengauer, and P. Ettmayer, Practical Solutions to Engineering Problems, C.C. Berndt, Ed., ASM International, Materials Park, OH, 1996, p 97-106

G. Bolelli, R. Giovanardi, L. Lusvarghi, and T. Manfredini, Corrosion Resistance of HVOF-Sprayed Coatings for Hard Chrome Replacement, Corros. Sci., 2006, 48, p 3375-3397

A. Wank, B. Wielage, H. Pokhmurska, E. Friesen, and G. Reisel, Comparison of Hardmetal and Hard Chromium Coatings Under Different Tribological Conditions, Surf. Coat. Technol., 2006, 201, p 1975-1980

G. Bolelli, L.M. Berger, M. Bonetti, and L. Lusvarghi, Comparative Study of the Dry Sliding Wear Behaviour of HVOF-Sprayed WC-(W, Cr)2C-Ni and WC-CoCr Hardmetal Coatings, Wear, 2014, 309, p 96-111

G. Bolelli, L.-M. Berger, T. Börner, H. Koivuluoto, L. Lusvarghi, C. Lyphout, N. Markocsan, V. Matikainen, P. Nylén, P. Sassatelli, R. Trache, and P. Vuoristo, Tribology of HVOF- and HVAF-Sprayed WC-CoCr Hardmetal Coatings: A Comparative Assessment, Surf. Coat. Technol., 2015, 265, p 125-144

Q. Wang, S. Zhang, Y. Cheng, J. **ang, X. Zhao, and G. Yang, Wear and Corrosion Performances of WC-10Co4Cr Coatings Deposited by Different HVOF and HVAF Spraying Processes, Surf. Coat. Technol., 2013, 218, p 127-136

M. Barletta, G. Bolelli, B. Bonferroni, and L. Lusvarghi, Wear and Corrosion Behaviour of HVOF-Sprayed WC-CoCr Coatings on Al Alloys, J. Therm. Spray Technol., 2010, 19(1-2), p 358-367

ASTM G99-05, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus, ASTM International, West Conshohocken, PA, 2010. www.astm.org

ASTM G77-, Standard Test Method for Wear Testing with a Ball-on-Disk Apparatus, ASTM International

S. Luyckx and A. Love, The Dependence of the Contiguity of WC on Co Content and Its Independence from WC Grain Size in WC-Co Alloys, Int. J. Refract. Metals Hard Mat., 2005, V24, p 75-79

C. Lyphout, J. Kitamura, K. Sato, J. Yamada, and S. Dizdar, Tungsten Carbide Deposition Processes for Hard Chrome Alternative: Preliminary Study of HVAF vs. HVOF Thermal Spray Processes, Proceedings ITSC 2013, Busan, South Korea, 2013

C. Lyphout, S. Björklund, M. Karlsson, M. Runte, G. Reisel, and P. Boccaccio, Screening Design of Supersonic Air Fuel Processing for hard Metal Coatings, J. Therm. Spray Technol., 2014, 23(8), p 1323-1332

C. Lyphout and K. Sato, Screening Design of Hard Metal Feedstock Powders for Supersonic Air Fuel Processing, Surf. Coat. Technol., 2014, 258(2014), p 447-457

J.C.P. Zuñega, M.G. Gee, R.J.K. Wood, and J. Walker, Scratch Testing of WC/Co Hardmetals, Tribol. Int., 2012, 54, p 77-86

G. Bolelli, A. Candeli, H. Koivuluoto, L. Lusvarghi, T. Manfredini, and P. Vuoristo, Microstructure-Based Thermo-Mechanical Modelling of Thermal Spray Coatings, J. Therm. Spray Technol., 2015, 73(15), p 20-34

W.A. Glaeser, Wear Debris Classification, Modern Tribology Handbook—Volume One—Macrotribology, B. Bhushan, F.E. Kennedy, and A.Z. Szeri, Ed., CRC Press, Boca Raton, Florida (USA), 2001, p 301-315

J.V. Gabrusenoks, P.D. Cikmach, A.R. Lusis, J.J. Kepleris, and G.M. Ramans, Electrochromic Colour Centres in Amorphous Tungsten Trioxide Thin Films, Solid State Ionics, 1984, 14, p 25-30

M.F. Daniel, B. Desbat, J.C. Lassegues, B. Gerand, and M. Figlarz, Infrared and Raman Study of WO3 Tungsten Trioxides and WO3 xH2O Tungsten Trioxide Hydrates, J. Solid State Chem., 1987, 67, p 235-247

S. Usmani, S. Sampath, D.L. Houck, and D. Lee, Effect of Carbide Grain Size on the Sliding and Abrasive Wear Behavior of Thermally Sprayed WC-Co Coatings, Tribol. Trans., 1997, 40(3), p 470-478

T. Sudaprasert, P.H. Shipway, and D.G. McCartney, Sliding Wear Behaviour of HVOF Sprayed WC-Co Coatings Deposited With Both Gas-Fuelled and Liquid-Fuelled Systems, Wear, 2003, 255, p 943-949

Q. Yang, T. Senda, and A. Ohmori, Effect of Carbide Grain Size on Microstructure and Sliding Wear Behavior of HVOF Sprayed WC-12% Co Coatings, Wear, 2003, 254(1-2), p 23-34

Q. Yang, T. Senda, and A. Hirose, Sliding Wear Behavior of WC-12% Co Coatings at Elevated Temperatures, Surf. Coat. Technol., 2006, 200(14-15), p 4208-4212

C. Verdon, A. Karimi, and J.-L. Martin, A Study of High Velocity Oxy-Fuel Thermally Sprayed Tungsten Carbide Based Coatings. Part 1: Microstructures, Mater. Sci. Eng. A, 1998, 246(1-2), p 11-24

L.-M. Berger, R. Puschmann, J. Spatzier, and S. Matthews, Potential of HVAF Spray Process, Therm. Spray Bull., 2013, 6(1), p 16-20

G.W. Stachowiak and A.W. Batchelor, Engineering Tribology, 2nd ed., Butterworth-Heinemann, Woburn, MA, 2001, p 483-531

I. Konyashin, Cemented Carbides for Mining, Construction and Wear Parts, Comprehensive Hard Materials—Volume I: Hardmetals, V.K. Sarin, D. Mari, L. Llanes, and C.E. Nebel, Ed., Elsevier, Amsterdam, The Netherlands, 2014, p 425-451

G.W. Stachowiak and A.W. Batchelor, Engineering Tribology, 2nd ed., Butterworth-Heinemann, Woburn, MA, USA, 2001, p 560-569

J.R. Davis, Ed., ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys, ASM International, Materials Park, OH, USA, 2000, p 382-383

A.S. Kurlov and A.I. Gusev, Tungsten Carbides—Structure, Properties and Application in Hardmetals, Springer Series in Materials Science, Vol 184, R. Hull, C. Jagadish, R.M. Osgood, J. Parisi, and Z.M. Wang, Ed., Springer, Cham, 2013, p 34-36

A.M. Human and H.E. Exner, The Relationship Between Electrochemical Behaviour and In-service Corrosion of WC Based Cemented Carbides, Int. J. Refract. Met. Hard Mater., 1997, 15, p 65-71

A.M. Human and H.E. Exner, Electrochemical Behaviour of Tungsten-Carbide Hardmetals, Mater. Sci. Eng. A, 1996, 209, p 180-191

Acknowledgments

The authors gratefully acknowledge SP Institute (Borås, Sweden) for NSS and AASS corrosion investigations, and Carolina Pettersson at SWEREA IVF (Mölndal, Sweden) for her contribution to SEM analysis at high magnification.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lyphout, C., Sato, K., Houdkova, S. et al. Tribological Properties of Hard Metal Coatings Sprayed by High-Velocity Air Fuel Process. J Therm Spray Tech 25, 331–345 (2016). https://doi.org/10.1007/s11666-015-0285-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0285-4