Abstract

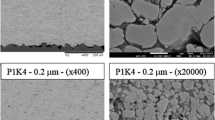

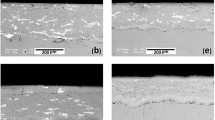

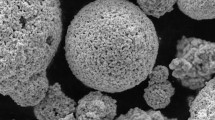

In this study, the friction wear performance of a High-velocity oxy-fuel (HVOF) sprayed WC-10Co-4Cr coated AA7075-T6 substrate was investigated against a WC-4Co ball at different temperatures using a pin-on-disk tribometer. WC-10Co-4Cr coating was deposited with a commercial HVOF-K2 spray (GTV MF-HVOF-K 1000 compact), O2 and kerosene as fuel gases with flow rates of 900 L/min and 26 L/h, respectively. Spraying was carried out with a rotation speed of 200 rpm, a particle feed rate of 1.8 rpm at a distance of 380 mm and a scanning distance of 5 mm. As HVOF spray, a commercial WC-10Co-4Cr powder (GTV 80.76.1.G) with a particle density of 4.63 g/\({\mathrm{cm}}^{3}\) was utilized. The diffusion of coating to the substrate was investigated by scanning electron microscopy (SEM) and energy-dispersive x-ray spectroscopy (EDX). The hardness of the as-sprayed coating was measured using a micro Vickers hardness tester. The friction and wear tests were performed at a sliding speed of 100 mm/s for 1800 s under a fixed load of 3 N at 25, 100, 200 and 300 °C. The wear rate increased five times at 300 °C testing compared to room temperature (RT), but the average coefficient of friction (COF) value increased from 0.30 to 0.48 for 200 °C testing and then decreased to 0.36 for 300 °C. The powder and coating microstructures were analyzed using x-ray diffractometer (XRD) analysis. Morphological characterizations were accomplished by SEM and a wide field confocal microscope (WCM/profilometer), and wear mechanisms were examined. The wear mechanism was abrasive until 100 °C, but a temperature increase allowed for adhesive wear, plastic deformation and oxidation fatigue. Oxide layers and crack propagation took place in accordance with applied load and thermal expansion of the AA7075-T6 substrate. Oxide layers on the worn surface enabled the coefficient of friction to decrease after 200 °C. Oxide delamination and pile-ups were observed at 300 °C.

Similar content being viewed by others

References

P. Zhang, L. Zeng, X. Mi, Y. Lu, S. Luo, and W. Zhai, Comparative Study on the Fretting Wear Property of 7075 Aluminum Alloys under Lubricated and Dry Conditions, Wear, 2021, 474–475, p 203760.

Z. Zenyu, Y. Guang-lei, Z. Qiu-yang, G. Ma, Y. Senbin, D. Cong, and P. Zhong-yu, Wear Behavior of 7075-Aluminum After Ultrasonic-Assisted Surface Burnishing, J. Manuf. Process., 2020, 51, p 1–9.

P.L. Srinivasamurthy, B.N. Sarada, B.S. Karthik, and S.S. Holla, Effect of Retrogression and Reaging Heat Treatment on Microstructure and Corrosion Properties of Al-7075, Int. J. Innov. Res. Sci. Eng. Technol., 2007, 3297(11), p 6434–6441.

E.A. Starke and J.T. Staley, Application of Modern Aluminum Alloys to Aircraft, Prog. Aerosp. Sci., 1996, 32(2–3), p 131–172.

R.R. Boyer, J.D. Cotton, M. Mohaghegh, and R.E. Schafrik, Materials Considerations for Aerospace Applications, MRS Bull., 2015, 40(12), p 1055–1066.

M.S. El-Eskandarany, Mechanical Alloying—Energy Storage, Protective Coatings, and Medical Applications: Utilization of Ball-Milled Powders for Surface Protective Coating, 3rd ed. Elsevier, Amsterdam, 2020.

M.A. Javed, A.S.M. Ang, C.M. Bhadra, R. Piola, W.C. Neil, C.C. Berndt, M. Leigh, H. Howse, and S.A. Wade, Corrosion and Mechanical Performance of HVOF WC-based Coatings with Alloyed Nickel Binder for Use in Marine Hydraulic Applications, Surf. Coat. Technol., 2021, 418, p 127239.

N. Abu-warda, G. Boissonnet, A.J. López, M.V. Utrilla, and F. Pedraza, Analysis of Thermo-Physical Properties of NiCr HVOF Coatings on T24, T92, VM12 and AISI 304 Steels, Surf. Coat. Technol., 2021, 416, p 127163.

K. Weman, Welding Processes Handbook: Surface Cladding and Hardfacing Methods, Elsevier, Amsterdam, 2012.

R. Shankar, K.R. Balasubramanian, S.P. Sivapirakasam, and K. Ravikumar, ANN and RSM Models Approach for Optimization of HVOF Coating, Mater. Today Proc., 2020. https://doi.org/10.1016/j.matpr.2020.01.211.

S. Mohan and A. Mohan, Anti-Abrasive Nanocoatings—Current and Future Applications: Wear, Friction and Prevention of Tribo-Surfaces by Coatings/Nanocoatings, Elsevier, Amsterdam, 2014.

P. Singh and P. Kumar, Improvement in Surface Integrity of Thermally Sprayed Cermet Coatings, Mater. Today Proc., 2021, 45, p 4431–4436. https://doi.org/10.1016/j.matpr.2020.12.522.

Y. Wang, W. Zhang, D. Chen, X. Liu, W. Hu, L. Liu, J. Yan, and X. **ong, High Temperature Friction and Wear Performance of TiB2-50Ni Composite Coating Sprayed by HVOF Technique, Surf. Coat. Technol., 2021, 407, p 126766.

T.K. Mishra, A. Kumar, and S.K. Sinha, Experimental Investigation and Study of HVOF Sprayed WC-12Co, WC-10Co-4Cr and Cr3C2-25NiCr Coating on Its Sliding Wear Behavior, Int. J. Refract. Met. Hard Mater., 2021, 94, p 105404.

L. Qiao, Y. Wu, S. Hong, W. Long, and J. Cheng, Wet Abrasive Wear Behavior of WC-Based Cermet Coatings Prepared by HVOF Spraying, Ceram. Int., 2020, 47(2), p 1829–1836.

H. Asgari, G. Saha, and M. Mohammadi, Tribological Behavior of Nanostructured High Velocity Oxy-Fuel (HVOF) Thermal Sprayed WC-17NiCr Coatings, Ceram. Int., 2017, 43(2), p 2123–2135.

S. Hong, Z. Wei, K. Wang, W. Gao, Y. Wu, and J. Lin, The Optimization of Microbial Influenced Corrosion Resistance of HVOF Sprayed Nanostructured WC-10Co-4Cr Coatings by Ultrasound-Assisted Sealing, Ultrason. Sonochem., 2021, 72, p 105438.

B. Song, J.W. Murray, R.G. Wellman, Z. Pala, and T. Hussain, Dry Sliding Wear Behaviour of HVOF Thermal Sprayed WC-Co-Cr and WC-Crxcy-Ni Coatings, Wear, 2019, 442–443, p 203114.

Y. Wu, B. Wang, S. Hong, J. Zhang, Y. Qin, and G. Li, Dry Sliding Wear Properties of HVOF Sprayed WC–10Co–4Cr Coating, Trans. Indian Inst. Met., 2015, 68, p 581–586.

Y. Ishikawa, S. Kuroda, J. Kawakita, Y. Sakamoto, and M. Takaya, Sliding Wear Properties of HVOF Sprayed WC-20%Cr3C2-7%Ni Cermet Coatings, Surf. Coat. Technol., 2007, 201, p 4718–4727.

S. Hong, Y. Wu, B. Wang, J. Zhang, Y. Zheng, and L. Qiao, The Effect of Temperature On the Dry Sliding Wear Behavior of HVOF Sprayed Nanostructured WC-CoCr Coatings, Ceram. Int., 2017, 43, p 458–462.

Y.Y. Ozbek, N. Canikoglu, and M. Ipek, The Surface Properties of WC-Co-Cr Based Coatings Deposited by High Velocity Oxygen Fuel Spraying, Acta Phys. Pol. A., 2017, 131, p 186–189.

Q. Wang, S. Zhang, Y. Cheng, J. **ang, X. Zhao, and G. Yang, Wear and Corrosion Performance of WC-10Co4Cr Coatings Deposited by Different HVOF and HVAF Spraying Processes, Surf. Coat. Technol., 2013, 218, p 127–136.

P. Mi, H. Zhao, T. Wang, and F. Ye, Sliding Wear Behavior of HVOF Sprayed WC-(Nano-WC-Co) Coating at Elevated Temperatures, Mater. Chem. Phys., 2018, 206, p 1–6.

J. Pulsford, F. Venturi, Z. Pala, S. Kamnis, and T. Hussain, Application of HVOF WC-Co-Cr Coatings On the Internal Surface of Small Cylinders: Effect of Internal Diameter On the Wear Resistance, Wear, 2019, 432–433, p 202965.

J.A. Picas, A. Forna, R. Rilla, and E. Martína, HVOF Thermal Sprayed Coatings on Aluminium Alloys and Aluminium Matrix Composites, Surf. Coat. Technol., 2005, 200(1–4), p 1178–1181.

M. Bjordal, E. Bardal, T. Rogne, and T.G. Eggen, Erosion and Corrosion Properties of WC Coatings and Duplex Stainless Steel in Sand-Containing Synthetic Sea Water, Wear, 1995, 186–187, p 508–514.

Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus, ASTM G99-05, American Society for Testing and Materials, 2005. https://doi.org/10.1520/G0099-05.

E.A. Almond and B. Roebuck, Identification of Optimum Binder Phase Compositions for Improved WC Hard Metals, Mater. Sci. Eng., 1988, 105–106, p 237–248.

J.A.R. Wesmann and N. Espallargas, Effect of Atmosphere, Temperature and Carbide Size On the Sliding Friction of Self-Mated HVOF WC-CoCr Contacts, Tribol. Int., 2016, 101, p 301–313.

P.J. Blau, Friction and Wear Transitions of Materials, Noyes Publishing, New Jersey, 1989.

Y.C. Zhu, K. Yukimura, C.X. Ding, and P.Y. Zhang, Tribological Properties of Nanostructured and Conventional WC-Co Coatings Deposited by Plasma Spraying, Thin Solid Films, 2001, 388(1–2), p 277–282.

Acknowledgments

The authors acknowledge the support of Trakya University Scientific Research Projects Coordination Unit under project number of TUBAP 2019/248 and Kirklareli University Mechanical Engineering Department Laboratory.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing interests that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ceviz, M., Misirli, C. & Karabeyoglu, S.S. The Effect of Temperature on Wear Performance of High-Velocity Oxy-Fuel Sprayed WC-10Co-4Cr Coating on AA7075-T6 Substrate. J. of Materi Eng and Perform 31, 128–138 (2022). https://doi.org/10.1007/s11665-021-06169-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06169-2