Abstract

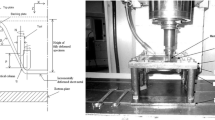

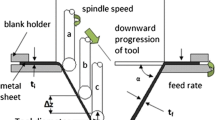

This paper describes an experimental investigation of surface roughness and forming time of parts formed by multi-stage single-point incremental forming (MSPIF). Process parameters, namely tool size, feed rate, step depth, sheet thickness, and spindle speed, are considered in the present study. Experiments are designed using the central composite design (CCD) method. Analysis of variance (ANOVA) is used to identify significance of process parameters for surface roughness and forming time. It is found that tool size is the most significant process parameter followed by step depth, spindle speed and sheet thickness for influencing surface roughness. Surface roughness initially decreases and then increases with increase in tool size. It decreases with decrease in step depth, spindle speed and sheet thickness. For forming time, step depth and feed rate are found significant. Forming time decreases with increase in step depth and feed rate. Regression models of surface roughness and forming time are also developed. Further, process parameters are optimized to minimize surface roughness and forming time of parts.

Similar content being viewed by others

References

S. Golovashchenko and A. Krause, Improvement of Formability of 6xxx Aluminum Alloys Using Incremental Forming Technology, J. Mater. Eng. Perform, 2005, 14(4), p 503–507. https://doi.org/10.1361/105994905X56133

P. Shrivastava and P. Tandon, Effect of Preheated Microstructure vis-à-vis Process Parameters and Characterization of Orange Peel in Incremental Forming of AA1050 Sheets, J. Mater. Eng. Perform, 2019, 28(5), p 2530–2542. https://doi.org/10.1007/s11665-019-04032-z

J.R. Duflou, J. Verbert, B. Belkassem, J. Gu, H. Sol, C. Henrard, and A.M. Habraken, Process Window Enhancement for Single Point Incremental Forming Through Multi-Step Toolpaths, CIRP Ann., 2008, 57(1), p 253–256. https://doi.org/10.1016/j.cirp.2008.03.030

T.J. Kim and D.Y. Yang, Improvement of Formability for the Incremental Sheet Metal Forming Process, Int. J. Mech. Sci., 2000, 42(7), p 1271–1286. https://doi.org/10.1016/S0020-7403(99)00047-8

Z. Liu, W.J. Daniel, Y. Li, S. Liu, and P.A. Meehan, Multi-Pass Deformation Design for Incremental Sheet Forming: Analytical Modeling, Finite Element Analysis and Experimental Validation, J. Mater. Process. Technol., 2014, 214(3), p 620–634. https://doi.org/10.1016/j.jmatprotec.2013.11.010

J. Jeswiet, F. Micari, G. Hirt, A. Bramley, J. Duflou, and J. Allwood, Asymmetric Single Point Incremental Forming of Sheet Metal, CIRP Ann., 2005, 54(2), p 88–114. https://doi.org/10.1016/S0007-8506(07)60021-3

G. Ambrogio, L. De Napoli, L. Filice, F. Gagliardi, and M. Muzzupappa, Application of Incremental Forming Process for High Customised Medical Product Manufacturing, J. Mater. Process. Technol., 2005, 162, p 156–162. https://doi.org/10.1016/j.jmatprotec.2005.02.148

M. Bambach, B. Taleb Araghi, and G. Hirt, Strategies to Improve the Geometric Accuracy in Asymmetric Single Point Incremental Forming, Prod. Eng., 2009, 3(2), p 145–56.

Z. Cui and L. Gao, Studies on Hole-Flanging Process Using Multistage Incremental Forming, CIRP. J. Manuf. Sci. Technol., 2010, 2(2), p 124–128. https://doi.org/10.1016/j.cirpj.2010.02.001

L. Junchao, S. Junjian, and W. Bin, A Multipass Incremental Sheet Forming Strategy of a Car Taillight Bracket, Int. J. Adv. Manuf, 2013, 69(9), p 2229–2236. https://doi.org/10.1007/s00170-013-5179-3

J. Li, P. Geng and J. Shen, Numerical Simulation and Experimental Investigation of Multistage Incremental Sheet Forming, Int J Adv Manuf Technol, 2013, 68, p 2637–2644.

N. Moser, E. Ndip-Agbor, H.Q. Ren, Z.X. Zhang, K. Ehmann, and J. Cao, Challenges and Process Strategies Concerning Multi-Pass Double Sided Incremental Forming, Key Eng. Mater., 2015, 651, p 1122–1127. https://doi.org/10.4028/www.scientific.net/KEM.651-653.1122

J. Verbert, B. Belkassem, C. Henrard, A.M. Habraken, J. Gu, H. Sol, B. Lauwers, and J.R. Duflou, Multi-Step Toolpath Approach to Overcome Forming Limitations in Single Point Incremental Forming, Int. J. Mater. Form., 2008, 1, p 1203–1206. https://doi.org/10.1007/s12289-008-0157-2

R. Malhotra, A. Bhattacharya, A. Kumar, N.V. Reddy, and J. Cao, A New Methodology for Multi-Pass Single Point Incremental Forming with Mixed Toolpaths, CIRP Ann., 2011, 60(1), p 323–326. https://doi.org/10.1016/j.cirp.2011.03.145

L. Manco, L. Filice, and G. Ambrogio, Analysis of the Thickness Distribution Varying Tool Trajectory in Single-Point Incremental Forming, Proc. Inst. Mech. Eng. B. J. Eng. Manuf., 2011, 225 (3), p 348–56.

J. Li, J. Hu, J. Pan, and P. Geng, Thickness Distribution and Design of a Multi-Stage Process for Sheet Metal Incremental Forming, Int. J. Adv. Manuf. Technol., 2012, 2(9), p 981–988. https://doi.org/10.1007/s00170-011-3852-y

Z. Liu, Y. Li, and P.A. Meehan, Tool Path Strategies and Deformation Analysis In Multi-Pass Incremental Sheet Forming Process, Int. J. Adv. Manuf. Technol., 2014, 5(1), p 395–409. https://doi.org/10.1007/s00170-014-6143-6

X. Shi, G. Hussain, G. Zha, M. Wu, and F. Kong, Study on Formability of Vertical Parts Formed by Multi-Stage Incremental Forming, Int. J. Adv. Manuf. Technol., 2014, 75(5), p 1049–1053. https://doi.org/10.1007/s00170-014-6192-x

Z. Li, S. Lu, T. Zhang, Z. Mao, and C. Zhang, Analysis of Geometrical Accuracy Based on Multistage Single Point Incremental Forming of a Straight Wall Box Part, Int. J. Adv. Manuf. Technol., 2017, 93(5), p 2783–2789. https://doi.org/10.1007/s00170-017-0723-1

S. Wu, Y. Ma, L. Gao, Y. Zhao, S. Rashed, and N. Ma, A Novel Multi-Step Strategy Of Single Point Incremental Forming for High Wall Angle Shape, J. Manuf. Process., 2020, 56, p 697–706. https://doi.org/10.1016/j.jmapro.2020.05.009

H.K. Nirala, P.K. Jain, J.J. Roy, M.K. Samal, and P. Tondon, An Approach to Eliminate Stepped Features in Multistage Incremental Sheet Forming Process: Experimental and FEA Analysis, J. Mech. Sci. Technol, 2017, 31(2), p 599–604. https://doi.org/10.1007/s12206-017-0112-6

M. Shamsari, M.J. Mirnia, M. Elyasi, and H. Baseri, Formability Improvement in Single Point Incremental Forming of Truncated Cone Using a Two-Stage Hybrid Deformation Strategy, Int. J. Adv. Manuf, 2018, 94(5), p 2357–2368. https://doi.org/10.1007/s00170-017-1031-5

P. Dai, Z. Chang, M. Li, and J. Chen, Reduction of Geometric Deviation by Multi-Pass Incremental Forming Combined with Tool Path Compensation for Non-Axisymmetric Aluminum Alloy Component with Stepped Feature, Int. J. Adv. Manuf, 2019, 102(1), p 809–817. https://doi.org/10.1007/s00170-018-3194-0

E. Ndip-Agbor, P. Cheng, N. Moser, K. Ehmann, and J. Cao, Prediction of Rigid Body Motion in Multi-Pass Single Point Incremental Forming, J. Mater. Process. Technol., 2019, 269, p 117–127. https://doi.org/10.1016/j.jmatprotec.2019.02.007

M. Skjoedt, M.B. Silva, P.A. Martins, and N. Bay, Strategies and Limits in Multi-Stage Single-Point Incremental Forming, J. Strain Anal. Eng. Des., 2010, 45(1), p 33–44.

S. Gajjar, V. Sisodia, R. Jagtap, K. More, and S. Kumar Experimental investigation on geometric accuracy and surface roughness of formed part in multistage single point incremental forming (spif) process, In Innovative Design, 2021. https://doi.org/10.1007/978-981-15-6619-6_22

H. Lu, H. Liu, and C. Wang, Review on Strategies for Geometric Accuracy Improvement in Incremental Sheet Forming, Int. J. Adv. Manuf, 2019, 102(9), p 3381–3417. https://doi.org/10.1007/s00170-019-03348-3

I. Cerro, E. Maidagan, J. Arana, A. Rivero, and P.P. Rodriguez, Theoretical and Experimental Analysis of the Dieless Incremental Sheet Forming Process, J. Mater. Process. Technol., 2006, 177(1–3), p 404–408.

O.U. Lasunon, Surface Roughness in Incremental Sheet Metal Forming of AA5052, Adv. Mater. Res., 2013, 753, p 203–206.

C. Raju and C.S. Narayanan, Application of a Hybrid Optimization Technique in a Multiple Sheet Single Point Incremental Forming Process, Measurement, 2016, 78, p 296–308.

A. Mulay, S. Ben, S. Ismail, and A. Kocanda, Experimental Investigations into the Effects of SPIF Forming Conditions on Surface Roughness and Formability by Design of Experiments, J. Braz. Soc. Mech. Sci. Eng., 2017, 39(10), p 3997–4010. https://doi.org/10.1007/s40430-016-0703-7

H.R. Dodiya, D.A. Patel, A.B. Pandey, D.D. Patel, and S. Saladi, Experimental Investigation of Surface Roughness for AA3003-0 Aluminium Alloy Using Single Point Incremental Forming, Mater. Today: Proc, 2021, 46, p 8655–8662.

S. Zhang, G.H. Tang, Z. Li, X. Jiang, and K. Li, Experimental Investigation on the Spring Back of AZ31B Mg Alloys in Warm Incremental Sheet Forming Assisted with oil Bath Heating, Int. J. Adv. Manuf, 2020, 109(1), p 535–551.

J. Antony, Design of Experiments for Engineers and Scientists, Elsevier, New York, 2014.

H.B. Lu, Y.L. Li, Z.B. Liu, S. Liu, and P.A. Meehan, Study on Step Depth for Part Accuracy Improvement in Incremental Sheet Forming Process, J. Adv. Mater. Res., 2014, 939, p 274–280.

P. Gupta and J. Jeswiet, Effect of Temperatures During Forming In Single Point Incremental Forming, Int. J. Adv. Manuf., 2018, 95(9), p 3693–3706.

Z. Chang and J. Chen, Analytical Model and Experimental Validation of Surface Roughness for Incremental Sheet Metal Forming Parts, Int. J. Mach. Tools Manuf., 2019, 146, p 103453.

G. Palumbo and M. Brandizzi, Experimental Investigations on the Single Point Incremental Forming of a Titanium Alloy Component Combining Static Heating with High Tool Rotation Speed, Mater. Des, 2012, 40, p 43–51.

AI Khuri 2006 Response surface methodology and related topics, World scientific

W.A. Jensen, Confirmation Runs in Design of Experiments, J. Qual. Technol., 2016, 48, p 162–177. https://doi.org/10.1080/00224065.2016.11918157

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bari, N., Kumar, S. Multi-stage Single-Point Incremental Forming: An Experimental Investigation of Surface Roughness and Forming Time. J. of Materi Eng and Perform 32, 1369–1381 (2023). https://doi.org/10.1007/s11665-022-07183-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07183-8