Abstract

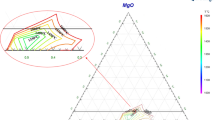

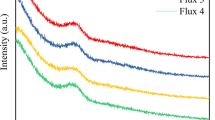

Herein, the effects of BaO (i.e. 5, 10, 15 and 20 pct) on the viscosity and structures of a new fluorine-free CaO-Al2O3-TiO2-based mold flux with w(CaO pct)/w(Al2O3 pct) ratio of 1.0 are investigated using a rotary viscometer, molecular dynamics (MD) simulations, and Raman spectroscopy. The viscosity of the samples (the testing temperature is 1300 °C) decrease from 0.46 to 0.21 Pa·s as the BaO content increased from 5 to 20 pct, and the activation energy decreases from 150.7 to 119.7 kJ·mol−1, the break temperature (Tbr) decreases from 1475 K to 1429 K which are achieved as the initial testing temperature of 1300 °C decreased under the furnace cooling. With the addition of BaO, the MD simulation results suggest that the coordination numbers (CNs) of Al (Ti)-O are reduced, while Q3, Q4, and Q5 are depolymerized into Q0, Q1, and Q2. The Raman spectroscopy results illustrate that the bridge oxygens (BOs) originating from the Ti-O-Ti (Al) linkages and Q2 (Al-O−) are depolymerized into Q1 (Si-O−) and Q0 (Al-O−) as the BaO content is increased. The Raman spectroscopy results agree well with those of the MD simulation. Therefore, BaO can simplify the structure of melts and decrease the viscosity of such systems. This work not only presents a new fluorine-free CaO-Al2O3-TiO2-based mold flux, but also deepens the understandings of the role of BaO in this system.

Similar content being viewed by others

References

1. J. H. Park, S. B. Lee, H. R. Gaye: Metall. Mater. Trans. B, 2008, vol. 39B, pp. 853-61.

2. D. S. Kim, J. H. Park, S. B. Lee, and H. G. Lee: Rev. Metall., 2004, vol. 4, pp. 291-99.

3. Z. L. Piao, L. G. Zhu, X. J. Wang, Z. X. Liu, H. B. **, X. S. Zhang, Q. L. Wang and C. Kong: High Temp. Mater. Proc., 2019, vol. 38, pp. 873-83.

4. S. X. Liu, C. J. Zhang, D. Lv, D. G. Ma and S. Li: Iron Steel Van. Tit., 2016, vol. 37, pp. 43-49.

5. Z. J. Huang, Y. T. Wang and J. G. Hu: J. Iron steel Res., 2012, vol. 40, pp. 20-22.

6. J. B. Chang, D. G. Ma, S. W. Li, Z. J. Han, S. X. Liu, Y. B. **ang: steelmaking, 2013, vol. 29, pp. 62-66.

7. J. B. Chang, D. G. Ma, S. W. Li, Z. J. Han, S. X. Liu and Z. Y. Xuan: Iron Steel, 2013, vol. 48, pp. 27-31.

8. J. L. Li, K. C. Chou, and Q. F. Shu: ISIJ Int., 2020, vol. 60, pp. 51-57.

9. X. J. Fu, G. H. Wen, P. Tang, Q. Liu and Z. Y. Zhou: Ironmak. Steelmak., 2014, vol. 41, 342-49.

10. B. X. Lu, K. Chen, W. L. Wang and B. B. Jiang: Metall. Mater. Trans. B, 2014, vol. 45, pp. 1496-09.

11. D. **ao, W. L. Wang and B. X. Lu: Metall. Mater. Trans. B, 2015, vol. 46, pp. 873-81.

12. H. Wang, P. Tang, G. H. Wen and X. Yu: Chin. J. Process Eng., 2010, vol. 10, pp. 905-10.

13. S. Y. Choi, D. H. Lee, D. W. Shin, S. Y. Choi, J. W. Cho and J. M. Park: J. Non-Cryst. Solids, 2004, vol. 345&346, pp. 157-60.

14. W. L. Wang, D. X. Cai and L. Zhang: ISIJ Int., 2018, vol. 58, pp. 1957-64.

15. A. B. Fox, K. C. Mills, D. Lever, C. Bezerra, C. Valadares, I. Unamuno, J. J. Laraudogoitia and J. Gisby: ISIJ Int., 2005, vol. 45, pp. 1051-58.

16. X. Qi, G. H. Wen and P. Tang: J. Non-Cryst. Solids, 2008, vol. 354, pp. 5444-52.

17. H. Nakada and K. Nagata: ISIJ Int., 2006, vol. 46, pp. 441-49.

18. G. R. Li: J. Iron steel Res., 2003, vol. 10, pp. 6-9.

19. Z. Y. Zhu, W. D. Han, C. J. Liu and M. F. Jiang: J. Iron steel Res., 2005, vol. 12, pp. 23-26.

20. T. Wu, Q. Wang, S. P. He, J. F. Xu, X. Long and Y. J. Lu: Steel Res. Int., 2012, vol. 83, pp1-9.

21. E. Z. Gao, W. L. Wang, L, Zhang: J. Non-Cryst. Solids, 2017, vol. 473, pp. 79-86.

22. Z. J. Wang, II Sohn: J. Am. Ceram. Soc., 2018, vol. 101, pp. 4285-96.

23. Z. R. Li, X. C. You, M. Li, Q. Wang, S. P. He, Q. Q. Wang: Metals, 2019, vol. 9, pp. 142-155.

G. H. Kim and II Sohn: Metall. Mater. Trans. B., 2011, vol. 42, pp. 1218-23.

H. Kim, H. Matsuura, F. Tsukihashi, W. L. Wang, D. J. Min and II Sohn: Metall. Mater. Trans. B., 2013, vol. 44, pp. 5-12.

26. P. C. **ao, Z. X. Liu, L. G. Zhu, Z. P. Wang and Z. L. Piao: High Temp. Mater. Proc., 2019, vol. 38, pp. 92-00.

27. S. P. Huang, G. C. Jiang; K. D. Xu, F. Yoshida and J. L. You: Metall. Mater. Trans. B, 2000, vol. 31, pp 1241-45.

28. P. Ganster, M. Benoit, W. Kob and J. M. Delaye: J. Chem. Phys. 2004, vol. 120, pp. 10172-81.

29. G. Z. Fan, S. P. Wu, T. Wu and Q. Wang: Metall. Mater. Trans. B, 2015, vol. 46, pp. 2005-13.

K. Hirao: Pasokon ni yoru sairyou sekkei, Shokabo, 1994.

31. K. Hirao, K. Kawamura: Materials Design Using Personal Computer, Shokabo, Tokyo, 1994.

32. J. M. Delaye, V. Louis-Achille, D. Ghaleb: J. Non-Cryst. Solids, 1997, vol. 210, pp. 232-42.

33. K. C. Mills and B. J. Keene: Int. Mater. Rev., 1987, vol. 32, pp. 1-120.

34. R. Knoche, D. B. Dingwell, and S. L. Webb: Geochim. Cosmochim. Ac., 1995, Vol. 59, pp. 4645-52.

35. II. Sohn, W. Wang, H. Matsuura, F. Tsukihashi and D. J. Min: ISIJ Int., 2012, vol. 52, pp. 158-60.

36. H. Kim, W.H. Kim, II. Sohn and D.J. Min: Steel Res. Int., 2010, vol. 81, pp. 261-64.

H. S. Park, H. Kim and II Sohn: Metall. Mater. Trans. B., 2011, vol. 42, pp. 324-30.

H. S. Park, S. S. Park and II Sohn: Metall. Mater. Trans. B., 2011, vol. 42, pp. 692-99.

39. S. Sridhar, K. C. Mills, O. D. C. Afrange, H. P. Lorz and R. Carli: Ironmak. Steelmak., 2000, vol. 27, pp. 238-42.

40. Y. Sasaki and K. Ishii: ISIJ Int., 2004, vol. 44, pp. 43-49.

41. Y. Sasaki, H. Urata and K. Ishii: ISIJ Int., 2003, vol. 43, pp. 1897-03.

42. A. C. Hannon and J. M. Parker: J. Non-Cryst. Solids, 2000, vol. 274, pp. 102-09.

43. B. W. M. Thomas, R. N. Mead and G. Mountjoy: J. Phys. Cond. Matt. 2006, vol. 18, pp. 4697-08.

44. T. Wu, Q. Wang, T. H. Yao and S. P. He: J. Non-Cryst. Solids, 2016, vol. 435, pp. 17-26.

45. S. F. Zhang, X. Zhang, C. G. Bai, L. Y. Wen and X. W. Lv: ISIJ Int., 2013, vol. 53, pp. 1131-37.

46. V. V. Hoang: Phys. Stat. Sol., 2007, vol. 244, pp. 1280-87.

47. K. Shimoda and K. Saito: ISIJ Int., 2007, vol. 47, pp. 1275-79.

48. B. O. Mysen, D. Virgo and C. M. Scarfe: Am. Mineral., 1980, vol. 65, pp. 290-01.

49. D. Manara, A. Grandjean and D. R. Neuville: Am. Mineral., 2009, vol. 94, pp. 777-84.

D. R. Neuville, L. Cormier, D. Massiot: Geochim. Cosmochim. Acta, vol. 68, pp. 5701-79 (2004).

51. L. M. Thompson and J. F. Stebbins: J. Non-Cryst. Solids, 2012, vol. 358, pp. 1783-89.

52. D. R. Neuville, L. Cormier and D. Massiot: Chem. Geol., 2006, vol. 229, pp. 173-85.

53. M. Licheron, V. Montouillout, F. Millot and D. R. Neuville: J. Non-Cryst. Solids, 2011, vol. 357, pp. 2796-01.

54. D. R. Neuville, G. S. Henderson, L. Cormier and D. Massiot: Am. Mineral., 2010, vol. 95, pp. 1580-89.

55. J. L. Li, Q. F. Shu and K. C. Chou: Can. Metall. Quart., 2015, vol. 54, pp. 85-91.

56. Y. Q. Sun and Z. T. Zhang: Metall. Mater. Trans. B, 2015, vol. 46, pp. 1549-54.

57. J. L. You, G. C. Jiang and K. D. Xu: J. Non-Cryst. Solids, 2001, vol. 282, pp. 125-31.

G. H. Kim and II Sohn: Metall. Mater. Trans. B, 2014, vol. 45, pp. 86-95.

59. T. Yano, N. Kunimine, S. Shibata and M. Yamane: J. Non-Cryst. Solids, 2003, vol. 321, pp. 147-56.

60. T. Yano, N. Kunimine, S. Shibata, M. Yamane: J. Non-Cryst. Solids, 2003, vol. 321, pp. 137-46.

61. T. Yano, N. Kunimine, S. Shibata, M. Yamane: J. Non-Cryst. Solids, 2003, vol. 321, pp. 157-68.

Acknowledgments

The authors gratefully express their appreciation to the National Natural Science Foundation of China (51974133 and 51774141); the Natural Science Foundation of Hebei Province of China (E2019209543 and E2018209195); and the National Youth Natural Science Foundation of China (51904107) for sponsoring this work. We would like to thank Editage (www.editage.cn) for English language editing.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted on April 28, 2020.

Rights and permissions

About this article

Cite this article

Piao, Z., Zhu, L., Wang, X. et al. Effects of BaO on the Viscosity and Structure of a New Fluorine-Free CaO-Al2O3-TiO2-Based Mold Flux for High Titanium Steel. Metall Mater Trans B 51, 2119–2130 (2020). https://doi.org/10.1007/s11663-020-01915-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01915-8