Abstract

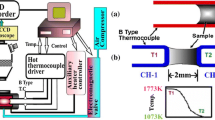

With the development of advanced high strength steel (AHSS), a large amount of aluminum was added into steels. The reaction between aluminum in the molten steel and silica based mold flux in the continuous-casting process would tend to cause a series of problems and influence the quality of slabs. To solve the above problems caused by the slag–steel reaction, nonreactive lime-alumina-based mold flux system has been proposed. In this article, the effect of Li2O and Na2O on the crystallization behavior of the lime-alumina-silica-based mold flux has been studied by using the single hot thermocouple technology (SHTT) and double hot thermocouple technology (DHTT). The results indicated that Li2O and Na2O in the above mold flux system play different roles as they behaved in traditional lime-silica based mold flux, which would tend to inhibit general mold flux crystallization by lowering the initial crystallization temperature and increasing incubation time, especially in the high-temperature region. However, when their content exceeds a critical value, the crystallization process of mold fluxes in low temperature zone would be greatly accelerated by the new phase formation of LiAlO2 and Na x Al y Si z O4 crystals, respectively. The crystalline phases precipitated in all samples during the experiments are discussed in the article.

Similar content being viewed by others

References

K.C. Mills, A.B. Fox, Z. Li, and R.P. Thackray: Ironmaking Steelmaking, 2005, vol. 32, no. 1, pp. 26-34.

K. Blazek, H. Yin, G. Skoczylas, M. McClymonds, and M. Frazee: AISTech 2011, AIST, Warrendale, PA, 2011.

Y. Kanbe, T. Ishii, H. Todoroki, and K. Mizuno: Int. J. Cast. Met. Res., 2009, vol. 22, p. 143.

Z. Zhang, G.H. Wen, P. Tang, and S. Sridhar: ISIJ Int., 2008, vol. 48, p. 739.

J. Liao, Y. Zhang, S. Sridhar, X. Wang, and Z. Zhang: ISIJ Int., 2012, vol. 52, p. 753.

H. Kim and I. Sohn: ISIJ Int., 2011, vol. 51, p. 1.

H.S. Park, H. Kim, and I. Sohn: Metall. Mater. Trans. B, 2011, vol. 42B, p. 324.

W. Wang, K. Blazek, and A. Cramb: Metall. Mater. Trans. B, 2008, vol. 39B, p. 66.

K. Blazek, H. Yin, G. Skoczylas, M. McClymonds, and M. Frazee: ECCC-METEC, Steel Institute VDEh, Düsseldorf, Germany, 2011.

J.-W. Cho, K. Blazek, M. Frazee, and H. Yin: ISIJ Int., 2013, vol 53, no. 1, pp. 62-70.

M. Hayashi, T. Watanabe, H. Nakada, and K. Nagata: ISIJ Int., 2006, vol. 46, pp. 1805-09.

Y. Kashiwaya, C.E. Cicutti, and A.W. Cramb: Proc. Steelmaking Conf., Toronto, Ontario, Canada, Iron and Steel Society, 1998, pp. 185–91.

T. Omoto, H. Ogata, and J. Itoh: Shinagawa Tech. Rep., 2006, vol. 49, p. 73.

H. Wang, P. Tang, G.H. Wen, and X. Yu: Ironmaking Steelmaking, 2011, vol. 38, p. 369.

L. Zhou, W. Wang, D. Huang, J. Wei, and J. Li: Metall. Mater. Trans. B, 2012, vol. 43B, p. 925.

Z. Li, R. Thackray, and K.C. Mills: J. S. Afr. Inst. Min. Metall., 2004, pp. 813–29.

Y. Meng and B.G. Thomas: Metall. Mater. Trans. B, 2003, vol. 34B, pp. 707-25.

A.W. Cramb: Report: American Iron and Steel Institute, Technology Roadmap Program, Pittsburgh, PA, 2003.

L. Zhou and W. Wang: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 925-36.

G.H. Kim, C. Kim, and I. Sohn: ISIJ Int., 2013, vol. 53, pp. 170-76.

S.S. Jung, G.H. Kim, and I. Sohn. Trans. Indian Inst. Met., 2013, vol. 66, pp. 577-85.

X. Yu: Ph.D. Dissertation, Chongqing University, Chongqing, China, 2011.

W. Yan, W. Chen, C. Lippold, and H. Zheng. Special Steel, 2013, vol. 34, pp. 45-48.

Acknowledgments

The financial support from NSFC (51274244 and 51322405) and the Fundamental Research Funds for the Central Universities (2011JQ010) is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 17, 2013.

Rights and permissions

About this article

Cite this article

Lu, B., Chen, K., Wang, W. et al. Effects of Li2O and Na2O on the Crystallization Behavior of Lime-Alumina-Based Mold Flux for Casting High-Al Steels. Metall Mater Trans B 45, 1496–1509 (2014). https://doi.org/10.1007/s11663-014-0063-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-014-0063-6