Abstract

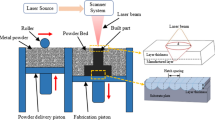

A cermet composite was prepared by employing thermal spraying flame onto stainless steel surfaces of (304) type. Hence 25,50% of aluminum was mixed with matrix of (10% Al2O3- SiO2). A spray system consistis of oxygen barrel, acetylene and spray gun that contains powders feeder at different spray distances (5, 10, 15, 20 and 25 cm). The thermal treatment of the samples resulting from spraying was performed at 1 100 °C for 1.5 hr. Some physical examinations (porosity and adhesion), mechanical tests (hardness and wear rate) and Atomic Force Microscope (AFM) test were performed before and after thermal treatment. The test results showed that the best mixing rate was (50%) and the best spray distance was (15cm) where the quality of coating layer improved after thermal treatment at 1 100 °C for 1.5 hr with a porosity ratio reduced from 11.2% to 6.6%, and adhesion strength improved with the increase in the alumina content to 50%. The results demonstrated that the best adhesion value after thermal treatment was 30.98 MPa. The hardness of coating layer increased from 45.78 to 54.88 HV; while the lowest rate of wear was at 50% of alumina with a spray distance of 15cm. Also, there was a clear improvement based on AFM within grain size, root mean square and roughness rate.

Similar content being viewed by others

References

Bhargava A K. Engineering Materials: Polymers, Ceramics and Composites[M]. Delhi: PHI Learning Pvt. Ltd., 2012

Campbell, Flake C. Structural Composite Materials[M]. Houston: ASM International, 2010

Mondolfo, Lucio F. Aluminum Alloys: Structure and Properties[M]. Amsterdam: Elsevier, 2013

Mahade, Satyapal. Exploiting Suspension Plasma Spraying to Deposit Wear-resistant Carbide Coatings[J]. Materials, 2019,12(15): 2344–2350

Dorfman, Mitchell R. Thermal Spray Coatings. Handbook of Environmental Degradation of Materials[M]. Amsterdam: William Andrew Publishing, 2018

Mohammed, Sameen F, and Salih Y Darweesh. Effect of Thermal Treatment on Some Physical and Mechanical Properties of Cermet Coating by Flame Spraying Technology[J]. Journal of University of Babylon for Pure and Applied Sciences, 2018, 26(7): 269–280

Adil N Ayash. Study of the Heat Treatment Effect on Electrical and Porosity of Cermet Coating Layers (ZrO2-Y2O3) Prepared by Thermal Spraying[J]. Iraq Journal of Physics, 2009, 7(10): 77–83

Singh, Reeti. Influence of Coating Thickness on Residual Stress and Adhesion-Strength of Cold-Sprayed Inconel 718 Coatings[J]. Surface and Coatings Technology, 2018, 350: 64–73

Jassim I K, and S Y Darweesh. Manufacturing of Composite (Ni-Al+ Al2O3-ZrO2) by Using Flame Thermal Spray Technique[J]. Tikrit Journal of Pure Science, 2018, 23(5): 140–144

Kumar, Dipak, and K N Pandey. Optimization of the Process Parameters in Generic Thermal Barrier Coatings Using the Taguchi Method and Grey Relational Analysis[J]. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 2017, 231(7): 600–610

Darweesh S Y. Parameters of Effecting in the Coating of Turbine Blades by Thermal Spraying[C]. Proceeding of First International and the Third Scientific Conference, 2018

Nahvi S M, and Majid Jafari. Microstructural and Mechanical Properties of Advanced HVOF-Sprayed WC-Based Cermet Coatings[J]. Surface and Coatings Technology, 2016, 286: 95–102

Berger, Lutz-Michael. Application of Hardmetals as Thermal Spray Coatings[J]. International Journal of Refractory Metals and Hard Materials, 2015, 49: 350–364

Darweesh, Salih Y. The Effect of Some Physical and Mechanical Properties of Cermet Coating on Petroleum Pipes Prepared by Thermal Spray Method[J]. Journal of Failure Analysis and Prevention, 2019, 19(6): 1726–1738

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Humeedi, S.H., Abdulkareem, S.M. & Darweesh, S.Y. The Synthetic and Mechanical Properties of a Silica Matrix Cermet Composite. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 37, 423–428 (2022). https://doi.org/10.1007/s11595-022-2548-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-022-2548-5