Abstract

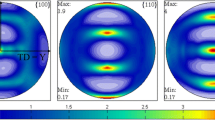

The present study deals with the development and the application of the through-hole drilling method for the residual stress analysis in orthotropic materials. Through a systematic theoretical study of the stress field present on orthotropic plates with a circular hole, the relationships between the relaxed strains measured by a rectangular strain gauge rosette and the Cartesian components of the unknown residual stresses are obtained. The theoretical formulas of each influence coefficient allow the user an easy application of the method to the analysis of uniform-residual stresses on a generic homogeneous orthotropic material. Furthermore, to extend the method to the analysis of the residual stresses on orthotropic laminates, caused by initial in-plane loadings, an alternative formulation is implemented. The accuracy of the proposed method has been assessed through 3D numerical simulations and experimental tests carried out on unidirectional, cross-ply and angle-ply laminates.

Similar content being viewed by others

References

Mathar J (1934) Determination of initial stresses by measuring the deformation around drilled holes. Trans ASME 56:249–254.

Soete W (1949) Measurement and relaxation of residual stress. Sheet Met Ind 26(266):1269–1281.

Rendler NJ, Vigness I (1966) Hole-drilling strain-gage method of measuring residual stresses. Exp Mech 6(12):577–586.

Schajer GS (1981) Application of finite element calculations to residual stress measurements. J Eng Mater Technol 103(2):157–163.

Schajer GS (1988) Measurement of non-uniform residual stress using the hole-drilling method. Part I—stress calculation procedures. J Eng Mater Technol 110(4):338–343.

Schajer GS (1988) Measurement of non-uniform residual stress using the hole-drilling method. Part II—practical application of the integral method. J Eng Mater Technol 110(4):344–349.

Zuccarello B (1999) Optimal calculation steps for the evaluation of residual stress by the incremental hole-drilling method. Exp Mech 39(2):117–124.

ASTM E 837-01 (2001) Standard test method for determining residual stresses by the hole-drilling strain gauge method. Annual book of ASTM standards, American Society for Testing and Materials, Philadelphia.

Petrucci G, Zuccarello B (1998) A new calculation procedures for non-uniform residual stress analysis by the hole drilling method. J Strain Anal 33(1):27–37.

Bert CW, Thompson GL (1968) A method for measuring planar residual stresses in rectangularly orthotropic materials. J Compos Mater 2(2):244–253.

Lake BR, Appl FJ, Bert CW (1970) An investigation of the hole-drilling technique for measuring planar residual stress in rectangularly orthotropic materials. Exp Mech 10(10):233–239.

Prasad CB, Prabhakaran R, Thompkins S (1987) Determination of calibration constants for hole-drilling residual stress measurement technique applied to orthotropic composites. Composite structures, Part I: theoretical considerations 8(2):105–118; Part II: experimental evaluations 8(3):165–172.

Sicot O, Gong XL, Cherouat A, Lu J (2003) Determination of residual stress in composite laminates using the incremental hole-drilling method. J Compos Mater 37(9):831–844.

Sicot O, Gong XL, Cherouat A, Lu J (2004) Influence of experimental parameters on determination of residual stress in composite laminates using the incremental hole-drilling method. Compos Sci Technol 64:171–180.

Schajer GS, Yang L (1994) Residual-stress measurement in orthotropic materials using the hole-drilling method. Exp Mech 34(4):324–333.

Càrdenas-Garìa JF, Ekwaro-Osire S, Berg JM, Wilson WH (2005) Non-linear last-squares solution to the moiré hole method problem in orthotropic materials. Part I: residual stresses. Exp Mech 45(4):301–313.

Lekhnitskii SG (1968) Anisotropic plates. Gordon and Breach, New York.

Savin GN (1961) Stress concentration around holes. In: Johnson W (ed). Pergamon, New York (translated by Mr. E. Gros for the Department of Science and Industrial Research).

Tan SC (1994) Stress concentration in laminates composites. Technomic, Lancaster, PA.

Pagliaro P (2004) Analisi delle tensioni residue in laminati compositi mediante il metodo del foro. Tesi di Laurea, Facoltà di Ingegneria, Università degli Studi di Palermo.

Pagliaro P, Zuccarello B (2004) Analisi delle tensioni residue in laminati compositi mediante il metodo del foro. Atti del XXXII Convegno Nazionale AIAS, Bari.

Muskhelishvili NI (1953) Some basic problems in the mathematical theory of elasticity. Noordhoff, Groningen, Holland.

Maksimenko VN, Podruzhin EG (2005) Singular solution for an anisotropic plate with an elliptical hole. J Appl Mech Tech Phys 46(1):117–123.

Barbero EJ (1998) Introduction to composite materials design. Taylor & Francis, Philadelphia

Kabiri M (1986) Toward more accurate residual-stress measurement by the hole-drilling method: analysis of relieved-strain coefficients. Exp Mech 26(1):14–21.

Ajovalasit A (1989) Experimental stress analysis of residual stresses: comparison of hole drilling, core and ring methods. OIAZ 418–420.

Schajer GS (1993) Use of displacement data to calculate strain gauge response in non-uniform strain fields. Strain 29(1):9–13.

Ajovalasit A, Zuccarello B (2005) Local reinforcement effect of a strain gauge installation on low modulus materials. J Strain Anal 40(7):643–654.

ASTM D-3039-93 (1993) Standard test method for tensile properties of polymeric matrix composite materials. Annual book of ASTM standards, American Society for Testing and Materials, Philadelphia.

ASTM D-4255-83 (1983) Standard guide for testing inplane shear properties of composites laminates. Annual book of ASTM standards, American Society for Testing and Materials, Philadelphia.

Acknowledgements

The authors thank Dr. Micheal B. Prime (Los Alamos National Laboratory, Los Alamos, NM) for the fruitful discussions and good suggestions. The authors also thank Dr. Tim Wong (Los Alamos National Laboratory, Los Alamos, NM) that has read the paper.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A

1.1 Conformal Map** and Superposition Principle

Using the Lekhnitskii approach [17], the complex functions \( \Phi ^{\prime }_{1} \) and \( \Phi ^{\prime }_{2} \) related to a generic uniaxial stress σ φ applied at the hole edge and oriented at an angle φ from the longitudinal material direction L, is given by:

In equations (33) f k (x,y) (k = 1,2) functions are obtained by the conformal map** [17–19, 22, 23] of the complex plane \( z_{k} = {\left( {x + \mu _{k} y} \right)} \) in the region around the hole; indicating with r a the hole radius, it follows:

where ζ k (k = 1,2) are:

In the previous equations, only the roots with positive real part should be considered.

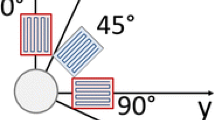

For the superposition principle, the components \( \sigma ^{{{\left( r \right)}}}_{L} \), \( \sigma ^{{{\left( r \right)}}}_{T} \), \( \tau ^{{{\left( r \right)}}}_{{LT}} \) of the residual stresses relaxed after drilling a hole in a component subjected to a residual stress distribution characterized by the generic Cartesian components σ L , σ T , τ LT , can be obtained by adding the contributions due to the three residual stress components σ L (φ = 0°), σ T (φ = 90°) and τ LT (φ = 45°) present before drilling the hole. Substituting into equation (33) φ=0°, 90° and ±45° (the contribution of τ LT is obtained by considering a tensile stress at +45° and a compressive stress at −45°) and adding the corresponding expressions so obtained, the general formulation of the complex functions represented by equation (3) is obtained.

Appendix B

1.1 Generalized Hooke’s Law in Terms of Dimensionless Constants and Derivation of Equations (5)

Considering a generic orthotropic material, for a plane stress state the relationship between the Cartesian strain components and corresponding stress components is expressed by the well known generalized Hooke’s law [24]; in particular, considering the Cartesian reference axes constituted by the material axes L–T, it can be written as [24]:

Therefore, considering the relaxed stress components \( \sigma ^{{{\left( r \right)}}}_{L} \), \( \sigma ^{{{\left( r \right)}}}_{T} \), \( \tau ^{{{\left( r \right)}}}_{{LT}} \) and introducing the dimensionless elastic constant \( \overline{E} \), \( \overline{G} \) and \( \overline{\nu } \) [20, 21] into equation (36), it becomes:

Finally, substituting equation (4) into equation (37), equations (5) are obtained after simple algebra.

Appendix C

1.1 Relationship Between \( {\left[ {\widetilde{E}} \right]}_{k} \) and [E] k

The stiffness matrix [E] k of an orthotropic ply in the principal coordinate system 1–2 (see Fig. 5), is given by [24]:

where E 1, E 2, G 12, ν 12 and ν 21 are the ply elastic properties in the coordinate system 1–2.

Indicating with α k the angle between the laminate longitudinal direction L and the principal direction 1 of the kth ply, the stiffness matrix \( {\left[ {\widetilde{E}} \right]}_{k} \) of the ply in the coordinate system L–T is given by [24]:

where \({\left[ {E^{ * } } \right]}_{k} \) is the matrix that is obtained by substituting into the matrix [E] k the term G 12 with 2G 12, and [T(α k )] is the in-plane transformation matrix given by:

Moreover, \( {\left[ {\overline{T} {\left( {\alpha _{k} } \right)}} \right]} \) is the matrix obtained by multiplying by two the term of the third row of the matrix [T(α k )].

Rights and permissions

About this article

Cite this article

Pagliaro, P., Zuccarello, B. Residual Stress Analysis of Orthotropic Materials by the Through-hole Drilling Method. Exp Mech 47, 217–236 (2007). https://doi.org/10.1007/s11340-006-9019-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-006-9019-3