Abstract

During the last decade, modern micro-electro-mechanical systems (MEMS) technology has been used to create cells that can act as catalytic nanoreactors and fit into the sample holders of transmission electron microscopes. These nanoreactors can maintain atmospheric or higher pressures inside the cells as they seal gases or liquids from the vacuum of the TEM column and can reach temperatures exceeding 1000 °C. This has led to a paradigm shift in electron microscopy, which facilitates the local characterization of structural and morphological changes of solid catalysts under working conditions. In this review, we outline the development of state-of-the-art nanoreactor setups that are commercially available and are currently applied to study catalytic reactions in situ or operando in gaseous or liquid environments. We also discuss challenges that are associated with the use of environmental cells. In catalysis studies, one of the major challenge is the interpretation of the results while considering the discrepancies in kinetics between MEMS based gas cells and fixed bed reactors, the interactions of the electron beam with the sample, as well as support effects. Finally, we critically analyze the general role of MEMS based nanoreactors in electron microscopy and catalysis communities and present possible future directions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Micro-electro-mechanical systems (MEMS) refer to devices that have characteristic dimensions in the micrometer regime. They combine electrical and mechanical components on a single chip and are fabricated by integrated circuit batch-processing technologies. In recent years the level of miniaturization and integration of MEMS technology has been used to scale down laboratory systems such as sensors or heaters to length-scales that are compatible with electron microscopes and allows for their integration. This has enabled a new era of in situ (scanning) transmission electron microscopy ((S)TEM), which is a reference technique for the spatially-resolved structural and chemical analysis of solids [1,2,3,4].

These novel lab-on-a-chip systems enable live imaging of structural and morphological changes of solids from the microscale down to the atomic scale under various external stimuli, such as heat, mechanical stress or electrical bias, which can be also combined with gaseous or liquid environments [5, 6]. These functions are embarked on small chips that fit into the tips of TEM sample holders. Using off-the-shelf holders combined with MEMS-based nanoreactors, any standard (S)TEM instrument can now be transformed into an in situ setup for the investigation of catalytic materials in realistic working conditions. Gases and liquids can run through these devices, in which pressures surmounting 1000 mbar can be achieved. As opposed to designing the entire instrument around the desired in situ experiment, as it has been done with differentially pumped environmental TEM (ETEM) setups, a simple holder exchange is sufficient to switch between different in situ experiments. As such, MEMS-based technology has crucially enhanced the experimental flexibility, performance and accessibility of in situ TEM systems. These advances have contributed to a significant growth of scientific contributions in the field of in situ TEM for catalysis, as evidenced by the large number of review articles that have been published recently [7,8,9,10,11,12,13,14]. A chronological summary of the combined MEMS and in situ TEM developments can be found in Fig. 1.

Besides their prominent use for in situ TEM measurements, MEMS devices are part of a variety of different applications ranging from neuroscience [15] to biosensors [16] and scientific instrumentation [17]. MEMS technology has also been utilized for the design of miniature catalytic systems [18] such as proton exchange membrane fuel cells (PEMFCs) [19], methanol reformers [20] and sensors [21]. Examples of such systems can be found in Fig. 2. We believe that the contributions of MEMS to the entire field of heterogeneous catalysis warrant a review of their own.

Examples of applications of MEMS based devices in heterogeneous catalysis. a Photomicrograph of a packed bed miniaturized reactor with an active carbon catalyst. The inlet openings are 30 µm wide and 300 µm deep. b Microfabricated catalyst packing manufactured by deep reaction ion-edging (DRIE). c–e Illustration of a MEMS-based microreactor for a H2O2 monopropellant micropropulsion system. c SEM micrograph that shows scaffolds of sample pillars obtained from DRIE etching. The pillars are 20 µm wide and 5 µm high. d Schematic diagram of the reactor geometry. e Imaging of H2O2 decomposition through a single row of catalytic pillars. Reproduced with permissions from [32,33,34]

Here, we specifically focus on the contributions of MEMS-based nanoreactors to the TEM investigation of heterogeneous catalysts in a reactive environment. These nanoreactors have been used to probe the chemical dynamics of heterogeneous catalysts in real time, either in situ i.e. in a controlled environment such as a solution or reaction gas mixture, or operando, when the catalytic conversion is additionally measured alongside TEM observations [22,23,24,25,26]. The operando approach can help establish detailed local structure–property relationships. Such insights will enable novel rational catalyst design strategies that are more advanced compared to current catalyst development workflows which usually consist of ex situ characterization and empirical optimization. Rational design will result in more efficient catalysts. Insights into the live operation of catalytic materials is also relevant to industry, as over 90% of commercially available chemicals interact, at least in one production step with the surface of a heterogeneous catalyst [27]. Furthermore, liquid cells have also enabled seminal in situ works, especially in the investigation of electrocatalysis [28, 29] and the synthesis of nanomaterials [67] or light organic molecules [68]. A review of atomically resolved in situ studies powered by differentially pumped ETEM investigations has recently been published by Boyes et al. [65]. However, these microscopes only work at low operating pressures, in the 102–103 Pa range [67], corresponding to a gas path length of 7 mm. At higher pressures, the background scattering will be too high to achieve satisfactory TEM observations. It is worth noting here that the scattering cross-section does not depend only on pressure, but on accelerating voltage and on the atomic number of the gas as well [67, 69].

Differentially pumped ETEM experiments come with several drawbacks. Besides the question of cost, as they require a wholly dedicated instrument—whereas any electron microscopy laboratory can potentially equip itself with a nanoreactor holder—differentially pumped ETEM setups do not allow for the control of the gas flow, as they use a large quantity of gas around the sample. Controlling the inlet gas flow is crucial to quantitative TEM catalysis experiments as it will impact the kinetics of the reaction of interest, as we discuss further on. Furthermore, closed-cell designs can withstand atmospheric pressure, effectively bridging the existing “pressure gap” between differentially pumped ETEM experiments and industrial reactors. This is critical to the relevance of in situ results to real applications in catalysis research. The properties of nanomaterials depend strongly on their structure and morphology [70,71,72,73], which are themselves dependent on experimental conditions [74, 75]. In the gas phase, activity depends on partial pressures, which in turn affect the Gibbs free energy of the system and can lead to different dynamical behavior of the catalysts. To date, it is still unclear how the structural response of nanomaterials at lower pressures relates to their dynamic behavior at ambient pressure conditions. Finally, STEM operation in ETEMs is limited, as the differential pum** apertures below the specimen shadows most of the high-angle annular dark-field (HAADF) detector. Thus, heavy elements can be imaged with superior contrast inside MEMS-based nanoreactors, which is pivotal to the study of metallic heterogeneous catalysts.

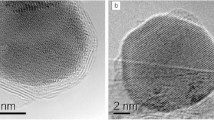

Allard et al. [55] reported atomic column resolution in Rh nanoparticles using 30 nm thick windows. It is a considerable improvement over the 0.2 nm Cu(200) lattice spacing resolution obtained with the initial gas cell design from Creemer et al. [58], which in addition used windows only 10 nm thick. De Jonge et al. [76] demonstrated in another similar MEMS-based design a 0.4 nm STEM resolution through 50 nm thick SiNx windows and a 360 µm thick gas layer. Atomic resolution STEM imaging was also demonstrated for Pd [77, 78] and Pt3Co [79] nanoparticles deposited on 30 nm thick windows. These examples show that high resolution imaging is achievable with MEMS-based nanoreactors.

Alternative nanoreactor designs, which are not MEMS-based, have been proposed by Kawasaki et al. [80] and Yaguchi et al. [69]. Creemer et al. [81] introduced the monolithic cell, departing from the sandwich design the same authors have pioneered. Mehraeen et al. [82] proposed localized laser heating as an alternative to the microheater of existing in situ MEMS chips, with the aim to selectively heat the specimen and minimize heat conduction inside the cell. Overall the sandwich design with two MEMS chips, including one chip that integrates the microheater, was popularized and made into the commercial products that are currently offered by Hummingbird, DENSsolutions, and Protochips. The accessibility of gas cell TEM holders has made them increasingly ubiquitous for the characterization of heterogeneous catalysts [9, 25]. The technique has garnered attention from all sub-fields of catalysis [8, 9, 26].

Custom designs have also been published and although they are similar to commercial systems, some of them can be operated at higher pressures than the nominal atmospheric conditions of standard systems [81, 83, 84]. This is discussed in the next section.

4 Gas Cells—Towards Higher Operating Pressures

Although MEMS-based nanoreactors already improve the achievable operating pressure by almost two orders of magnitude compared to differentially pumped ETEM setups, even higher pressures are required to study certain catalytic processes under realistic operating conditions. Ethylene oxidation and ammonia synthesis for instance are done above 50 bars which is out of reach of typical nanoreactors [87].

As a result quasi in situ workflows have been proposed to bridge that pressure gap [88, 89]. A quasi in situ experiment goes as follows: (i) an area of interest is selected on a TEM grid for identical location imaging before the catalytic reaction. (ii) the grid is transferred under controlled atmosphere to a dedicated high pressure reactor where catalytic conversion can be measured by mass spectrometry [88]. (iii) It can then be transferred back to the TEM with the same protocol, and the location previously chosen can then be investigated for morphological and structural changes induced by catalysis. Detrimental interactions between the electron beam, the reactant species, and the catalyst sample can therefore be avoided. However, quasi in situ protocols (i) do not directly capture the dynamics of the catalytic process, (ii) do not allow for a direct correlation of catalytic conversion measurements with TEM observations as they are acquired separately and (iii) involve the characterization of catalysts in vacuum rather than in realistic operating conditions, which can influence a catalysts’ structure [74].

Researchers have proposed novel MEMS-based designs that have been reported to reach pressures exceeding 1 bar at high temperatures. These designs have improved on the mechanical properties of SiNx windows by tuning their geometries or have featured monolithic cells, which are fabricated on a single chip. In the first case, it was shown that lowering the lateral dimensions of windows and eliminating sharp corners led to more robust cells. For instance, it has been demonstrated that small circular 15 nm windows could sustain up to 4 bars, although the authors do not report any operation above 240 °C [83, 90]. This is significant as thermal expansion further stresses the electron transparent windows [91], hence operation at low temperatures does not guarantee stability at higher temperatures. Thinner windows could surprisingly also offer superior mechanical properties to sustain pressures differences compared to thicker ones. This difference was attributed to a lower number of critical defects, which can act as predetermined breaking points at smaller volumes. All MEMS-based designs, including the current commercial ones, adopted smaller circular windows etched in a larger central SiNx membrane, as illustrated in Fig. 4c.

Illustration of the monolithic high-pressure cell. a Schematic of the monolithic cell. All functionality is integrated on a single chip, as opposed to the popular «sandwich» design that uses two chips. SiNx pillars separate the top and bottom of the channel. This design can withstand pressures above 10 bars. b Photograph of two complete nanoreactors under different angles. c Optical image of the central membrane of the nanoreactor featuring a number of aligned SiNx transparent windows that are 2 to 5 µm thick. The inset shows the glowing of the chip at 800 °C. d Stress distribution within the central SiNx membrane. Reproduced with permissions from [81] and [90]

In the case of monolithic cells, microreactors are entirely fabricated from batch processing techniques on a single chip, rather than from the assembly of two chips. In the original paper [81], the cell features pillars that hold together the top and bottom SiNx membranes, thereby increasing their strength and rigidity and allowing reliable operation up to 14 bars at 800 °C. A similar design later demonstrated operational stability at 10 bars and 650 °C [84]. It is worth noting that sample preparation could be limiting with monolithic cells. Since the inside of the cell cannot readily be accessed, samples can only be introduced dispersed in a solution through the microfluidics inlet.

It is worth noting that at such high operating pressures the electron beam travels through a significantly denser gas atmosphere than under atmospheric conditions. This can be expressed in terms of a much longer gas path length [69, 81]. This would result in a higher scattering background for (S)TEM imaging, which would be detrimental to the signal-to-noise-ratio (SNR) and limit imaging resolution. More beam-induced chemistry is also to be expected, in the form of a higher amount of radiolysis products as discussed later on in the section on liquid cells. To our knowledge, these high pressure designs have to date not been used to investigate catalytic processes at pressures above 1 bar. We emphasize that proofs of concepts are available. However, they are likely to stay on that stage baring commercialization.

5 Gas Cells for Correlated X-ray Studies

Furthermore, the application of MEMS-based gas cells for the study of active heterogeneous catalysts has been extended to other microscopy techniques, such as scanning transmission X-ray microscopy (STXM) [92]. For instance, De Smit et al. [93] have carried out in situ STXM measurements using the original gas cell design from Creemer et al. [58, 59] the same year it was published. Correlative in situ X-ray absorption fluorescence spectroscopy (XAFS) and STEM analysis [94] were also performed in the same commercially available nanoreactors. This is extremely promising as these techniques are complementary since they probe different length scales. Another study combined STEM, electron energy loss spectroscopy (EELS) and STXM measurements on Co/TiO2 Fischer–Tropsch synthesis catalysts [95]. Thanks to the polyvalence of MEMS-based environmental cells for in situ microscopy investigations, multiple in situ approaches can be correlated, as illustrated in Fig. 5.

In situ STXM or EXAFS and TEM analysis can be correlated using the same gas cells. a Experimental set-up adapting a commercial TEM nanoreactor for in situ STXM acquisition. b Schematic of a gas cell for correlated in situ EXAFS and STEM acquisition. In the EXAFS experiment, all types of nanoparticles are probed, while in the STEM experiment only particles larger than ~ 1 nm are detectable. Reproduced with permissions from [93] and [94]

6 Gas Cells—On the Relevance of In Situ Results

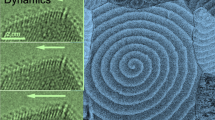

MEMS-based gas cells have been used to study a number of catalytic reactions. In general, applications focus on the morphological and structural evolution of catalysts under reactive conditions that mimic gas compositions, pressure and temperatures relevant to the water gas shift [96], ethylene hydrogenation [94], CO2 reduction [97] and CO oxidation [23, 24, 98,99,100,101] reactions. Nanoreactors have also been used to investigate the catalyzed growth of materials such as carbon nanostructures [102, 103] and the occurrence of strong metal-support interactions (SMSI) [77, 104]. Examples of in situ TEM results acquired with gas cell TEM holders are shown in Fig. 6, which illustrates the formation and removal of an SMSI induced overlayer on Pt and Pd nanoparticles deposited on TiO2 supports under different reaction conditions.

Examples of applications of MEMS based gas cells for in situ TEM studies of heterogeneous catalysts. a–j Evolution and dynamic structural changes of the overlayer in SMSI of Pt NP@TiO2. a, b A Pt NP exposed to H2 at 600 °C. c Subsequent change to O2. d, e Further switches between reducing and oxidizing atmosphere. f–j Interpretation of the phenomena revealed by in situ TEM, XRD and XPS. Insets for c–e show a magnified image of the observed overlayer structure. The scale bars are 5 nm. k–m Formation and disappearance on an overlayer on Pd NPs@TiOx under different gas mixtures, depending on the oxygen chemical potential µO. Adapted from [104] and [77]

It should be noted that in all of these works, with the exception of a few operando CO oxidation studies [23, 24, 100, 105, 106], catalytic activity is assumed but has not been demonstrated, i.e. catalytic conversion has not been proven in parallel to TEM observations. These CO oxidation studies achieved the simultaneous acquisition of conversion rates and TEM measurements. This is done using a mass spectrometer (MS) connected to the gas outlet of the in situ TEM holder [106] that allows a direct correlation of structure and reactivity and facilitates insights into local structure–function relationships [23, 24, 100, 105, 106]. Conversion can also be tracked via EELS analysis of the gas composition as demonstrated by Crozier et al. [107, 108]. With these independent measurements of catalytic activity, those studies have established that the structural changes they observe are directly linked to different activity regimes [24], and not merely a result of the thermal treatment. This shows that state-of-the-art gas cell TEM holders, when combined with online product analysis, can help elucidate fundamental structural and morphological aspects relevant to catalytic processes. Independent conversion measurements are necessary for robust data interpretation as unsubstantiated claims could be made from in situ data alone.

Examples that highlight the importance of conversion detection can be found in some in situ TEM studies of platinum nanoparticles (Pt NPs), where it was demonstrated that Pt NPs undergo different surface reconstructions under oxidizing or reducing atmospheres [99, 101]. Other studies showed that the particle size distribution changes after thermal treatments, under different gas mixtures that induced either sintering or etching processes [109, 110]. Although it is claimed in these works that those evolutions result from catalytic reactions, they can only be attributed to thermal treatments in a controlled atmosphere in the absence of conversion measurements. Another study proposed to reverse the loss of activity caused by sintering at high temperature using nitrogen-doped carbon shells on Pd, Au and Pt NPs [111]. However, the morphological investigation was conducted in an Ar atmosphere rather than under realistic reaction conditions. Changing operating conditions such as the gas composition, the partial pressures, the sample composition itself, or the electron dose used can have an impact on the appearance of nanoparticles. Claims made from data acquired under conditions that differ from realistic ones will thus be controversial.

Conversion detection during in situ TEM experiments is of paramount importance, especially given the vastly different kinetics that exist between MEMS-based gas cells and fixed bed reactors (FBRs) used in real application. Once again, catalytic activity in gas cells cannot be assumed. Comparing the catalytic activity measured in both operando TEM and FBR setups may allow one to judge on whether or not in situ TEM data can safely be attributed to a certain activity regime. A detailed description of the differences between FBR and MEMS-based gas cells is presented in the following:

-

(i)

Inlet gas flow Although the inlet gas flow of gas cell TEM holders can be adjusted from 5 mL/min to 1 µL/min [106], the gas flow is extremely fast relative to flows in FBRs due to the small volume of the nanoreactor. As a result the residence time of the gas mixture in the nanoreactor is in the millisecond regime [106], which is three orders of magnitude lower than typical values of FBRs. This is indicative of significantly different mass transport conditions. There is much more convection in MEMS based gas cells compared to FBRs.

-

(ii)

Catalyst bed geometry MEMS-based gas cells use a flat bed of catalyst particles that are loaded directly on the SiNx window. The coverage is sparse, as particle have to be clearly separated for TEM observation. The total amount of catalyst does not exceed 1 µg [106] and gases mostly diffuse over the catalyst bed rather than through it. Studies of other MEMS-based microreactors that feature similar beds of catalyst particles along the reactor walls found that catalytic processes were dominated by mass diffusion, owing to the inability of the reactant stream to adequately wet the catalyst bed [34]. In FBRs reactants migrate with lower speeds through a cylindrical, densely packed bed of supported catalysts. This makes comparing the kinetics of both systems difficult.

-

(iii)

Heat transfer Given that the particle coverage is sparse, there is no conductive heat transfer from one particle to another. Conduction is essential for faster kinetics in FBRs, as the heat of exothermic reactions can quickly thermalize the entire catalyst bed and, thus, maintain its operating temperature. Similar operation in gas cells would require the pre-heating of gases before flowing them in. This cannot be achieved in current commercially available gas cell TEM holders. In these nanoreactors cold gases flow fast over the deposited catalyst particles and cool them through convection. It then comes as no surprise that in operando CO oxidation studies [23, 24] the onset temperatures for conversion have been found to be higher than expected. Vendelbo et al. [91] used EELS measurements to show that the stagnant gas in their gas cell was on average 26 °C colder than the temperature indicated by the microheater. Moreover, with a high gas flow through the nanoreactor there is a temperature gradient along the gas channel [59]. A review of methods for temperature calibration in in situ experiments was recently published by Gaulandris et al. [112]. Such temperature gradients could cause the reaction of interest to proceed with uneven kinetics across the catalyst bed [113]. Since MS data is averaged over the whole bed, this could then lead to biased conclusions. Variations in local kinetics have been already revealed at the microscale by photoelectron electron microscopy (PEEM) [114, 115]. We would like to emphasize that new methods are required to reproduce this work at the nanoscale.

Overall, operando experiments are uniquely suited to investigate the structural and morphological evolution of model catalytic systems (such as phase changes and surface reconstruction) and their correlation to certain activity regimes. Fundamental processes such as sintering, nucleation and growth are further examples of phenomena that can be accessed with such experiments. However, reaching robust quantitative conclusions from operando work is challenging. It requires extreme care in assessing the discrepancies between model and real systems, as kinetics in gas cells differ from that of industrial reactors.

7 Liquid Cells

MEMS-based nanoreactors for liquid phase reactions were developed alongside closed gas cell technology [116,117,118]. The advent of liquid phase nanoreactors has provided a platform to study working electrocatalysts inside the TEM column and answer questions on the local structure and morphology of materials relevant to energy conversion [9, 28]. Liquid cells, like gas cells, use SiNx membranes strong enough to seal the liquid from the vacuum of the TEM column, yet thin enough (< 50 nm) to be transparent to the electron beam [119].

In this section, we will briefly outline the development of MEMS-based liquid cells, from early proposals to state-of-the-art systems. We then focus on the applications of liquid cells to the operando study of electrocatalysts. In situ electrochemical experiments inside the TEM have provided spatially-resolved insight into fuel cell catalysts [120] as well as into the growth mechanisms of catalytically active nanomaterials [121, 122]. Finally, we discuss the current challenges that come with liquid cell experiments, with a focus on the interactions of the electron beam with the electrolyte [123]. These interactions have been used intentionally to induce the nucleation and growth of nanoparticles [124]. It is worth noting here that the liquid phase is akin to a condensed gas phase. As a result considerations for electron beam-electrolyte interactions are to a lesser extent also relevant to gas phase reactions as well.

Liquid cells featuring SiNx windows were pioneered for SEM [125] investigations in 2004 and TEM [116] investigations in 2003. These early designs already featured the capability to conduct electrochemical experiments, as demonstrated with the galvanostatic in situ deposition of Cu clusters. An image resolution of 5 nm with a liquid thickness of 1 µm was achieved. A concept based on a “sandwich” of two MEMS chips [121] (rather than encapsulating the solution in one chip [116]) was later introduced. In this study, the liquid enclosure is thinned down to 200 nm by an indium spacer and allows for nanometer image resolution inside the TEM [121]. A microfluidic flow system [126,127,128] was then proposed, similar to the one described for MEMS-based TEM gas cells. This allows for the introduction and removal of solutions during experiments and facilitates cell assembly, as the cell can now be filled in situ. In addition, a SU-8 resist spacer was introduced. It is still present in today’s state-of-the-art systems. With this modern cell, the authors demonstrated the possibility to track Au NPs in biological cells in a 10 µm thick liquid chamber with 4 nm resolution by HAADF-STEM imaging [126]. It further shows that the high Z contrast of the HAADF detector can be used to image across thick layers of low-Z materials such as water. It is worth noting that the pressure difference of one atmosphere between the inside of the liquid cell and the vacuum of the TEM column leads to significant bulging of the SiNx windows [129]. Thus the cell can be 2 to 3 µm thicker in its center.

The operando capabilities of liquid phase TEM cells were further improved by patterning the MEMS chips. Up to ten Pt microelectrodes which can measure and apply currents down to the pA regime were integrated [130, 131]. This enables the detection of the electrochemical response of single nano-objects. Multiple stimuli can be applied within the same experiments with these electrodes, including heating, biasing and galvanostatic control. Today, Protochips, DENS solutions and Hummingbird offer commercial liquid cell TEM holders and MEMS chips for quantitative operando electrochemistry with pA sensitivity. A schematic illustration of a modern in situ TEM liquid Protochips holder and SEM micrographs of the corresponding MEMS chips can be found in Fig. 7. These TEM holders have made liquid phase (S)TEM experiments an accessible characterization tool for functional materials. However, liquid cells are more difficult to assemble than their gas counterparts as they use spacers that are an order of magnitude thinner.

Design of a modern MEMS based in situ TEM liquid cell. a Schematic illustration of the Protochips Poseidon 500 liquid cell system depicting the assembly of the MEMS within the tip of the in situ TEM holder. b SEM images of the MEMS chips used in the liquid cell. Reproduced with permissions from [29]

These thin liquid layers are necessary to minimize the background scattering for (S)TEM imaging and to reach higher SNR and resolutions. The state-of-the-art image resolution in aqueous medium is in the range of a few nanometers. Lattice resolution imaging has also been demonstrated for the in situ growth of Pt NPs [132] in a 400 nm thick cell with 50 nm thick SiNx windows. High resolution imaging was reported as well on the same system for a 100 nm thick cell with 10 nm thick windows [145]. Images with higher resolution are achievable and have been demonstrated in extremely thin cells that consist of liquids that are confined within 2D materials, such as graphene or boron nitride heterostructures [147, 148]. Those are, however, outside the scope of the present review.

9 Liquid Cells—Challenges

Although state-of-the-art setups come with the promise of quantitative electrochemical measurements and nanometer resolution, the reality is more nuanced. Both TEM and electrochemistry measurements are still mostly limited by the interaction of the electron beam with the liquid medium. Irradiation induces radiolysis in the electrolyte, which produces molecular and radical products such as atomic hydrogen and oxygen species, as well as solvated electrons [123, 149]. The steady-state concentration of radiolysis products was calculated by Schneider et al. (Fig. 9b). From this we can estimate the concentration of radiolysis products that were present in the experiment conducted by Liao et al. which is illustrated in Fig. 8. Their reported beam density is 5 × 105 A/m2 or about 1.2 × 1011 Gy/s (according to the approximation from De Jonge et al. [118]) and gives \(\left[{H}^{\cdot} \right]\approx {10}^{-5} M\) and \(\left[{OH}^{\cdot }\right]\approx {10}^{-3} M\). Such high concentrations of radicals are significant to the reactions of interest and they cannot be neglected. In some cases, in particular when hydrocarbon species are involved, radicals can be stabilized by inductive effects or the formation of resonance structures [150]. This increases the lifetime of the radicals, which are then more likely to react with the electrolyte or the catalyst surface. It will also affect ongoing electrochemical measurements such as cyclic voltammetry and can complicate the interpretation of the results. Unocic et al. [29] show for example that current profiles are offset by a few nA, if the electron beam is either on or off. This is significant given that the electrochemical response of individual nano-objects that are imaged can be in the order of pA, but could be dismissed when looking at larger systems.

Illustrations of phenomena to consider for in situ TEM liquid cells studies and examples of applications on heterogeneous catalysts. a ANSYS Maxwell static 3D electromagnetic finite element simulation of the electric field distribution in the in situ ec-liquid. b Calculated concentration of radiolysis products as a function of electron dose rate as a result of electron beam interactions with the aqueous medium. Reproduced with permissions from [123, 134]

Furthermore, Schneider et al. [123] showed that the steady state concentrations of radiolysis products varies greatly depending on the initial pH value of the electrolyte. These products will in turn modify the pH value and trigger, for instance, otherwise stable colloidal suspensions to aggregate under the beam [124, 143, 151]. Redox potentials also strongly depend on the pH and may be locally affected through this mechanism. This could induce different chemical dynamics in individual irradiated NPs. Moreover, NPs have been observed to either get etched or to grow under the electron beam. The extent of this phenomenon depends on the relative proportion of oxidizing or reducing radiolysis products [123].

It has been proposed that beam effects can be dismissed entirely if an appropriately low dose, inferior to the electrolyte damage threshold, is used [134, 144]. However, it is worth noting that this dose threshold is an order of magnitude higher for the carbonate solvent used in this study than for water. It is challenging in liquid-phase TEM experiments to keep the electron dose rate below the threshold value for complete water decomposition, which produces H2 bubbles [152] and is detrimental to TEM imaging and mass transport in the cell. In a recent in situ study focusing on photocatalytic water splitting over TiO2[153], a direct causal link is proposed between the observation of H2 bubbles and the catalytic activity. This conclusion was only possible after beam effects were dismissed thanks to rigorous control experiments. If bubble formation cannot be avoided, a flow cell can be beneficial since it accelerates the removal of irradiation products compared to a stagnant cell. It is worth noting here that additional mass and heat transfer is to be expected in flow cells, thus hel** mitigate the formation of gradients that might appear under irradiation. In addition, the flow could affect the motion of NPs in tracking experiments. The factors affecting the apparent diffusion of NPs in in situ TEM experiments were analyzed by Yesibolati et al. [129].

Lastly, the geometry of electrodes has to be considered as well in operando electrochemical measurements. Both the concentric [120, 154] and linear [134] electrode geometries available in commercial MEMS based systems do not create homogeneous electric fields, as illustrated in Fig. 9a. During the electrochemical reduction of metal cations, the nucleation or growth rates of NPs could be locally higher at the local maxima of the electric fields, or “hot spots”. This, alongside irradiation effects, should be carefully considered if reliable assessments of reaction products are to be made. Low-dose methodologies [153, 155, 156] can be used to reduce beam effects to a minimum.

10 On SiNx Windows and Support Interactions

Although several methodology and instrumentation papers have been published on in situ MEMS-based cells [106, 157], only a few have specifically discussed the role of SiNx windows, which are the cornerstones of MEMS-based nanoreactors. In this section, we discuss why SiNx materials are best for this application, their corrosion under particular operating conditions, and their role as catalyst supports when catalyst particles are directly deposited on SiNx windows.

SiNx materials deposited by low-pressure chemical vapor deposition (LPCVD) meet a number of criteria for gas cell TEM windows: (i) their amorphous structure does not contribute any diffraction background to TEM observations. It is worth mentioning that in our own work SiNx has been observed to crystallize in situ when temperatures above 800 °C are used under an oxygen-containing atmosphere. (ii) Silicon nitrides are chemically relatively inert, heat resistant and heat conductive [58, 158]. It should be noted that SiNx windows can in fact corrode under specific conditions [159, 160], which has to be taken into account for the planning of in situ experiments. Corrosion studies revealed that SiNx oxidation is aided by water vapor in an oxygen atmosphere [160]. In addition, our work has shown the corrosion and breakage of the SiNx window under O2 and H2 mixture at high temperature. (iii) The mechanical strength of SiNx allows the thin windows to sustain the colossal pressure difference that exists between the closed cell operating at atmospheric pressure and the high vacuum of the TEM column, even at thicknesses compatible with electron transparency. There are few other material candidates that have been tested for the design of closed cells. Attempts at using alumina windows were of limited use [60]. Amorphous carbon can be readily attacked by chemicals and does not possess sufficient mechanical strength. Graphene on the other hand contributes extremely little scattering background to TEM measurements, but graphene cells are exceedingly difficult to produce reproducibly, are of random dimensions, and do not allow for the application of external stimuli [161]. However, advanced 2-dimensional (2-D) heterostructures that stack patterned flakes of boron nitride and graphene have been proposed to build cells of total thicknesses of 30 nm or thinner in a reliable manner [148]. These 2-D cells could be used for liquid phase studies that use the electron beam as the sole external stimulus, but not for experiments that require heating or flowing of gases and liquids. Recently, the in situ capability of such 2-D heterostructures has been demonstrated for the lithiation of a graphene sheet [162], where a bias was applied to a graphene cell. In the future, such highly specialized devices might be tailored from 2D materials to fit the requirements of specific experiments.

SiNx windows often act as catalyst supports, as catalyst particles can be directly prepared on their surface [23, 24, 105]. The catalytic properties of deposited materials are affected through support interactions [158]. Thus, an inhomogeneous SiNx surface could play a role in the uneven behavior of NPs under reaction conditions as seen for instance, in operando investigations of the morphological evolution of Pt NPs [24]. Although further studies are required, it can be hypothesized that some particles show lesser activity because of different local metal-support interactions mediated by local inhomogeneities in the SiNx window surface. Studies of SiNx as a catalyst support have shown that amorphous SiNx supports are detrimental to the catalytic performance of Pt catalysts for the partial oxidation of methane, as it forms a SiO2 overlayer on the Pt NPs [163]. Moreover, Pt/a-SiNx catalysts have shown catalytic activity superior to Pt/MgO reference systems for propane dehydrogenation which was attributed to the basic nature of SiNx[158]. Hullman et al. [164] showed that carbon, boron or titanium do** of the SiNx support can significantly influence its catalytic properties. Similar support effects could be present when other metals are used as dopants.

In the course of the development of MEMS-based cells manufacturers and researchers have also tuned the composition of SiNx to optimize the internal tensile stress of the windows [165]. This minimizes bulging and allows for higher pressures in the nanoreactors. It has been shown that higher silicon contents are desirable for this application [166], i.e. compositions closer to SiN are preferred compared to the stoichiometric Si3N4. Silicon atoms can be more easily oxidized in such silicon-rich compositions and a case can be made for a likely oxygen or OH termination on the surface of the windows. Santos Aires et al. [158] performed X-ray photoelectron spectroscopy (XPS) measurements on amorphous SiNx particles and found significant amounts of surface oxygen. Zaluzec et al. detected small amounts of both O and Cl incorporated into SiNx films deposited by LPCVD [167]. Control EELS measurements in an operando TEM study have also revealed oxygen in SiNx membranes [133]. Other works reported the presence of a duplex oxide layer on CVD SiNx. The layer was found to consist of an outer layer of silica and an inner layer of silicon oxynitride [168].

It is our opinion that working with catalyst supports whose metal-support interactions are better understood compared to the support effects of SiNx windows leads to more robust interpretations of the results and should be preferred. This can be accomplished by modifying chips through the same microfabrication techniques that are involved in the fabrication of MEMS devices. These techniques include optical and e-beam lithography to pattern chips with thin film depositions from CVD techniques, such as atomic layer deposition (ALD). Focused ion beam (FIB) patterning is another possibility. Using such processes, MEMS chips have already been modified with oxide layers such as Al2O3[169] that acted as catalyst support in subsequent in situ studies.

11 On Cell Thickness

Another crucial parameter for in situ TEM experiments using MEMS based gas cells is the overall thickness of the closed cell. Since the density of gases is almost three orders of magnitude lower than it is for liquids, the overall thickness of the cell matters most during liquid-phase experiments. The thickness of the cell can be adapted quickly to specific experimental needs by varying the thickness of SU-8 spacers. It is worth noting here that the presence of such organic materials in the cell has the drawback of making carbon contamination a major problem at low operating temperatures in gas cells. Below 200 °C, thick carbon layers are deposited under the beam and make (S)TEM observation impossible.

In liquid cells, the electrolyte layer significantly contributes to the additional scattering background measured in TEM images. Thinner cells are thus desirable, as they contribute a lower background and lead to a better SNR, which can result in high resolution images as demonstrated by Liao et al. with a liquid layer as thin as 100 nm [ Pennycook SJ, Boatner LA (1988) Chemically sensitive structure-imaging with a scanning transmission electron microscope. Nature 336:565–567. https://doi.org/10.1038/336565a0 Haider M, Uhlemann S, Schwan E et al (1998) Electron microscopy image enhanced. Nature 392:768–769. https://doi.org/10.1038/33823 Batson PE, Dellby N, Krivanek OL (2002) Sub-aångstrom resolution using aberration corrected electron optics. Nature 418:617–620. https://doi.org/10.1038/nature00972 Urban KW (2008) Studying atomic structures by aberration-corrected transmission electron microscopy. Science 80-(321):506–510. https://doi.org/10.1126/science.1152800 Crozier PA, Hansen TW (2015) In situ and operando transmission electron microscopy of catalytic materials. MRS Bull 40:38–45. https://doi.org/10.1557/mrs.2014.304 Taheri ML, Stach EA, Arslan I et al (2016) Current status and future directions for in situ transmission electron microscopy. Ultramicroscopy 170:86–95. https://doi.org/10.1016/j.ultramic.2016.08.007 Tao F, Salmeron M (2011) In situ studies of chemistry and structure of materials in reactive environments. Science 80-(331):171–174. https://doi.org/10.1126/science.1197461 Dai S, Gao W, Graham GW, Pan X (2018) In situ atmospheric transmission electron microscopy of catalytic nanomaterials. MRS Adv 3:2297–2303. https://doi.org/10.1557/adv.2018.435 Hwang S, Chen X, Zhou G, Su D (2020) In situ transmission electron microscopy on energy-related catalysis. Adv Energy Mater 10:1902105. https://doi.org/10.1002/aenm.201902105 He B, Zhang Y, Liu X, Chen L (2020) In-situ transmission electron microscope techniques for heterogeneous catalysis. ChemCatChem 12:1853–1872. https://doi.org/10.1002/cctc.201902285 Wu J, Shan H, Chen W et al (2016) In situ environmental TEM in imaging gas and liquid phase chemical reactions for materials research. Adv Mater 28:9686–9712. https://doi.org/10.1002/adma.201602519 Wu F, Yao N (2015a) Advances in windowed gas cells for in-situ TEM studies. Nano Energy 13:735–756. https://doi.org/10.1016/j.nanoen.2015.03.015 Ye F, Xu M, Dai S et al (2020) In situ tem studies of catalysts using windowed gas cells. Catalysts 10:1–20. https://doi.org/10.3390/catal10070779 Tao F, Crozier PA (2016) Atomic-scale observations of catalyst structures under reaction conditions and during catalysis. Chem Rev 116:3487–3539. https://doi.org/10.1021/cr5002657 Seymour JP, Wu F, Wise KD, Yoon E (2017) State-of-the-art mems and microsystem tools for brain research. Microsyst Nanoeng 3:1–16. https://doi.org/10.1038/micronano.2016.66 Arlett JL, Myers EB, Roukes ML (2011) Comparative advantages of mechanical biosensors. Nat Nanotechnol 6:203–215. https://doi.org/10.1038/nnano.2011.44 Gad-el-Hak M (2001) The MEMS handbook. CRC Press, Boca Raton Löwe H, Ehrfeld W (1999) State-of-the-art in microreaction technology: concepts, manufacturing and applications. Electrochim Acta 44:3679–3689. https://doi.org/10.1016/S0013-4686(99)00071-7 Min KB, Tanaka S, Esashi M (2006) Fabrication of novel MEMS-based polymer electrolyte fuel cell architectures with catalytic electrodes supported on porous SiO2. J Micromech Microeng 16:505–511. https://doi.org/10.1088/0960-1317/16/3/005 Kim T, Hwang JS, Kwon S (2007) A MEMS methanol reformer heated by decomposition of hydrogen peroxide. Lab Chip 7:835–841. https://doi.org/10.1039/b700040e Korotcenkov G, Do HS, Stetter JR (2009) Review of electrochemical hydrogen sensors. Chem Rev 109:1402–1433. https://doi.org/10.1021/cr800339k Kooyman PJ (2017) Development of operando transmission electron microscopy. In: Frenken J, Groot I (eds) Operando research in heterogeneous catalysis. Springer International Publishing, Cham, pp 111–129 Vendelbo SB, Elkjær CF, Falsig H et al (2014) Visualization of oscillatory behaviour of Pt nanoparticles catalysing CO oxidation. Nat Mater 13:884–890. https://doi.org/10.1038/nmat4033 Plodinec M, Nerl HC, Girgsdies F et al (2020) Insights into chemical dynamics and their impact on the reactivity of Pt nanoparticles during CO oxidation by operando TEM. ACS Catal 10:3183–3193. https://doi.org/10.1021/acscatal.9b03692 Helveg S, Kisielowski CF, **schek JR et al (2015) Observing gas-catalyst dynamics at atomic resolution and single-atom sensitivity. Micron 68:176–185. https://doi.org/10.1016/j.micron.2014.07.009 Dai S, Gao W, Zhang S et al (2017) Transmission electron microscopy with atomic resolution under atmospheric pressures. MRS Commun 7:798–812. https://doi.org/10.1557/mrc.2017.125 Ertl G, Knözinger H, Weitkamp J (1997) Handbook of heterogeneous catalysis. Wiley, New York Hodnik N, Dehm G, Mayrhofer KJJJ (2016) Importance and challenges of electrochemical in situ liquid cell electron microscopy for energy conversion research. Acc Chem Res 49:2015–2022. https://doi.org/10.1021/acs.accounts.6b00330 Unocic RR, Sacci RL, Brown GM et al (2014) Quantitative electrochemical measurements using in situ ec-S/TEM devices. Microsc Microanal 20:452–461. https://doi.org/10.1017/S1431927614000166 Liao H-GHG, Zherebetskyy D, **n H et al (2014) Facet development during platinum nanocube growth. Science 80-(345):916–919. https://doi.org/10.1126/science.1253149 Park JH, Grogan JM, Bau HH et al (2012) In situ liquid cell transmission electron microscopic observation of electron beam induced Au crystal growth in a solution. Microsc Microanal 18:1098–1099. https://doi.org/10.1017/S1431927612007349 Losey MW, Schmnidt MA, Jensen KF (2001) Microfabricated multiphase packed-bed reactors: characterization of mass transfer and reactions. Ind Eng Chem Res 40:2555–2562. https://doi.org/10.1021/ie000523f Jensen KF (2001) Microreaction engineering — is small better? Chem Eng Sci 56:293–303. https://doi.org/10.1016/S0009-2509(00)00230-X Widdis SJ, Asante K, Hitt DL et al (2013) A MEMS-based catalytic microreactor for a H2O2 monopropellant micropropulsion system. IEEE/ASME Trans Mechatron 18:1250–1258. https://doi.org/10.1109/TMECH.2013.2249085 Saif MTA, MacDonald NC (1996) A millinewton microloading device. Sens Actuators A Phys 52:65–75. https://doi.org/10.1016/0924-4247(96)80127-0 Haque MA, Saif MTA (2002) In-situ tensile testing of nano-scale specimens in SEM and TEM. Exp Mech 42:123–128. https://doi.org/10.1177/0018512002042001797 Zhu Y, Moldovan N, Espinosa HD (2005) A microelectromechanical load sensor for in situ electron and x-ray microscopy tensile testing of nanostructures. Appl Phys Lett 86:013506. https://doi.org/10.1063/1.1844594 Colla MS, Amin-Ahmadi B, Idrissi H et al (2015) Dislocation-mediated relaxation in nanograined columnar palladium films revealed by on-chip time-resolved HRTEM testing. Nat Commun 6:1–8. https://doi.org/10.1038/ncomms6922 Sharpe WN (2008) A review of tension test methods for thin films. In: Materials Research Society Symposium Proceedings. Cambridge University Press, pp 3–14 Espinosa HD, Bernal RA, Filleter T (2012) In situ TEM electromechanical testing of nanowires and nanotubes. Small 8:3233–3252. https://doi.org/10.1002/smll.201200342 Peng B, Locascio M, Zapol P et al (2008) Measurements of near-ultimate strength for multiwalled carbon nanotubes and irradiation-induced crosslinking improvements. Nat Nanotechnol 3:626–631. https://doi.org/10.1038/nnano.2008.211 Haque MA, Espinosa HD, Lee HJ (2010) MEMS for in situ testing - Handling, actuation, loading, and displacement measurements. MRS Bull 35:375–381. https://doi.org/10.1557/mrs2010.570 Nafari A, Karlen D, Rusu C et al (2008) MEMS sensor for in situ TEM atomic force microscopy. J Microelectromechanical Syst 17:328–333. https://doi.org/10.1109/JMEMS.2007.912714 Xu Y, MacDonald NC, Miller SA (1995) Integrated micro-scanning tunneling microscope. Appl Phys Lett 67:2305. https://doi.org/10.1063/1.115134 Tabak FC, Disseldorp ECM, Wortel GH et al (2010) MEMS-based fast scanning probe microscopes. Ultramicroscopy 110:599–604. https://doi.org/10.1016/j.ultramic.2010.02.018 Lutwyche MI, Wada Y (1995) Manufacture of micromechanical scanning tunnelling microscopes for observation of the tip apex in a transmission electron microscope. Sens Actuators A Phys 48:127–136. https://doi.org/10.1016/0924-4247(94)00986-R Zhang M, Efremov MY, Schiettekatte F et al (2000) Size-dependent melting point depression of nanostructures: nanocalorimetric measurements. Phys Rev B 62:10548–10557. https://doi.org/10.1103/PhysRevB.62.10548 Heide HG (1962) Electron microscopic observation of specimens under controlled gas pressure. J Cell Biol 13:147–152. https://doi.org/10.1083/jcb.13.1.147 Green ED, Kino GS (1991) Atmospheric scanning electron microscopy using silicon nitride thin film windows. Cit J Vac Sci Technol B 9:1557. https://doi.org/10.1116/1.585422 Tiggelaar RM, Berenschot JW, De Boer JH et al (2005) Fabrication and characterization of high-temperature microreactors with thin film heater and sensor patterns in silicon nitride tubes. Lab Chip 5:326–336. https://doi.org/10.1039/b414857f Zhang M, Olson EA, Twesten RD et al (2005) In situ transmission electron microscopy studies enabled by microelectromechanical system technology. J Mater Res 20:1802–1807. https://doi.org/10.1557/JMR.2005.0225 Spruit RG, Tijn Van Omme J, Ghatkesar MK, Hugo Pérez Garza H (2017) A review on development and optimization of microheaters for high-temperature in situ studies. J Microelectromechanical Syst 26:1165–1182. https://doi.org/10.1109/JMEMS.2017.2757402 Allard LF, Bigelow WC, Jose-Yacaman M et al (2009) A new MEMS-based system for ultra-high-resolution imaging at elevated temperatures. Microsc Res Tech 72:208–215. https://doi.org/10.1002/jemt.20673 Baker RTK (1979) In situ electron microscopy studies of catalyst particle behavior. Catal Rev 19:161–209. https://doi.org/10.1080/03602457908068055 Allard LF, Overbury SH, Bigelow WC et al (2012) Novel MEMS-based gas-cell/heating specimen holder provides advanced imaging capabilities for in situ reaction studies. Microsc Microanal 18:656–666. https://doi.org/10.1017/S1431927612001249 Giorgio S, Sao Joao S, Nitsche S et al (2006) Environmental electron microscopy (ETEM) for catalysts with a closed E-cell with carbon windows. Ultramicroscopy 106:503–507. https://doi.org/10.1016/j.ultramic.2006.01.006 Konishi H, Ishikawa A, Jiang Y-B et al (2003) Sealed environmental cell microscopy. Microsc Microanal 9:902–903. https://doi.org/10.1017/s1431927603444516 Creemer JF, Helveg S, Hoveling GH et al (2008) Atomic-scale electron microscopy at ambient pressure. Ultramicroscopy 108:993–998. https://doi.org/10.1016/j.ultramic.2008.04.014 Creemer JF, Helveg S, Kooyman PJ et al (2010) A MEMS reactor for atomic-scale microscopy of nanomaterials under industrially relevant conditions. J Microelectromechanical Syst 19:254–264. https://doi.org/10.1109/JMEMS.2010.2041190 Doll T, Hochberg M, Barsic D, Scherer A (2000) Micro-machined electron transparent alumina vacuum windows. Sens Actuators A Phys 87:52–59. https://doi.org/10.1016/S0924-4247(00)00461-1 Boyes ED, Gai PL (1997) Environmental high resolution electron microscopy and applications to chemical science. Ultramicroscopy 67:219–232. https://doi.org/10.1016/S0304-3991(96)00099-X Sharma R, Crozier PA, Marx R, Weiss K (2003) An environmental transmission electron microscope for in-situ observation of chemical processes at the nanometer level. Microsc Microanal 9:912–913. https://doi.org/10.1017/s1431927603444565 Sharma R (2012) Experimental set up for in situ transmission electron microscopy observations of chemical processes. Micron 43:1147–1155. https://doi.org/10.1016/j.micron.2012.01.007 Ramade J, Langlois C, Pellarin M et al (2017) Tracking the restructuring of oxidized silver-indium nanoparticles under a reducing atmosphere by environmental HRTEM. Nanoscale 9:13563–13574. https://doi.org/10.1039/c7nr02986a Boyes ED, Lagrow AP, Ward MR et al (2020) Single atom dynamics in chemical reactions. Acc Chem Res. https://doi.org/10.1021/acs.accounts.9b00500 Sharma R, Crozier PA (2005) Environmental transmission electron microscopy in nanotechnology. In: Yao N, Wang ZL (eds) Handbook of microscopy for nanotechnology. Springer, Boston, pp 531–565 Hansen TW, Wagner JB (2012) Environmental transmission electron microscopy in an aberration-corrected environment. Microsc Microanal 18:684–690. https://doi.org/10.1017/S1431927612000293 Yoshida H, Kuwauchi Y, **schek JR et al (2012) Visualizing gas molecules interacting with supported nanoparticulate catalysts at reaction conditions. Science 80-(335):317–319. https://doi.org/10.1126/science.1213194 Yaguchi T, Suzuki M, Watabe A et al (2011) Development of a high temperature-atmospheric pressure environmental cell for high-resolution TEM. J Electron Microsc (Tokyo) 60:217–225. https://doi.org/10.1093/jmicro/dfr011 El-Sayed MA (2001) Some interesting properties of metals confined in time and nanometer space of different shapes. Acc Chem Res 34:257–264. https://doi.org/10.1021/ar960016n Jaeger NI (2001) Bridging gaps and opening windows. Science 80-(293):1601–1602. https://doi.org/10.1126/science.1064595 Topsøe H (2000) In situ characterization of catalysts. Stud Surf Sci Catal 130:1–21. https://doi.org/10.1016/s0167-2991(00)80942-8 Topsøe H (2003) Developments in operando studies and in situ characterization of heterogeneous catalysts. J Catal 216:155–164. https://doi.org/10.1016/S0021-9517(02)00133-1 Hansen PL, Wagner JB, Helveg S et al (2002) Atom-resolved imaging of dynamic shape changes in supported copper nanocrystals. Science 80-(295):2053–2055. https://doi.org/10.1126/science.1069325 Piccolo L (2020) Restructuring effects of the chemical environment in metal nanocatalysis and single-atom catalysis. Catal Today. https://doi.org/10.1016/j.cattod.2020.03.052 De Jonge N, Bigelow WC, Veith GM (2010) Atmospheric pressure scanning electron microscopy. Nano Lett 10:1028–1031. https://doi.org/10.1021/nl904254g Zhang S, Plessow PN, Willis JJ et al (2016) Dynamical observation and detailed description of catalysts under strong metal-support interaction. Nano Lett 16:4528–4534. https://doi.org/10.1021/acs.nanolett.6b01769 Zhang S, Chen C, Cargnello M et al (2015) Dynamic structural evolution of supported palladium-ceria core-shell catalysts revealed by in situ electron microscopy. Nat Commun 6:1–6. https://doi.org/10.1038/ncomms8778 Dai S, You Y, Zhang S et al (2017) In situ atomic-scale observation of oxygen-driven core-shell formation in Pt3Co nanoparticles. Nat Commun. https://doi.org/10.1038/s41467-017-00161-y Kawasaki T, Ueda K, Ichihashi M, Tanji T (2009) Improvement of windowed type environmental-cell transmission electron microscope for in situ observation of gas-solid interactions. Rev Sci Instrum. https://doi.org/10.1063/1.3250862 Creemer JF, Santagata F, Morana B, et al (2011) An all-in-one nanoreactor for high-resolution microscopy on nanomaterials at high pressures. In: 2011 IEEE 24th international conference on micro electro mechanical systems. IEEE, pp 1103–1106 Mehraeen S, McKeown JT, Deshmukh PV et al (2013) A (S)TEM gas cell holder with localized laser heating for in situ experiments. Microsc Microanal 19:470–478. https://doi.org/10.1017/S1431927612014419 Yokosawa T, Alan T, Pandraud G et al (2012) In-situ TEM on (de)hydrogenation of Pd at 0.5-4.5bar hydrogen pressure and 20–400°C. Ultramicroscopy 112:47–52. https://doi.org/10.1016/j.ultramic.2011.10.010 Pandraud G, Morana B, Wei J, Juffermans C (2016) 10 bar nanoreactors for in situ transmission electron microscopy. In: European Microscopy Congress 2016: Proceedings. Wiley-VCH Verlag GmbH & Co. KGaA, pp 277–278 DENSsolutions DENS climate. https://denssolutions.com/products/climate/ Song B, Yang TT, Yuan Y et al (2020) Revealing sintering kinetics of MoS 2 -supported metal nanocatalysts in atmospheric gas environments via operando transmission electron microscopy. ACS Nano 14:4074–4086. https://doi.org/10.1021/acsnano.9b08757 Erdamar AK, Malladi S, Tichelaar FD, Zandbergen HW (2016) Closed cell systems for in situ TEM with gas environments ranging from 0.1 to 5 bar. Controlled atmosphere transmission electron microscopy. Springer International Publishing, Cham, pp 165–210 Masliuk L, Swoboda M, Algara-Siller G et al (2018) A quasi in situ TEM grid reactor for decoupling catalytic gas phase reactions and analysis. Ultramicroscopy 195:121–128. https://doi.org/10.1016/j.ultramic.2018.09.001 van Hoof AJF, van der Poll RCJ, Friedrich H, Hensen EJM (2020) Dynamics of silver particles during ethylene epoxidation. Appl Catal B Environ 272:118983. https://doi.org/10.1016/j.apcatb.2020.118983 Alan T, Yokosawa T, Gaspar J et al (2012) Micro-fabricated channel with ultra-thin yet ultra-strong windows enables electron microscopy under 4-bar pressure. Appl Phys Lett 100:081903. https://doi.org/10.1063/1.3688490 Vendelbo SB, Kooyman PJ, Creemer JF et al (2013) Method for local temperature measurement in a nanoreactor for in situ high-resolution electron microscopy. Ultramicroscopy 133:72–79. https://doi.org/10.1016/j.ultramic.2013.04.004 Meirer F, Weckhuysen BM (2018) Spatial and temporal exploration of heterogeneous catalysts with synchrotron radiation. Nat Rev Mater 3:324–340. https://doi.org/10.1038/s41578-018-0044-5 De Smit E, Swart I, Creemer JF et al (2008) Nanoscale chemical imaging of a working catalyst by scanning transmission X-ray microscopy. Nature 456:222–225. https://doi.org/10.1038/nature07516 Li Y, Zakharov D, Zhao S et al (2015) Complex structural dynamics of nanocatalysts revealed in Operando conditions by correlated imaging and spectroscopy probes. Nat Commun 6:7583. https://doi.org/10.1038/ncomms8583 Cats KH, Andrews JC, Stéphan O et al (2016) Active phase distribution changes within a catalyst particle during Fischer-Tropsch synthesis as revealed by multi-scale microscopy. Catal Sci Technol 6:4438–4449. https://doi.org/10.1039/c5cy01524c Xu M, Yao S, Rao D et al (2018) Insights into interfacial synergistic catalysis over Ni@TiO2- x catalyst toward water-gas shift reaction. J Am Chem Soc 140:11241–11251. https://doi.org/10.1021/jacs.8b03117 Resasco J, Dai S, Graham G et al (2018) Combining in-situ transmission electron microscopy and infrared spectroscopy for understanding dynamic and atomic-scale features of supported metal catalysts. J Phys Chem C 122:25143–25157. https://doi.org/10.1021/acs.jpcc.8b03959 Yoshida H, Matsuura K, Kuwauchi Y et al (2011) Temperature-dependent change in shape of platinum nanoparticles supported on CeO2 during catalytic reactions. Appl Phys Express 4:065001. https://doi.org/10.1143/APEX.4.065001 Altantzis T, Lobato I, De Backer A et al (2019) Three-dimensional quantification of the facet evolution of Pt nanoparticles in a variable gaseous environment. Nano Lett 19:477–481. https://doi.org/10.1021/acs.nanolett.8b04303 Tan SF, Chee SW, Baraissov Z et al (2019) Real-time imaging of nanoscale redox reactions over bimetallic nanoparticles. Adv Funct Mater 29:1–10. https://doi.org/10.1002/adfm.201903242 Avanesian T, Dai S, Kale MJ et al (2017) Quantitative and atomic-scale view of CO-induced Pt nanoparticle surface reconstruction at saturation coverage via DFT calculations coupled with in situ TEM and IR. J Am Chem Soc 139:4551–4558. https://doi.org/10.1021/jacs.7b01081 Bahri M, Dembélé K, Sassoye C et al (2018) In situ insight into the unconventional ruthenium catalyzed growth of carbon nanostructures. Nanoscale 10:14957–14965. https://doi.org/10.1039/c8nr01227j Huang X, Farra R, Schlögl R, Willinger MG (2019) Growth and termination dynamics of multiwalled carbon nanotubes at near ambient pressure: an in situ transmission electron microscopy study. Nano Lett 19:5380–5387. https://doi.org/10.1021/acs.nanolett.9b01888 Beck A, Huang X, Artiglia L et al (2020) The dynamics of overlayer formation on catalyst nanoparticles and strong metal-support interaction. Nat Commun 11:1–40. https://doi.org/10.1038/s41467-020-17070-2 Chee SW, Arce-Ramos JM, Li W et al (2020) Structural changes in noble metal nanoparticles during CO oxidation and their impact on catalyst activity. Nat Commun 11:1–9. https://doi.org/10.1038/s41467-020-16027-9 Plodinec M, Nerl HC, Farra R et al (2020) Versatile homebuilt gas feed and analysis system for operando TEM of catalysts at work. Microsc Microanal 26:220–228. https://doi.org/10.1017/S143192762000015X Crozier PA, Chenna S (2011) In situ analysis of gas composition by electron energy-loss spectroscopy for environmental transmission electron microscopy. Ultramicroscopy 111:177–185. https://doi.org/10.1016/j.ultramic.2010.11.005 Chenna S, Crozier PA (2012) Operando transmission electron microscopy: a technique for detection of catalysis using electron energy-loss spectroscopy in the transmission electron microscope. ACS Catal 2:2395–2402. https://doi.org/10.1021/cs3004853 Delariva AT, Hansen TW, Challa SR, Datye AK (2013) In situ transmission electron microscopy of catalyst sintering. J Catal 308:291–305. https://doi.org/10.1016/j.jcat.2013.08.018 Yu J, Yuan W, Yang H et al (2018) Fast gas–solid reaction kinetics of nanoparticles unveiled by millisecond in situ electron diffraction at ambient pressure. Angew Chem Int Ed 57:11344–11348. https://doi.org/10.1002/anie.201806541 Zhou H, Zhao Y, Xu J et al (2020) Recover the activity of sintered supported catalysts by nitrogen-doped carbon atomization. Nat Commun. https://doi.org/10.1038/s41467-019-14223-w Gaulandris F, Simonsen SB, Wagner JB et al (2020) Methods for calibration of specimen temperature during in situ transmission electron microscopy experiments. Microsc Microanal 26:3–17. https://doi.org/10.1017/S1431927619015344 Bataineh KM (2016) Develo** of an environmental cell TEM holder for dynamic in situ observation. Rev Sci Instrum. https://doi.org/10.1063/1.4942245 Vogel D, Spiel C, Suchorski Y et al (2011) Map** the local reaction kinetics by PEEM: CO oxidation on individual (100)-type grains of Pt foil. Surf Sci 605:1999–2005. https://doi.org/10.1016/j.susc.2011.07.018 Vogel D, Spiel C, Suchorski Y et al (2012) Local catalytic ignition during CO oxidation on low-index Pt and Pd surfaces: a combined PEEM, MS, and DFT study. Angew Chem Int Ed 51:10041–10044. https://doi.org/10.1002/anie.201204031 Williamson MJ, Tromp RM, Vereecken PM et al (2003) Dynamic microscopy of nanoscale cluster growth at the solid-liquid interface. Nat Mater 2:532–536. https://doi.org/10.1038/nmat944 Ross FM (2015) Opportunities and challenges in liquid cell electron microscopy. Science 80(350):6267. https://doi.org/10.1126/science.aaa9886 de Jonge N, Houben L, Dunin-Borkowski RE, Ross FM (2019) Resolution and aberration correction in liquid cell transmission electron microscopy. Nat Rev Mater 4:61–78. https://doi.org/10.1038/s41578-018-0071-2 Jonge N, Ross F (2011) Electron microscopy of specimens in liquid. Nat Nanotechnol 6:695–704. https://doi.org/10.1038/nnano.2011.161 Zhu GZ, Prabhudev S, Yang J et al (2014) In situ liquid cell TEM study of morphological evolution and degradation of Pt-Fe nanocatalysts during potential cycling. J Phys Chem C 118:22111–22119. https://doi.org/10.1021/jp506857b Zheng H, Smith RK, Jun YW et al (2009) Observation of single colloidal platinum nanocrystal growth trajectories. Science 80-(324):1309–1312. https://doi.org/10.1126/science.1172104 Murray CB (2009) Watching nanocrystals grow. Science 80-(324):1276–1277. https://doi.org/10.1126/science.1174666 Schneider NM, Norton MM, Mendel BJ et al (2014) Electron–water interactions and implications for liquid cell electron microscopy. J Phys Chem C 118:22373–22382. https://doi.org/10.1021/jp507400n Wang M, Park C, Woehl TJ (2018) Quantifying the nucleation and growth kinetics of electron beam nanochemistry with liquid cell scanning transmission electron microscopy. Chem Mater 30:7727–7736. https://doi.org/10.1021/acs.chemmater.8b03050 Thiberge S, Nechushtan A, Sprinzak D et al (2004) Scanning electron microscopy of cells and tissues under fully hydrated conditions. Proc Natl Acad Sci USA 101:3346–3351. https://doi.org/10.1073/pnas.0400088101 de Jonge N, Peckys DB, Kremers GJ, Piston DW (2009) Electron microscopy of whole cells in liquid with nanometer resolution. Proc Natl Acad Sci USA 106:2159–2164 Ring EA, De Jonge N (2010) Microfluidic system for transmission electron microscopy. Microsc Microanal 16:622–629. https://doi.org/10.1017/S1431927610093669 Verpoorte E, De Rooij NF (2003) Microfluidics meets MEMS. In: Proceedings of the IEEE. Institute of Electrical and Electronics Engineers Inc., pp 930–953 Yesibolati MN, Mortensen KI, Sun H et al (2020) Unhindered brownian motion of individual nanoparticles in liquid-phase scanning transmission electron microscopy. Nano Lett 20:7108–7115. https://doi.org/10.1021/acs.nanolett.0c02352 Leenheer AJ, Sullivan JP, Shaw MJ, Harris CT (2015) A sealed liquid cell for in situ transmission electron microscopy of controlled electrochemical processes. J Microelectromechanical Syst 24:1061–1068. https://doi.org/10.1109/JMEMS.2014.2380771 Leenheer AJ, Jungjohann KL, Thomas Harris C (2015) Design of a heated liquid cell for in-situ transmission electron microscopy. Microsc Microanal 21:1293–1294. https://doi.org/10.1017/s1431927615007254 Li D, Nielsen MH, Lee JRI et al (2012) Direction-specific interactions control crystal growth by oriented attachment. Science 80-(336):1014–1018. https://doi.org/10.1126/science.1219643 Tanase M, Winterstein J, Sharma R et al (2015) High-resolution imaging and spectroscopy at high pressure: a novel liquid cell for the transmission electron microscope. Microsc Microanal 21:1629–1638. https://doi.org/10.1017/S1431927615015482 Mehdi BL, Qian J, Nasybulin E et al (2015) Observation and quantification of nanoscale processes in lithium batteries by operando electrochemical (S)TEM. Nano Lett 15:2168–2173. https://doi.org/10.1021/acs.nanolett.5b00175 Mayrhofer KJJ, Meier JC, Ashton SJ et al (2008) Fuel cell catalyst degradation on the nanoscale. Electrochem commun 10:1144–1147. https://doi.org/10.1016/j.elecom.2008.05.032 Hodnik N, Cherevko S (2019) Spot the difference at the nanoscale: identical location electron microscopy in electrocatalysis. Curr Opin Electrochem 15:73–82. https://doi.org/10.1016/j.coelec.2019.03.007 Jungjohann KL, Bliznakov S, Sutter PW et al (2013) In situ liquid cell electron microscopy of the solution growth of Au-Pd core-shell nanostructures. Nano Lett 13:2964–2970. https://doi.org/10.1021/nl4014277 Beermann V, Holtz ME, Padgett E et al (2019) Real-time imaging of activation and degradation of carbon supported octahedral Pt-Ni alloy fuel cell catalysts at the nanoscale using: In situ electrochemical liquid cell STEM. Energy Environ Sci 12:2476–2485. https://doi.org/10.1039/c9ee01185d Fan K, Zou H, Lu Y et al (2018) Direct observation of structural evolution of metal chalcogenide in electrocatalytic water oxidation. ACS Nano 12:12369–12379. https://doi.org/10.1021/acsnano.8b06312 Ortiz Peña N, Ihiawakrim D, Han M et al (2019) Morphological and structural evolution of Co3O4 nanoparticles revealed by in situ electrochemical transmission electron microscopy during electrocatalytic water oxidation. ACS Nano 13:11372–11381. https://doi.org/10.1021/acsnano.9b04745 Abidi W, Remita H (2011) Gold based nanoparticles generated by radiolytic and photolytic methods. Recent Patents Eng 4:170–188. https://doi.org/10.2174/187221210794578556 Evans JE, Jungjohann KL, Browning ND, Arslan I (2011) Controlled growth of nanoparticles from solution with in situ liquid transmission electron microscopy. Nano Lett 11:2809–2813. https://doi.org/10.1021/nl201166k Woehl TJ, Evans JE, Arslan I et al (2012) Direct in situ determination of the mechanisms controlling nanoparticle nucleation and growth. ACS Nano 6:8599–8610. https://doi.org/10.1021/nn303371y Holtz ME, Yu Y, Gao J et al (2013) In situ electron energy-loss spectroscopy in liquids. Microsc Microanal 19:1027–1035. https://doi.org/10.1017/S1431927613001505 Lewis EA, Haigh SJ, Slater TJA et al (2014) Real-time imaging and local elemental analysis of nanostructures in liquids. Chem Commun 50:10019–10022. https://doi.org/10.1039/c4cc02743d Malis T, Cheng SC, Egerton RF (1988) EELS log-ratio technique for specimen-thickness measurement in the TEM. J Electron Microsc Tech 8:193–200. https://doi.org/10.1002/jemt.1060080206 Algara-Siller G, Lehtinen O, Wang FC et al (2015) Square ice in graphene nanocapillaries. Nature 519:443–445. https://doi.org/10.1038/nature14295 Kelly DJ, Zhou M, Clark N et al (2018) Nanometer resolution elemental map** in graphene-based TEM liquid cells. Nano Lett 18:1168–1174. https://doi.org/10.1021/acs.nanolett.7b04713 Schneider NM (2016) Electron beam effects in liquid cell TEM and STEM. Liquid cell electron microscopy. Cambridge University Press, Cambridge, pp 140–163 Rehn SM, Jones MR (2018) New strategies for probing energy systems with in situ liquid-phase transmission electron microscopy. ACS Energy Lett 3:1269–1278. https://doi.org/10.1021/acsenergylett.8b00527 Grogan JM, Rotkina L, Bau HH (2011) In situ liquid-cell electron microscopy of colloid aggregation and growth dynamics. Phys Rev E 83:061405. https://doi.org/10.1103/PhysRevE.83.061405 Grogan JM, Schneider NM, Ross FM, Bau HH (2014) Bubble and pattern formation in liquid induced by an electron beam. Nano Lett 14:359–364. https://doi.org/10.1021/nl404169a Lu Y, Yin WJ, Peng KL et al (2018) Self-hydrogenated shell promoting photocatalytic H2 evolution on anatase TiO2. Nat Commun. https://doi.org/10.1038/s41467-018-05144-1 Wu F, Yao N (2015b) Advances in sealed liquid cells for in-situ TEM electrochemial investigation of lithium-ion battery. Nano Energy 11:196–210. https://doi.org/10.1016/j.nanoen.2014.11.004 Buban JP, Ramasse Q, Gipson B et al (2010) High-resolution low-dose scanning transmission electron microscopy. J Electron Microsc (Tokyo) 59:103–112. https://doi.org/10.1093/jmicro/dfp052 Krivanek OL, Dellby N, Murfitt MF et al (2010) Gentle STEM: ADF imaging and EELS at low primary energies. Ultramicroscopy 110:935–945. https://doi.org/10.1016/J.ULTRAMIC.2010.02.007 Miller BK, Barker TM, Crozier PA (2015) Novel sample preparation for operando TEM of catalysts. Ultramicroscopy 156:18–22. https://doi.org/10.1016/j.ultramic.2015.05.003 Santos Aires FJC, Bertolini JC (2009) On the use of silicon nitride in catalysis. Top Catal 52:1492–1505. https://doi.org/10.1007/s11244-009-9296-z Kim H-E, Moorhead AJ (1990) High-temperature gaseous corrosion of Si3N4 in H2–H2O and Ar–O2 environments. J Am Ceram Soc 73:3007–3014. https://doi.org/10.1111/j.1151-2916.1990.tb06708.x Munro RG, Dapkunas SJ (1993) Corrosion characteristics of silicon carbide and silicon nitride. J Res 98:607–631. https://doi.org/10.6028/jres.098.040 Textor M, de Jonge N (2018) Strategies for preparing graphene liquid cells for transmission electron microscopy. Nano Lett 18:3313–3321. https://doi.org/10.1021/acs.nanolett.8b01366 Kühne M, Börrnert F, Fecher S et al (2018) Reversible superdense ordering of lithium between two graphene sheets. Nature. https://doi.org/10.1038/s41586-018-0754-2 Monnet F, Schuurman Y, Cadete Santos Aires F et al (2001) Silicon nitride supported platinum catalysts for the partial oxidation of methane at high temperatures. Catal Today 64:51–58. https://doi.org/10.1016/S0920-5861(00)00508-3 Hullmann D, Wendt G, Šingliar U, Ziegenbalg G (2002) Propane dehydrogenation over supported platinum silicon nitride catalysts. Appl Catal A Gen 225:261–270. https://doi.org/10.1016/S0926-860X(01)00871-7 Claassen WAP, Valkenburg WGJN, Habraken FHPM, Tamminga Y (1983) Characterization of plasma silicon nitride layers. J Electrochem Soc 130:2419–2423. https://doi.org/10.1149/1.2119600 French PJ, Sarro PM, Mallée R et al (1997) Optimization of a low-stress silicon nitride process for surface-micromachining applications. Sens Actuators A Phys 58:149–157. https://doi.org/10.1016/S0924-4247(96)01397-0 Zaluzec NJ (2015) When is Si3N4 not Si3N4? When it is a low stress SiNx membrane window. Microsc Microanal 21:959–960. https://doi.org/10.1017/s1431927615005590 Du H (1989) Oxidation studies of crystalline CVD silicon nitride. J Electrochem Soc 136:1527. https://doi.org/10.1149/1.2096955 Simonsen SB, Chorkendorff I, Dahl S et al (2010) Direct observations of oxygen-induced platinum nanoparticle ripening studied by in situ TEM. J Am Chem Soc 132:7968–7975. https://doi.org/10.1021/ja910094r **n HL, Niu K-Y, Alsem DH, Zheng H (2013) In situ TEM study of catalytic nanoparticle reactions in atmospheric pressure gas environment. Microsc Microanal 19:1558–1568. https://doi.org/10.1017/S1431927613013433 Protochips Incorporated (2020) Protochips atmosphere. https://www.protochips.com/products/atmosphere/ Miller BK, Crozier PA (2014) Analysis of catalytic gas products using electron energy-loss spectroscopy and residual gas analysis for operando transmission electron microscopy. Microsc Microanal 20:815–824. https://doi.org/10.1017/S1431927614000749 Meti S, Balavald KB, Sheeparmatti BG (2016) MEMS piezoresistive pressure sensor : a survey. Int J Engin Res App 6:23–31 Khan MI, Mukherjee K, Shoukat R, Dong H (2017) A review on pH sensitive materials for sensors and detection methods. Microsyst Technol 23:4391–4404. https://doi.org/10.1007/s00542-017-3495-5 Wood PM (1988) The potential diagram for oxygen at pH 7. Biochem J 253:287–289. https://doi.org/10.1042/bj2530287 Schlögl R (2015) Heterogeneous catalysis. Angew Chem Int Ed 54:3465–3520. https://doi.org/10.1002/anie.201410738References

Acknowledgements

All previous and current members of the electron microscopy group of the department of inorganic chemistry at Firtz-Haber-Institut der Max-Planck-Gesellschaft are acknowledged for their excellent work on chemical, in situ and operando electron microscopy.

Funding

Open Access funding enabled and organized by Projekt DEAL. This work was funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under Germany´s Excellence Strategy – EXC 2089/1–390776260.

Author information

Authors and Affiliations

Contributions

Article idea: TL. Literature research and writing: MB. Critical revisions: TL, MP, RS.

Corresponding author

Ethics declarations

Conflict of interest

All the authors declared that they have no conflict of interest.

Additional information

Dedicated to Prof. Dr. Norbert Kruse on the occasion of his 70th birthday.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Boniface, M., Plodinec, M., Schlögl, R. et al. Quo Vadis Micro-Electro-Mechanical Systems for the Study of Heterogeneous Catalysts Inside the Electron Microscope?. Top Catal 63, 1623–1643 (2020). https://doi.org/10.1007/s11244-020-01398-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-020-01398-6