Abstract

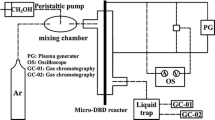

The on-board reforming technique for de-NOx is attracting increasing interest because of the fast start-up and size of the device. However, due to the limited amount of energy available from the battery, a full understanding of the characteristics of the plasma reforming reaction is important to optimise this technology to achieve hydrogen production with minimal power consumption. This paper reports the relative role of the thermal effect of plasma in octane oxidation induced by rotating arc plasma. The thermal effect or gas temperature increased with increased electric power; the conversion of the electric energy to heat was estimated to be higher than 40%. The increased thermal effect was the main consequence of further increasing the plasma power, which controlled the syngas yield and was the main determinant of the energy efficiency of the reaction. In comparison, although the O2/C ratio was the main parameter determining the thermal environment in the reactor, it had only a small influence on the energy efficiency of the reaction. The optimal O2/C ratio for maximum energy efficiency depends on the electric power (e.g. the optimal O2/C was 0.8 at 80 W and 0.5 at 280 W). The results provide guidance for determining the optimal conditions for plasma-driven reforming processes.

Similar content being viewed by others

References

Toops TJ, Parks JE, Pihl JA, Huff S, Prikhodko V (2012) Emissions control for lean gasoline engines, Proceedings of Advanced Combustion Engines Program, ACE033

Monaghan ML (2000) Future gasoline and diesel engines-review. Int J Automot Technol 1:1–8

Bijgner W, Krämer M, Krutzsch B, Pischinger S, Voigtlgnder D, Wenninger G, Wirbeleit F, Brogan MS, Brisley RJ, Webster DE (1995) Removal of nitrogen oxides from the exhaust of a lean-tune gasoline engine. Appl Catal B Environ 7:153–171

Durrett R. Opportunities and challenges of lean combustion in automotive IC engines, GM Global Research & Development

Chambon P, Huff S, Norman K, Edwards KD, Thomas J, Prikhodko V (2011) European lean gasoline direct injection vehicle benchmark. SAE, Warrendale

Takeuchi M, Matsumoto S (2004) NOx storage-reduction catalysts for gasoline engines. Top Catal 28:1–4

Philipp S, Hoyer R, Adam F, Eckhoff S, Wunsch R, Schoen C, Vent G (2013) Exhaust gas after treatment for lean gasoline direct injection engines—potential for future applications. SAE, Warrendale

Alkemade UG, Schumann B (2006) Engines and exhaust after treatment systems for future automotive applications. Solid State Ionics 177:2291–2296

Johnson TV (2001) Diesel emission control: 2001 in review. SAE, Warrendale

Kwak JH, Kim DH, Szanyi J, Peden CHF (2008) Excellent sulfur resistance of Pt/BaO/CeO2 lean NOx trap catalysts. Appl Catal B Environ 84:545–551

Koebel M, Elsener M, Kleemann M (2000) Urea-SCR: a promising technique to reduce NOx emissions from automotive diesel engines. Catal Today 59:335–345

Forzatti P (2001) Present status and perspectives in de-NOx SCR catalysis. Appl Catal A 222:221–236

Buscaa G, Lietti L, Ramis G, Berti F (1998) Chemical and mechanistic aspects of the selective catalytic reduction of NOx by ammonia over oxide catalysts: a review. Appl Catal B Environ 18:1–36

Novaa I, Liettia L, Casagrandea L, Dall’Acquab L, Giamellob E, Forzatti P (1998) Characterization and reactivity of TiO2 supported MoO3 De-Nox SCR catalysts. Appl Catal B Environ 17:245–258

Ciambelli P, Corbo P, Migliardini F (2000) Potentialities and limitations of lean de-NOx catalysts in reducing automotive exhaust emissions. Catal Today 59:279–286

Mrad R, Aissat A, Cousin R, Courcot D, Siffert S (2015) Catalysts for NOx selective catalytic reduction by hydrocarbons (HC-SCR). Appl Catal A Gen 504:542–548

Abu-Jraia A, Tsolakisa A, Megaritis A (2007) The influence of H2 and CO on diesel engine combustion characteristics, exhaust gas emissions, and after treatment selective catalytic NOx reduction. Int J Hydrogen Energy 32:3565–3571

HyerimGu KM, Chun SS (2015) The effects of hydrogen on the efficiency of NOx reduction via hydrocarbon-selective catalytic reduction (HC-SCR) at low temperature using various reductants. Int J Hydrogen Energy 40:9602–9610

Lee DH, Lee J-O, Kim K-T, Song Y-H, Kim E, Han H-S (2012) Hydrogen in plasma-assisted hydrocarbon selective catalytic reduction. Int J Hydrogen Energy 37:3225–3233

Breen JP, Burch R (2006) A review of the effect of the addition of hydrogen in the selective catalytic reduction of NOx with hydrocarbons on silver catalysts. Top Catal 39:53–58

Cohn DR, Rabinovich A, Titus CH, Bromberg L (1997) Near-term possibilities for extremely low emission vehicles using onboard plasmatron generation of hydrogen. Int J Hydrogen Energy 22:715–723

Rabinovich A, Bromberg L, Cohn DR, Surma J, Virden JW (1998) Onboard plasmatron reforming of biofuels, gasoline and diesel fuel. SAE, Warrendale, p 981920

Green JB, Bromberg L, Cohn DR et al (2000) Experimental evaluation of SI engine operation supplemented by hydrogen rich gas from a compact plasma boosted reformer. SAE, Warrendale, p 2206

Spivey JJ, Kim MH, Nam I-S (2005) New opportunity for HC-SCR technology to control NOx emission from advanced internal combustion engines. Catalysis 18:116–185

More PM, Nguyen DL, Granger P, Dujardin C, Dongare MK, Umbarkar SB (2015) Activation by pretreatment of Ag–Au/Al2O3 bimetallic catalyst to improve low temperature HC-SCR of NOx for lean burn engine exhaust. Appl Catal B 174–175:145–156

Lee DH, Lee J-O, Kim K-T, Song Y-H, Kim E, Han H-S (2011) Characteristics of plasma-assisted hydrocarbon SCR system. Int J Hydrogen Energy 36:11718–11726

Cho BK, Lee J-H, Crellin CC, Olson KL, Hilden DL, Kim MK, Kim PS, Heo I, Oh SH, Nam I-S (2012) Selective catalytic reduction of NOx by diesel fuel: plasma-assisted HC/SCR system. Catal Today 191:20–24

Petitpasa G, Rollier J-D, Darmon A, Gonzalez-Aguilar J, Metkemeijer R, Fulcheri L (2007) Review: a comparative study of non-thermal plasma assisted reforming technologies. Int J Hydrogen Energy 32:2848–2867

Lee DH, Kim K-T, Cha MS, Song Y-H (2010) Effect of excess oxygen in plasma reforming of diesel fuel. Int J Hydrogen Energy 35:4668–4675

Dinh DK, Kang HS, Jo S, Lee DH, Song Y-H (2017) Partial oxidation of diesel fuel by plasma: kinetic aspects of the reaction. Int J Hydrogen Energy 42:22756–22764

Liu J-L, Park H-W, Chung W-J, Ahn W-S, Park D-W (2016) Simulated biogas oxidative reforming in AC-pulsed gliding arc discharge. Chem Eng J 285:243–251

Lee DH, Kim K-T, Cha MS, Song Y-H (2007) Optimization scheme of a rotating gliding arc reactor for partial oxidation of methane. Proc Combust Inst 31:3343–3351

Rollier J-D, Petitpas G, Gonzalez-Aguilar J, Darmon A, Fulcheri L, Metkemeijer R (2008) Thermodynamics and kinetics analysis of gasoline reforming assisted by arc discharge. Energy Fuels 22:1888–1893

Rollier J-D, Gonzalez-Aguilar J, Petitpas G, Darmon A, Fulcheri L, Metkemeijer R (2008) Experimental study on gasoline reforming assisted by nonthermal arc discharge. Energy Fuels 22:556–560

Gonzalez-Aguilar J, Petitpas G, Lebouvier A, Rollier J-D, Darmon A, Fulcheri L (2009) Three stages modeling of n-octane reforming assisted by a nonthermal arc discharge. Energy Fuels 23:4931–4936

Bossel U (2003) Well-to-wheel studies, heating values, and the energy conservation principle, Proceedings of European Fuel Cell Forum

Lee DH, Kim K-T, Song Y-H, Kang WS, Jo S (2013) Map** plasma chemistry in hydrocarbon fuel processing processes. Plasma Chem Plasma Process 33:249–269

Lee DH, Kim K-T, Cha MS, Song Y-H (2010) Plasma-controlled chemistry in plasma reforming of methane. Int J Hydrogen Energy 35:967–976

Hwang NK, Cha MS, Lee DH, Kim SJ, Song Y-H (2008) Role of plasma chemistry in methane decomposition in an arc jet reactor. Int J Plasma Environ Sci Technol 2:95–99

Benilova MS, Naidis GV (2006) Modeling of hydrogen-rich gas production by plasma reforming of hydrocarbon fuels. Int J Hydrogen Energy 31:769–774

Lee DH, Kim K-T, Kang HS, Jo S, Song Y-H (2014) Optimization of NH3 decomposition by control of discharge mode in a rotating arc. Plasma Chem Plasma Process 34:111–124

Hwang N, Lee J, Lee DH, Song Y-H (2012) Interactive phenomena of a rotating arc and a premixed CH4 flame. Plasma Chem Plasma Process 32:187–200

Richard F, Cormier JM, Pellerin S, Chapelle J (1996) Physical study of a gliding arc discharge. J Appl Phys 79:2245–2250

Dinh DK, Choi S, Lee DH, Song Y-H, Jo S, Kim K-T (2018) Arc length control for efficiency enhancement of energy usage in plasma dry reforming process. J CO2 Util 28:274–282

Dinh DK, Choi S, Lee DH, Jo S, Kim K-T, Song Y-H (2018) Energy efficient dry reforming process using low temperature arcs. Plasma Process Polym 15:1700203

Dinh DK, Lee DH, Song Y-H, Jo S, Kim K-T, Iqbal M, Kang H (2019) Efficient methane-to-acetylene conversion using low-current arcs. RSC Adv 9:32403–32413

Jahn RE (1963) Temperature distribution and thermal efficiency of low power arc-heated plasma jets. Br J Appl Phys 24:585–588

DuPont JN, Marder AR (1995) Thermal efficiency of arc welding processes. Weld J Incl Weld Res 74:406–416

Zhang X, Cha MS (2015) Partial oxidation of methane in a temperature-controlled dielectric barrier discharge reactor. Proc Combust Inst 35:3447–3454

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dinh, D.K., Lee, D.H., Iqbal, M. et al. Evaluation of the Thermal Effect of Arc Plasma in the Plasma-Driven Partial Oxidation of Octane. Plasma Chem Plasma Process 40, 483–497 (2020). https://doi.org/10.1007/s11090-019-10054-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-019-10054-1